Patents

Literature

31results about How to "Pollution-free production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

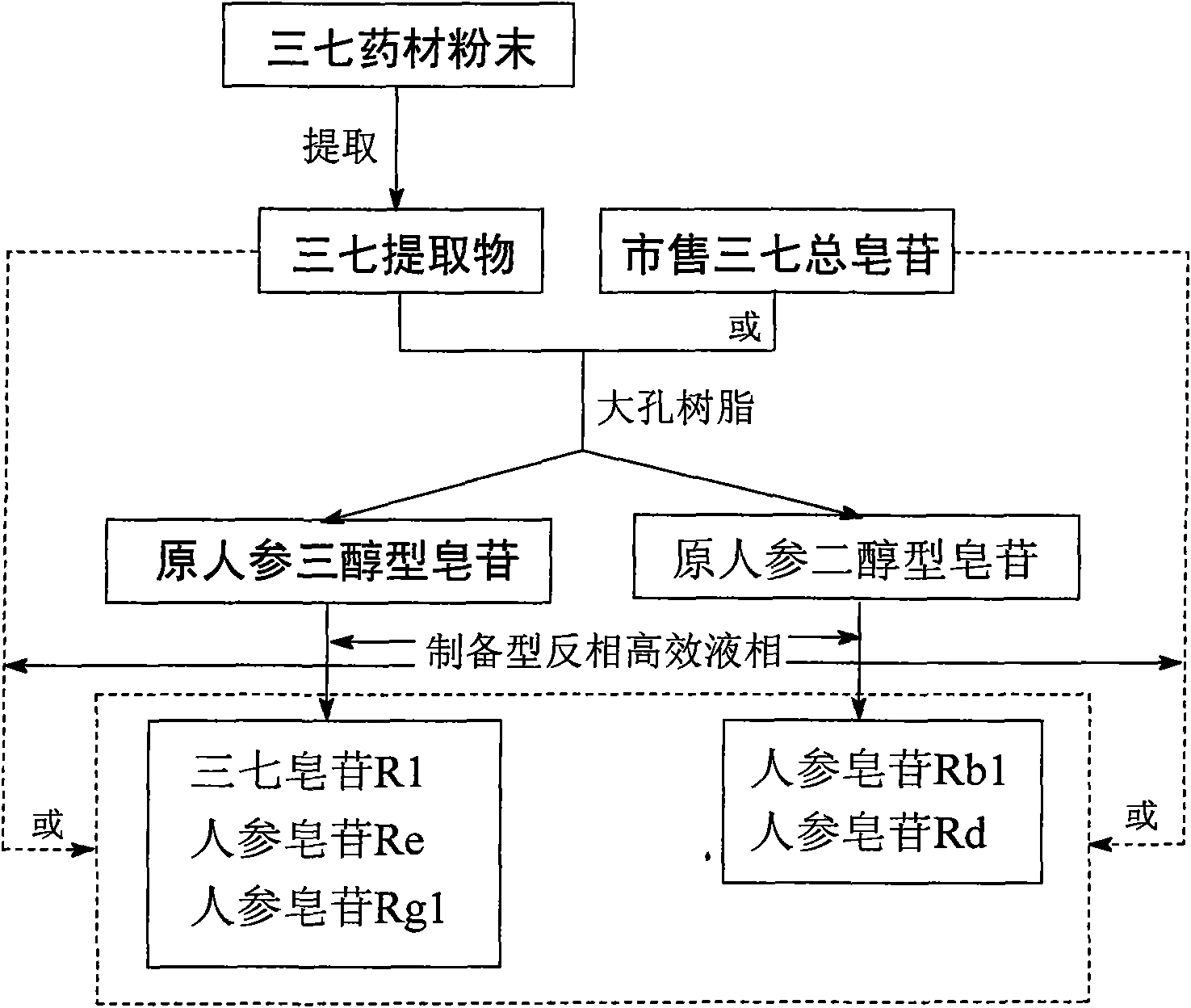

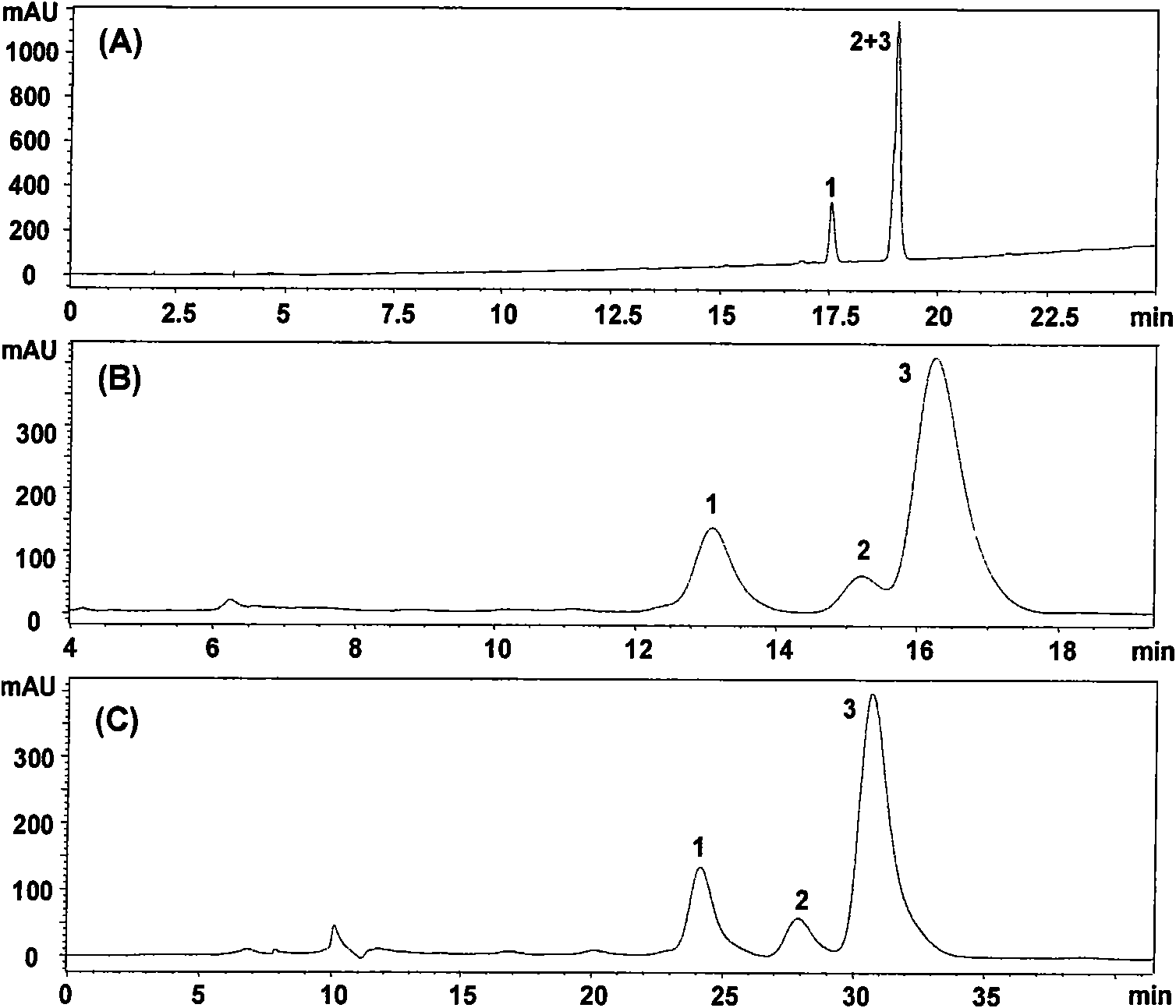

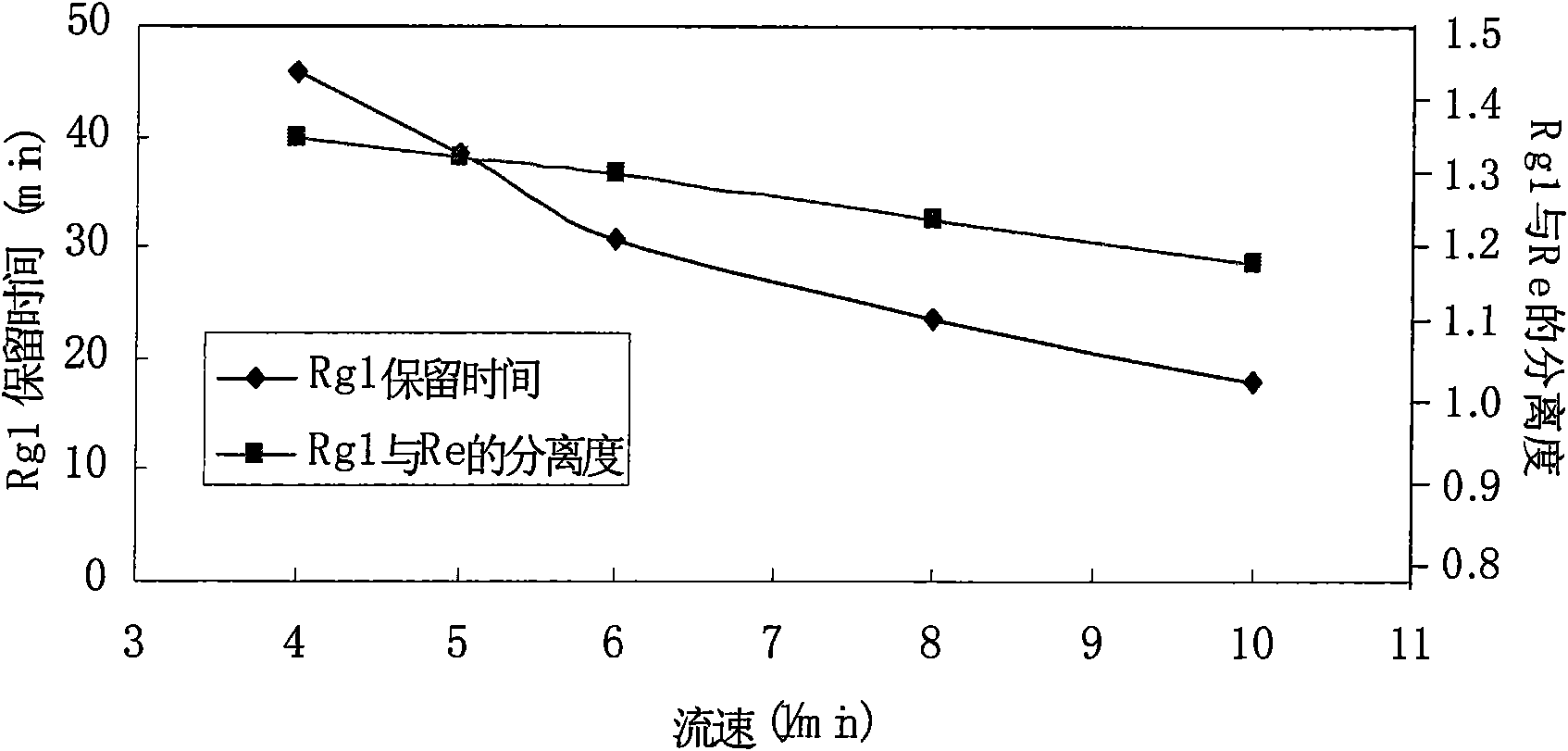

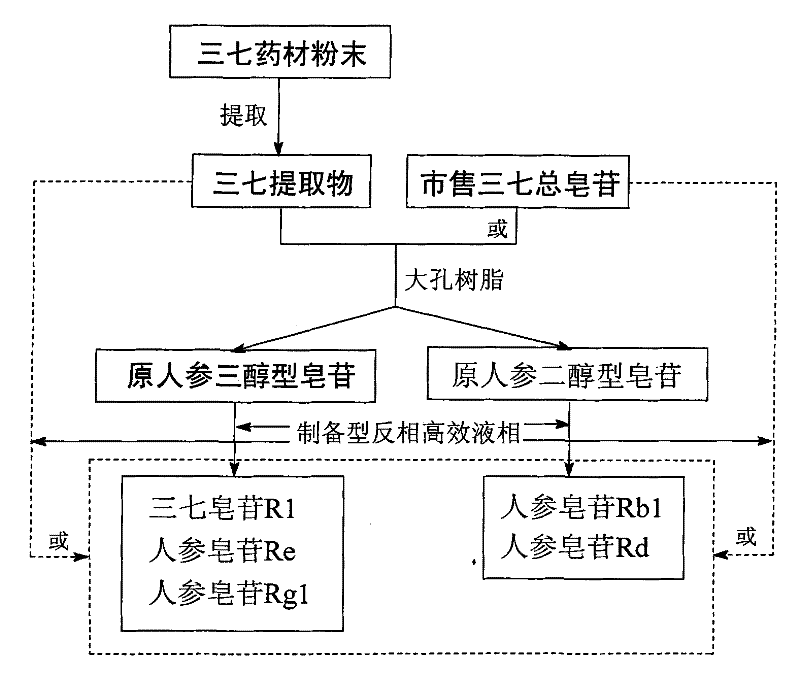

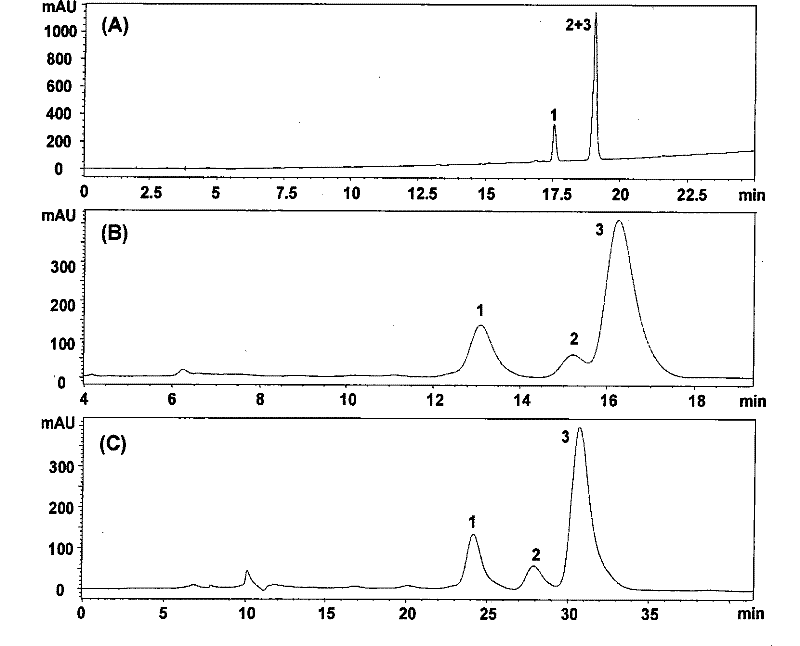

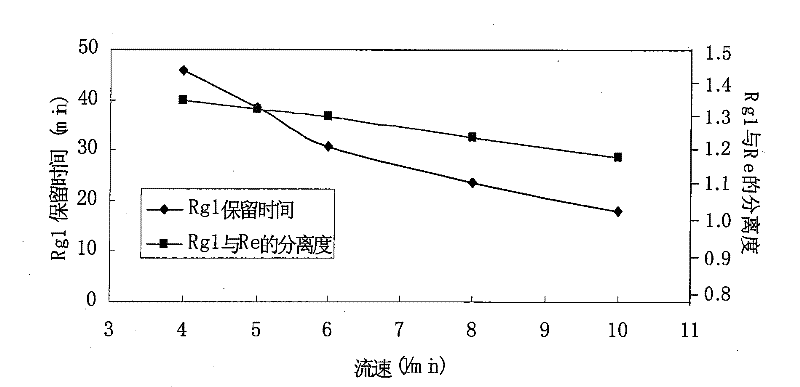

Method for preparing notoginsenoside R1 and ginsenoside Rg1, Re, Rb1 and Rd

InactiveCN101575357ASimple processShorten the production cycleSteroidsIsocratic elutionPanax notoginseng extract

The invention provides a method for simply, conveniently and quickly preparing notoginsenoside R1 and ginsenoside Rg1, Re, Rb1 and / or Rd, which can meet the requirement of industrial production and is environment-friendly. In the method, notoginseng extract and arasaponin or notoginsenoside intermediates are used as original materials, a preparative scale reversed phase high-performance liquid chromatography is adopted, and an ethanol-water system is used as a flow phase to carry out isocratic elution or gradient elution, wherein the ethanol-water system is an ethanol-water solution of 30 percent to 80 percent (V / V). The method has the advantages of simple process, no pollution, low cost and high purity, wherein the purity of products produced by the method is more than 97 percent.

