A production process of magnesium alloy ultra-thin strip warm rolling-ultra-low temperature cold rolling

A production process, magnesium alloy technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems affecting the quality of the plate, uneven structure of the plate, etc., achieve good comprehensive performance, improve comprehensive mechanical properties and strong The effect of toughness and pollution-free production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

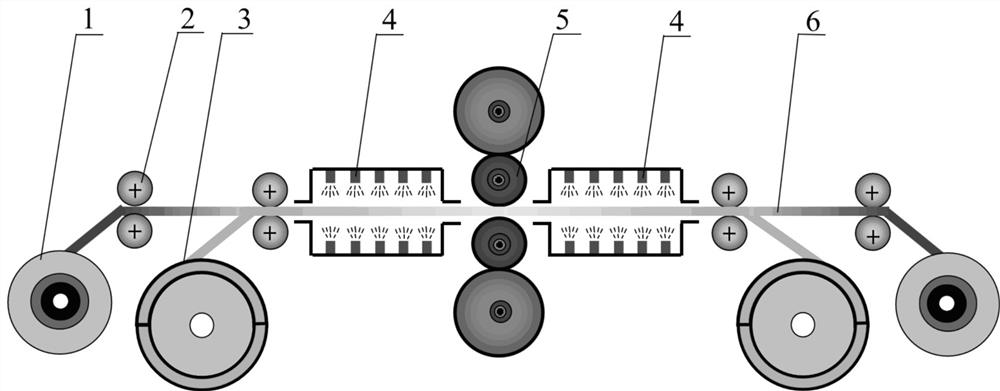

Method used

Image

Examples

Embodiment 1

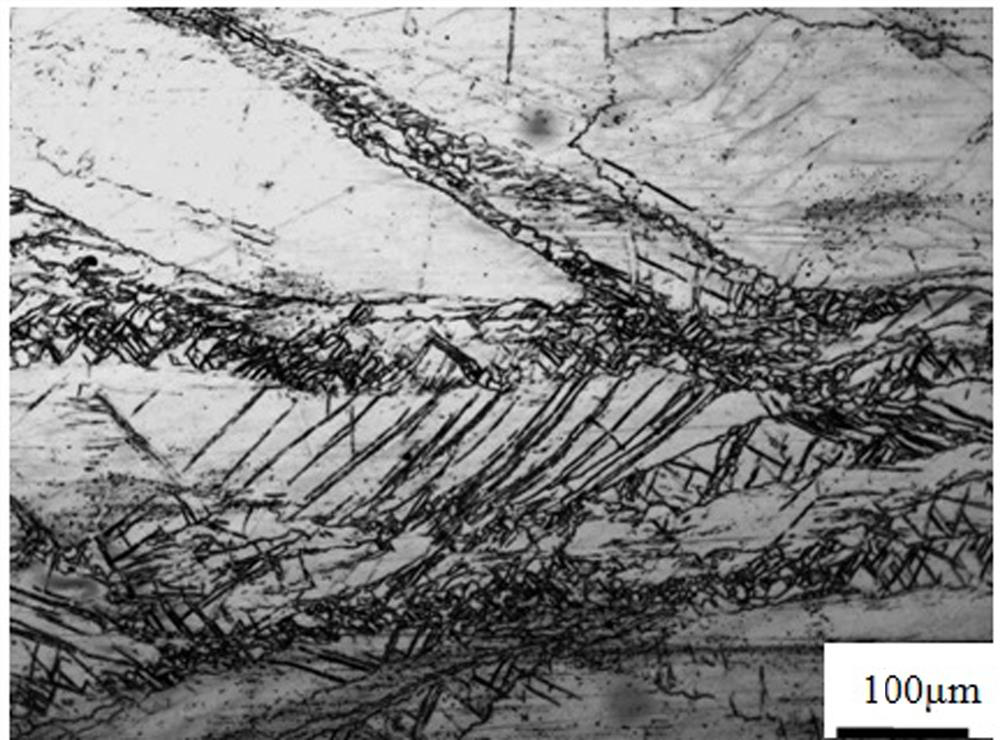

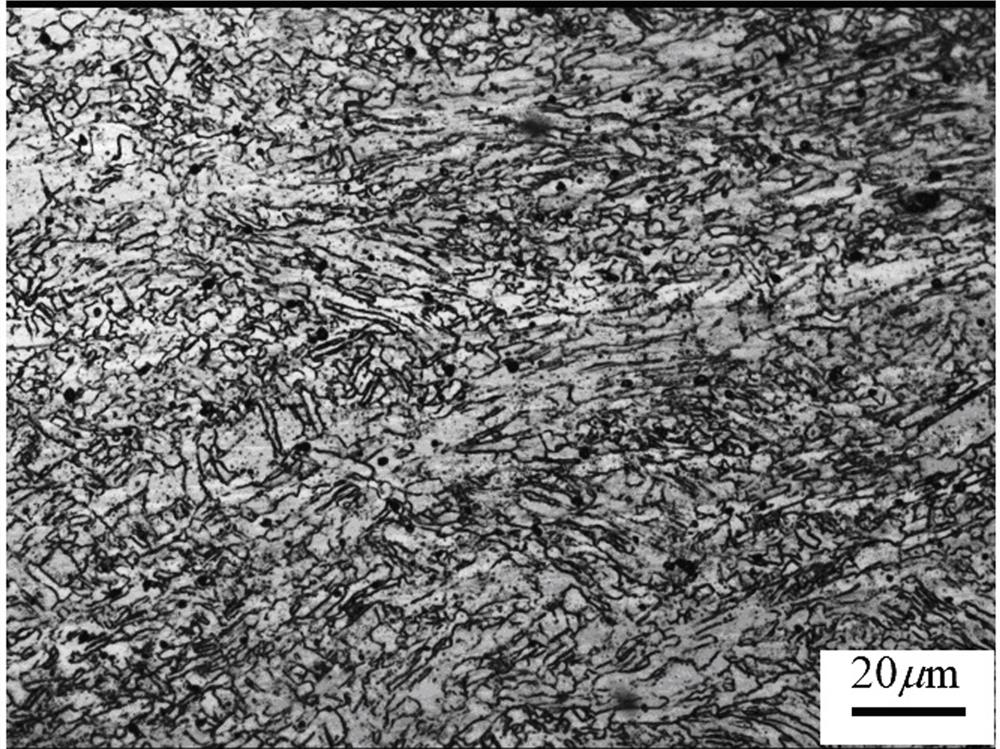

[0028] The 6mm thick AZ31 magnesium alloy strip is kept in a coiling furnace at a temperature of 300±10°C for 25min for homogenization treatment. Subsequently, isothermal reversible rolling is carried out between two heatable coiling furnaces to obtain a 1.7mm thick magnesium alloy thin strip; the liquid nitrogen controlled cooling device is turned on for ultra-rapid cooling with a cooling rate of 80°C / s and a final cooling temperature of -150±10℃, the magnesium alloy thin strip is sent to the thermal insulation and cold storage coiling device; the magnesium alloy thin strip that has reached the cooling temperature is continued to be reversibly rolled at low temperature in small passes between the two thermal insulation and cold storage coiling devices, and finally A magnesium alloy ultra-thin strip with a thickness of 0.5 mm was obtained. After cold rolling, the grain of the plate is refined to 3.6 μm, showing uniform and fine equiaxed grains, the surface of the plate is flat...

Embodiment 2

