Patents

Literature

216 results about "Styrene-isoprene-styrene block copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene-butadiene and styrene-isoprene block copolymers (SBR), also known as styrene-butadiene-styrene (SBS) and styrene-isoprene-styrene (SIS), two related triblock copolymers that consist of polystyrene sequences (or blocks) at each end of a molecular chain and a butadiene or isoprene sequence in the centre.

Asphalt modifier, modified asphalt and asphalt mixture

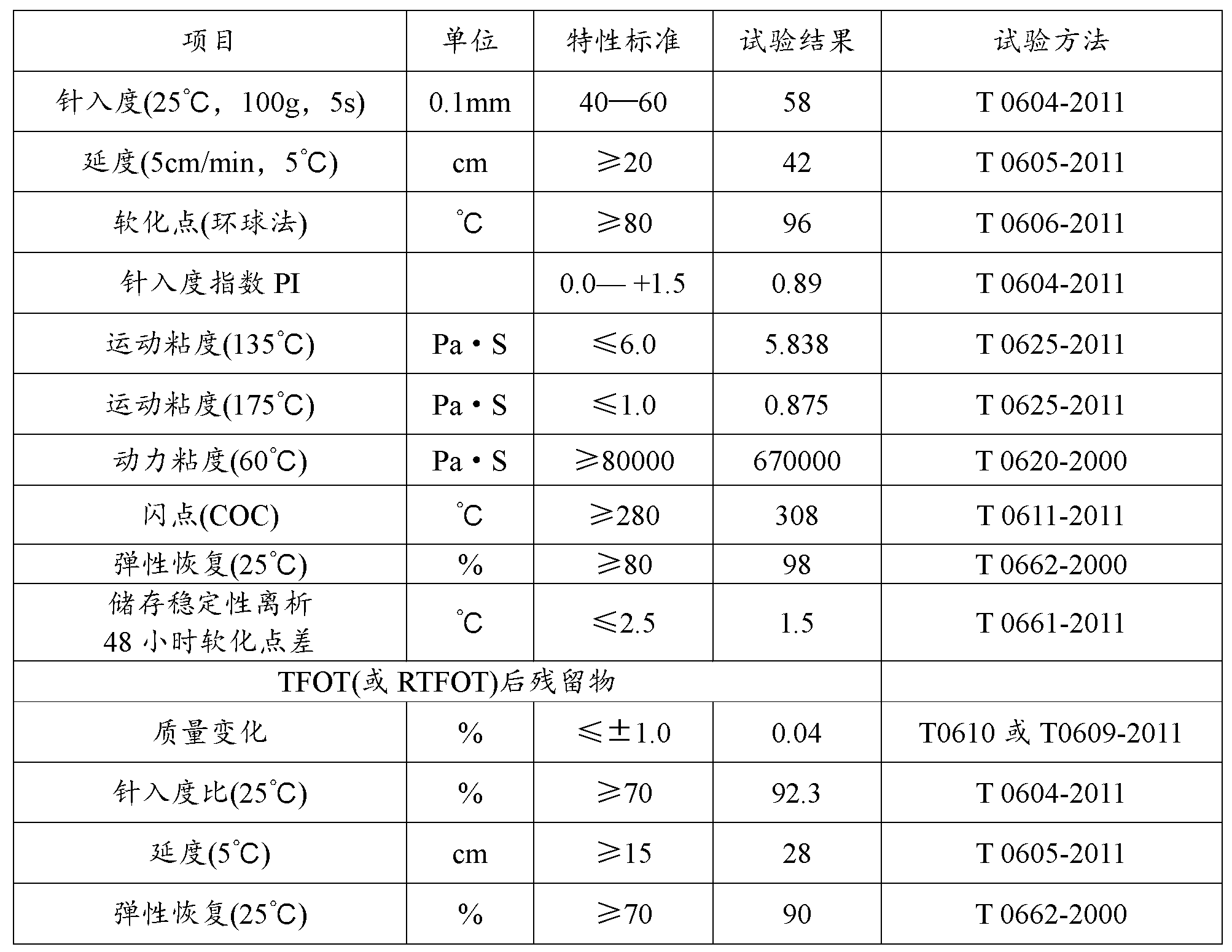

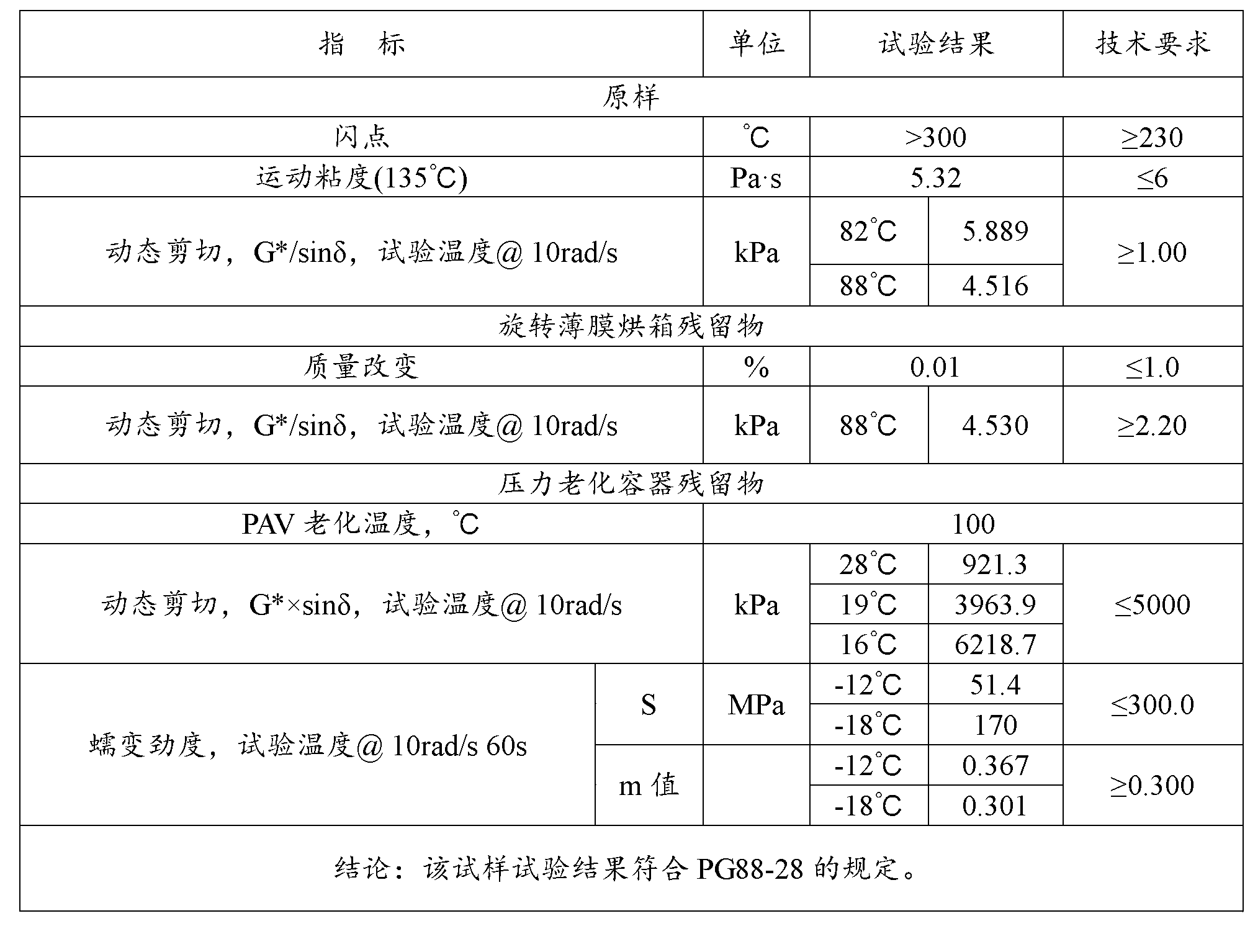

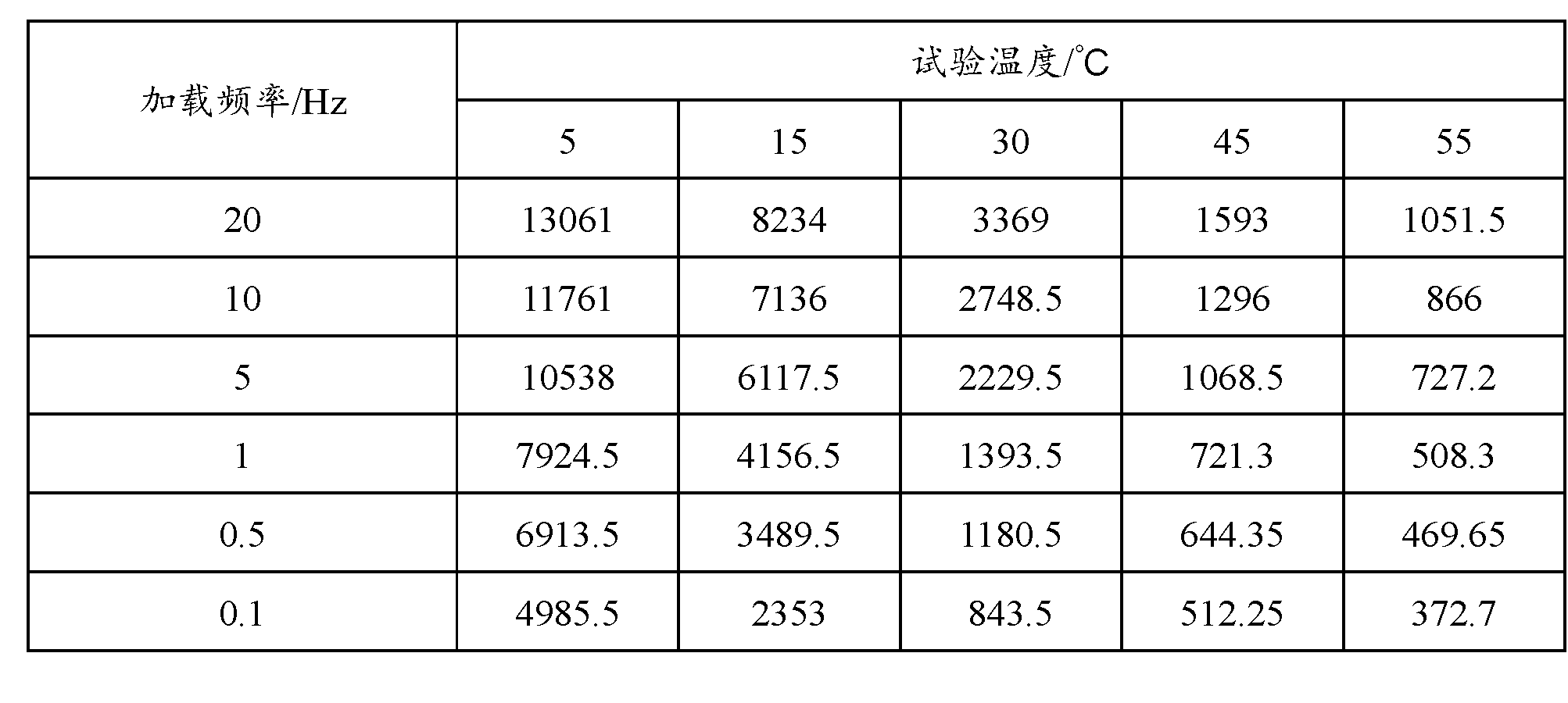

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

