Rotary floating cutting numerical control machine tool for silicon rod

A CNC machine tool and floating cutting technology, applied in the field of CNC machine tools, can solve the problems of delayed production, difficulty in cutting finished products, and rising production costs, and achieve the effects of reducing production costs, cutting time, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

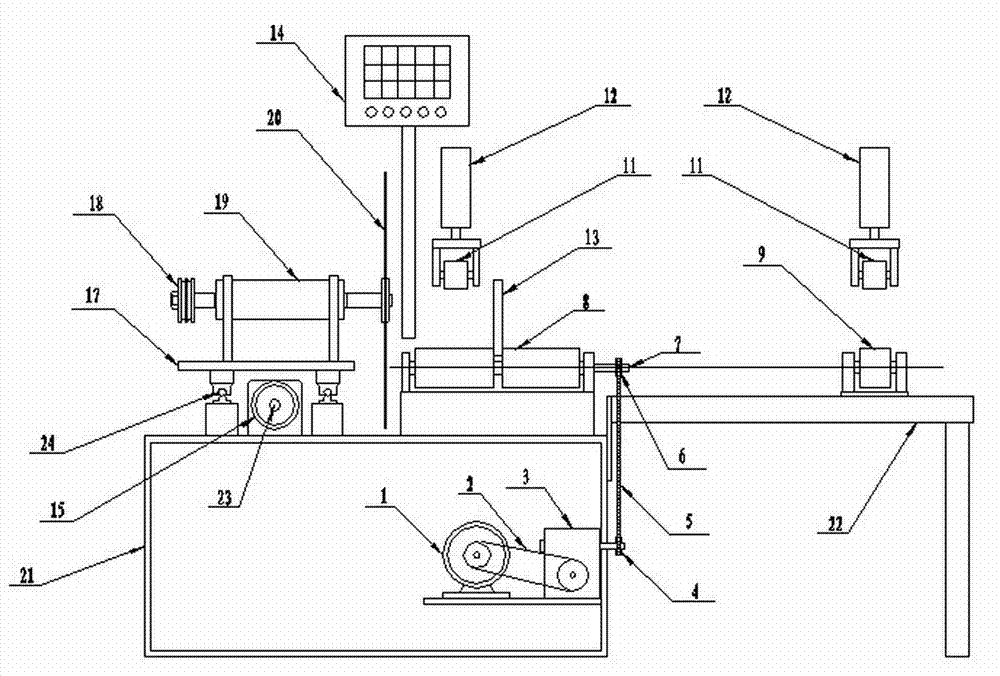

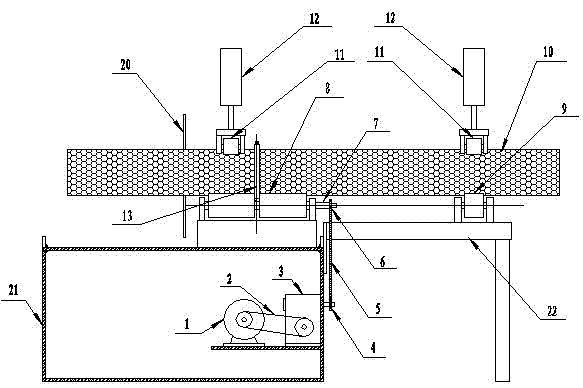

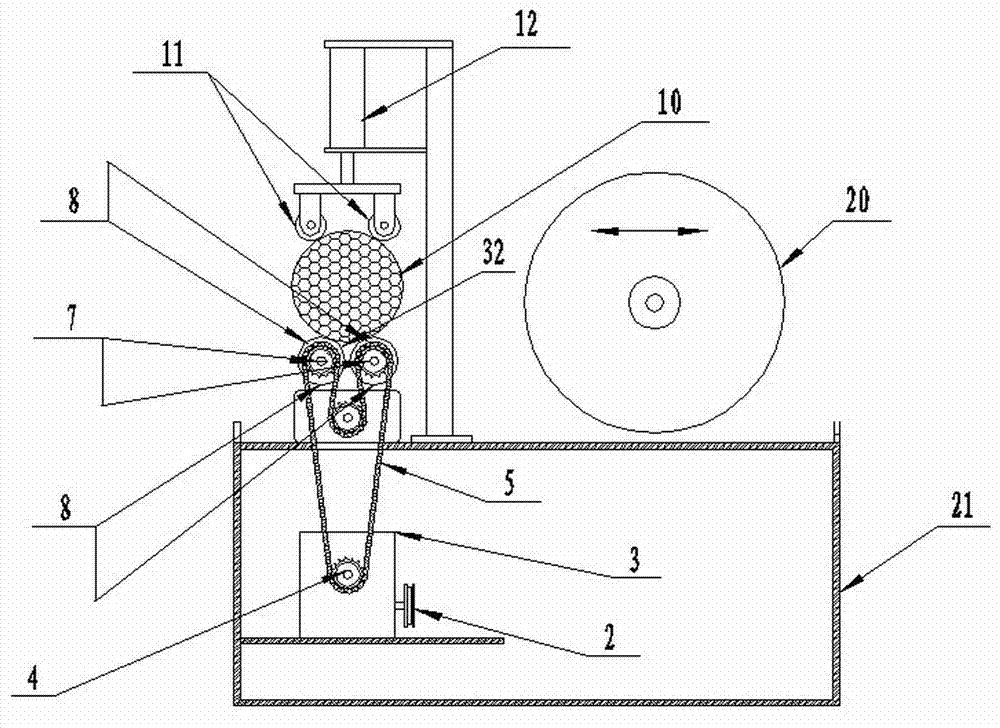

[0042] A silicon rod rotary floating cutting CNC machine tool, including a numerical control box, a bed, a transmission mechanism, a cutting mechanism arranged on the bed, and a silicon rod clamping mechanism, is characterized in that: the silicon rod clamping mechanism includes a vertically coordinated The active rotating supporting wheel 8 and the floating rotating pressing wheel 11 holding the silicon rod 10; Non-concentric axial rotation on the horizontal position of the supporting wheel 9

[0043] The floating rotary pressing wheel 11 is vertically located above the silicon rod 10 and is connected to the elastic extruding device 12, which drives the floating rotating pressing wheel 11 to press the silicon rod 10 tightly around the shape of the outer circle of the silicon rod.

[0044] The active rotating support roller 8 is located below the silicon rod 10 and is connected with the transmission mechanism, and the transmission mechanism drives the silicon rod 10 to rotate ...

Embodiment 2