[0030] The 16mm AZ91 magnesium alloy strip obtained after hot rolling is kept in a coiling furnace at a temperature of 400±10°C for 60 minutes for homogenization treatment. Subsequently, isothermal reversible rolling is carried out between two heatable coiling furnaces to obtain a 1.7mm thick magnesium alloy thin strip, and the liquid nitrogen controlled cooling device is turned on for ultra-rapid cooling at a cooling rate of 90°C / s. For liquid nitrogen temperature, the magnesium alloy thin strip is sent to the heat preservation and cold preservation coiling device; after that, the magnesium alloy plate is subjected to multi-pass reversible rolling with a small reduction of 3%, and finally a 0.47mm thick magnesium with uniform and fine grains is obtained. Alloy ultra-thin plate and strip, the plate surface is flat, and the comprehensive performance is good.

Embodiment 3

[0032] The 10mm ZK60 magnesium alloy intermediate plate obtained after hot rolling is used, and is kept in a coiling furnace at a temperature of 350±10° C. for 35 minutes for homogenization treatment. Subsequently, isothermal reversible rolling is carried out between two heatable coiling furnaces to obtain a 1.26mm thick magnesium alloy thin strip, and the liquid nitrogen controlled cooling device is turned on for ultra-rapid cooling, and the magnesium alloy is rolled at a cooling rate of 70°C / s The sheet strip is cooled to -100°C, coiled, and kept warm, and finally a 1.06mm thick magnesium alloy ultra-thin sheet with uniform and fine grains is obtained. The sheet surface is flat and the overall performance is good.

[0033] On the premise of not changing the chemical composition of the magnesium alloy plate, the present invention obviously improves the comprehensive mechanical properties and strength and toughness of the plate through the controlled cooling and ultra-low tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com