Owner:UNIVERSITY OF MACAU

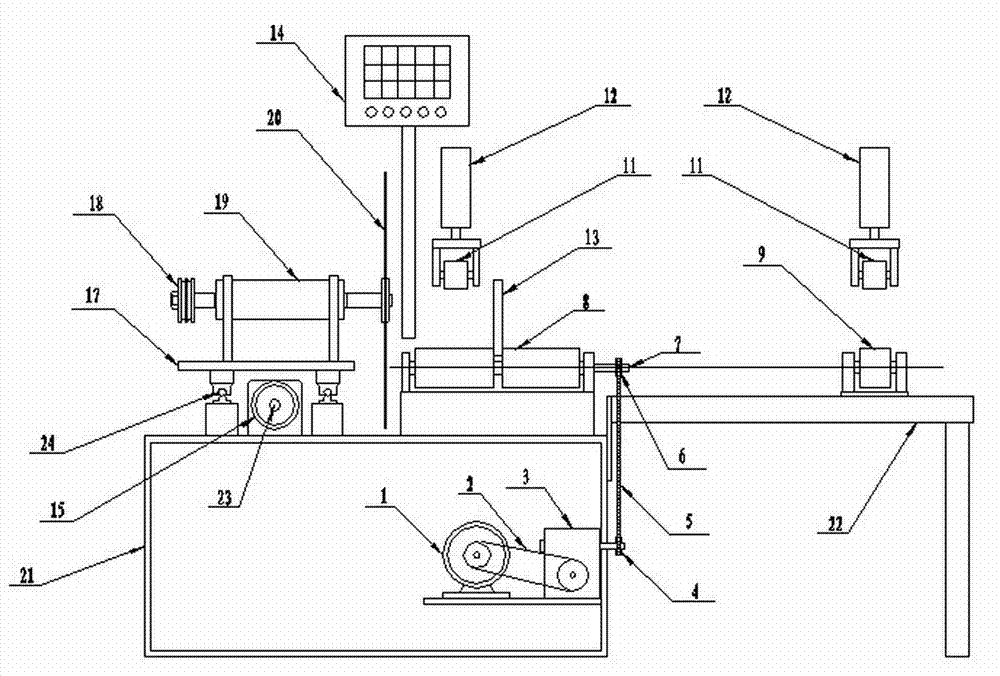

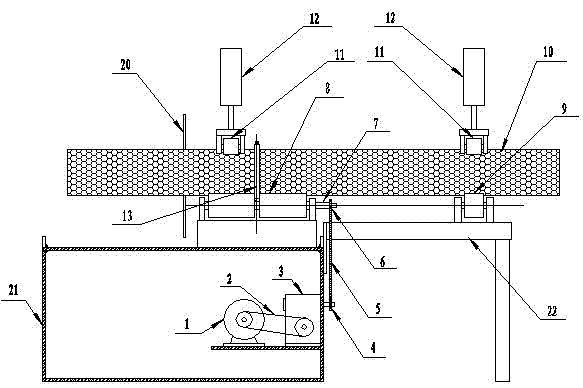

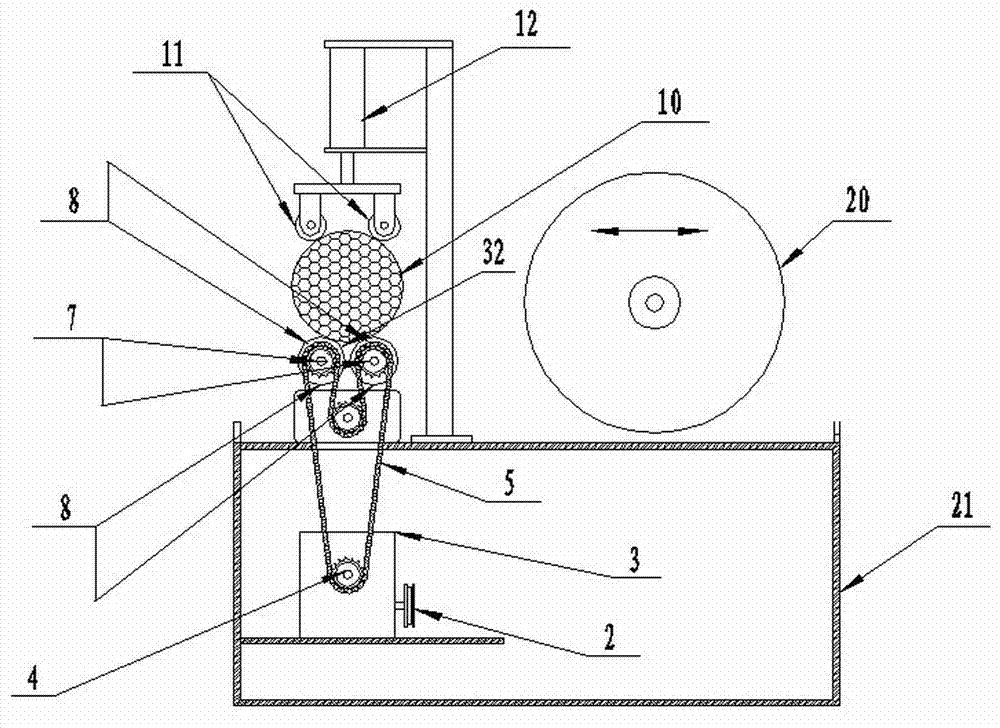

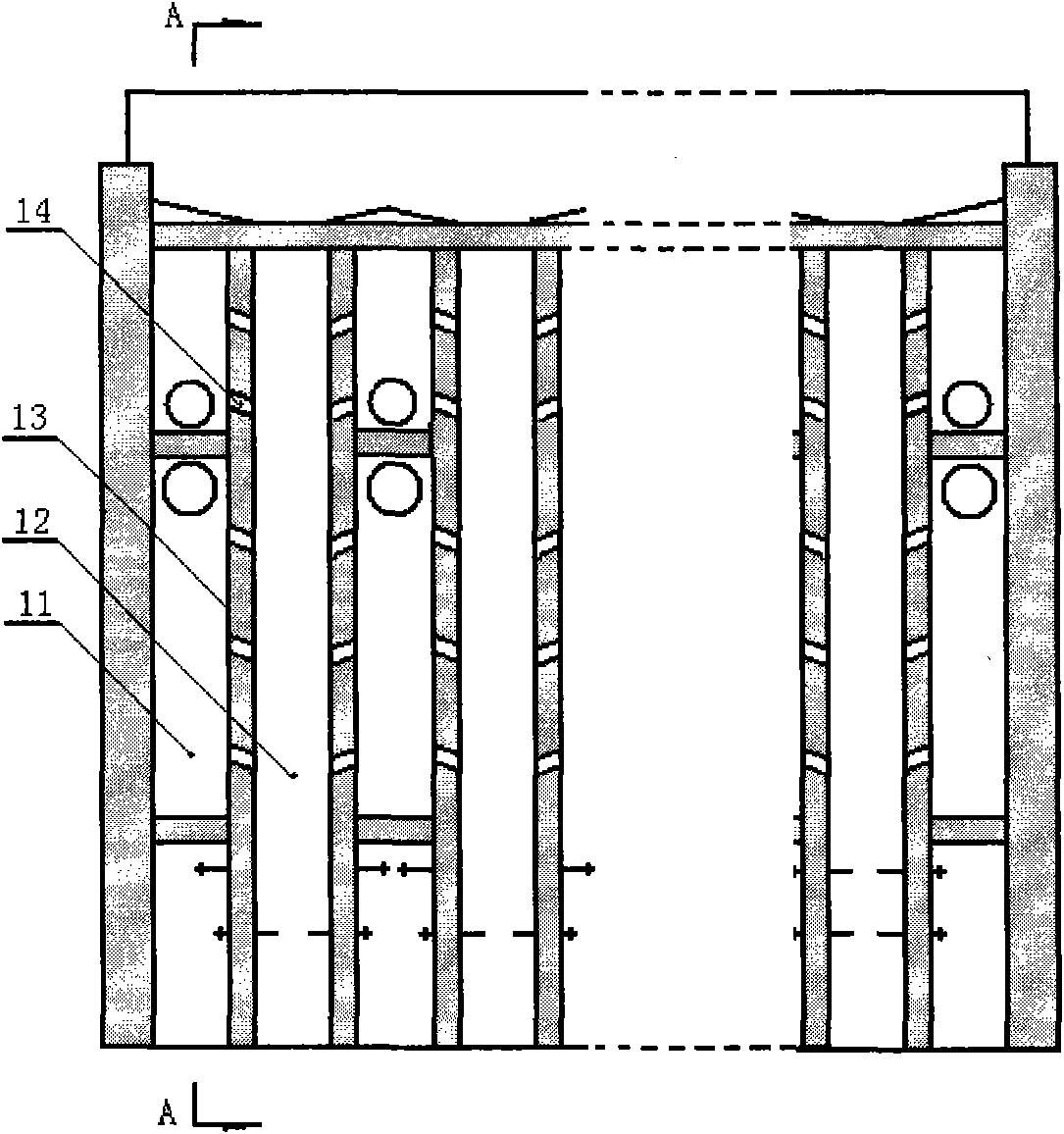

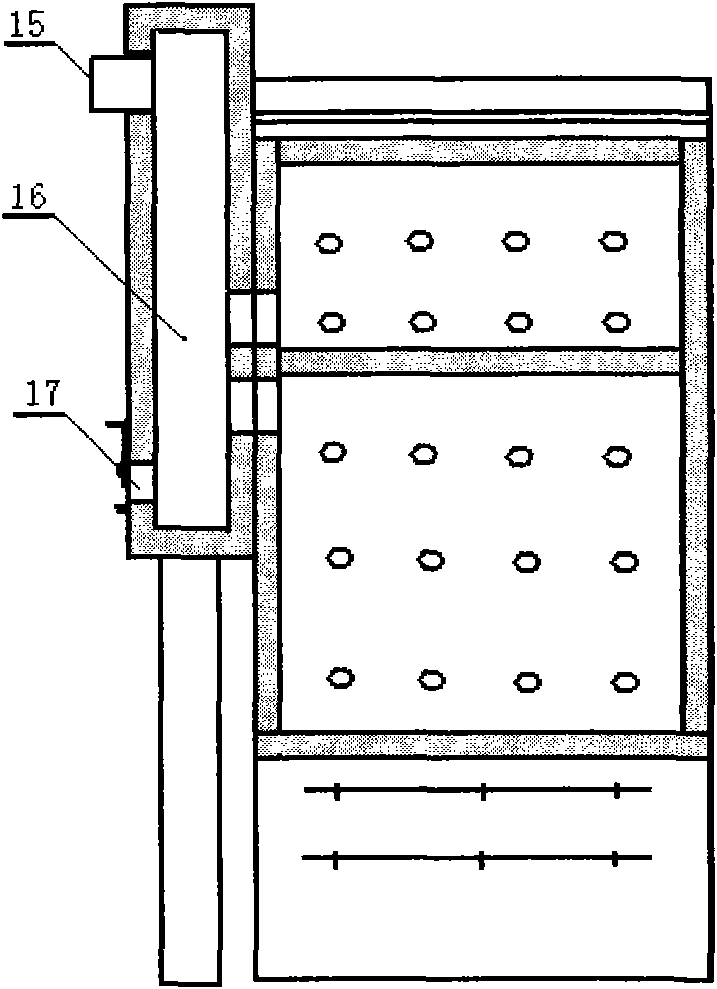

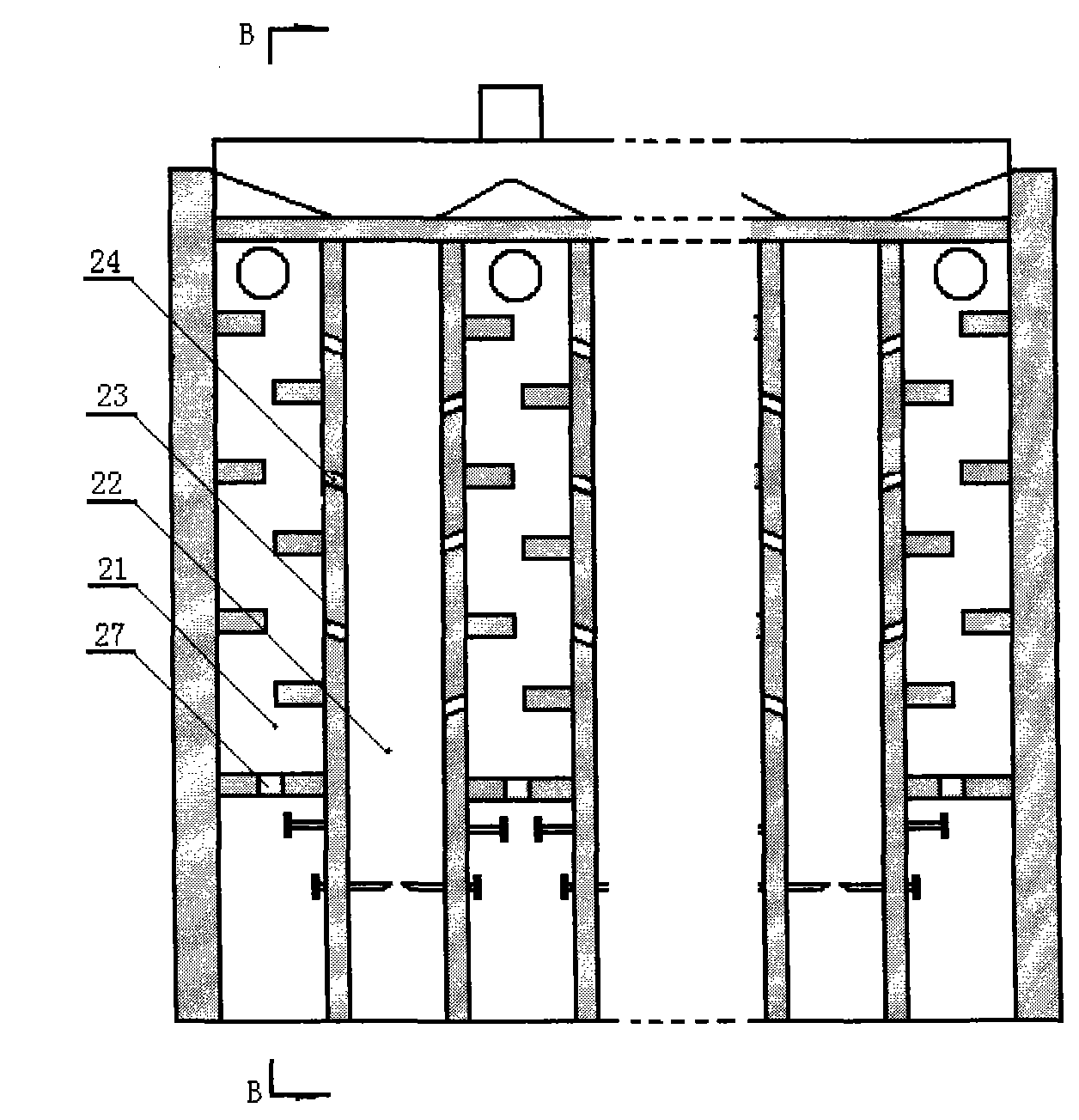

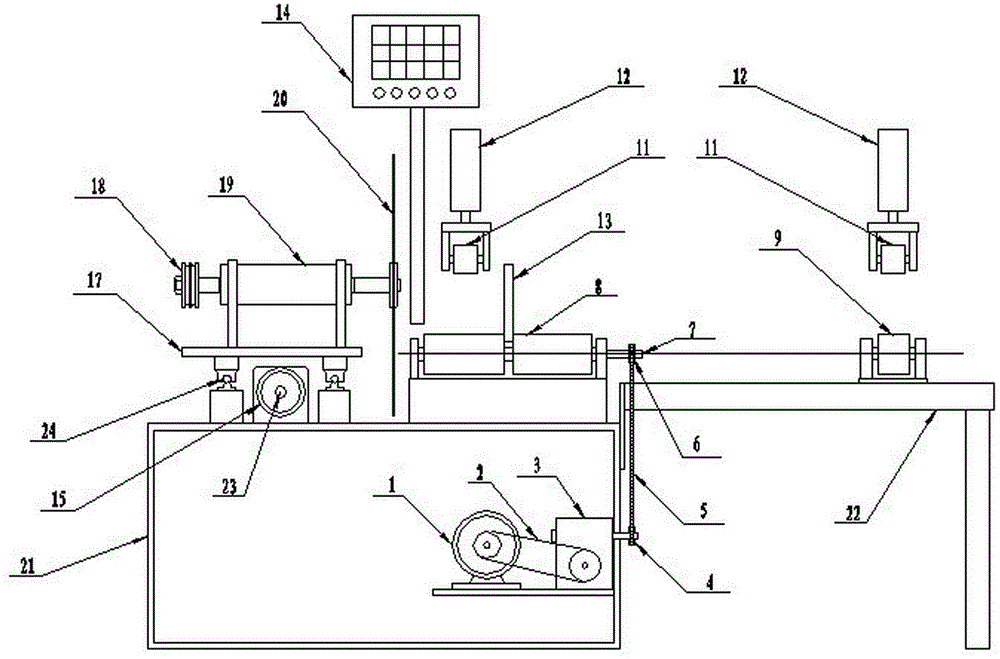

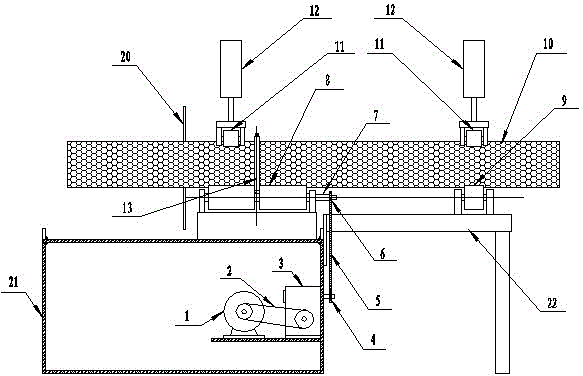

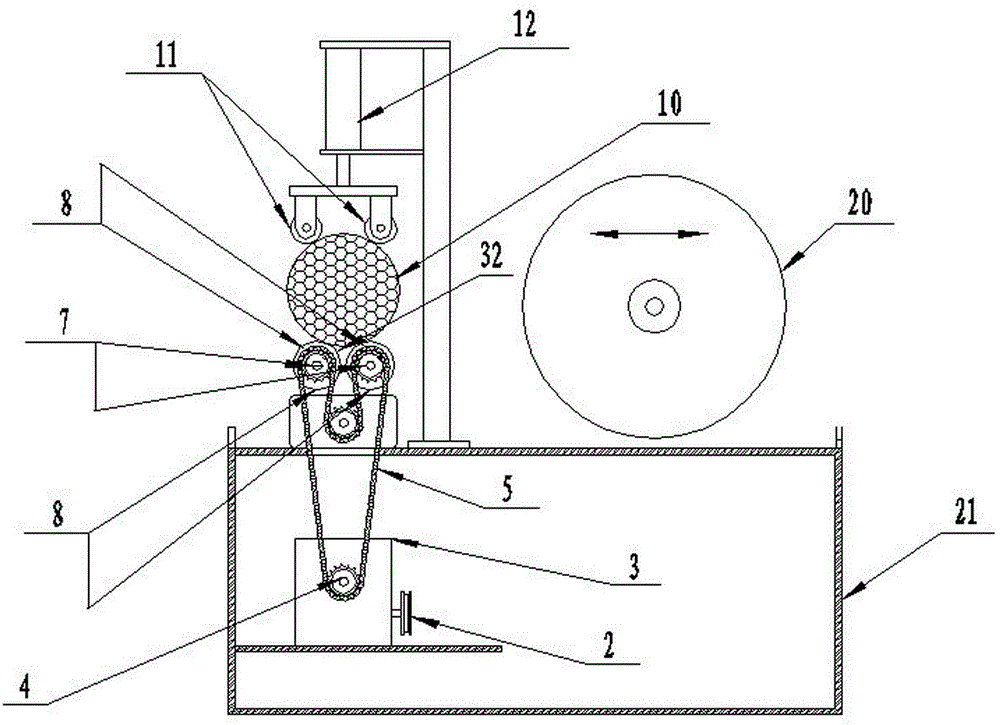

Rotary floating cutting numerical control machine tool for silicon rod

InactiveCN102862239AControl BrokenReduce vibrationWorking accessoriesFine working devicesNumerical controlEngineering

The invention discloses a rotary floating cutting numerical control machine tool for a silicon rod, and relates to a numerical control machine tool, in particular to a numerical control cutting machine for cutting the silicon rod. The rotary floating cutting numerical control machine tool comprises a numerical control box, a machine tool body, a transmission mechanism, and a cutting mechanism and a silicon rod clamping mechanism which are arranged on the machine tool body, and is characterized in that the silicon rod clamping mechanism comprises a driving rotation support wheel which clamps the silicon rod in a matching manner in the vertical direction, and a floating rotary pressing wheel; the floating rotary pressing wheel is connected with an elastic pressing device which drives the floating rotary pressing wheel to tightly press the silicon rod; and the transmission mechanism is connected with a shaft of the driving rotation support wheel. The rotary floating cutting numerical control machine tool can realize the non-concentric axial rotation floating radius cutting of polycrystalline silicon rods which have the characteristics that the material texture density is sparse, workpieces are bent in the axial direction, ovality exists in the diameter direction, the diameters are different, the appearances are not irregular, the breaking phenomenon is easy to generate, and the like in the floating rotation state, and is novel and capable of realizing the automatic radius cutting.

