A method of making polyester irregular granules by using polyester waste

A technology of irregular and particulate matter, which is applied in the field of waste plastic recycling, can solve the problems of product performance degradation, achieve the effect of improving intrinsic viscosity, improving mechanical properties, and ensuring the supply of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

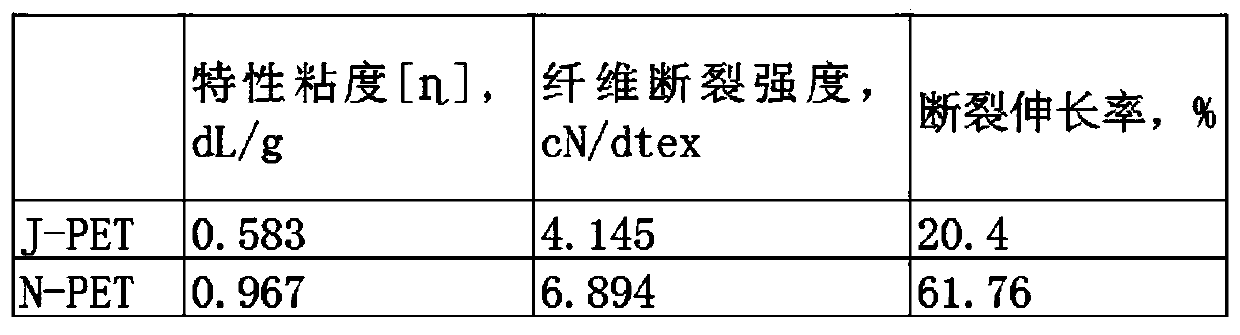

Examples

Embodiment 1

[0024] The present embodiment provides a kind of method that utilizes polyester waste to make polyester irregular particle, comprises the following steps:

[0025] (1) Cutting and crushing.

[0026] Cut and crush the recovered polyester waste into fragments with a length of 10-50cm, wash with hot water at 90°C, and dry at 120-140°C for 7-10 hours under a vacuum of -0.95MPa to obtain a moisture content of less than 65 ppm dry fines.

[0027] (2) Screw extrusion.

[0028] The dry crushed material obtained in step (1) is fed into the feeding port of the parallel twin-screw extruder (Zhejiang Jinhu Plastic Machinery Co., Ltd.) through the front conveying device. After shearing, stirring, pressurizing, extruding, tearing and heat treatment, the polyester is extruded at the front of the screw and pelletized. Wherein the heating temperature is controlled at about 270°C. 6 additional high-strength bolts are set at the front end of the screw to facilitate the control of the crushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com