[0052] Such as figure 1 , figure 2 As shown, a silicon rod rotary floating cutting numerical control machine tool includes a numerical control box 14, a bed 21, a transmission mechanism, a cutting mechanism and a silicon rod clamping mechanism are respectively arranged on the bed, and the silicon rod clamping mechanism includes a vertically coordinated The active rotating support roller 8 and the floating rotating pressure wheel 11 holding the silicon rod 10; the floating rotating pressure wheel is connected to the floating cylinder, and the gas of the floating cylinder 12 drives the drive shaft of the cylinder, and the cylinder drive shaft is connected to the floating rotating pressure wheel 11 to open the floating cylinder 12 , the cylinder drive shaft drives the floating rotating pressure wheel 11 to tightly press the outer circle of the silicon rod 10, and the floating rotating pressure wheel 11 moves up and down with the fluctuation of the outer circle of the silicon ro...

Embodiment 3

[0065] In the same way, the elastic extruding device 12 is a spring compression device, and the spring compression device ( Figure 7 ) is equipped with a spring 29 connected to a driving shaft 30, the other end of the driving shaft 30 is connected to a cross bar 31, and the two ends of the cross bar 31 are respectively connected to the floating rotating pressure wheel 11, and the spring 29 drives the driving shaft 30 to press down, driving the cross bar 31 to two The floating rotating pressure wheel (11) at the end surrounds the shape of the outer circle of the silicon rod and presses the outer circle of the silicon rod 10 in good time.

[0066] The active rotating supporting roller 8 is coaxially provided with two groups, and a positioning groove 32 is formed between the two groups; the silicon rod 10 is covered with a cutting and measuring ring 13, and the cutting and measuring ring 13 is located in the positioning groove. The cutting ring 13 rotates with the silicon rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com