Intelligent modularized continuous green devulcanizing and regenerating complete technology for waste rubber

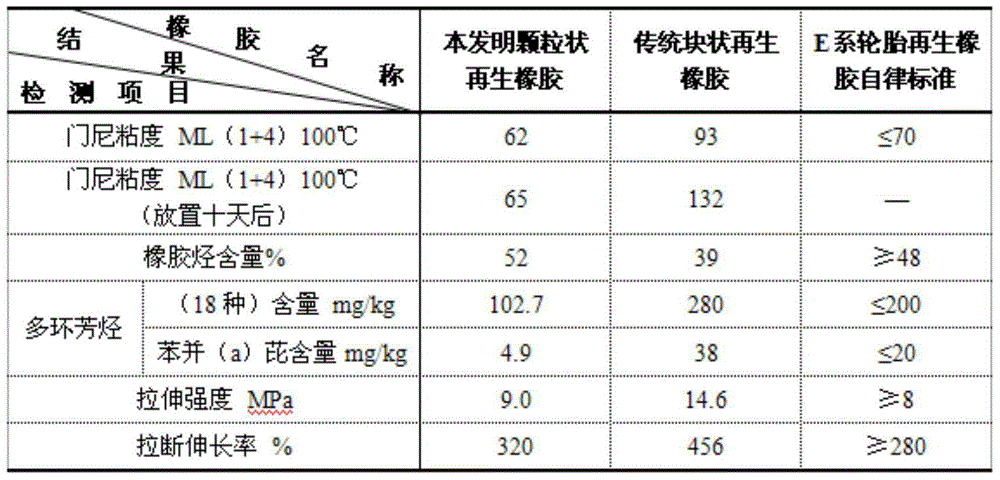

A waste rubber and intelligent module technology, applied in the field of waste rubber recycling, can solve the problems of poor product quality, discontinuity, and large pollution, and achieve the effects of excellent and stable product performance, avoiding difficult control, and reasonable equipment layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] (1), Module 1: Waste tires go through a set of intelligent fully enclosed continuous crushing and separation equipment, that is, they are cut into circles once by a ring cutter; ; After the first two stages of crushing, go through two-stage magnetic separation of belt magnetic separator and excitation magnetic separator; go through one airflow separation of airflow separator, and finally get the required 2-10mm rubber particles;

[0028] (2), module 2: without adding any chemical additives, the rubber particles of 2-10mm obtained in step (1) are fed into the screw rubber regenerator through the rubber quantitative feeder and are subjected to strong extrusion and shearing by the screw. Purely mechanical action, the sulfur-containing molecular chains are selectively broken, destroying its network structure, and realizing the green regeneration of rubber particles. Regeneration time 4-8min;

[0029] (3) Module 3: The regenerated rubber semi-finished product obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com