Owner:刘鸿彬

Environmental protection type transparent solid glue and preparation method thereof

ActiveCN102321443AColor transparentHigh hardnessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePreservative

The present invention discloses environmental protection type transparent solid glue. The glue comprises the following components, by weight, 40-50 parts of deionized water, 6-10 parts of an activator, 0.5-2 parts of an antifoaming agent, 15-20 parts of a lubricant, 20-30 parts of a moisturizing agent, 6-10 parts of sodium stearate, 20-30 parts of polyvinylpyrrolidone and 0.2-1 parts of a preservative. In addition, the present invention further provides a preparation method for the environmental protection type transparent solid glue. Compared to the prior art, the environmental protection type transparent solid glue provided by the present invention has characteristics of transparent color, high hardness, good moisture retention, smooth coating without dreg dropping, good oxidation resistance, environmental protection and no toxicity.

Owner:JIANGSU XINGDA STATIONERY GRP

High yield environmental protection type industrial separating method for ginseng saponin Rb1

The present invention relates to the extraction and separation of effective components in Chinese medicine. The ginsenoside Rb1 separating process includes dissolving ginsenoside, American ginsenoside or notoginseng general saponin in small amount of eluant, adding to stabilized chromatographic column to elute while detecting until reaching negative, merging the elutriant of ginsenoside Rb1, reducing recovering solvent, vacuum freeze drying to obtain freeze dried ginsenoside Rb1 powder, inspection and packing. The present invention has the advantages of simple technological process, short production period, no pollution, low cost, high product purity over 95 %, and high yield up to 20 %.

Owner:长春三和参业科技有限公司

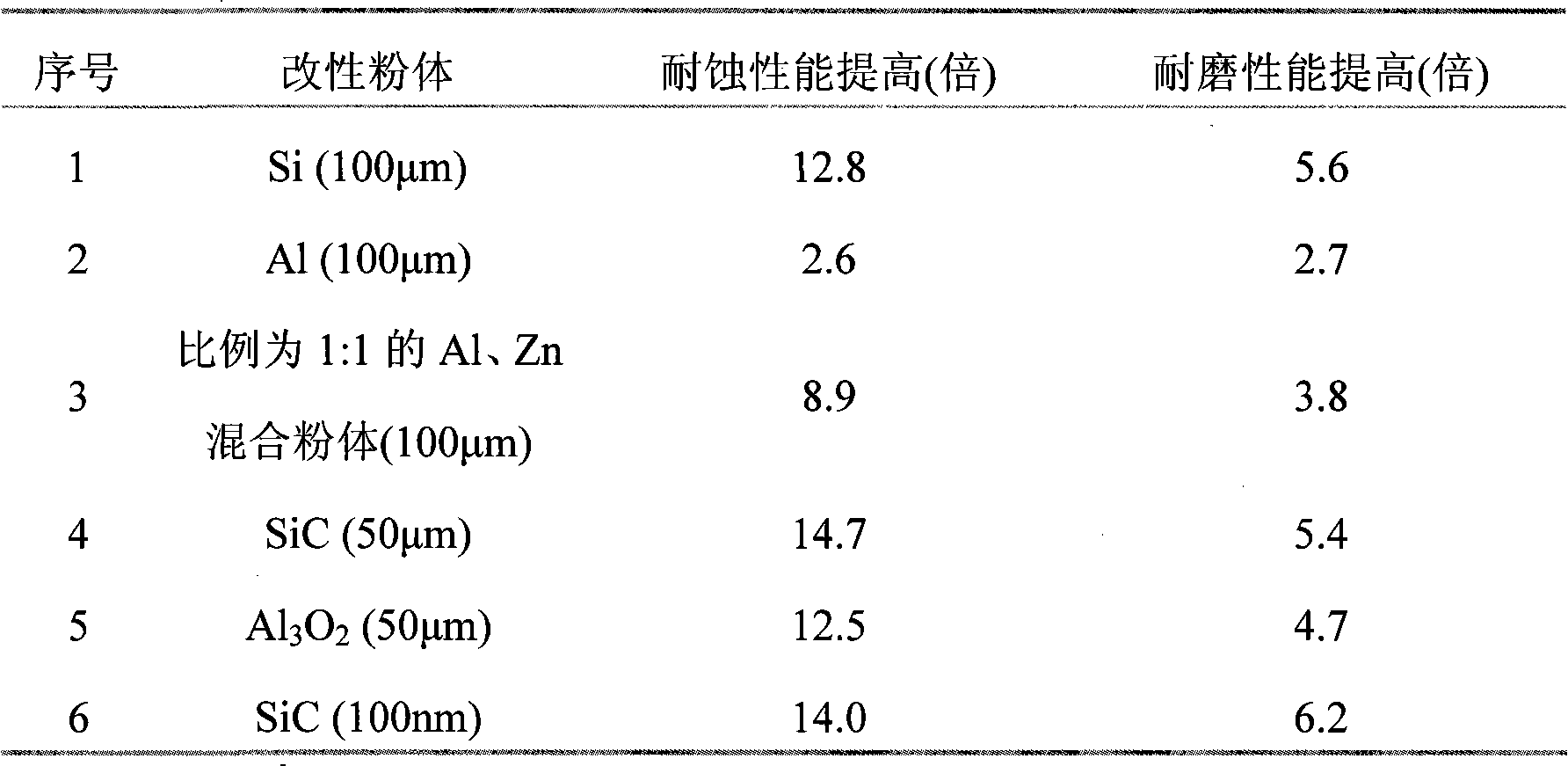

Die-casting magnesium alloy surface modified powder infiltration process

InactiveCN101402136AThe technical effect is obviousChange the physical and chemical properties of the surfaceHigh rateFiltration

The invention relates to a modified powder body filtration process for the surface of die casting magnesium alloy, which forms the gradient of alloy concentration on a surface layer of a die casting magnesium alloy part through an infiltration technology. The adopted technical proposal is as follows: different modified powder bodies without adding any adhesive are directly sprayed on the surface of a parting agent of a die casting mold, and a modification layer can be formed on the surface of the magnesium alloy part by casting liquid magnesium alloy in the metal casting mold by die casting and cooling. The process substantially changes the physicochemical property and the mechanical property of the surface of the magnesium alloy; the formed surface modification layer is continuous and compact, does not contain organic substances, and has good corrosion resistance and wear resistance; and the process simplifies the prior surface modification technology of the magnesium alloy, and realizes green, environment-friendly and pollution-free production. The process is simple, has easily controlled parameters and high rate of finished products, and can be widely used for industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

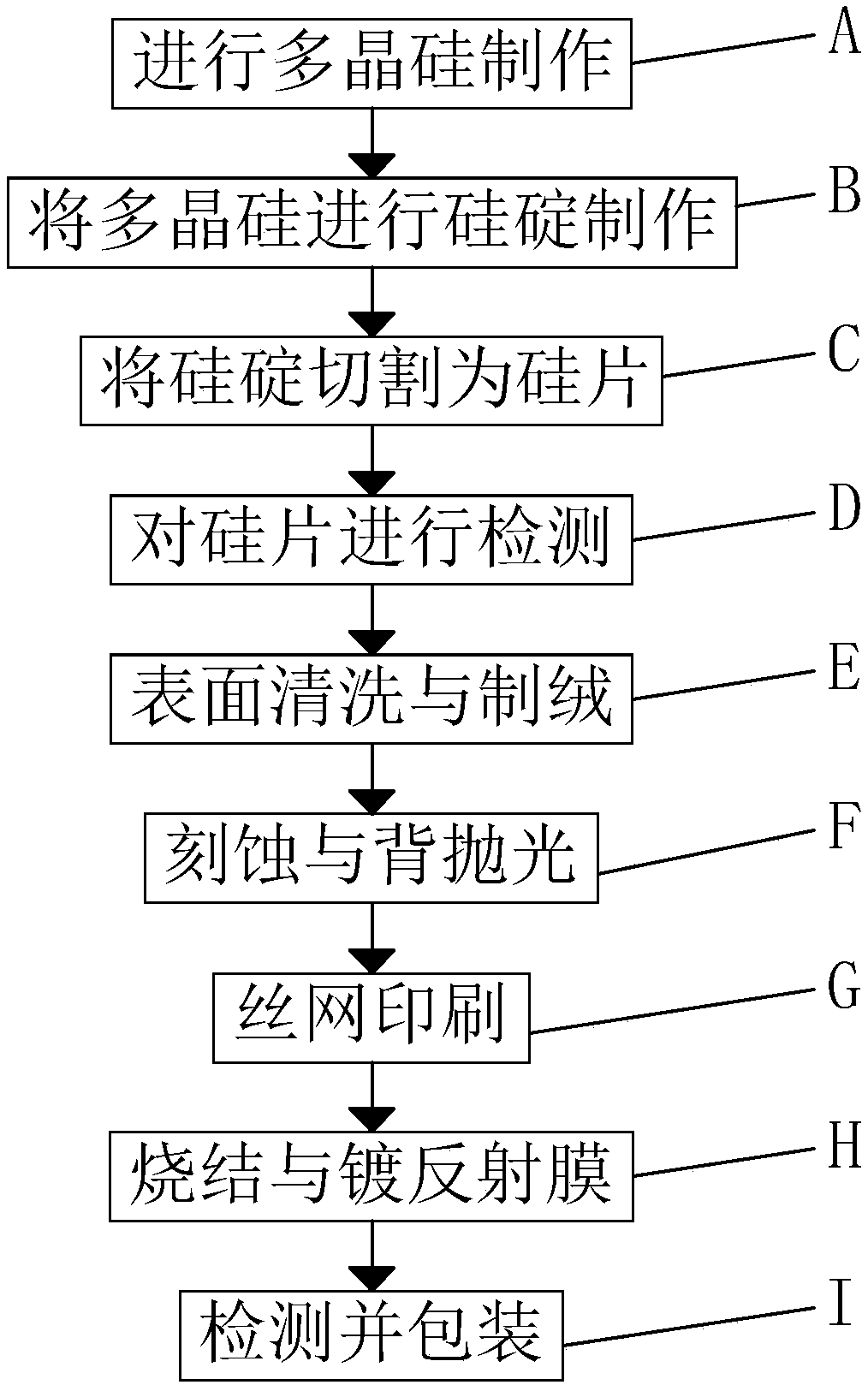

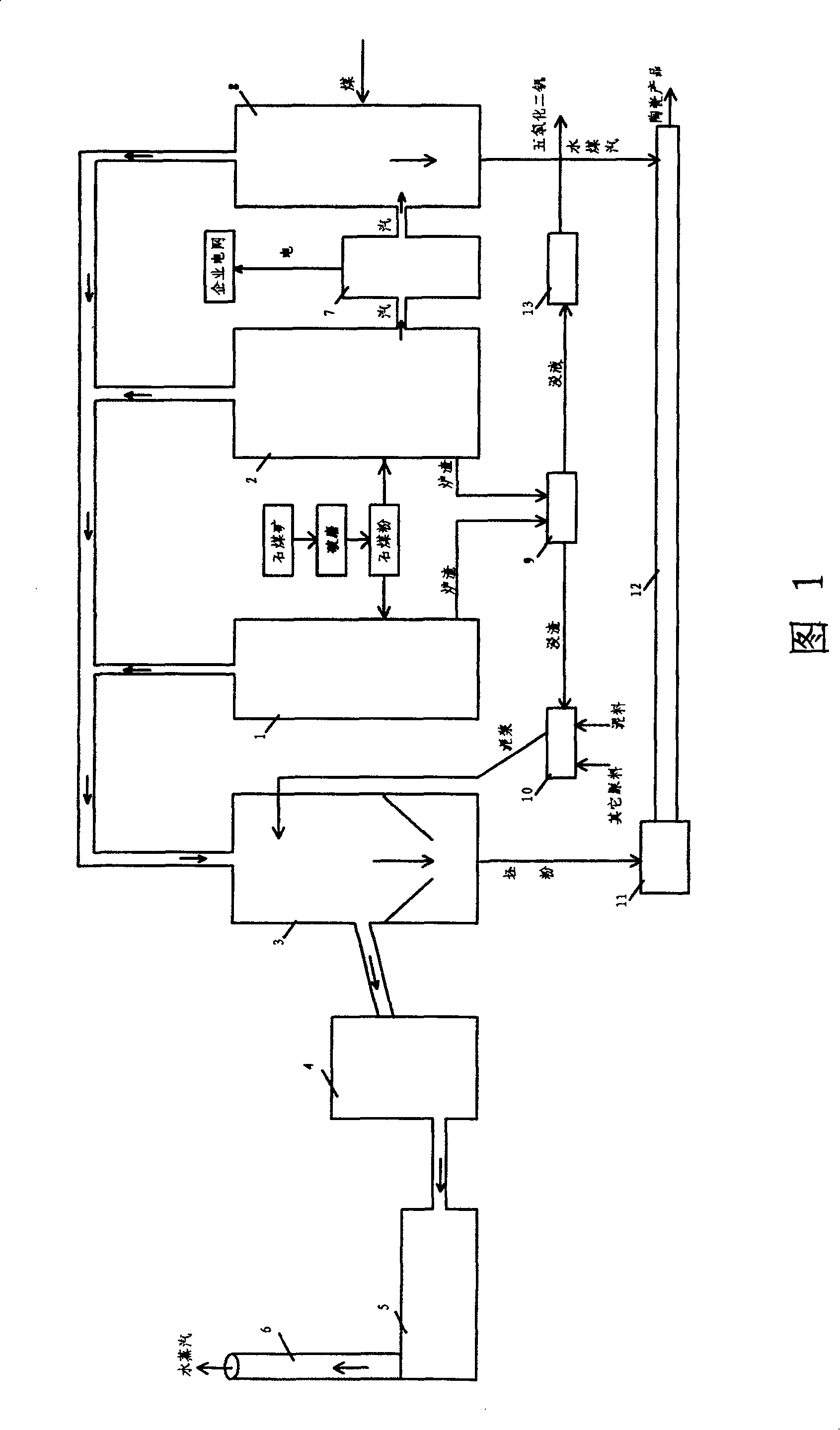

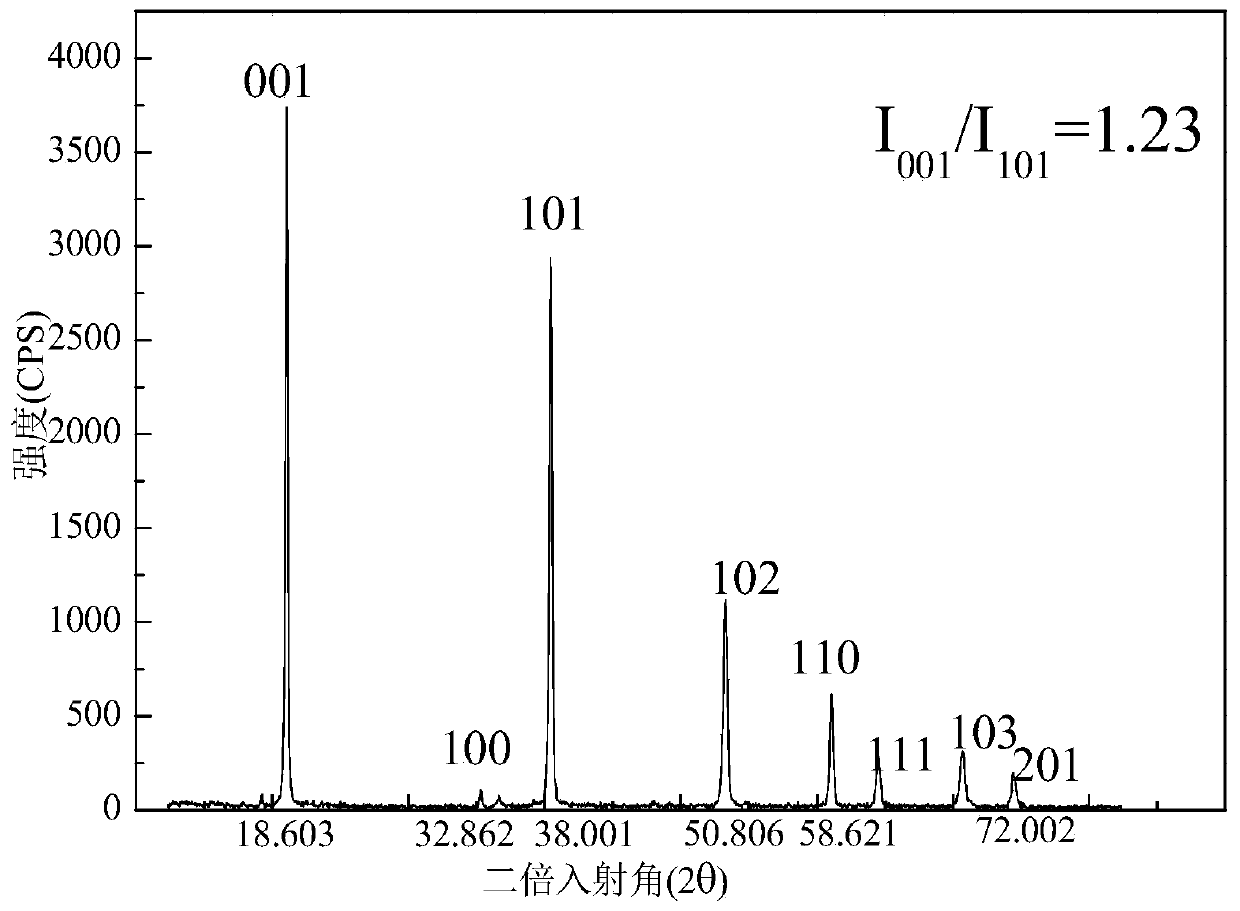

Solar cell production process

InactiveCN108172661APollution-free productionImproved cleaning methodFinal product manufacturePhotovoltaic energy generationPolycrystalline siliconSolar cell

