Efficient and energy-saving SCR denitration catalyst regeneration disposal technology and device

A denitrification catalyst and process technology, applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of secondary pollution, waste, pollution, etc., to save energy and cost, save investment cost, and reduce handling equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the examples.

[0030] The present invention adopts a high-efficiency regeneration disposal process flow, and determines the formula and activation time of the activation solution, the formula and pickling time of the pickling solution, and the liquid addition solution for each tank through manual sampling of a batch of modules to be treated. Position, ultrasonic cleaning time, bubbling cleaning time, etc., provide the basis for the next step of automatic operation. The time setting is completed by the adjustable time relay of the control system.

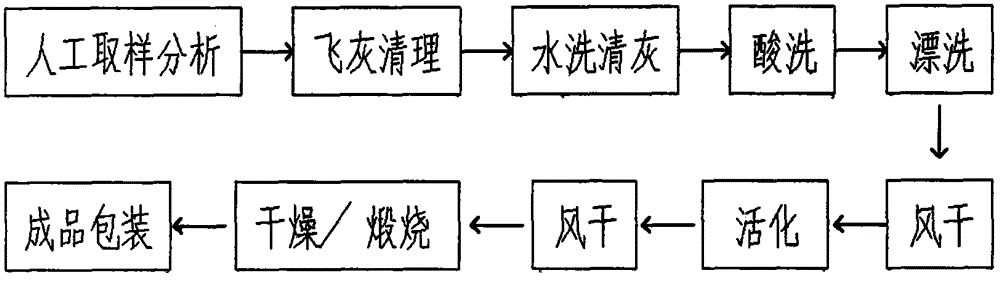

[0031] See the specific process figure 1 . Among them, manual sampling analysis: each batch (each time a power plant has used a batch of modules) the regenerative modules to be processed must first be manually sampled, and the main pollutants and pollution levels of the pollution must be manually detected to determine the composition and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com