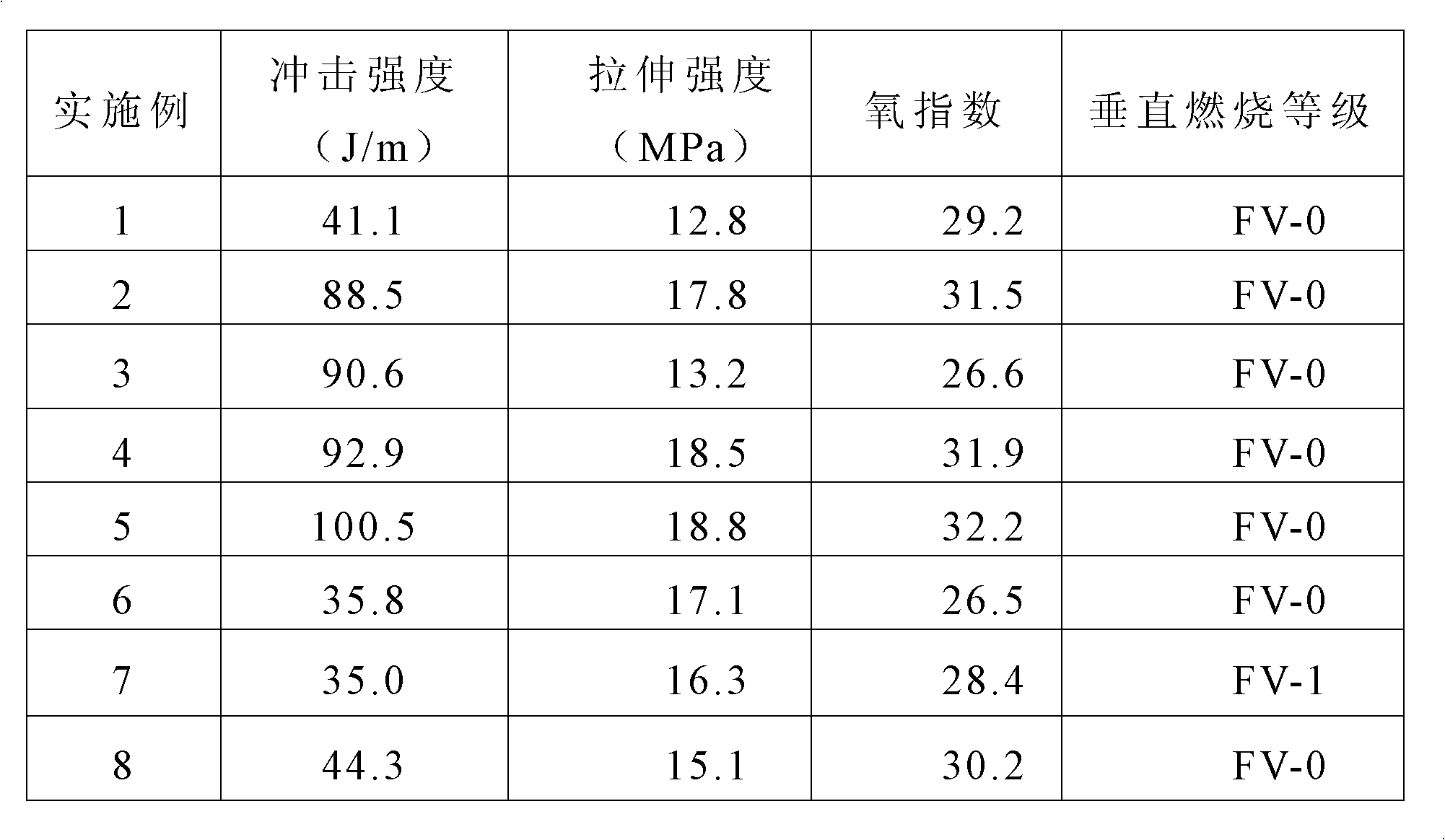

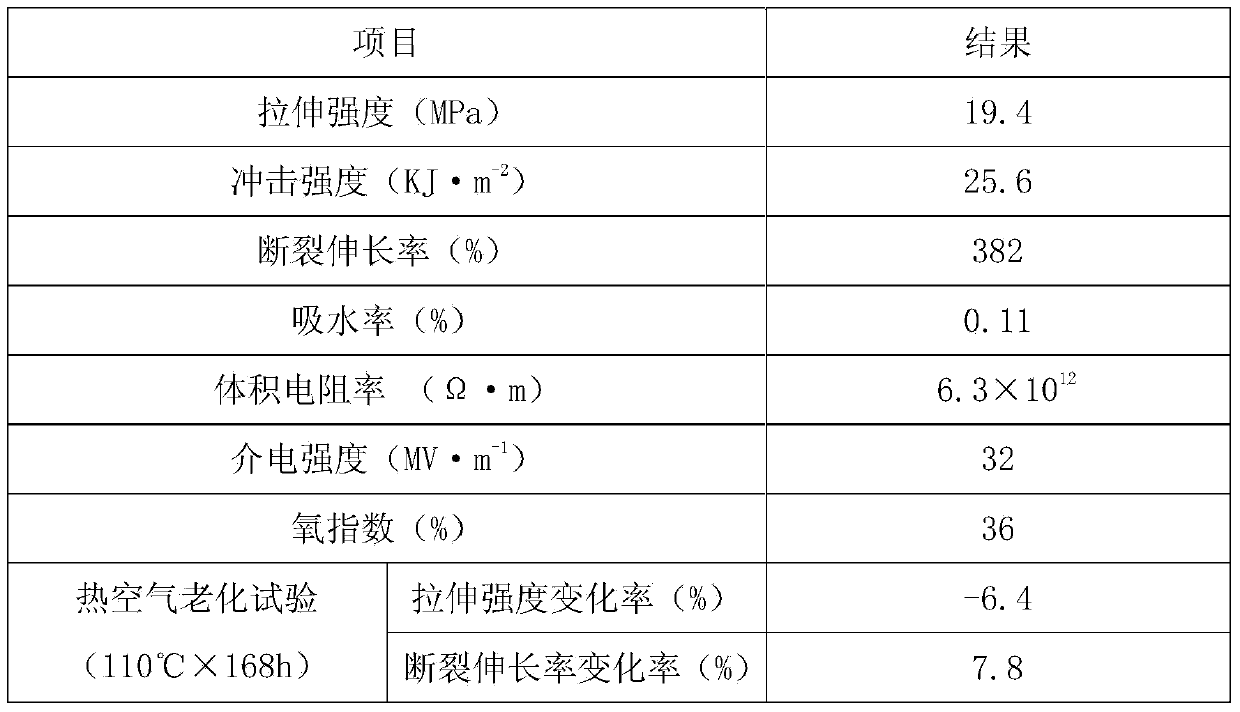

Magnesium hydroxide composite flame retardant material and preparation method thereof

The invention discloses a magnesium hydroxide flame-retardant composite material and a preparation method thereof. The flame-retardant material comprises the following components in parts by weight: 20-100 parts of high polymer, 40-80 parts of magnesium hydroxide and 5-20 parts of toughening agent, wherein the high polymer is one or more of polyethylene, polyvinyl chloride, polypropylene, polystyrene, polyamide, polyformaldehyde, rubber or nylon; and the toughening agent is one or more of dioctyl phthalate, poly(ethylene-octene) elastomer, tricresyl phosphate, styrene-butadiene-styrene block copolymer, hydrogenated styrene-butadiene-styrene block copolymer or styrene-isoprene-styrene block copolymer. Practice proves that the magnesium hydroxide flame-retardant composite material has the advantages of strong shock resistance, high tensile strength and high oxygen index. The preparation method of the composite material is simple in operation, has low cost and high production efficiency,and can be widely used in the field of engineering plastics.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

