Process for production of activated argil

A production method, activated clay technology, applied in chemical instruments and methods, silicate, other chemical processes, etc., can solve the problems of increasing the production cost of the reactor and the difficulty of operation, and achieve the effect of solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

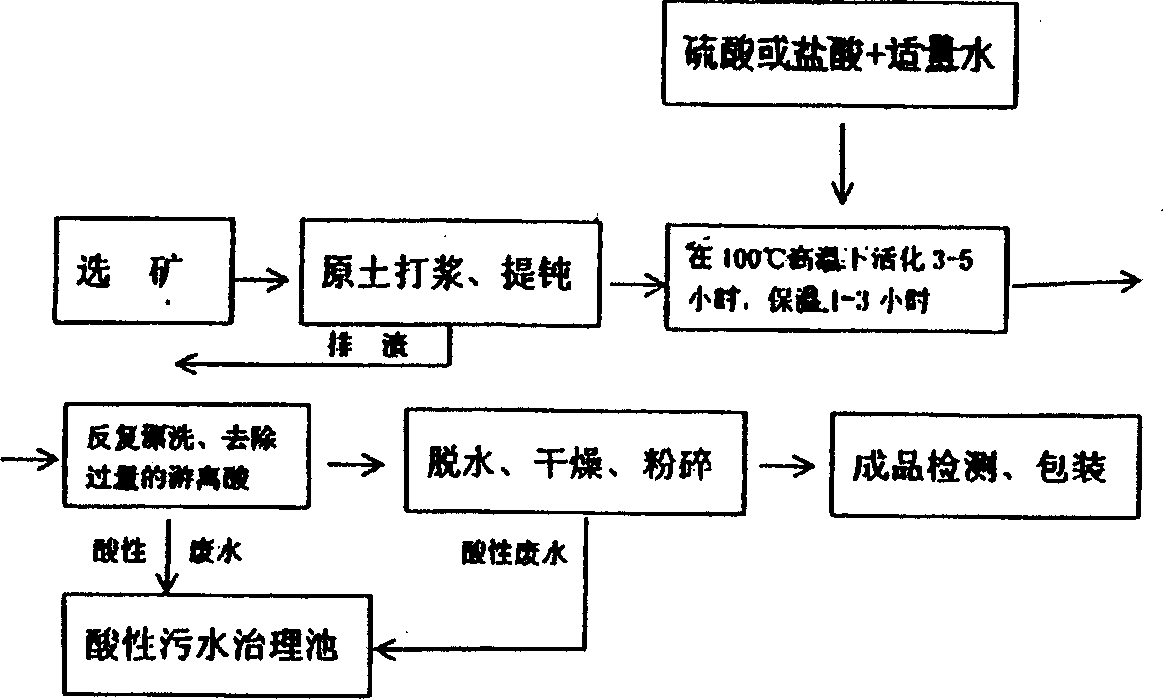

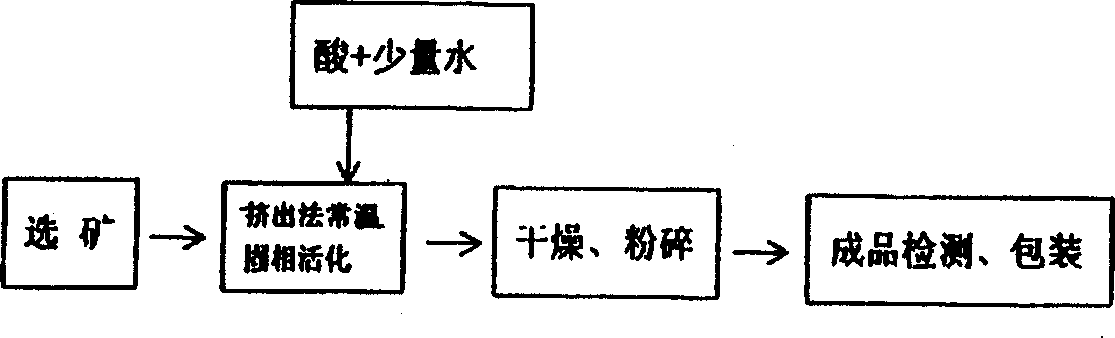

Method used

Image

Examples

Embodiment 1

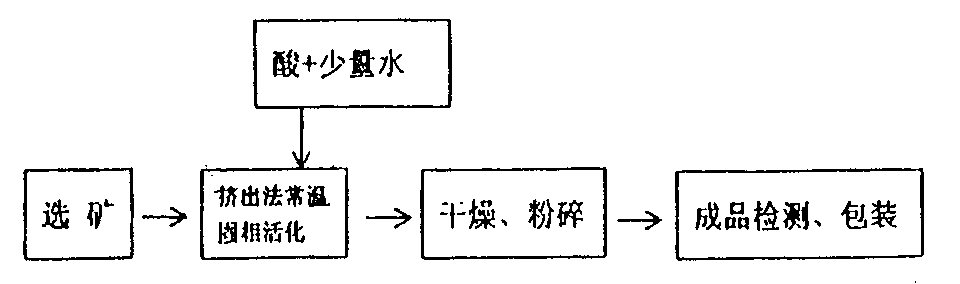

[0016] Embodiment 1, the production method of ordinary activated clay, without special instructions, is a mass percentage, and the benchmark is the mass of bentonite that needs to be activated.

[0017] (1) mineral processing;

[0018] (2) adding mass percentage concentration is 98% sulfuric acid and water to carry out extrusion method normal temperature solid-phase activation in bentonite, namely the three mass ratios of sulfuric acid, water, bentonite are 3%: 30%: 1, with bentonite quality as benchmark;

[0019] (3) drying and pulverizing then;

[0020] (4) Finished product testing and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com