The invention discloses a solar cell production process. The production process comprises the following steps: A, manufacturing polycrystalline silicon; B, making the polycrystalline silicon into a silicon ingot; C, cutting the silicon ingot into a silicon wafer; D, detecting the silicon wafer; E, carrying out the surface cleaning and texturing; F, etching and back polishing; G, performing silk-screen printing; H, sintering and plating a reflecting film; and I, detecting and packaging. According to the invention, the production process is adopted, all wastes in the whole production process canbe fully utilized, no waste is discharged, environment-friendly and pollution-free production can be realized, and various generated waste liquid can be used for recycling and treating scrapped failures and unqualified solar cells, the cleaning mode and the etching mode of the silicon wafer are improved, the technological process is effectively shortened, the required raw materials are easy to obtain, the production cost of the solar cell is reduced, and the benefits of the enterprise are met.

Owner:WENZHOU SAILAFU ENERGY

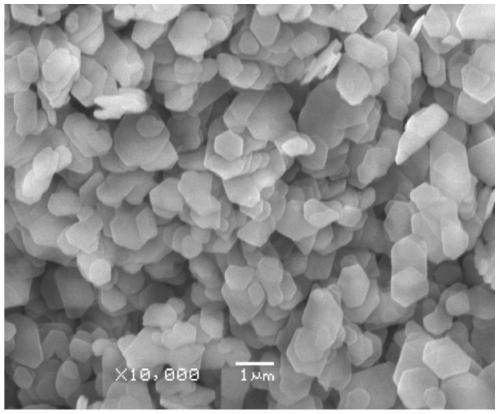

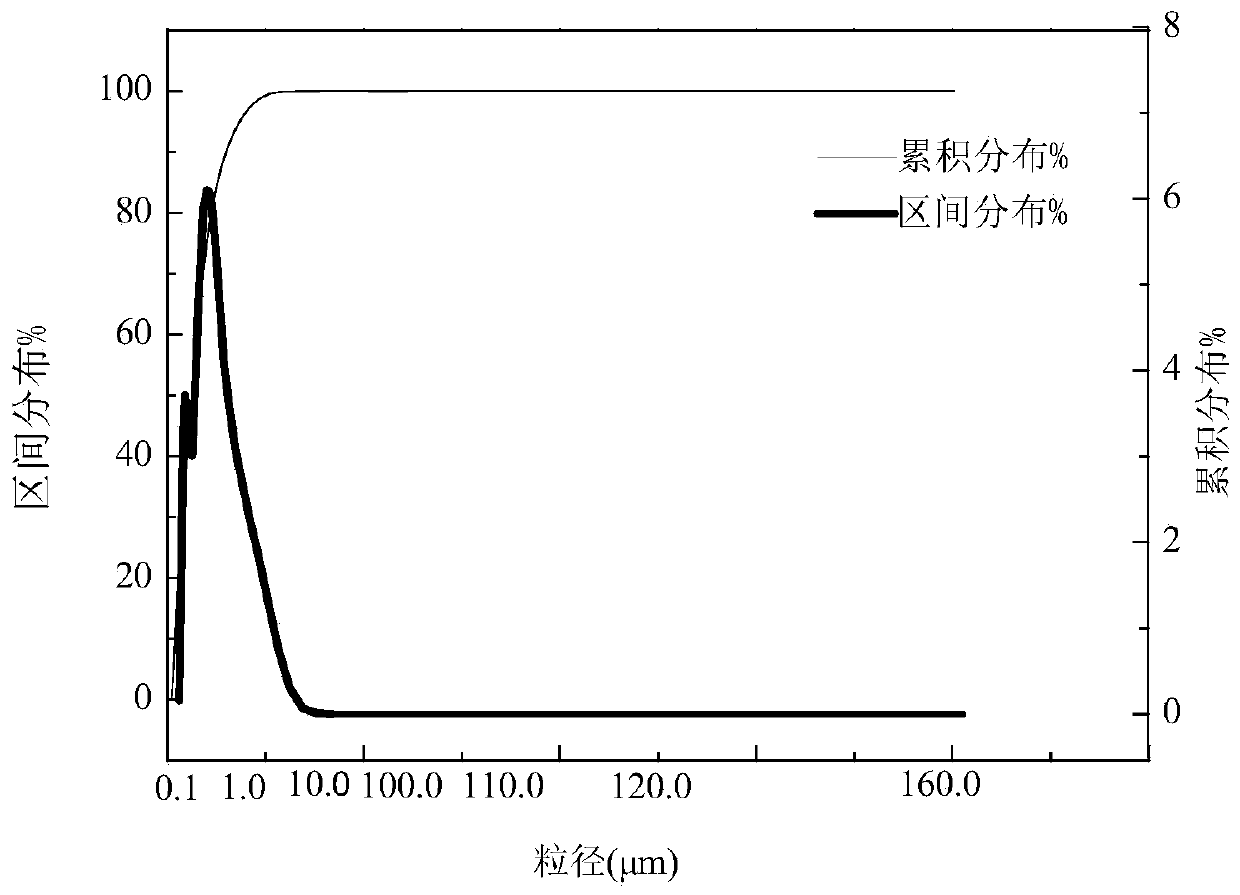

Method for preparing high surface-activity adsorbing carbon material through catalysis and activation synchronous process

ActiveCN101844069BControl pore size distributionAchieve balanceOther chemical processesPore diameterHigh surface

The invention provides a method for preparing a high surface-activity adsorbing carbon material through a catalysis and activation synchronous process, which can markedly reduce environmental pollution, can lower the production cost of the adsorbing carbon material, and is easy for industrialization. The method comprises the following steps of: firstly, pulverizing petroleum coke or a wooden husk, carbonizing, then mixing with an alkali medium activator, preactivating, then activating at different temperature segments of a high-temperature activation furnace, and controlling the specific surface area and the pore diameter distribution of the high surface-activity adsorbing carbon material by adopting a double-furnace three-segment catalysis and activation synchronous method. The method comprises the following steps of: carbonizing raw materials in the activation furnace for 2 hours at the temperature of 300-800 DEG C, then adding carbon powder and 1-5% of catalyst according to the proportion of the carbon powder and KOH of 1:1-1:2, directly mixing with the raw materials, and heating to 150-550 DEG C for carrying out preactivation reaction for 1-2 hours; then enabling the material to enter the high-temperature activation furnace, reacting for 1-2 hours at a medium temperature segment at the temperature of 650-850 DEG C, and then reacting for 1-2 hours at a high temperature segment at the temperature of 950-1050 DEG C.

Owner:成都益盛环境工程科技有限责任公司

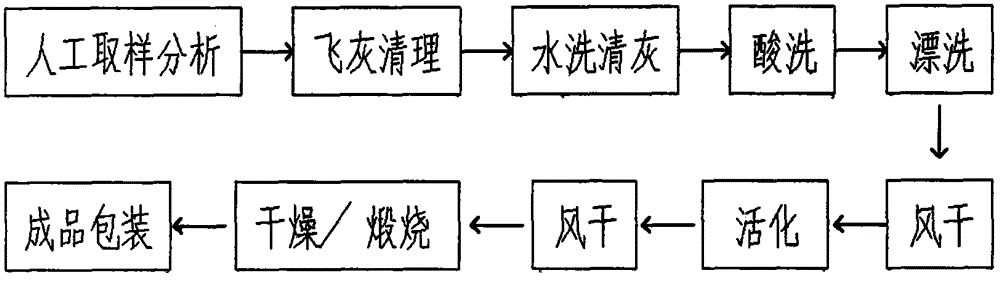

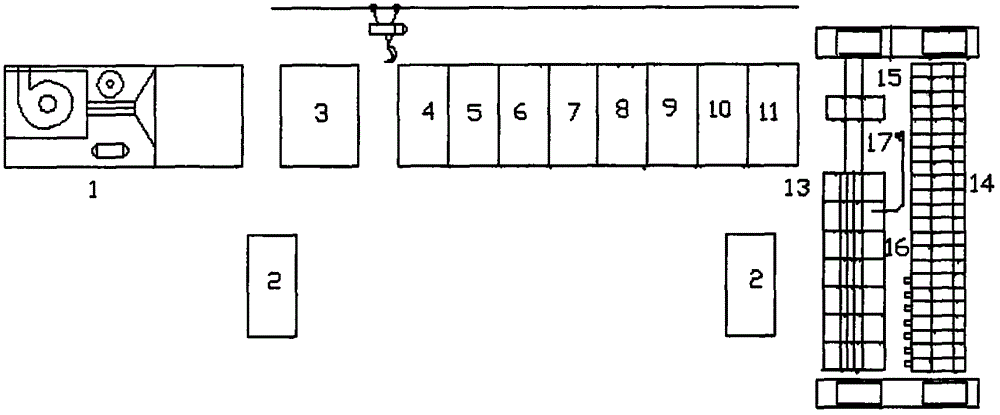

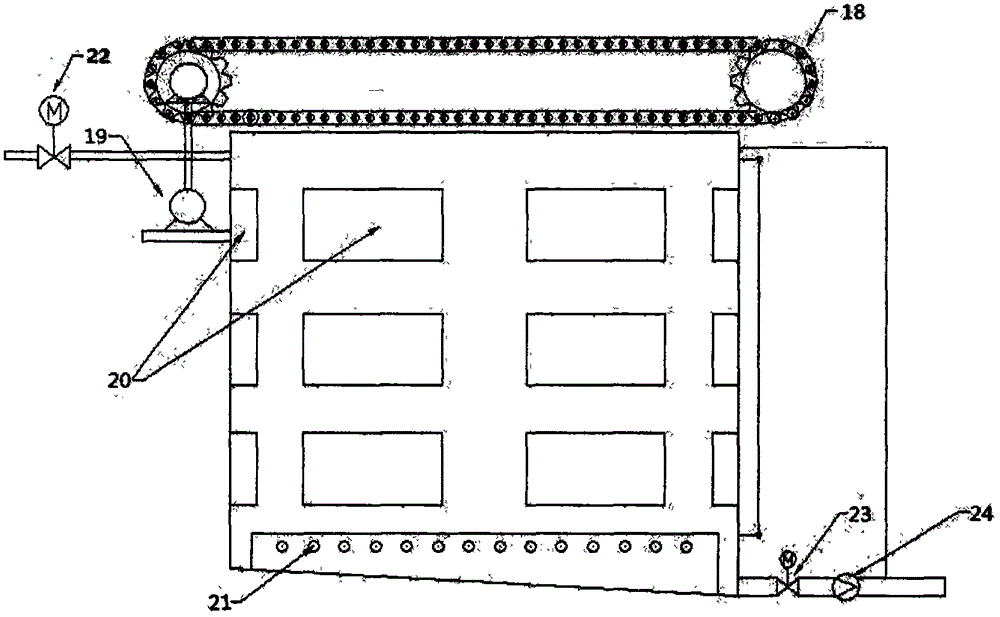

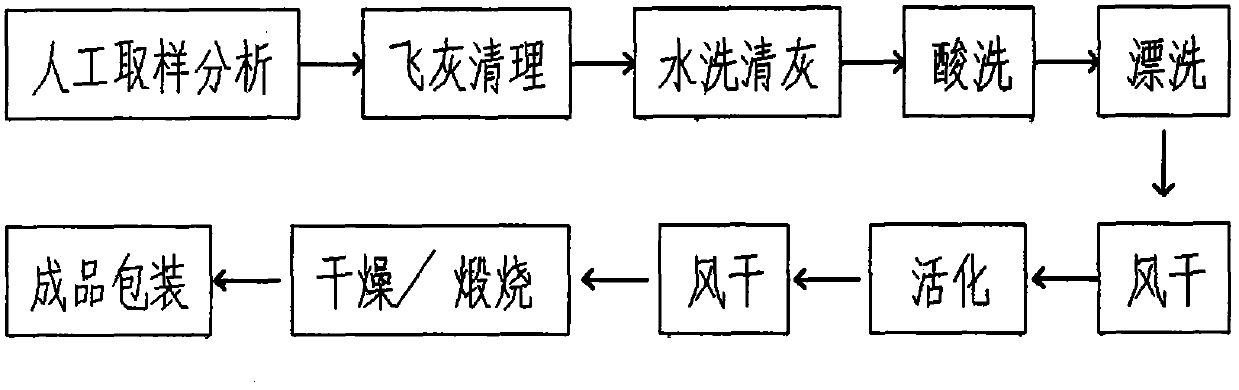

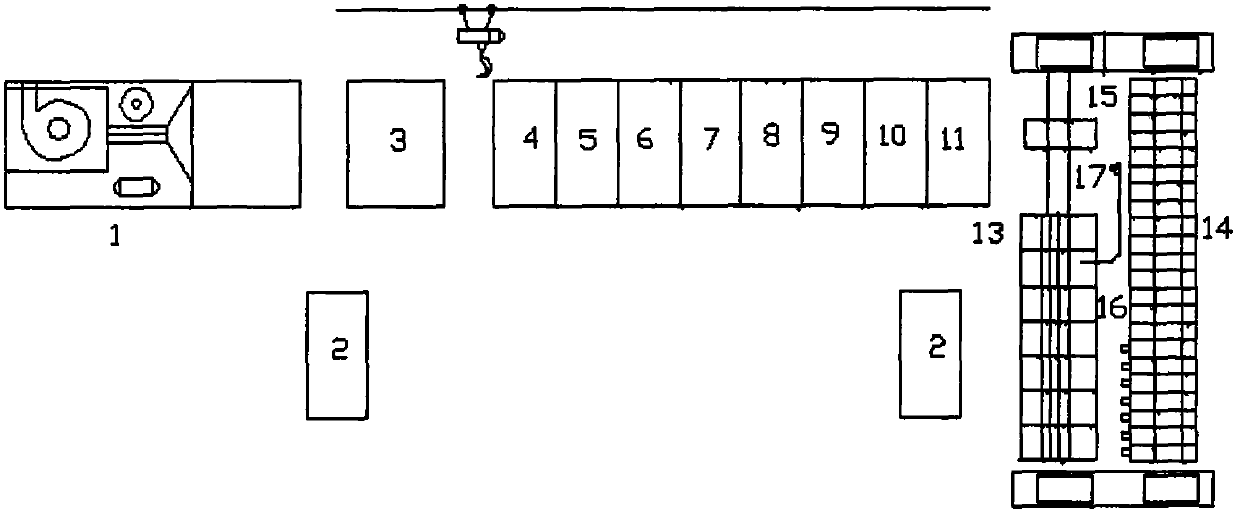

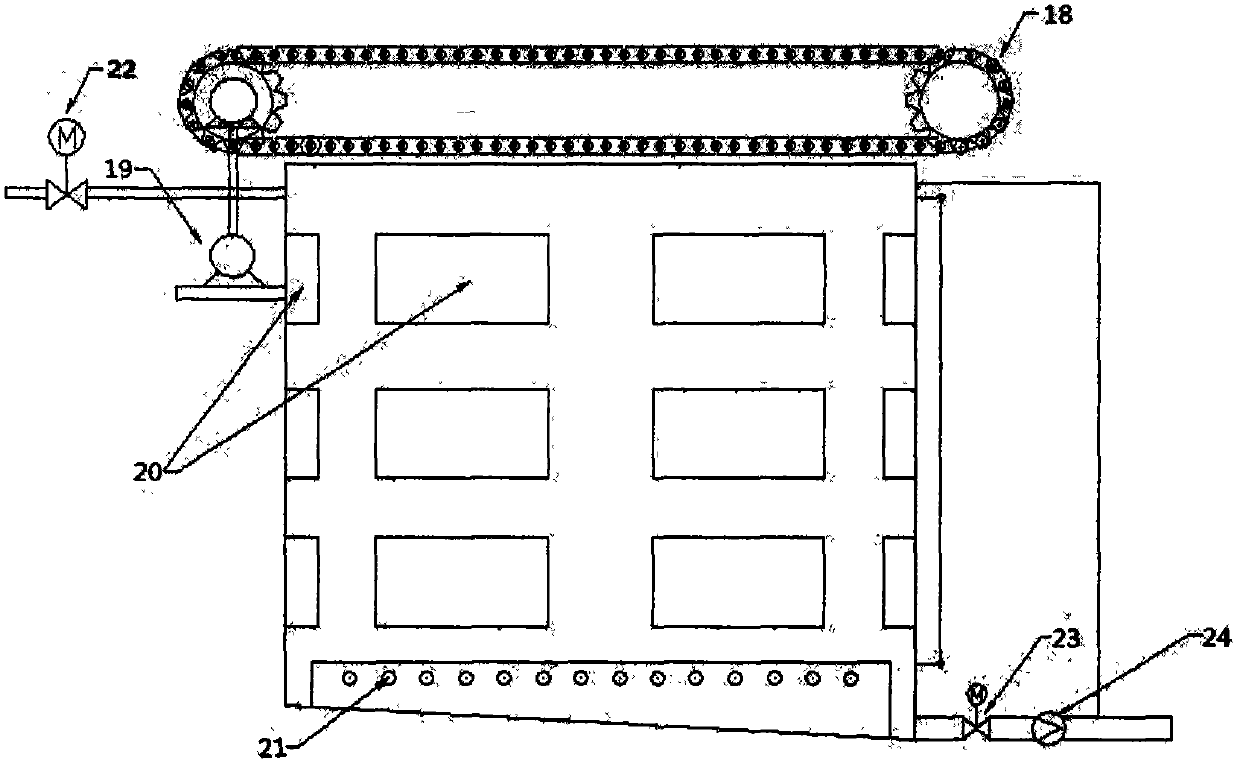

Efficient and energy-saving SCR denitration catalyst regeneration disposal technology and device

