Preparation method of 1,4-dioxane

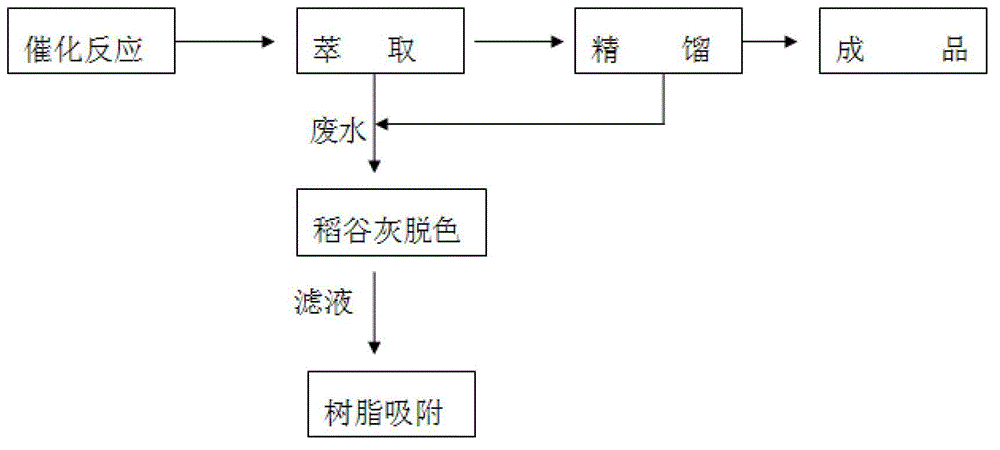

A technology of dioxane and diethylene glycol, which is applied in the field of preparation of 1,4-dioxane, can solve the problems of difficult wastewater treatment, inability to realize continuous production of products, environmental pollution, etc., and achieve increased production and The utilization rate of equipment, the realization of long-term pollution-free production, and the effect of improving the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] (1) Synthesis process: Preheat the synthesis tower with solid superacid resin to 115°C, transport diethylene glycol to the heater at a flow rate of 500Kg / h, and heat it to 120°C through steam or heat transfer oil. After heating, the two Glycol enters the preheated synthesis tower, and the feed liquid enters the vapor-liquid separator after passing through the synthesis tower. A small amount of unreacted feed liquid cools down and returns to the diethylene glycol raw material tank to continue the reaction. The vapor phase reaction products 1,4 -Dioxane and water enter the crude product receiving tank after condensation, go out crude product 410Kg / h, unreacted reflux diethylene glycol 90 Kg / h;

[0022] (2) Extraction process: the crude product enters the extraction tower from the upper distributor of the extraction tower at 405 Kg / h, and the extractant isopropyl ether enters the extraction tower from the lower distributor of the extraction tower at 150 Kg / h. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com