Preparation of a thiosulfinate compound and its application in antifouling coatings

A technology of thiosulfinate and compounds, applied in antifouling/underwater coatings, coatings, organic chemistry, etc., can solve problems such as shortened life, accelerated corrosion of sea-related facilities components, increased navigation resistance, etc., to achieve Good film-forming properties and anti-fouling properties, remarkable eco-friendly performance, simple preparation method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

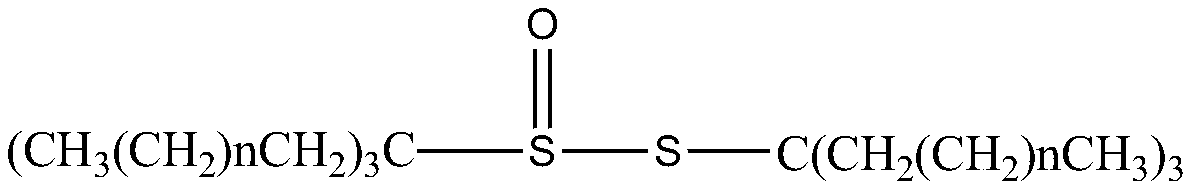

[0016] Embodiment 1: a kind of preparation method of thiosulfinate compound: in the four-necked reaction flask of equipment stirrer, addition funnel, reflux condensing device, thermometer, add 250mL water, 120g sodium hydroxide, stir, Dissolve, cool to 50°C, then add 64g sulfur powder, 1.5g PEG-600, keep stirring at 50°C for 2.5h, then slowly add 600g (CH 3 CH 2 CH 2 CH 2 CH 2 CH 2 ) 3 Toluene (500mL) solution of CCl, after adding 1h, keep the temperature at 50±5°C for 3h, separate the organic layer, wash with saturated brine three times, then dry with anhydrous calcium chloride, then distill toluene under reduced pressure, Obtain disulfide crude product, the structure of above-mentioned disulfide is (CH 3 CH 2 CH 2 CH 2 CH 2 CH 2 ) 3 C-S-S-C(CH 2 CH 2 CH 2 CH 2 CH 2 CH 3 ) 3 ; Then in an ice-water bath, in the four-necked reaction flask equipped with stirrer, addition funnel, reflux condensing device, thermometer, add 60g (CH 3 CH 2 CH 2 CH 2 CH 2 CH ...

Embodiment 2

[0017] Embodiment 2: a kind of preparation method of thiosulfinate compound: in the four-necked reaction flask of equipment stirrer, addition funnel, reflux condensing device, thermometer, add 250mL water, 120g sodium hydroxide, stir, Dissolve, cool to 50°C, then add 64g sulfur powder, 1.5g PEG-600, keep stirring at 50°C for 2.5h, then slowly add 560g (CH 3 CH 2 CH 2 CH 2 ) 3 Toluene (500mL) solution of CCl, after adding 1h, keep the temperature at 50±5°C for 3h, separate the organic layer, wash with saturated brine three times, then dry with anhydrous calcium chloride, then distill toluene under reduced pressure, Obtain di-tertiary hydrocarbyl disulfide compound; Then in ice-water bath, in the four-necked reaction flask of equipment stirrer, addition funnel, reflux condensing device, thermometer, add the dichloromethane (400mL) of 60g di-tertiary hydrocarbyl disulfide compound Solution, then slowly add 24g35% (W / V) peroxyacetic acid dropwise, 30min dripping, then continue...

Embodiment 3

[0018] Embodiment 3: a kind of preparation method of thiosulfinate compound: with (CH 3 CH 2 CH 2 CH 2 ) 3 CBr replaces (CH in embodiment 2 3 CH 2 CH 2 CH 2 ) 3 CCl, other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com