ActiveCN105879681AImprove efficiencySave energyDispersed particle separationWater useAutomatic control

The invention provides and designs a disposal technology and device for disposing SCR denitration catalyst regeneration in a factory. The technology comprises the steps that each working procedure of actual operation is executed starting from the procedure that an SCR catalyst module is conveyed to the factory, detection, carrying, flying ash removal, washing, acid pickling, rinsing, air drying, activation, drying, calcination and finished product packaging are performed; according to the technological process and disposal time of each working procedure, equipment is reasonably arranged, the carrying time is shortened, the number of links is reduced, time is reasonably utilized, and the production efficiency is improved; each disposal cell body is reasonably designed, control equipment is configured, a PLC control system is used, and disposal cell bodies are automatically operated, semi-automatic control over the overall disposal technology is achieved, and efficiency and disposal capacity are further improved; some water used by the technology is subjected to sedimentation, filtering and reutilization, and the cost and resources are saved; calcination and drying of a module are effectively combined together, the module is dried by means of waste heat of calcination, and energy sources are effectively saved.

Owner:HEBEI HANTANG HONGYUAN ENVIRONMENT PROTECTION TECH

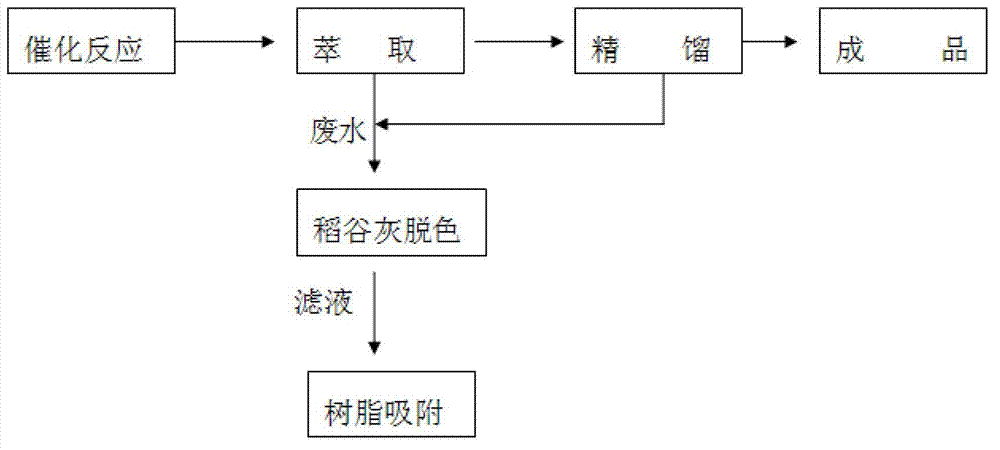

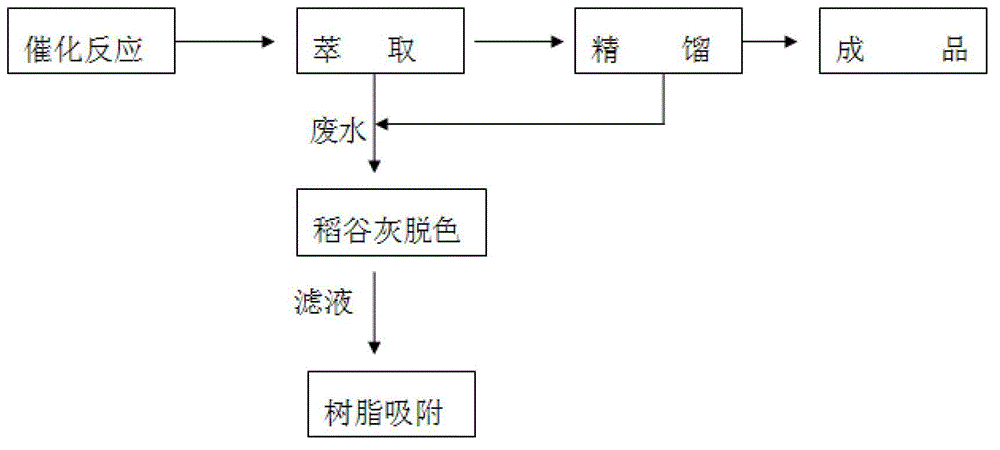

Preparation method of 1,4-dioxane

ActiveCN103193758AIncreased throughput and equipment utilizationLow costOrganic chemistryMultistage water/sewage treatmentIsopropyl etherChemistry

The invention discloses a preparation method of 1,4-dioxane. The method comprises using a solid super acid resin as a catalyst for a catalytic reaction with diglycol, then using isopropyl ether to extract and dehydrate crude products in a high-efficiency extraction tower, and treating waste water by using a cation resin tower. The method successfully overcomes many insufficiencies of a tradition technology, brings revolutionary advances for production of the 1,4-dioxane, and realizes a long-term pollution-free production of the products.

Owner:南通森萱药业有限公司

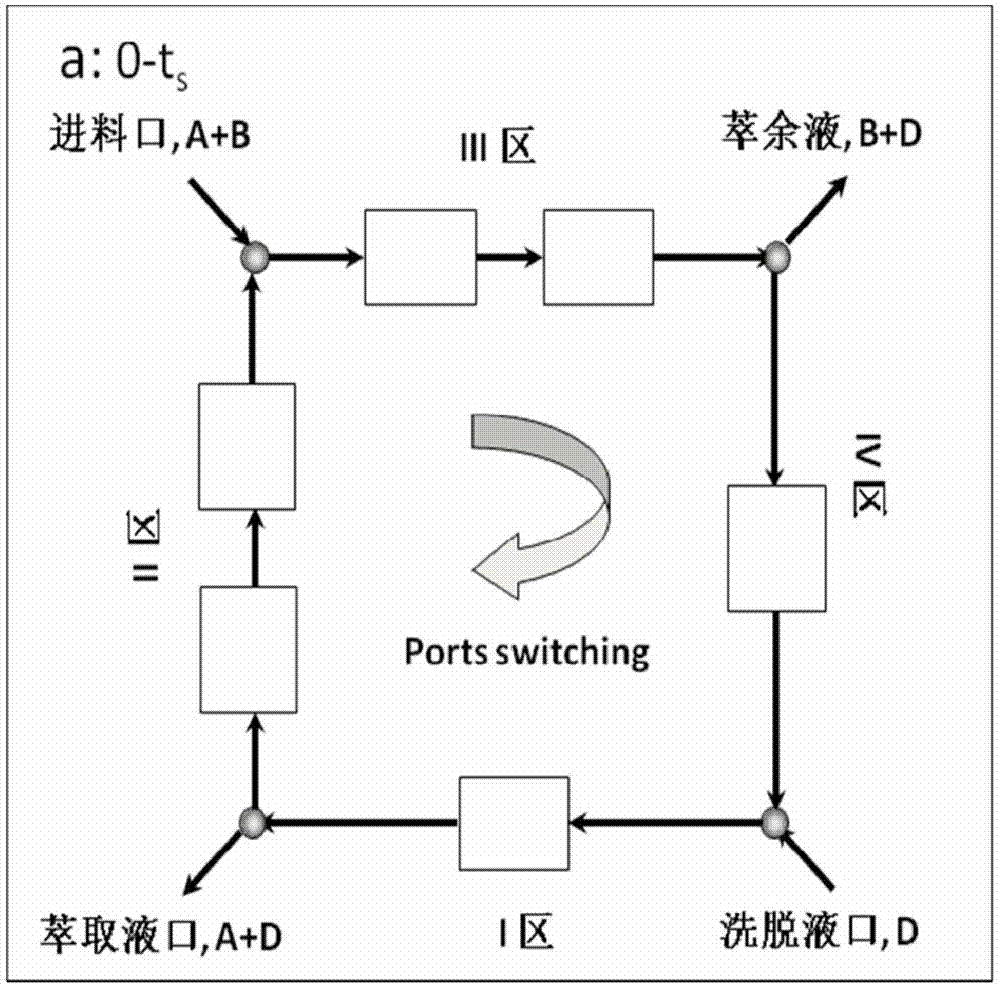

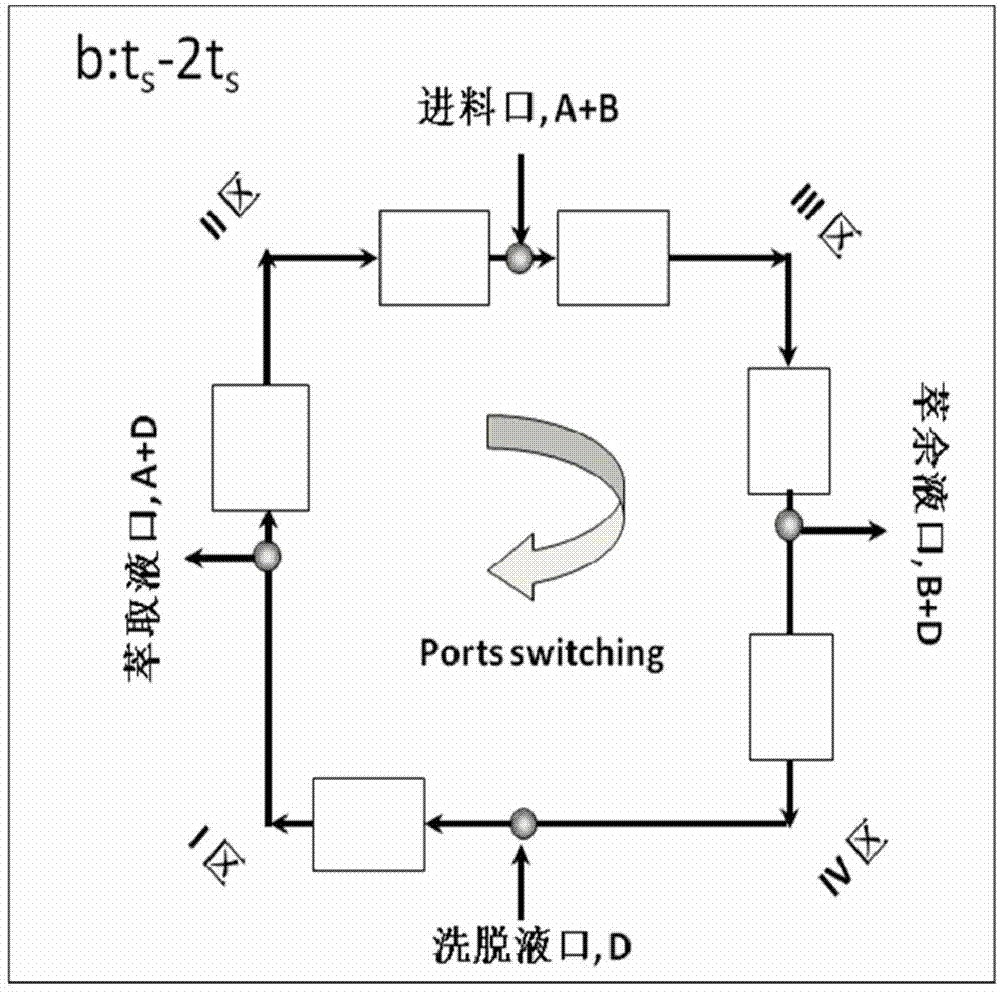

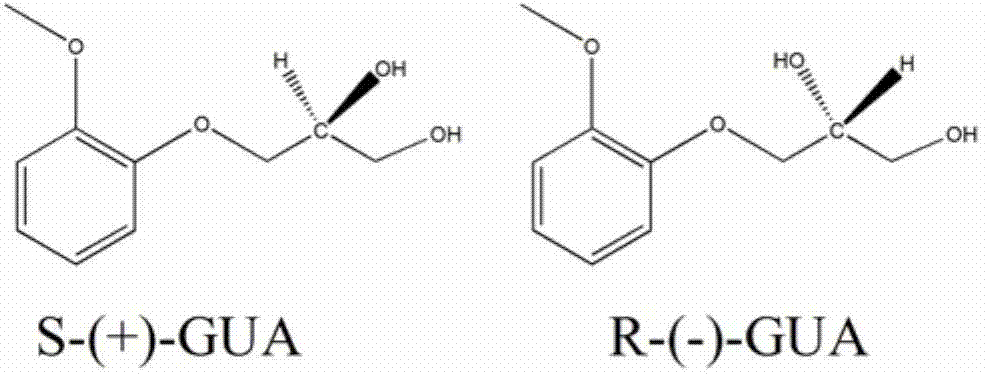

Method for separating guaiacol glyceryl ether enantiomer through simulated moving bed chromatography technology

InactiveCN103570512ASimple processHigh degree of automationEther separation/purificationSolid sorbent liquid separationCelluloseSimulated moving bed

The invention relates to a method for separating guaiacol glyceryl ether enantiomer through a simulated moving bed chromatography technology. The method comprises the steps of: coating cellulose-tris(3,5)-dimethylphenylcarbamate on silica gel as a chiral stationary phase, and n-hexane and ethanol mixture as a mobile phase by adopting a simulated moving bed chromatography system; separating the high-purity single enantiomer of R-(-)-guaiacol glyceryl ether and S-(+)-guaiacol glyceryl ether from racemic guaiacol glyceryl ether, wherein the mass fraction can achieve more than 99%. According to the method, the simulated moving bed chromatography technology is a continuous process and is simple in technique, and easy to automate, and on the basis of ensuring the purity and productivity of the products, the solvent in the whole process can be recycled, and the low-cost and pollution-free production mode can be realized.

Owner:EAST CHINA UNIV OF SCI & TECH

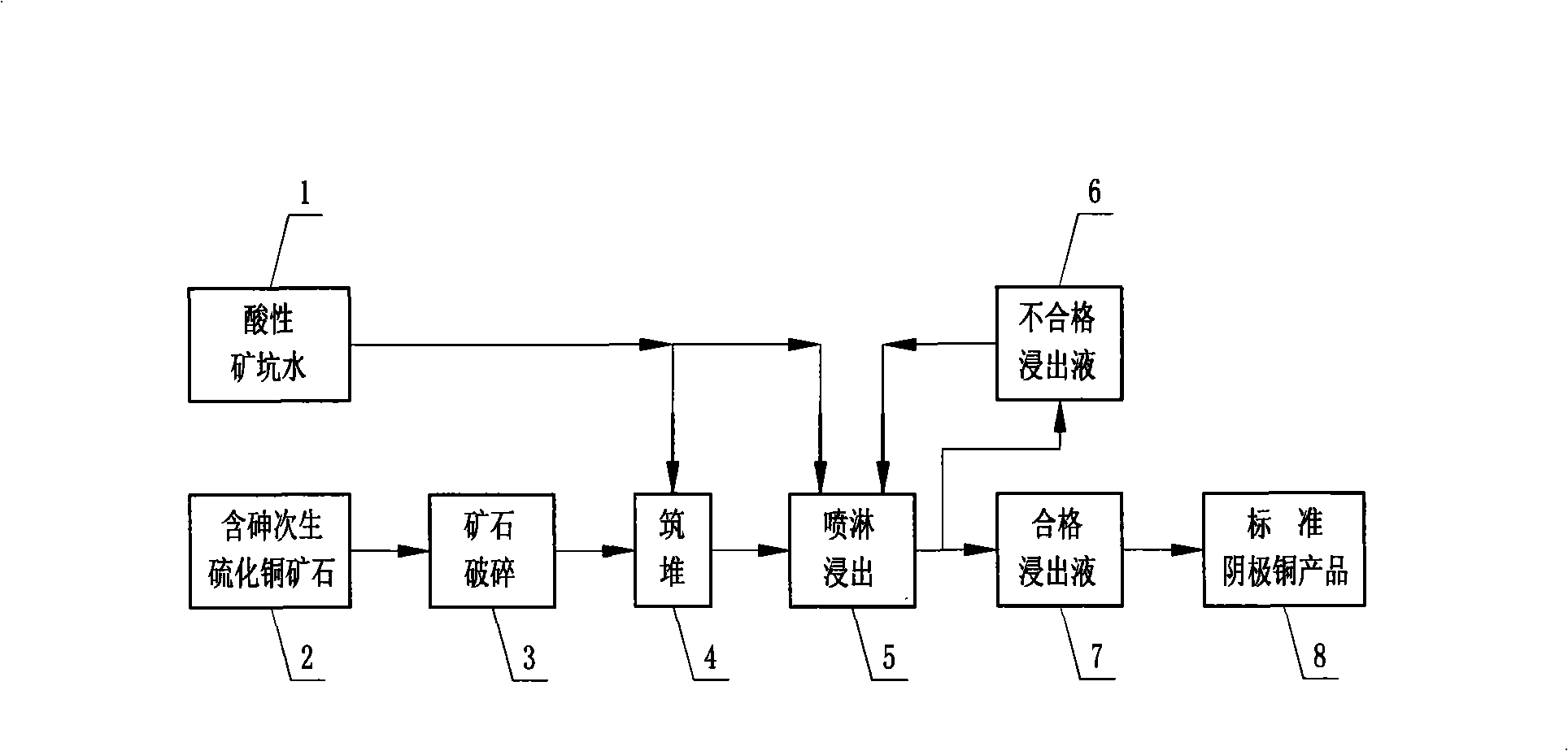

Earth's surface biological dump leaching process for secondary copper sulfide ore with higher arsenic content

InactiveCN101403037AConvenient sourceSimple and fast energy consumptionProcess efficiency improvementThiobacillus ferrooxidansDump leaching

The invention discloses a dump leaching technique of ground organism of secondary copper sulphide ore with high content of arsenic. The technique comprises the following steps: the secondary copper sulphide ore with high content of arsenic is crushed to 10 to 30mm, and acid mine water of mineral-leaching microorganism with thiobacillus ferrooxidans and thiobacillus thiooxidans is used for leaching the secondary copper sulphide ore with high content of arsenic; while most of the arsenic in the ore is still in leaching residue and a small part of the arsenic is in the leachate, faffinated and electrodeposition liquid; but closed cycle in the production has no effect on the extraction and electrodeposition and standard cathode copper product, thus avoiding the hazard of the arsenic to the environment. The technique has short process, little investment, low cost and energy consumption, no pollution and high rate of recovery, can process the copper ore with high content of arsenic which can not be processed by the traditional smelting technique, and also can process the secondary copper sulphide ore with high content of arsenic and similar secondary copper sulphide ore with high content of arsenic so as to expand the utilization range of resources.

