Extraction method of vanadium from stone coal with pollution treatment and ceramic production combination

A technology of ceramics and stone coal, which is applied in the production of ceramic materials, vanadium oxide, and the improvement of process efficiency. It can solve the problems of low added value of unburned bricks, limited production volume of freight costs, and limited amount of cement addition, so as to save investment costs. , reduce duplication of investment, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

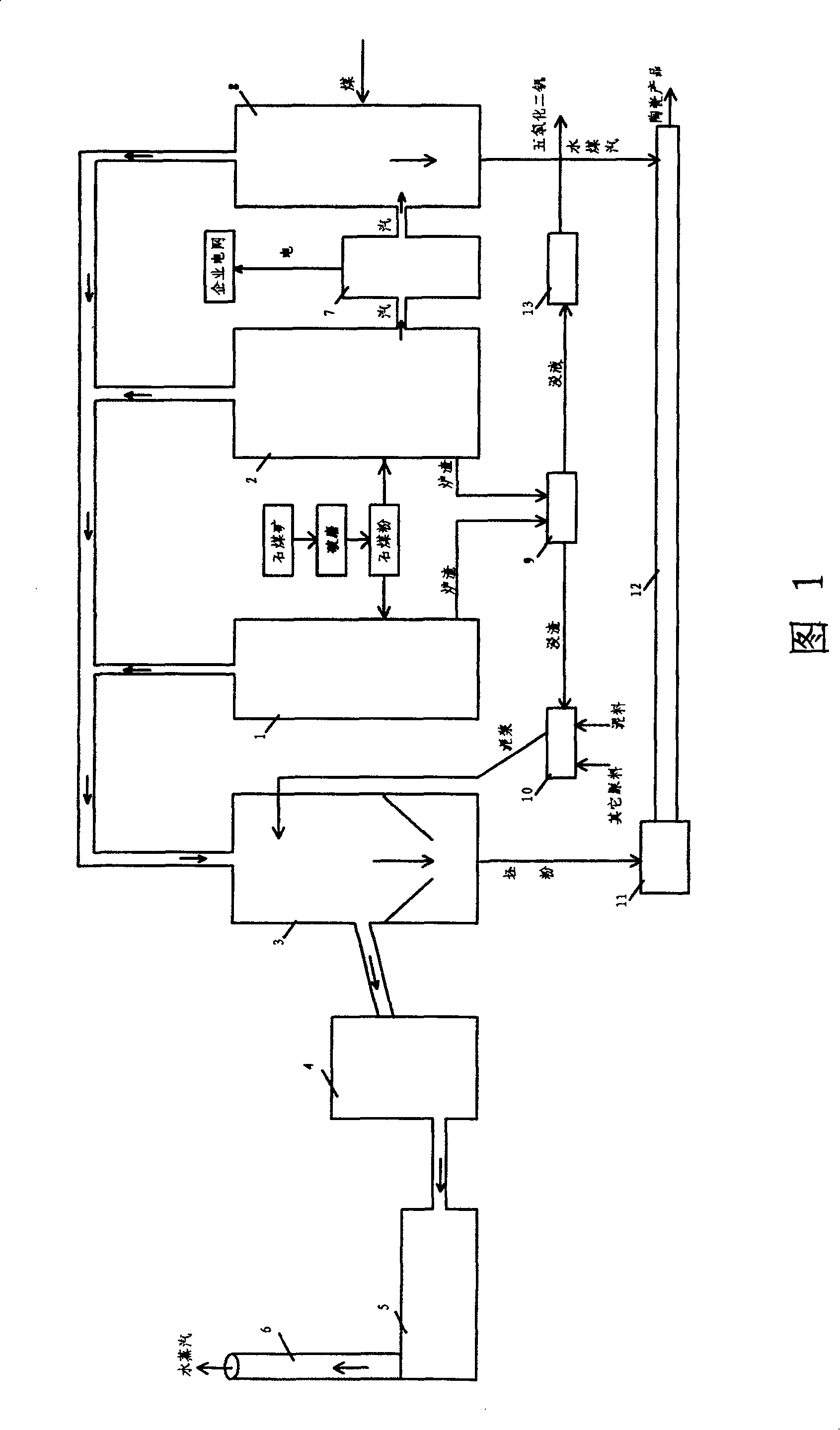

[0019] Referring to the accompanying drawings: after crushing vanadium-containing stone coal of 1-20mm, put it into roasting furnace 1 and circulating fluidized bed boiler 2 for low-sodium roasting, and the flue gas produced is introduced into spray drying tower 3 as hot air, and sprayed into mist The mud is heat-exchanged and dried, and its exhaust gas and newly evaporated water vapor are pumped into the cyclone dust collector 4 for further dust removal, and then discharged into the water curtain dust removal chamber 5. Harmful gases such as hydrogen chloride and chlorine gas are dissolved into the water, and finally discharged through the chimney 6 for clean water vapor.

[0020] The steam generating set 7 obtains high-pressure steam from the circulating fluidized bed 2 to generate electricity, and provides electric energy for the enterprise power grid. The investment in building large boilers is saved, and the more important thing is that the heat energy of steam after powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com