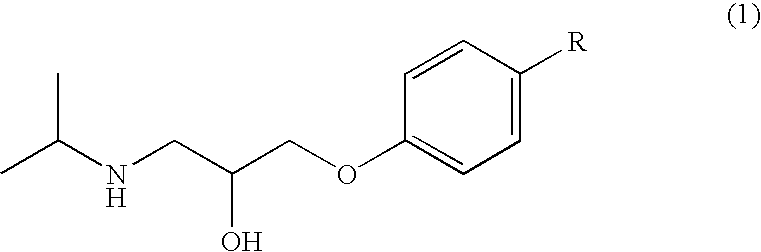

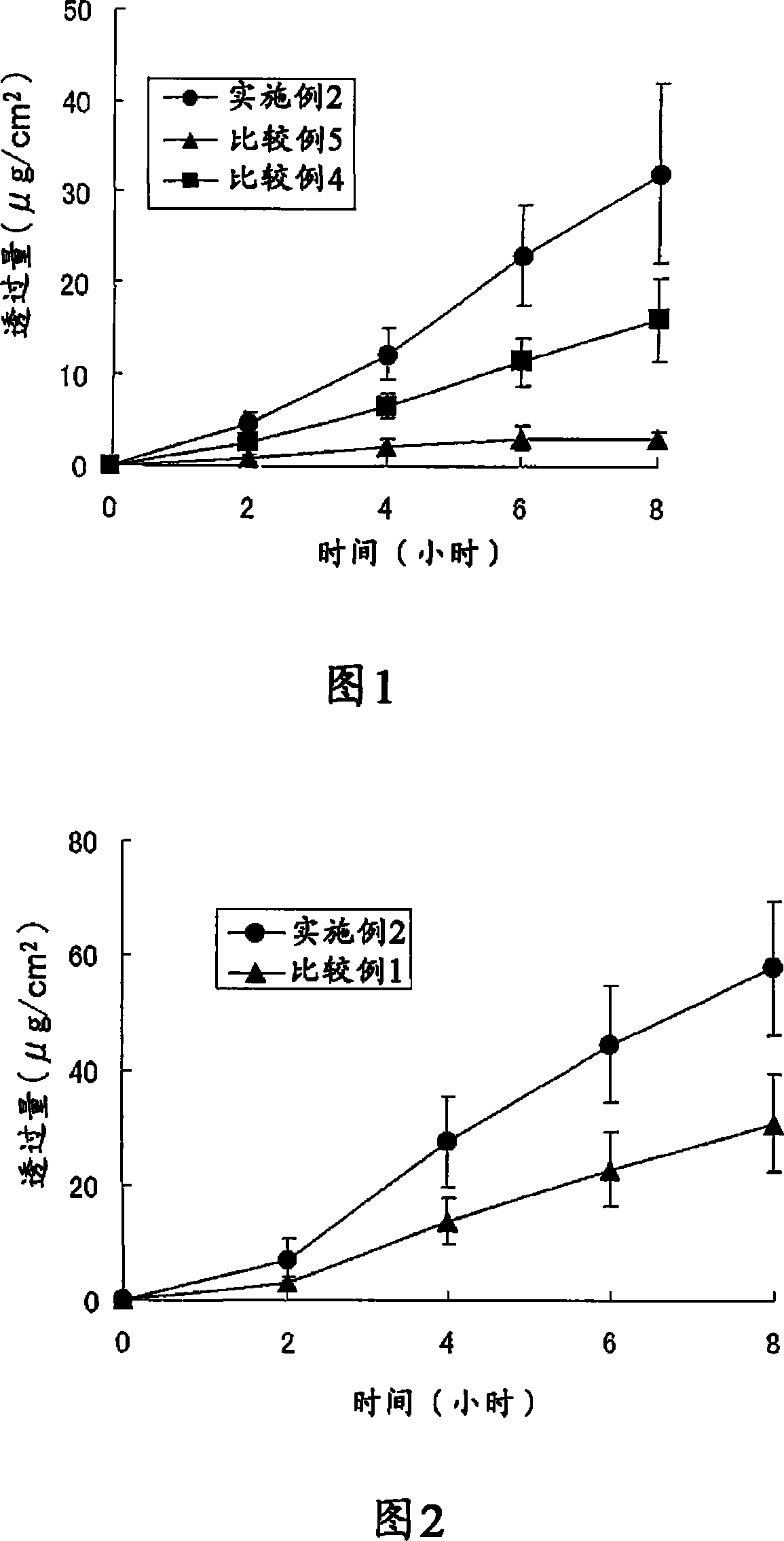

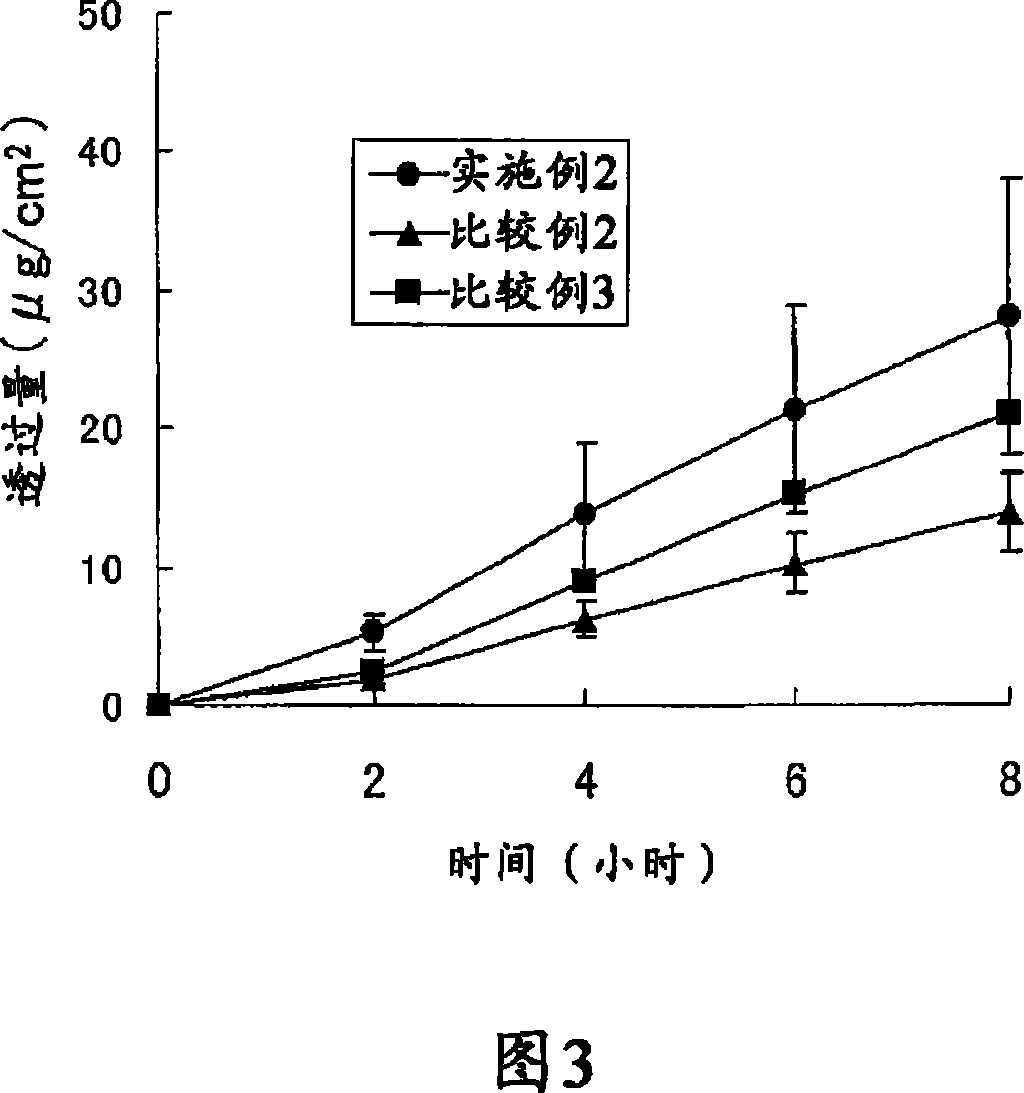

Adhesive patch

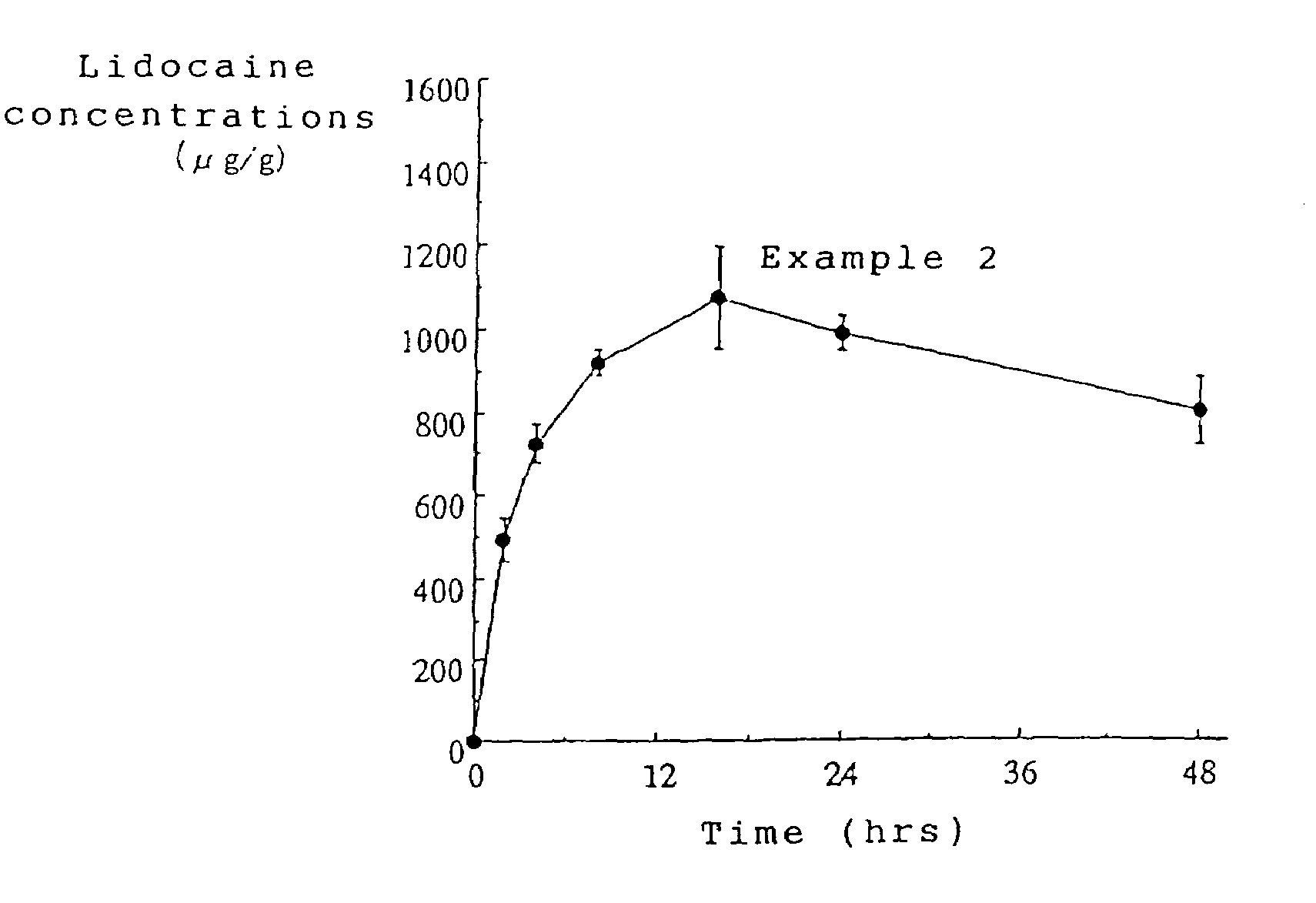

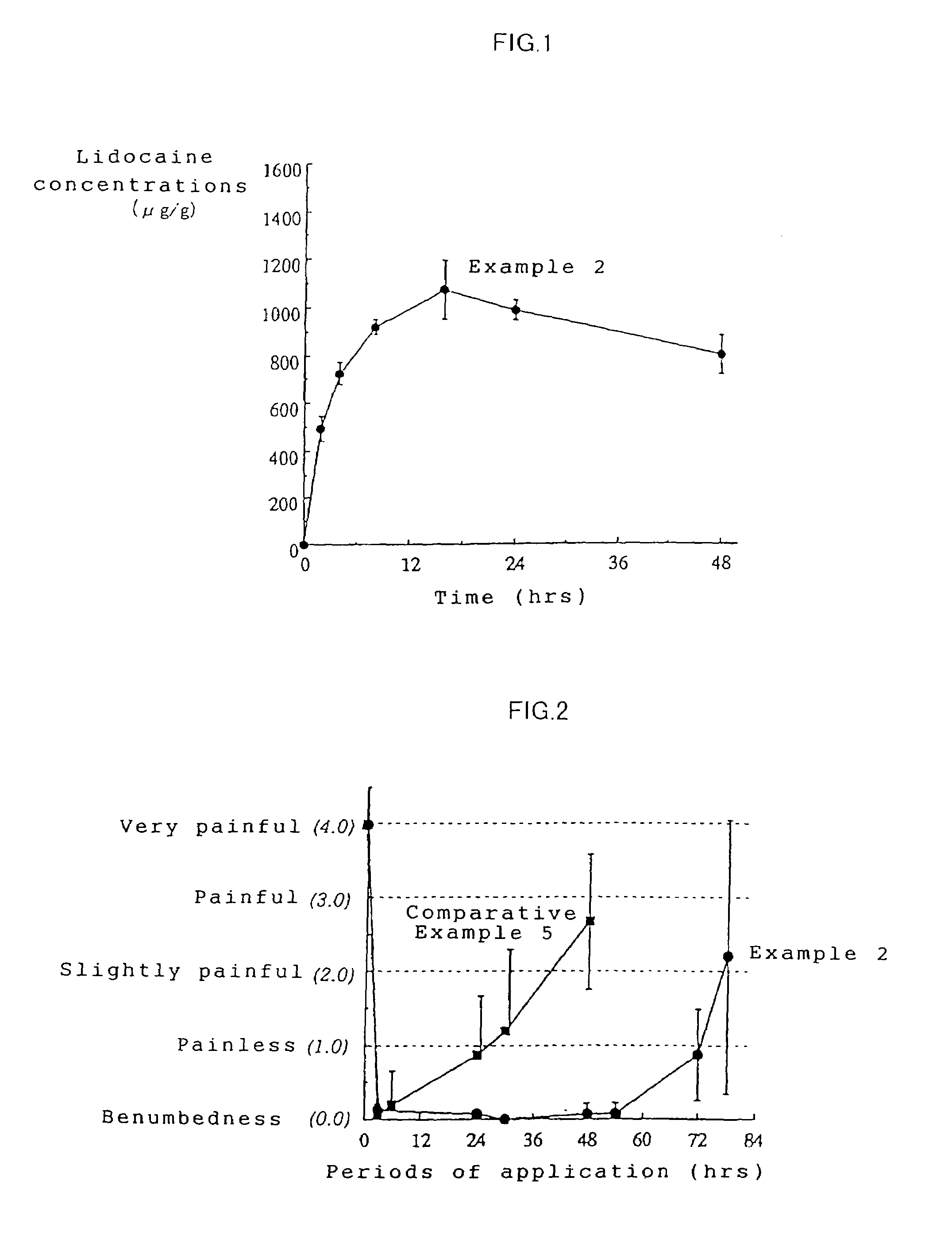

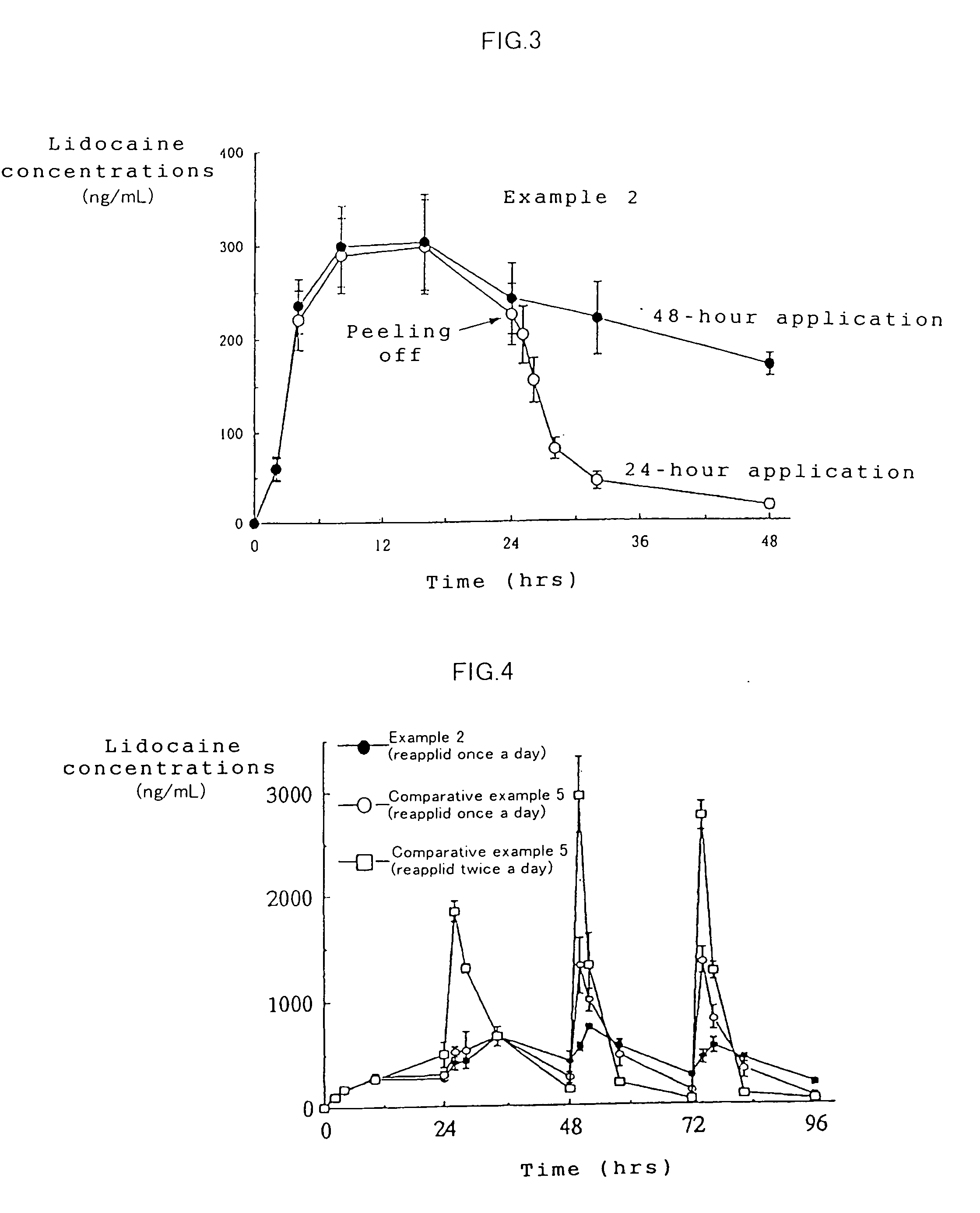

InactiveUS20050260255A1Improve the level ofGood skin permeabilityNervous disorderOrganic non-active ingredientsPolymer scienceStyrene-isoprene-styrene block copolymer

A patch comprising a backing layer and an adhesive layer disposed on the backing layer and compounded with a drug and an adhesive base agent, wherein the adhesive base agent comprises styrene-isoprene-styrene block copolymer, 2-ethylhexyl acrylate—vinyl acetate copolymer and a basic nitrogen-including polymer including a basic nitrogen and having no adhesion property at normal temperature.