Owner:CHINA NERIN ENG

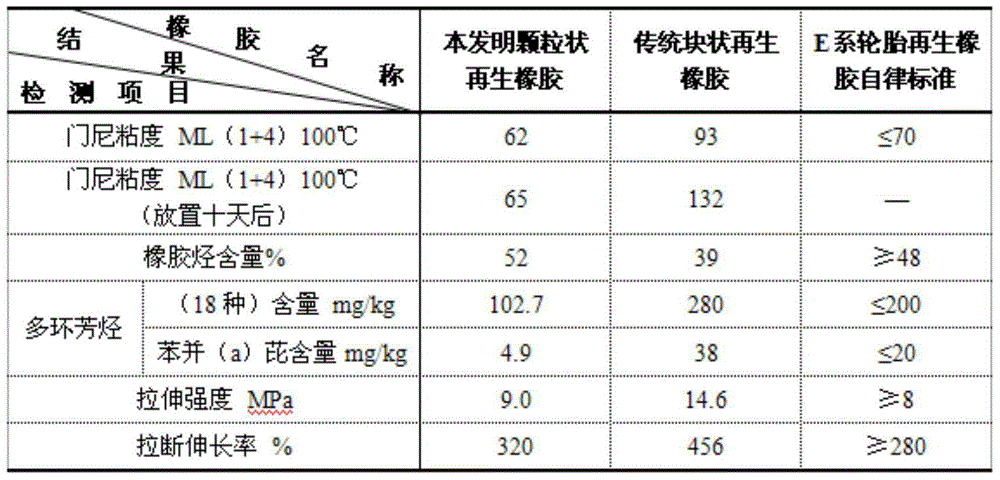

Intelligent modularized continuous green devulcanizing and regenerating complete technology for waste rubber

InactiveCN105150409AEquipment layout is reasonableSmall footprintPlastic recyclingMechanical material recoveryAirflowSulfur containing

The invention discloses an intelligent modularized continuous green devulcanizing and regenerating complete technology for waste rubber. A waste rtyre passes through intelligent fully-sealed type continuous crushing and separating equipment to carry out primary ring-cutting, tertiary crushing, secondary magnetic separating and primary airflow classifying to finally obtain required rubber particles; under the condition of not adding any chemical auxiliary agent, the rubber particles are fed into a screw rubber regenerator through a rubber quantitative feeder for being subjected to screw extrusion-shearing pure mechanical action, so that sulfur-containing molecular chains are selectively broken to break network structures of the sulfur-containing molecular chains, and therefore, green devulcanizing and regenerating of the rubber particles is realized; then, regenerated rubber enters intelligent filter equipment for filtering large particles, impurities and the like after being subjected to preliminary cooling; and finally, particle-shaped regenerated rubber is packed and stored after being waxed, cooled and dried. The intelligent modularized continuous green devulcanizing and regenerating complete technology for waste rubber disclosed by the invention realizes green, energy-saving, continuous, intelligent, efficient and safe production of the whole process from the waste tyre to particle-shaped regenerated rubber.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Method for preparing notoginsenoside R1 and ginsenoside Rg1, Re, Rb1 and Rd

Owner:UNIVERSITY OF MACAU

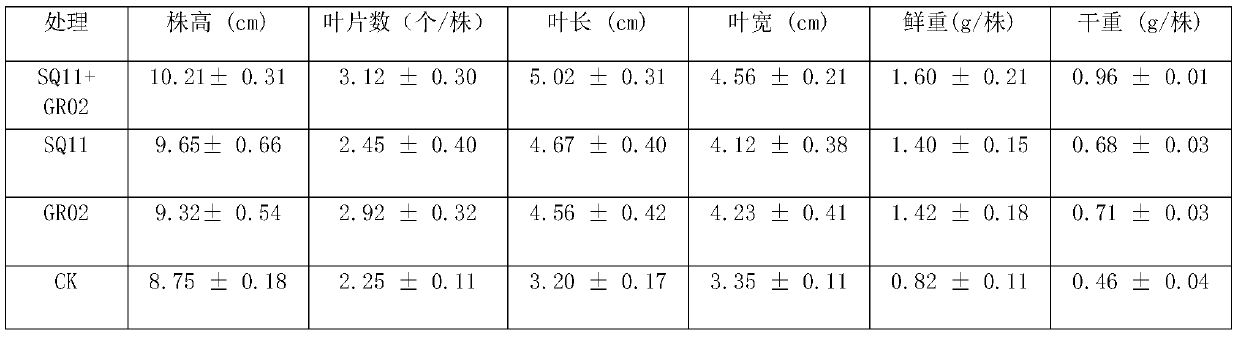

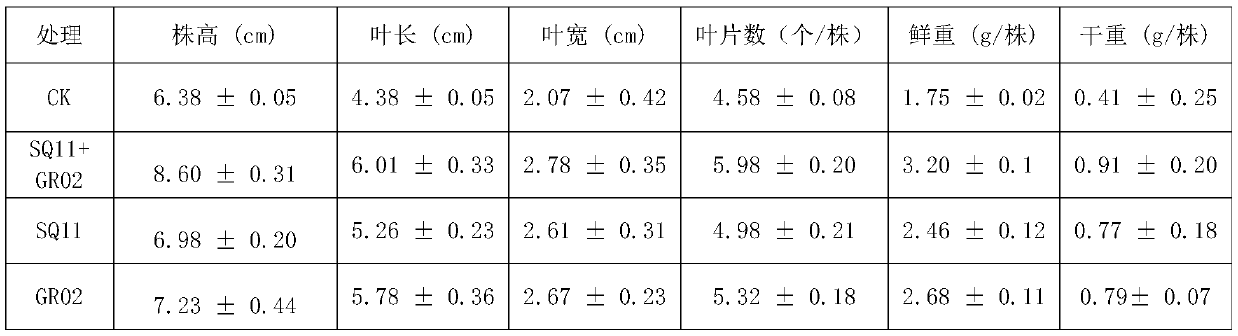

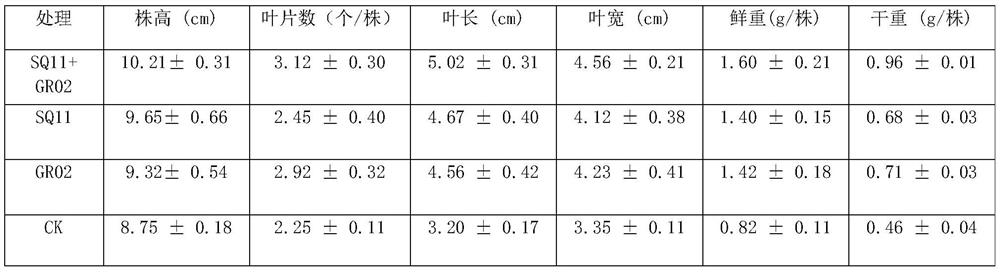

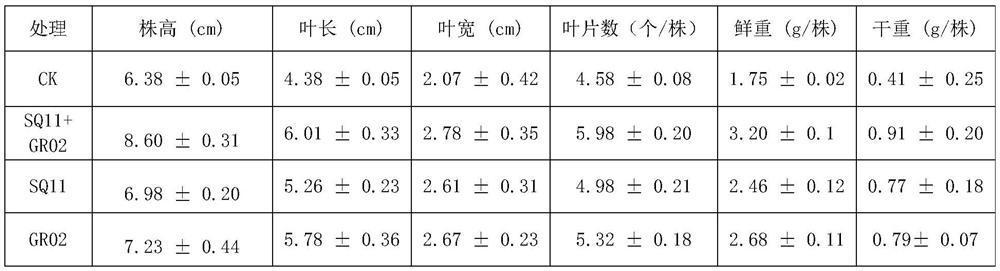

Continuous cropping-resistant compound microbial preparation and preparing method thereof

ActiveCN110129242ANo pollution in the processPollution-free productionPlant growth regulatorsBiocideBiotechnologyContinuous cropping

The invention discloses a continuous cropping-resistant compound microbial preparation and a preparing method thereof. The continuous cropping-resistant compound microbial preparation is a plant compound microbial agent. An active ingredient of the plant compound microbial agent is composed of streptomyces silaceus and clonostachys rosea. The streptomyces silaceus can be streptomyces silaceus SQ11, and the clonostachys rosea can be clonostachys rosea GR02. The continuous cropping-resistant compound microbial preparation can be prepared by a solid fermentation process, is simple and convenient,does not produce waste water and waste gas, has the advantages of pollution-free production, pure microbial microbial agent, and no addition of any hormones or chemical agents, guarantees the safetyof crop quality and zero pollution to the environment, reduces the production cost of farmers, guarantees the safe quality of agricultural products, and effectively reduces the amount of chemical fertilizers and pesticides.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

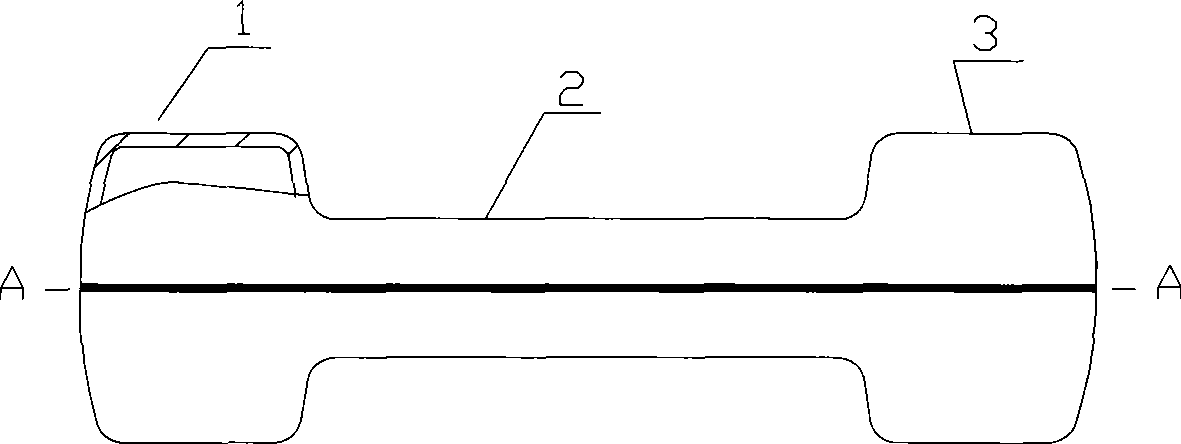

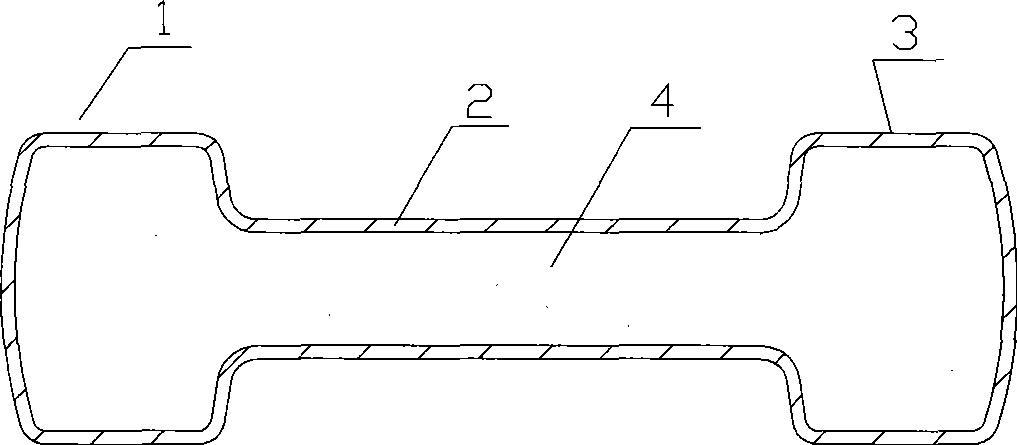

Stamping and filling type dumbbell and manufacturing method

The invention relates to a stamping and filling type dumbbell and a manufacturing method thereof, wherein the stamping and filling type dumbbell can be manufactured without casting. The stamping and filling type dumbbell comprises a dumbbell. Two dumbbell balls and a handle connecting two dumbbell balls are constituted of two halves of two metal stamping dumbbell ball shells and the mixed slurry is filled into the dumbbell cavity formed thereby. The dumbbell and the manufacturing method have the advantages that: firstly, the dumbbell made by stamping, welding and filling is high in strength as well as good in toughness, thus greatly reducing the production cost; secondly, the texture distribution in the dumbbell body is even and stable and cannot move along with the movement of the dumbbell, thus satisfying the requirements of training; and thirdly, defects that a large amount of coal is consumed in the production of casting dumbbells and environment is polluted are resolved basically, thus realizing pollution-free production.

Owner:杭州凯迪塑业有限公司

Combined firing method of active carbon and quicklime

InactiveCN101628716AEnergy savingOvercoming environmental pollution problemsEnergy inputCarbonizationWaste heat

The invention relates to a combined firing method of active carbon and quicklime, which is characterized in that a firing kiln is adopted alone; raw materials used by an active carbon kiln of the firing kiln are machine-made bar materials or shells made of various plants, and the carbonization process of the bar materials is carried out by self combustion of the bar materials and the like, thereby producing carbonized material products; fumes generated by the active carbon raw materials generate high-temperature hot fumes by gas combustion, and then the high-temperature hot fumes as energy resources are supplied to a quicklime kiln; quicklime products are produced under the condition that limestone raw materials in the quicklime kiln are indirectly baked and calcined by the high-temperature hot fumes, and the fumes in the quicklime kiln are led to the active carbon kiln for use. The invention completes the carbonization process in a carbonization kiln mainly by self energy of the raw materials, and completes the curing calcining process of the limestone in a lime kiln by using the waste heat of the fumes of the carbonization kiln. The energy resource is saved and the environment is not polluted on the premise that qualified products can be produced, so that the combined continuous production can be carried out. Moreover, equipment has simple structure, low manufacture cost and low operation cost, thereby having popularization value.

