Vibrating grate

A furnace grate and grate ring technology, applied in the field of slagging system in biomass gasification reaction chamber, can solve the problems of coking and ash that cannot be discharged smoothly and in time, manual slagging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

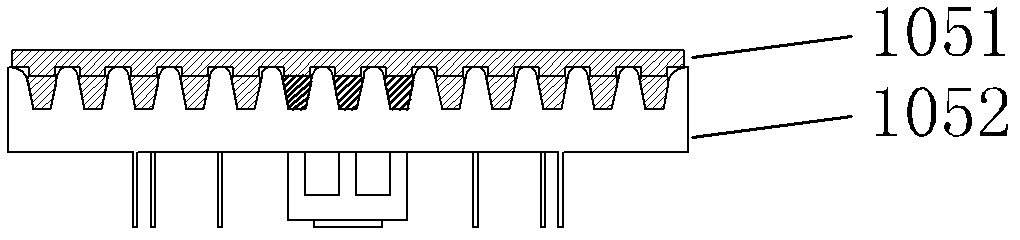

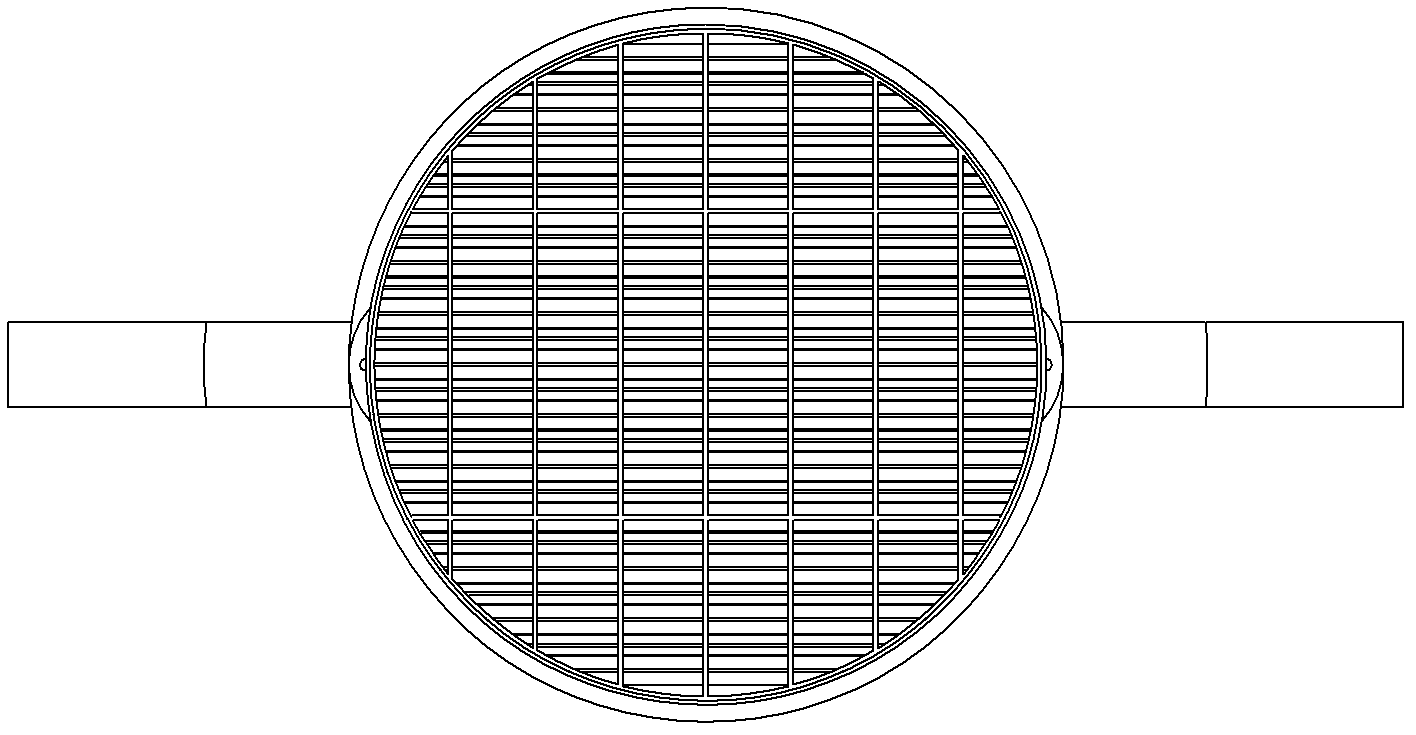

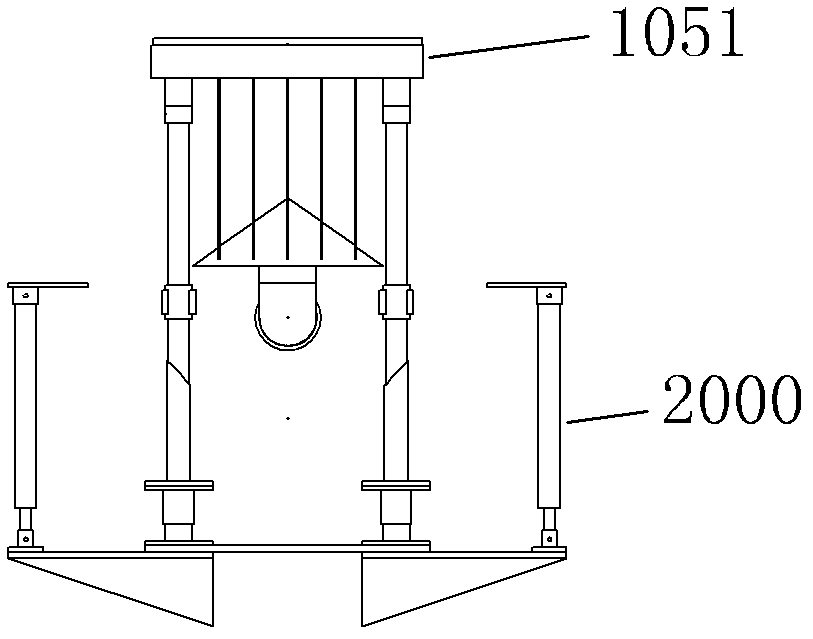

[0024] A vibrating grate 1, such as figure 1 As shown, it is made of high-temperature-resistant material and has a split structure of upper and lower layers; the lower grate 1052 is a fixed furnace composed of multiple trapezoidal stainless steel racks placed in a positive ladder shape and fixedly connected to the inner side of the grate ring through its two ends Castor, such as figure 2 As shown, it is fixed on the refractory material wall at the lower end of the gasification reaction chamber; the upper grate 1051 is a movable grate composed of multiple ladder-shaped stainless steel racks placed in an inverted ladder shape and fixedly connected to the inner side of the grate ring through its two ends ,Such as figure 2 As shown, it is connected and linked with the hydraulic cylinder 2000, such as image 3 As shown; the rack of the lower grate 1052 and the rack of the upper grate 1051 are correspondingly engaged, and the transverse gap at the joint is set according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com