Owner:HISAMITSU PHARM CO INC

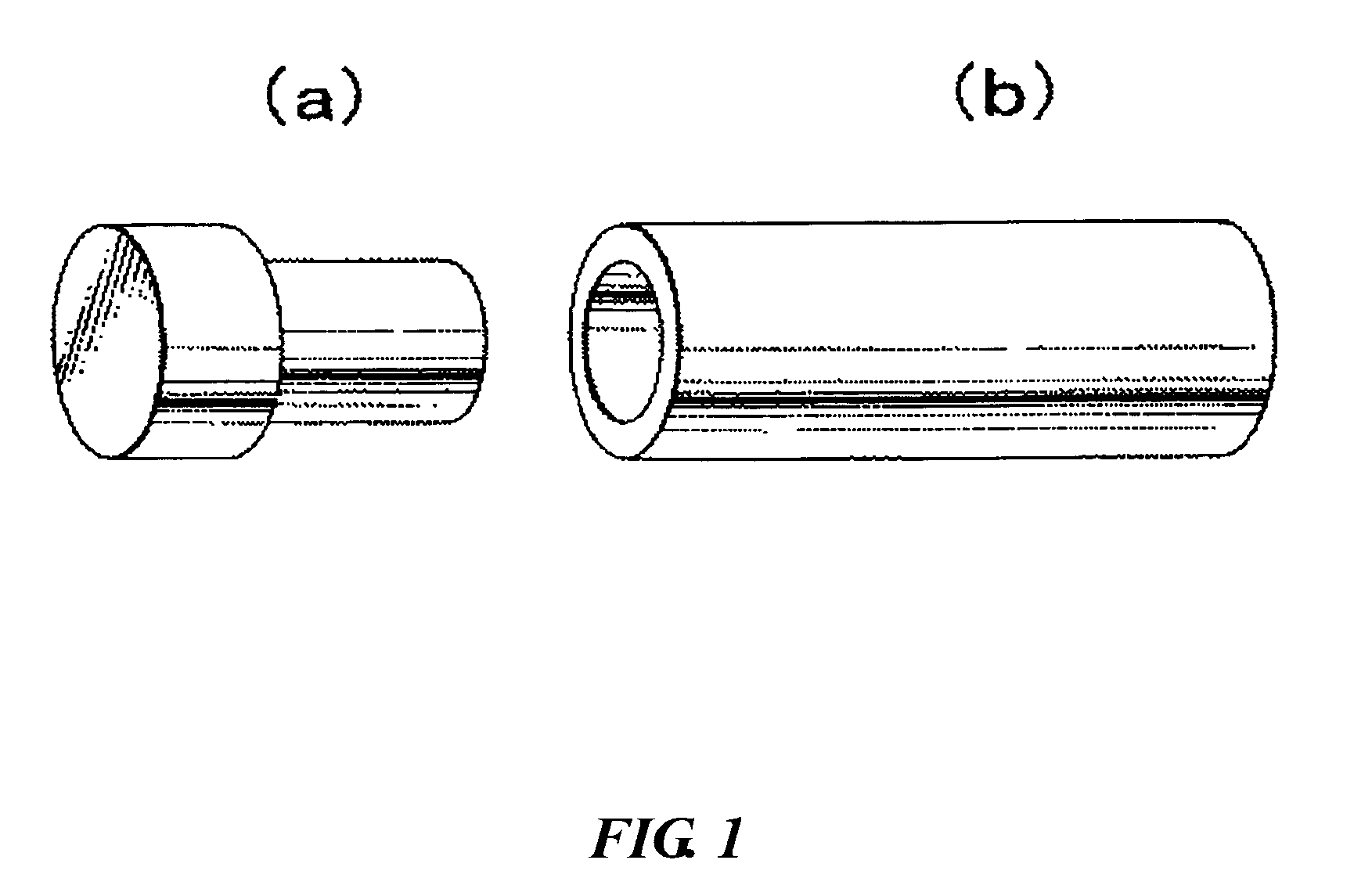

High performance ballistic composites having improved flexibility and method of making the same

ActiveUS20080064280A1Increase flexibilityComfortable to wearArmourSynthetic resin layered productsFiberPolyolefin

A composite material which has excellent ballistic performance and has improved flexibility. Surprisingly, it has been found that a combination of poly(alpha-olefin) fiber and matrix resin provides these desirable product features. The resin matrix is a block copolymer of a conjugated diene and a vinyl aromatic monomer, preferably a styrene-isoprene-styrene block copolymer, that is applied as an aqueous composition. The fiber has a tenacity of at least about 35 g / d and a tensile modulus of at least about 1200 g / d. The composite has a total density equal to or less than about 100 g / m2 and a stiffness of less than about 2.5 pounds (1.14 kg) for a two layer structure of the composite, and a total areal density equal to or less than about 190 g / m2 and a stiffness of less than about 3.0 pounds (1.36 kg) for a four layer structure of the composite. The Peel Strength for a two layer structure of less than about 1.0 pounds (0.45 kg) for a two layer structure of the composite, and less than about 0.7 pounds (0.32 kg) for a four layer structure of the composite. The process of this invention permits fabrication of these desirable products in a cost-effective manner. Body armor made from the composite has improved flexibility and excellent ballistic characteristics.

Owner:HONEYWELL INT INC

Pressure Sensitive Adhesive Composition and Pressure Sensitive Adhesive Tape

InactiveUS20110306677A1Improve balanceHigh bonding strengthBiocideHydroxy compound active ingredientsPolymer sciencePlasticizer

A pressure sensitive adhesive composition comprising, as a rubber component solid at ordinary temperature, from 10% by mass or more to less than 50% by mass of polyisoprene, from more than 50% by mass to 90% by mass or less of a styrene-isoprene-styrene block copolymer and 0 to 30% by mass of polyisobutylene, and further comprising, per 100 parts by mass of the solid rubber component, 1 to 30 parts by mass of polyisobutylene liquid at ordinary temperature, 50 to 120 parts by mass of a tackifier, and 1 to 40 parts by mass of a plasticizer liquid at ordinary temperature; and a pressure sensitive adhesive tape comprising a base material and the above-described pressure sensitive adhesive composition provided on the base material.

Owner:NICHIBAN CO LTD

Tape material for transcutaneous absorption

A preparation for transdermal absorption is disclosed which is suited for alleviating lasting pains caused by herpes zoster or postherpetic neuralgia and is practical and more improved in drug efficacy, safety and application characteristics. This tape preparation for transdermal absorption is obtained by causing an adhesive mass prepared by incorporating 1–30 parts by weight of a local anesthetic as an active ingredient in 100 parts by weight of a nonaqueous adhesive mass base comprising 5–50% by weight of a styrene-isoprene-styrene block copolymer, 1–60% by weight of an alicyclic saturated hydrocarbon resin, 5–60% by weight of liquid paraffin and 1–30% by weight of butyl rubber to be supported on a backing.