Owner:穆宝文

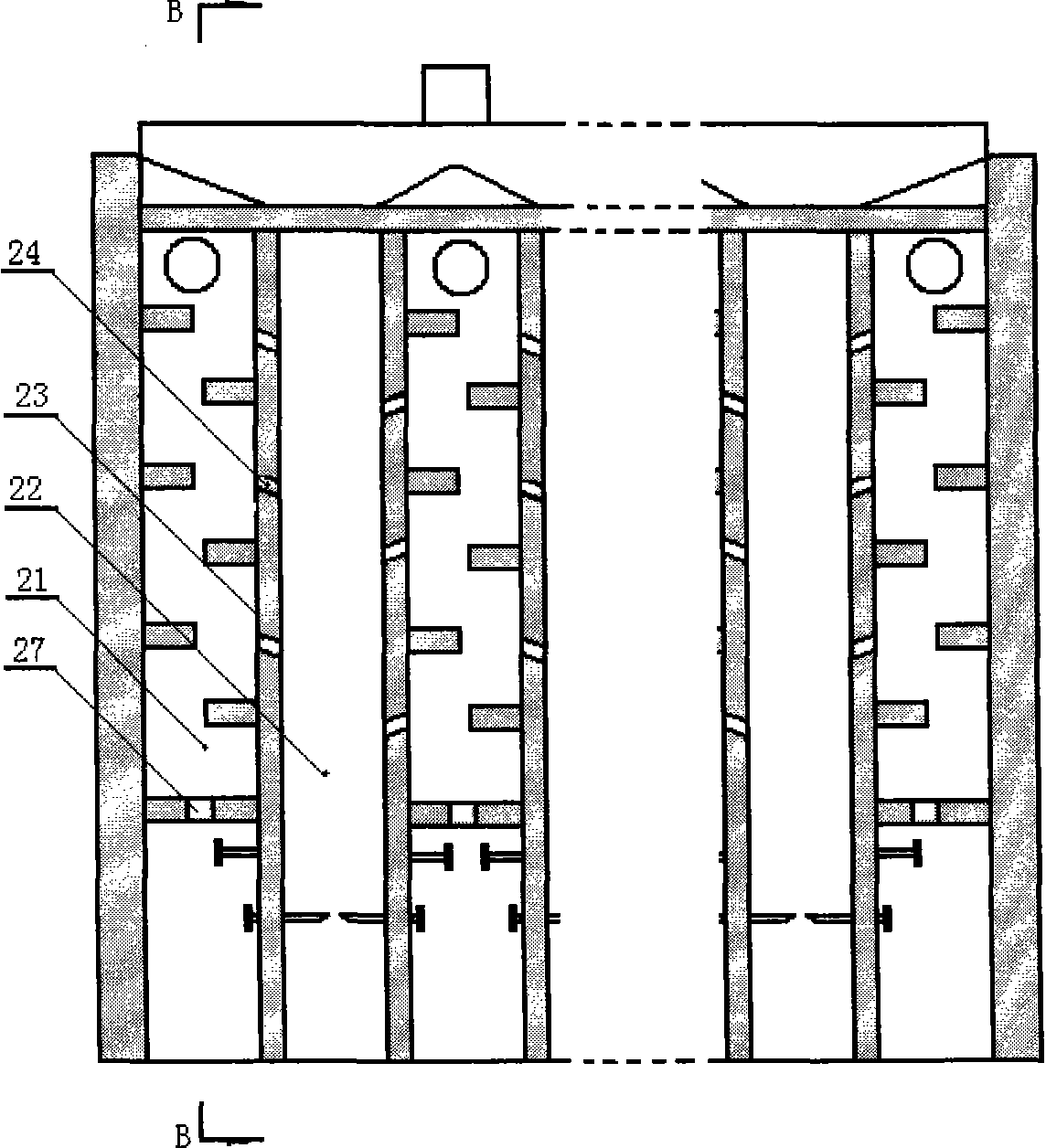

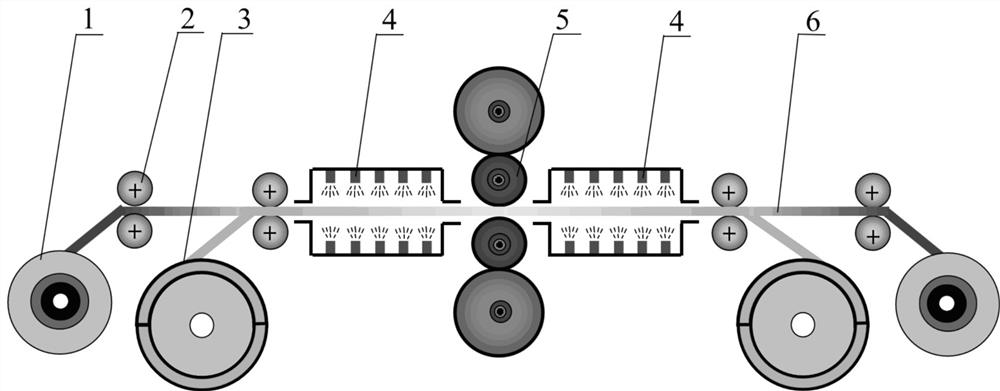

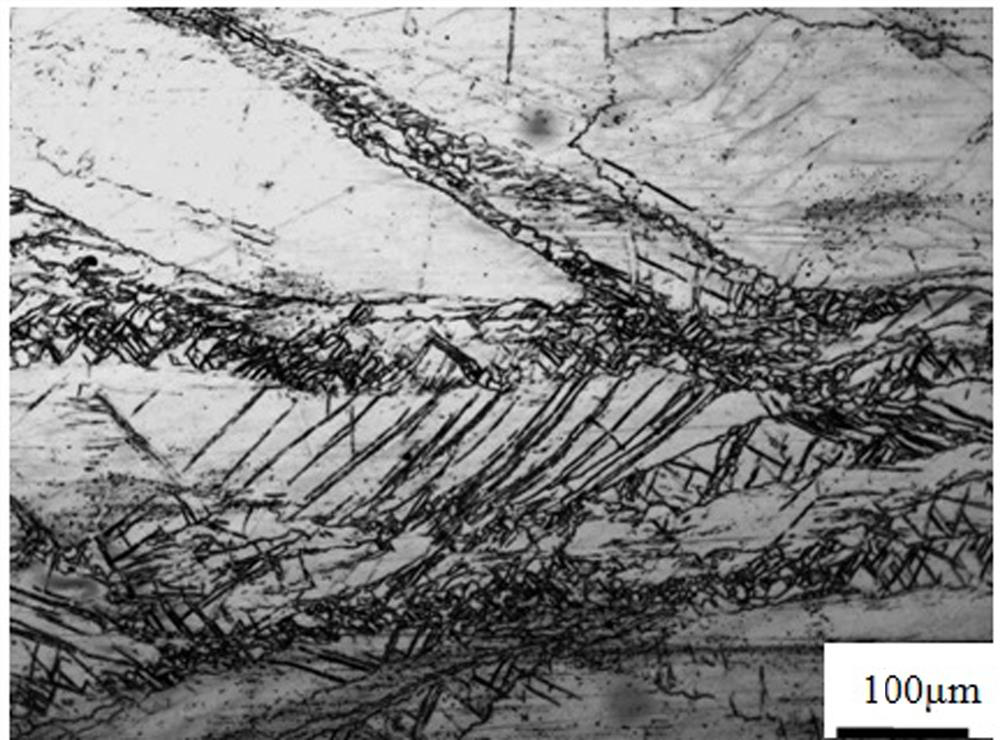

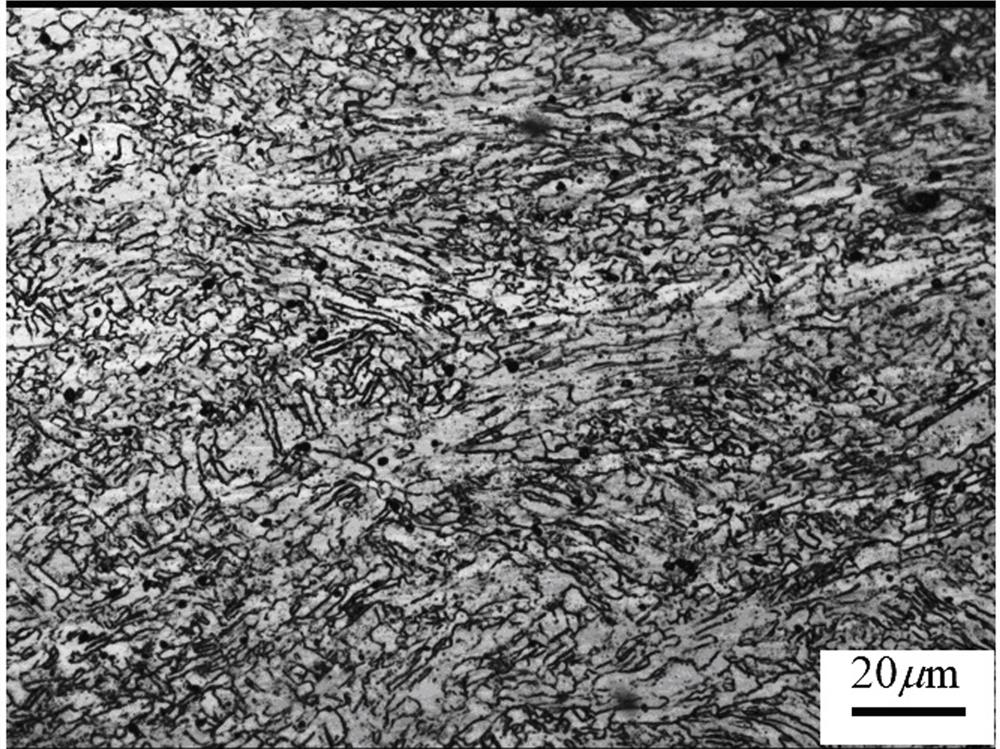

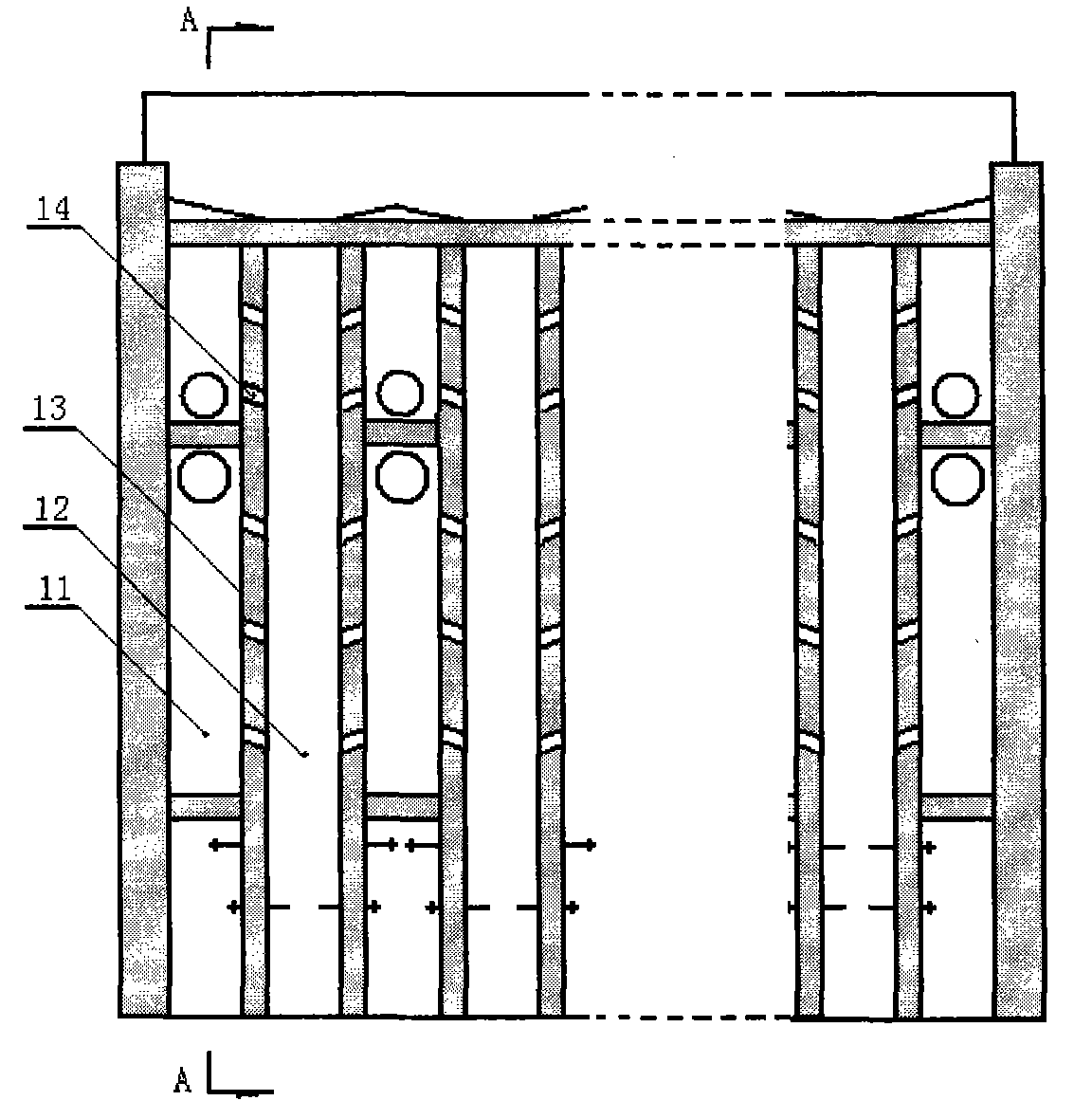

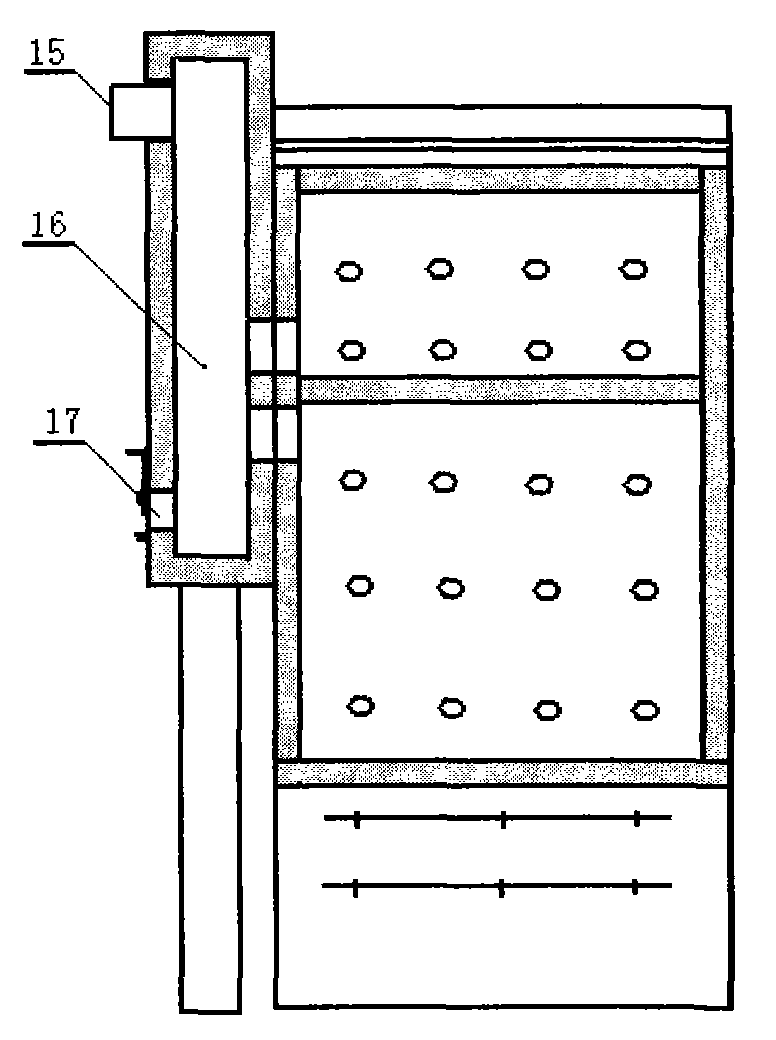

A production process of magnesium alloy ultra-thin strip warm rolling-ultra-low temperature cold rolling

ActiveCN110788134BImprove work efficiencyShorten the lengthWork cooling devicesWork heating devicesLiquid nitrogen coolingThin slab

The invention provides a magnesium alloy ultra-thin strip warm rolling-ultra-low temperature cold rolling continuous rolling production method. The initial magnesium alloy strip is heat-preserved at 300-400°C for homogenization treatment, and then multi-passed at 300-400°C Reversible isothermal rolling to obtain an intermediate rolling plate with a thickness of 1~2mm; the intermediate rolling plate obtained by hot rolling is sent to the coiling device on one side of the rolling mill through a liquid nitrogen controlled cooling device; then the magnesium alloy sheet is subjected to reversible low-temperature cold rolling , After the cold rolling is completed, the plate enters the cooler on the exit side of the rolling mill to cool, and is crimped and kept warm by the coiling machine, and finally the magnesium alloy fine-grained ultra-thin strip is obtained. In the present invention, the cooler and the coiling machine are arranged symmetrically on both sides of the rolling mill. By changing the steering direction of the rolling mill and the coiling machine, the subsequent multi-pass ultra-low temperature cold rolling of the magnesium alloy plate can be realized, and the grain refinement of the cooled magnesium alloy plate can be controlled by liquid nitrogen. Obviously, the fine and uniform grains can effectively improve the comprehensive mechanical properties of the magnesium alloy sheet and improve its subsequent processing performance.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Combined firing method of active carbon and quicklime

The invention relates to a combined firing method of active carbon and quicklime, which is characterized in that a firing kiln is adopted alone; raw materials used by an active carbon kiln of the firing kiln are machine-made bar materials or shells made of various plants, and the carbonization process of the bar materials is carried out by self combustion of the bar materials and the like, thereby producing carbonized material products; fumes generated by the active carbon raw materials generate high-temperature hot fumes by gas combustion, and then the high-temperature hot fumes as energy resources are supplied to a quicklime kiln; quicklime products are produced under the condition that limestone raw materials in the quicklime kiln are indirectly baked and calcined by the high-temperature hot fumes, and the fumes in the quicklime kiln are led to the active carbon kiln for use. The invention completes the carbonization process in a carbonization kiln mainly by self energy of the raw materials, and completes the curing calcining process of the limestone in a lime kiln by using the waste heat of the fumes of the carbonization kiln. The energy resource is saved and the environment is not polluted on the premise that qualified products can be produced, so that the combined continuous production can be carried out. Moreover, equipment has simple structure, low manufacture cost andlow operation cost, thereby having popularization value.

Owner:穆宝文

Extraction method of vanadium from stone coal with pollution treatment and ceramic production combination

InactiveCN100398451CAchieve sharingReduce duplication of investmentVanadium oxidesProcess efficiency improvementToxic gasSlag

A method for extracting vanadium from bone coal and controlling pollution combined with ceramic production is carried out by taking vanadium-contained bone coal as fuel and raw material, break grinding, roasting, diffusing to obtain vanadium-contained brining, utilizing waste gas from roasting process as heat source for generation and ceramic spraying dry tower, clean discharging by dust-proofing and scrubbing system treatment, and utilizing fag end from diffusion process as ceramic ingot components to realize zero discharge. It has no poisonous gas and environmental pollution, has better quality, shares producer and costs low.

