Surface alloying process of Mg or Mg-alloy product by heating and solid diffusion in furnace

A surface alloying and solid-state diffusion technology, which is applied in the direction of solid-state diffusion coating, metal material coating process, coating, etc., to achieve reasonable process design, simple operation, and the effect of changing the physical and chemical properties of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Process of preparing metal coating material with aluminum powder to make surface alloy layer of magnesium alloy products

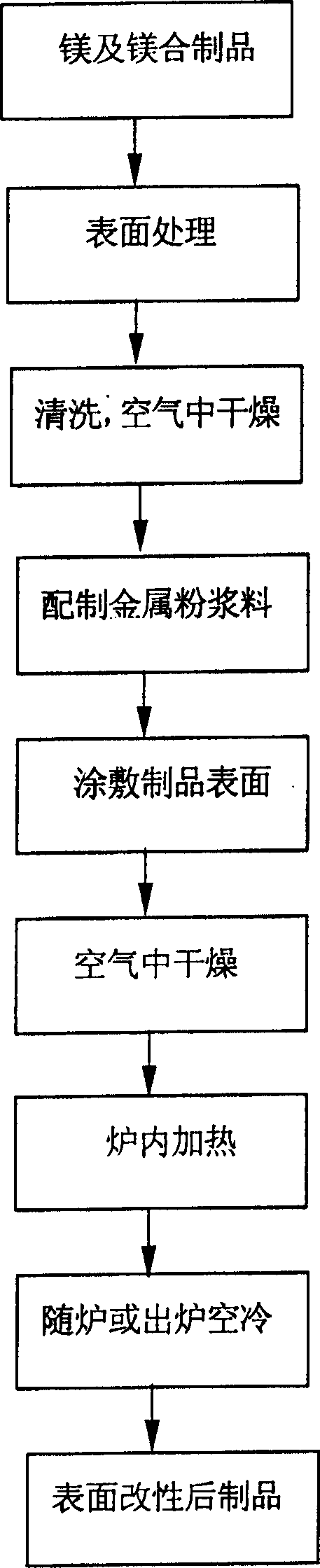

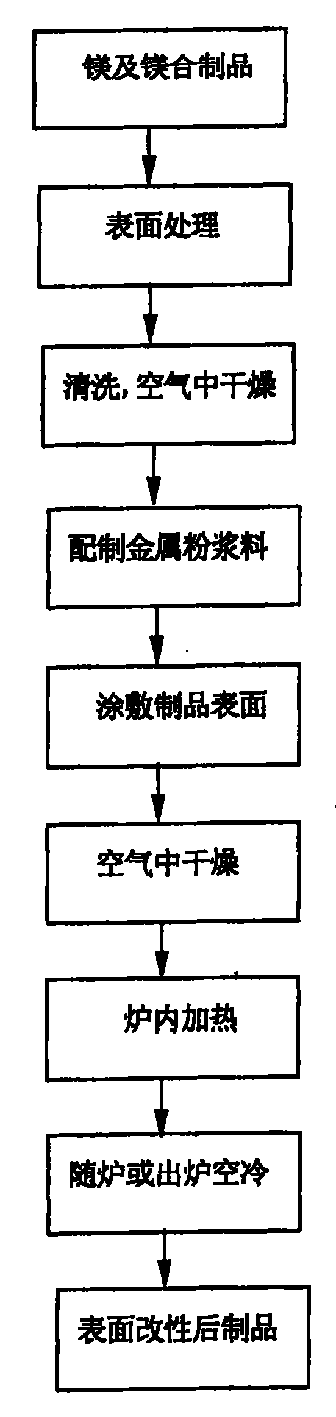

[0051] The specific steps are as follows: see figure 1 .

[0052] a. Carry out surface treatment (such as sandblasting, shot blasting, etc.) to magnesium alloy products to remove surface pollutants, rinse with alcohol, and then dry in the air;

[0053] b. Select aluminum powder with a particle size range of 200 to 320 mesh, use polyvinyl butyral (or dextrin) as a binder, and prepare metal coating materials; polyvinyl butyral (or dextrin) dextrin is about 0.1% of the total aluminum powder;

[0054] c. Apply the prepared metal coating material evenly on the surface of the magnesium alloy product, and the coating thickness is about 0.05mm;

[0055] d. Place the coated magnesium alloy product in the air to dry naturally until the organic solvent evaporates; then,

[0056] e. Place the magnesium alloy product in the furnace to heat the solid-state di...

Embodiment 2

[0060] Process of preparing metal coating material with zinc powder to make surface alloy layer of magnesium alloy products

[0061] The specific steps are as follows: see figure 1 .

[0062] a. Carry out surface treatment (such as sandblasting, shot blasting, etc.) to magnesium alloy products to remove surface pollutants, rinse with alcohol, and then dry in the air;

[0063] b. Select zinc powder with a particle size range of 200-320 mesh, use polyvinyl butyral (or dextrin) as a binder, and prepare metal coating materials; polyvinyl butyral (or dextrin) accounts for about 0.15% of the total powder;

[0064] c. Apply the prepared metal coating material evenly on the surface of the magnesium alloy product, and the coating thickness is about 0.2mm;

[0065] d. Place the coated magnesium alloy product in the air to dry naturally until the organic solvent evaporates;

[0066] e. Place the magnesium alloy product in the furnace to heat the solid-state diffusion. The temperature...

Embodiment 3

[0070] Process of preparing metal coating material with silicon powder to make surface alloy layer of magnesium alloy products

[0071] The specific steps are as follows: see figure 1 .

[0072] a. Carry out surface treatment (such as sandblasting, shot blasting, etc.) to magnesium alloy products to remove surface pollutants, rinse with alcohol, and then dry in the air;

[0073] b. Select silicon powder with a particle size range of 200-320 mesh, use dextrin (or polyvinyl butyral) as a binder, and prepare metal coating materials; dextrin (or polyvinyl butyral) accounts for about 0.2% of the total powder;

[0074] c. Apply the prepared metal coating material evenly on the surface of the magnesium alloy product, and the coating thickness is about 1.0mm;

[0075] d. Place the coated magnesium alloy product in the air to dry naturally until the organic solvent evaporates;

[0076] e. Place the magnesium alloy product in the furnace to heat the solid-state diffusion. The temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com