A radiation-crosslinked medical pressure-sensitive adhesive and its preparation method

A pressure-sensitive adhesive and irradiation technology, applied in the field of pressure-sensitive adhesives, can solve problems such as skin allergies, and achieve the effects of improving integrity, improving integrity and viscosity, and improving solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention also discloses a preparation method of radiation-crosslinked medical pressure-sensitive adhesive, the preparation method comprising the following steps:

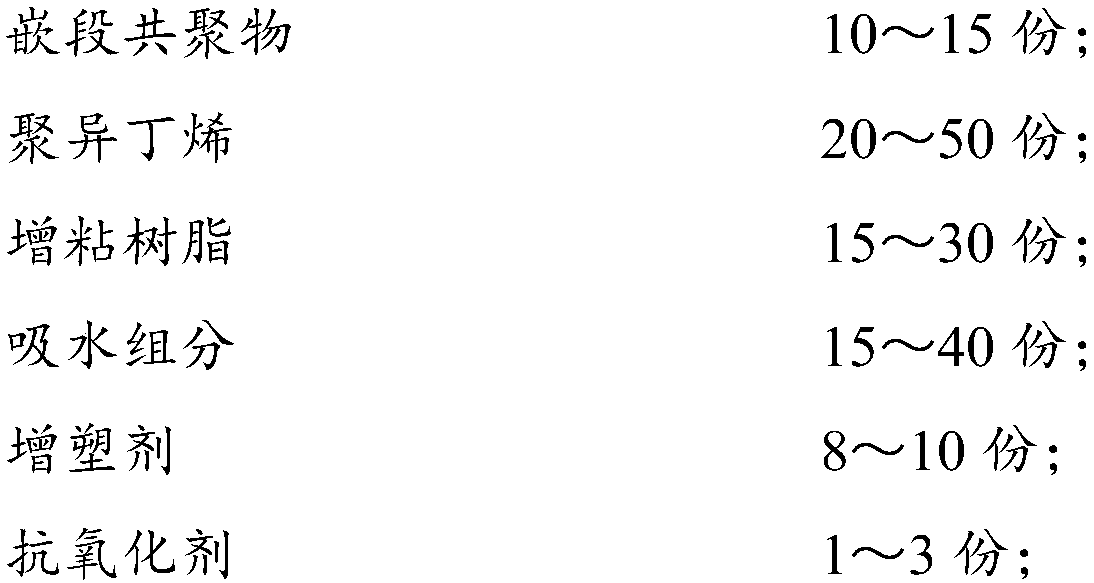

[0030] Step 1): at 130-160° C., banburying the block copolymer, polyisobutylene, tackifying resin, antioxidant and plasticizer by parts by weight for 1-10 minutes;

[0031] Step 2): After lowering the temperature to 90-100°C, add water-absorbing components and continue banburying for 5-10 minutes;

[0032] Step 3): After taking out the banburying product of step 2), use a flat vulcanizing machine at 100-120°C to press it into a 1-2mm thick sheet-like plate;

[0033] Step 4): putting the sheet-like plate into an electron accelerator for radiation cross-linking, the radiation dose is 5-8 Mrad.

Embodiment 1

[0035] Using a Brabender internal mixer, at 140°C, 15 parts of block copolymer SIS, 20 parts of polyisobutylene, 20 parts of tackifying resin, 1 part of antioxidant After banburying 10 minutes of plasticizer and 9 parts of plasticizer, the temperature was lowered to 100°C and 40 parts of water-absorbing components were added and mixed for 10 minutes to obtain a blend. Press into a sheet-like sample with a thickness of 1mm.

[0036] The polyisobutene is composed of two kinds of polyisobutene with weight average molecular weights of 85000 and 40000 respectively mixed in a weight ratio of 1:2; the tackifying resin is rosin resin, and the antioxidant is antioxidant 1010; the plasticizer is naphthene oil; the water-absorbing component is guar gum.

Embodiment 2

[0038] Using a Brabender internal mixer, at 140°C, 15 parts of block copolymer SIS, 20 parts of polyisobutylene, 20 parts of tackifying resin, 1 part of antioxidant After banburying 10 minutes of plasticizer and 9 parts of plasticizer, the temperature was lowered to 100°C and 40 parts of water-absorbing components were added and mixed for 10 minutes to obtain a blend. Press into a sheet-like sample with a thickness of 1mm. Put the prepared flake sample into an electron accelerator for irradiation cross-linking, and the irradiation dose is 7Mrad.

[0039] The polyisobutene is composed of two kinds of polyisobutene with weight average molecular weights of 85000 and 40000 respectively mixed in a weight ratio of 1:2; the tackifying resin is rosin resin, and the antioxidant is antioxidant 1010; the plasticizer is naphthene oil; the water-absorbing component is guar gum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com