Owner:王雄鹰 +1

Dry or semi-dry hawthorn wine and brewing method thereof

ActiveCN101967440BGuaranteed tasteGuaranteed nutritionMicroorganism based processesAlcoholic beverage preparationFiberAdditive ingredient

The invention relates to dry or semi-dry hawthorn wine. The hawthorn wine is characterized in that: the alcoholic strength is 9 to 13 percent V / V; based on glucose, the total sugar is 3 to 15g / L; based on citric acid, the total acid is 6 to 9g / L; and based on standard rutin, the total flavonoid content is 45 to 70mg / L. A brewing method comprises the following steps of: extracting hawthorn juice rich in flavone biological effective ingredient by using hawthorn as a raw material and adopting an enzymatic leaching process, adding the sugar into the hawthorn juice and performing low-temperature controlled fermentation by using active wine dry yeast to obtain raw hawthorn wine; and performing biological de-acidification and wine body stability treatment on the raw wine, and obtaining the hawthorn wine by blending. The wine body stability treatment comprises the following steps of: adding a metal ion complexing agent to complex metal ions in the wine body to inhibit non-biological browning of the wine body; adding silica gel at a low temperature to adsorb cold muddy protein in the wine body; and adding biological antioxidant enzyme with anti-oxidation browning effect on the hawthorn wine into the wine. Malt dextrin, lactose and the like are added into byproducts after the hawthorn wine is processed, and the materials are mixed, dried, crushed and packed to obtain hawthorn fiber powder.

Owner:TIANJIN UNIV OF SCI & TECH

A kind of compound microbial preparation against heavy cropping and preparation method thereof

ActiveCN110129242BNo pollution in the processPollution-free productionBiocidePlant growth regulatorsBiotechnologyContinuous cropping

The invention discloses a compound microbial preparation against heavy cropping and a preparation method thereof. The compound microorganism preparation against repeated cropping is a compound microorganism preparation for plants, and the active ingredients of the composite microorganism preparation for plants are composed of Streptomyces yellow ochreus and Clonospora pink. The Streptomyces silaceus may be Streptomyces silaceus SQ11, and the Clonostachys rosea may be Clonostachys rosea GR02. The anti-stubble compound microbial preparation of the present invention can be prepared by a solid fermentation process, which is simple and convenient, does not produce waste water, waste gas, and is produced without pollution. The pure microbial agent does not add any hormones and chemical preparations, ensuring crop quality safety and zero environmental impact. Pollution, reduce farmers' production costs, ensure the quality and safety of agricultural products, and effectively reduce the amount of chemical fertilizers and pesticides.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

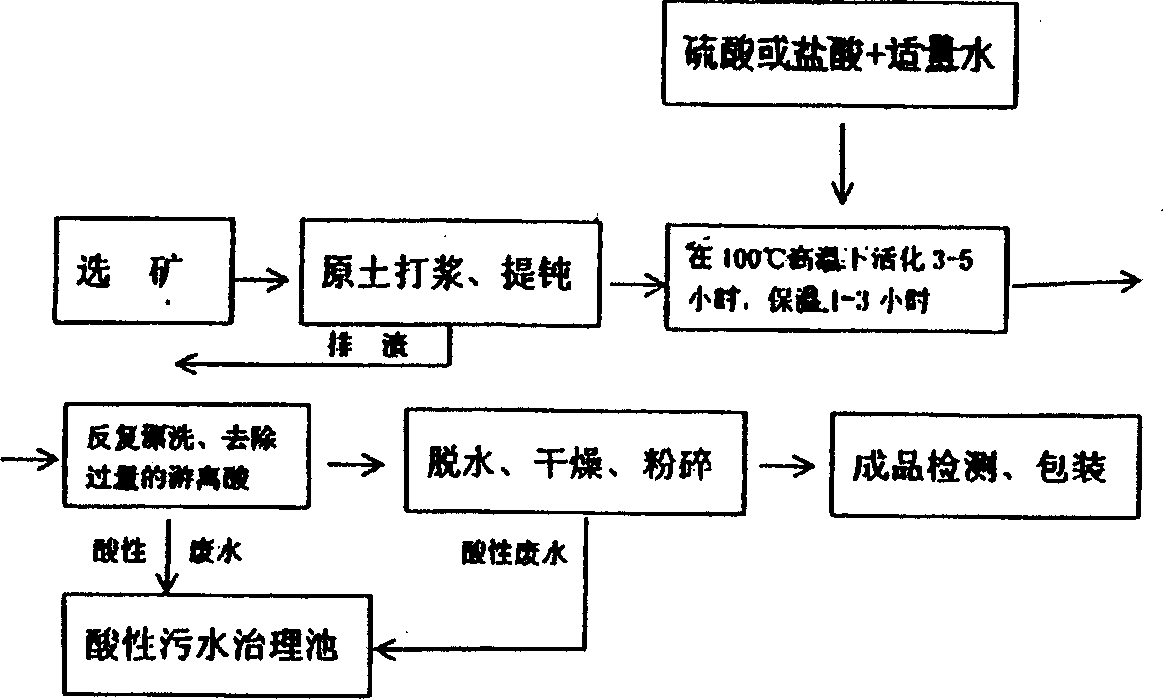

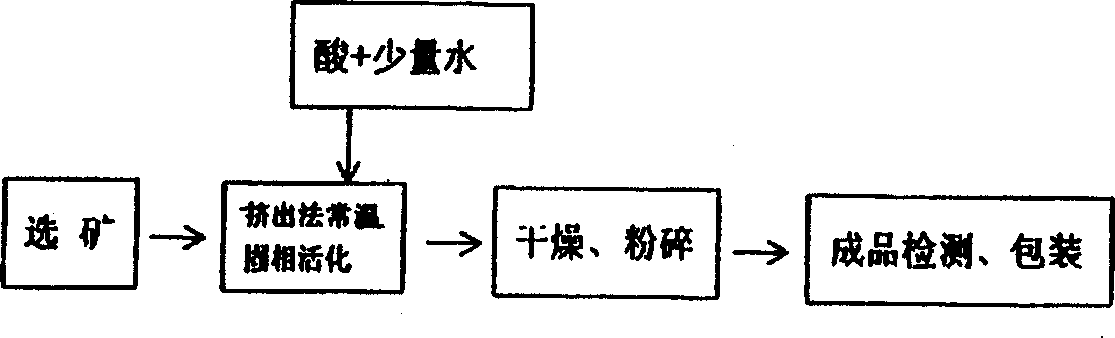

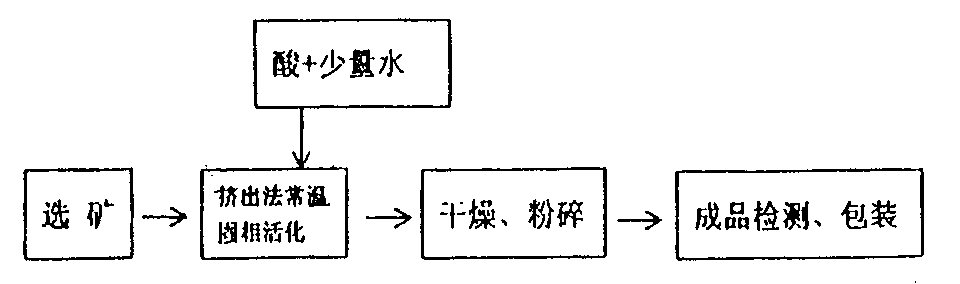

Process for production of activated argil

InactiveCN1089078CReduce manufacturing costIncrease profit marginsOther chemical processesAluminium silicatesWastewaterSlurry

A process for producing activated argil without discharge of acidic water and waste water includes such technological steps as dressing ore, ordinary-temp. solid activating by adding acid and water and use of extruding out method, drying, crushing and examination, or dressing ore, beating raw argil to obtain slurry, purifying while discharging sand and water, adding acid and water, activating at 80-100 deg.C for 10-30 min while high-speed stirring at 1000 rpm, suction filter, drying, breaking and examination. Its advantages are no pollution, low cost and simple operation.

Owner:李沧海

A method for refining high-purity egg yolk lecithin by demulsification

ActiveCN106632457BHigh purityKeep aliveGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsEmulsionCentrifugation

The invention belongs to the technical field of processing of pharmaceutical raw materials and particularly relates to a method for refining high-purity egg yolk lecithin through demulsification. According to the method, a lecithin crude product obtained through extraction with ethanol and supercritical carbon dioxide is further refined; significant progress is made after adoption of sulfate, so that an emulsion system formed by lecithin in the lecithin crude product and a minute quantity of neutral fat such as triglyceride, cholesterol and the like is damaged, phase separation of lecithin in the lecithin crude product and the neutral fat occurs, and furthermore, a minute quantity of neutral fat such as triglyceride, cholesterol and the like is removed through secondary cooling under the high-speed centrifugation condition, and the high-purity egg yolk lecithin is prepared through refining. The purity of the product is improved to 98% or higher, clean and pollution-free production of high-purity egg yolk lecithin is realized, and the requirement that the lecithin product is used as the pharmaceutical raw material is completely met.

Owner:FUJIAN ZHENGSHI HUAXIANG FOOD CO LTD

High yield environmental protection type industrial separating method for ginseng saponin Rb1

The present invention relates to the extraction and separation of effective components in Chinese medicine. The ginsenoside Rb1 separating process includes dissolving ginsenoside, American ginsenoside or notoginseng general saponin in small amount of eluant, adding to stabilized chromatographic column to elute while detecting until reaching negative, merging the elutriant of ginsenoside Rb1, reducing recovering solvent, vacuum freeze drying to obtain freeze dried ginsenoside Rb1 powder, inspection and packing. The present invention has the advantages of simple technological process, short production period, no pollution, low cost, high product purity over 95 %, and high yield up to 20 %.

Owner:长春三和参业科技有限公司

High-efficiency and energy-saving scr denitrification catalyst regeneration and disposal process and device

ActiveCN105879681BFacilitate timely interventionImprove efficiencyDispersed particle separationWater useAutomatic control

The invention provides and designs a disposal technology and device for disposing SCR denitration catalyst regeneration in a factory. The technology comprises the steps that each working procedure of actual operation is executed starting from the procedure that an SCR catalyst module is conveyed to the factory, detection, carrying, flying ash removal, washing, acid pickling, rinsing, air drying, activation, drying, calcination and finished product packaging are performed; according to the technological process and disposal time of each working procedure, equipment is reasonably arranged, the carrying time is shortened, the number of links is reduced, time is reasonably utilized, and the production efficiency is improved; each disposal cell body is reasonably designed, control equipment is configured, a PLC control system is used, and disposal cell bodies are automatically operated, semi-automatic control over the overall disposal technology is achieved, and efficiency and disposal capacity are further improved; some water used by the technology is subjected to sedimentation, filtering and reutilization, and the cost and resources are saved; calcination and drying of a module are effectively combined together, the module is dried by means of waste heat of calcination, and energy sources are effectively saved.

Owner:HEBEI HANTANG HONGYUAN ENVIRONMENT PROTECTION TECH

Environmental protection type transparent solid glue and preparation method thereof

ActiveCN102321443BColor transparentHigh hardnessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePreservative

The present invention discloses environmental protection type transparent solid glue. The glue comprises the following components, by weight, 40-50 parts of deionized water, 6-10 parts of an activator, 0.5-2 parts of an antifoaming agent, 15-20 parts of a lubricant, 20-30 parts of a moisturizing agent, 6-10 parts of sodium stearate, 20-30 parts of polyvinylpyrrolidone and 0.2-1 parts of a preservative. In addition, the present invention further provides a preparation method for the environmental protection type transparent solid glue. Compared to the prior art, the environmental protection type transparent solid glue provided by the present invention has characteristics of transparent color, high hardness, good moisture retention, smooth coating without dreg dropping, good oxidation resistance, environmental protection and no toxicity.

Owner:JIANGSU XINGDA STATIONERY GRP

Silicon rod rotary floating cutting CNC machine tool

InactiveCN102862239BControl BrokenReduce vibrationWorking accessoriesFine working devicesNumerical controlEngineering

The invention discloses a rotary floating cutting numerical control machine tool for a silicon rod, and relates to a numerical control machine tool, in particular to a numerical control cutting machine for cutting the silicon rod. The rotary floating cutting numerical control machine tool comprises a numerical control box, a machine tool body, a transmission mechanism, and a cutting mechanism and a silicon rod clamping mechanism which are arranged on the machine tool body, and is characterized in that the silicon rod clamping mechanism comprises a driving rotation support wheel which clamps the silicon rod in a matching manner in the vertical direction, and a floating rotary pressing wheel; the floating rotary pressing wheel is connected with an elastic pressing device which drives the floating rotary pressing wheel to tightly press the silicon rod; and the transmission mechanism is connected with a shaft of the driving rotation support wheel. The rotary floating cutting numerical control machine tool can realize the non-concentric axial rotation floating radius cutting of polycrystalline silicon rods which have the characteristics that the material texture density is sparse, workpieces are bent in the axial direction, ovality exists in the diameter direction, the diameters are different, the appearances are not irregular, the breaking phenomenon is easy to generate, and the like in the floating rotation state, and is novel and capable of realizing the automatic radius cutting.

Owner:刘鸿彬

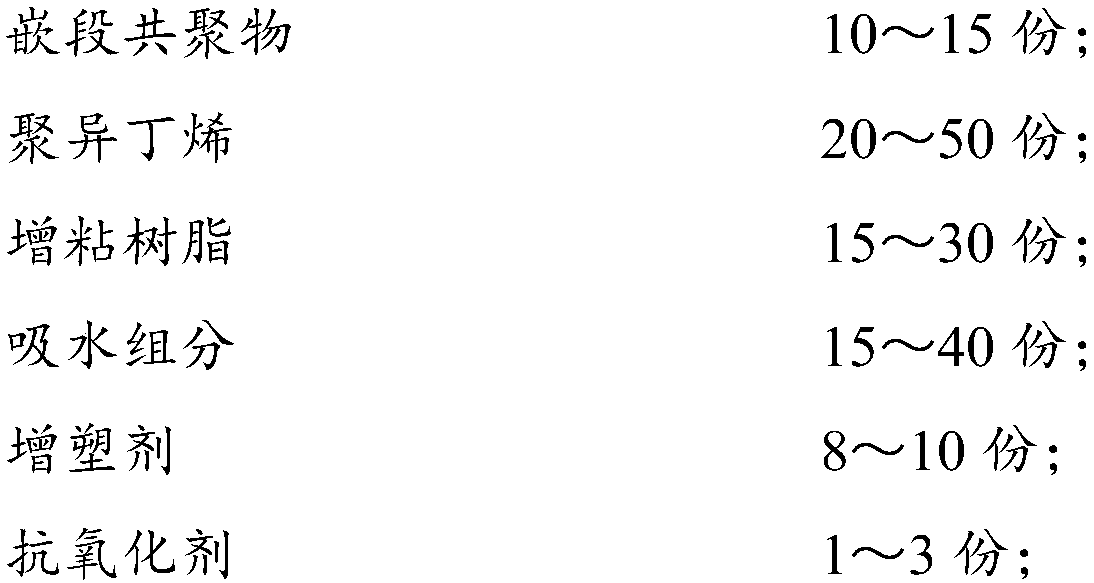

A radiation-crosslinked medical pressure-sensitive adhesive and its preparation method

ActiveCN107057618BIncrease stickinessImprove integrityMacromolecular adhesive additivesCross-linkAntioxidant

The invention discloses a novel irradiation crosslinking medical pressure-sensitive adhesive. The medical pressure-sensitive adhesive is prepared from, by weight, 10-15 parts of block copolymer, 20-50 parts of polyisobutene, 15-30 parts of tackifying resin, 15-40 parts of water absorption component, 8-10 parts of plasticizer and 1-3 parts of antioxidant, wherein the block copolymer is a styrene-isoprene-styrene block copolymer, and the block ratio S / I is 15 / 85. The medical pressure-sensitive adhesive prepared through irradiation crosslinking has the good mechanical property and adhesive property, and the integrity obtained after water absorption and the viscosity are improved. By means of adopting the method of electronic irradiation for crosslinking in the preparation technology, the prepared medical pressure-sensitive adhesive has the advantages of no solvent, environmental protection and non-pollution production, and moreover, by adding no crosslinking agent, the prepared medical pressure-sensitive adhesive is non-irritating and harmless to a human body, which accords with the medical conditions.

Owner:HUBEI UNIV

A kind of production method of extracting magnesium hydroxide and calcium carbonate from dolomite

ActiveCN107399748BAchieve separationAchieve recyclingCalcium/strontium/barium carbonatesMagnesium hydroxideChemical industryFiltration

The invention relates to a production method for extracting magnesium hydrate and calcium carbonate from dolomite, and belongs to the technical field of chemical industry novel materials. The production method for extracting magnesium hydrate and calcium carbonate from dolomite comprises the following steps of (1) preparing caustic calcined dolomite powder; (2) guiding a mixture of the caustic calcined dolomite powder obtained in the step (1) and ammonium salt water solution into a reaction vessel to perform ammonia distilling reaction at 80 to 105 DEG C at the stirring speed of 200 to 1000r / min; after performing the reaction for 0.5 to 4 hours, performing suction filtration to obtain ammonia distilling liquid; recovering distilled ammonia gas into an ammonia gas storage tank through a gas-liquid mixer; (3) preparing magnesium hydroxide; (4) preparing calcium carbonate.

Owner:沈阳凯镁客科技有限公司

Preparation method of 1,4-dioxane

ActiveCN103193758BIncrease profitSolve the problem of producing tarOrganic chemistryMultistage water/sewage treatmentWastewaterDiethylene glycol

The invention discloses a preparation method of 1,4-dioxane. The method comprises using a solid super acid resin as a catalyst for a catalytic reaction with diglycol, then using isopropyl ether to extract and dehydrate crude products in a high-efficiency extraction tower, and treating waste water by using a cation resin tower. The method successfully overcomes many insufficiencies of a tradition technology, brings revolutionary advances for production of the 1,4-dioxane, and realizes a long-term pollution-free production of the products.

Owner:南通森萱药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com