Owner:YUTOKU PHARMA IND +1

Hot melt adhesive for quick joint coating of metallic pipeline and preparation method thereof

The invention belongs to the technical field of pipeline joint coating anticorrosive hot melt adhesives, and particularly relates to a hot melt adhesive for quick joint coating of a metallic pipeline and a preparation method thereof. The hot melt adhesive comprises the following components in percentage by weight: 20 to 50 percent of styrene-isoprene-styrene block copolymer, 5 to 10 percent of styrene-butadiene-styrene block copolymer, 5 to 10 percent of ethylene-vinyl acetate copolymer, 5 to 10 percent of ethylene-ethyl acrylate copolymer, 5 to 10 percent of maleic anhydride grafted polyethylene, 10 to 25 percent of softening agent, 5 to 10 percent of inorganic filler, 0.1 to 2 percent of antioxidant and the balance of tackifying resin, wherein the total weight is 100 percent. The hot melt adhesive is prepared by kneading the components by a kneader at a high speed and extruding the mixture by a twin-screw extruder. Because the hot melt adhesive prepared by the method has high bonding strength, high weathering resistance and high construction mobility, the hot melt adhesive can be widely used in the field of quick joint coating and corrosion prevention of metallic pipelines.

Owner:TONGJI UNIV

Anti-adhesion biological membrane and preparation method thereof

ActiveCN103405811AGood biocompatibilityGood physical barrier anti-adhesion effectSurgeryLight whitePharmaceutical Substances

The invention provides an anti-adhesion biological membrane and a preparation method thereof. The anti-adhesion biological membrane is a dry membrane which is formed by SIS (styrene isoprene styrene block copolymer) as a support material, compound hyaluronic acid, functional proteins and anti-inflammotary medicines. The anti-adhesion biological membrane is semi-transparent from light white to faint yellow. The thickness of the anti-adhesion biological membrane is 0.01-0.5mm. Compared with the prior art, the anti-adhesion biological membrane has very good biocompatibility, good physical barrier anti-adhesion effect and the effects of resisting inflammatory, stopping bleeding and promoting fiber degradation. The effects of the anti-adhesion biological membrane are obviously superior to those of existing anti-adhesion biological membrane products. Animal experiments prove that the effective rate of the anti-adhesion biological membrane prepared by the method for preventing the adhesion after abdominal surgery reaches above 90%, the effective rate for preventing the adhesion after pelvic cavity surgery reaches above 80%, and the effective rate for preventing the adhesion after tendon surgery reaches above 70%.

Owner:XIAN TISSUE ENG & REGENERATIVE MEDICINE RES INST

Facial Patch

ActiveUS20150320606A1Less irritatingLess residual adhesiveHead bandagesMedical patchesMass ratioStyrene-isoprene-styrene block copolymer

Provided is a facial patch including a support, a pressure-sensitive adhesive layer, and a release layer in this order, in which (a) the pressure-sensitive adhesive layer satisfies the following conditions (a-1) to (a-3): (a-1) the pressure-sensitive adhesive layer contains a styrene-isoprene-styrene block copolymer, a tackifier resin, and a softening agent; (a-2) the ratio (mass ratio) of the styrene-isoprene-styrene block copolymer and the tackifier resin is 1:2 to 1:4; and (a-3) the content of the softening agent is 40% to 60% by mass; and (b) the support has elastic moduli with a Young's modulus of 0.01 GPa to 0.5 GPa, and also provided is a method for producing the facial patch, the method including a step of forming a pressure-sensitive adhesive layer on the upper surface of the release layer.

Owner:NICHIBAN CO LTD

Latex, dip-forming composition, and dip-formed article

InactiveUS20150087761A1High strengthCoatingsSolid ballsStyrene-isoprene-styrene block copolymerAlicyclic Hydrocarbons

A latex of synthetic polyisoprene and / or a styrene-isoprene-styrene block copolymer with a weight average molecular weight of 10,000 to 5,000,000, a volume average particle size of 0.5 to 10 μm, and a content of a total of an alicyclic hydrocarbon solvent and aromatic hydrocarbon solvent of 500 weight ppm or less are provided.

Owner:ZEON CORP

Pressure-sensitive adhesive material

InactiveUS6414073B1Improve cohesionImprove powerNatural rubber adhesivesInksStyrene-isoprene-styrene block copolymerAdhesive materials

A pressure-sensitive adhesive material comprises a pressure-sensitive adhesive layer comprising 100 parts by weight of natural rubber and 10 to 120 parts by weight of styrene-isoprene-styrene block copolymer (SIS) having a radiate configuration with a styrene content of 10 to 45% by weight. Preferably, the pressure-sensitive adhesive layer is free of metals or metal compounds. The pressure-sensitive adhesive layer may contain 5 to 150 parts by weight of a tackifier having an acid value of 1.5 or more. The pressure-sensitive adhesive material includes (A) a backing-less tape having a release liner having on one surface thereof the pressure-sensitive adhesive layer and (B) a double-coated tape having a backing having respective pressure-sensitive adhesive layers on surfaces thereof, at least one of which is constituted by the pressure-sensitive adhesive layer of the above-described type.

Owner:NITTO DENKO CORP

Low volatile organic compound adhesive for attaching thermoplastic polyolefin roofing membranes

Adhesive compositions formulated with blends of styrene-isoprene-styrene block copolymers and hydrocarbon resins are provided. Also provided are methods for bonding substrates, including roofing membranes, using the adhesive compositions. The adhesive compositions are characterized by high solids contents, low viscosities and improved bonding characteristics, including high peel strengths when adhered to roofing membranes, such as thermoplastic polyolefin (“TPO”) membranes.

Owner:ILLINOIS TOOL WORKS INC

Formula and its production for shock-absorbing EVA foaming sectional material

InactiveCN1982363AExcellent shock absorptionImprove impact absorption performanceFoaming agentMetallurgy

Formula of shock-absorbing EVA foaming sections and its production are disclosed. The formula consists of vinyl-vinyl acetate multi-polymer 30 proportion, styrene-isoprene-styrene block multi-polymer 25 proportion, vinyl-acrylic acid multi-polymer 10 proportion, hydrated magnesium silicate 20 proportion, zinc oxide 1.5 proportion, bridging agent 1.2 proportion, bridging auxiliaries, foaming agent 3.25 proportion and colorant 3 proportion. The process is carried out by blending, internally mixing, open milling, tying to obtain plate and grain, mold pressing or injection mold pressing, grinding while cutting for foaming plate and secondary foaming. It can be used to produce EVA sole.

Owner:郭廷志

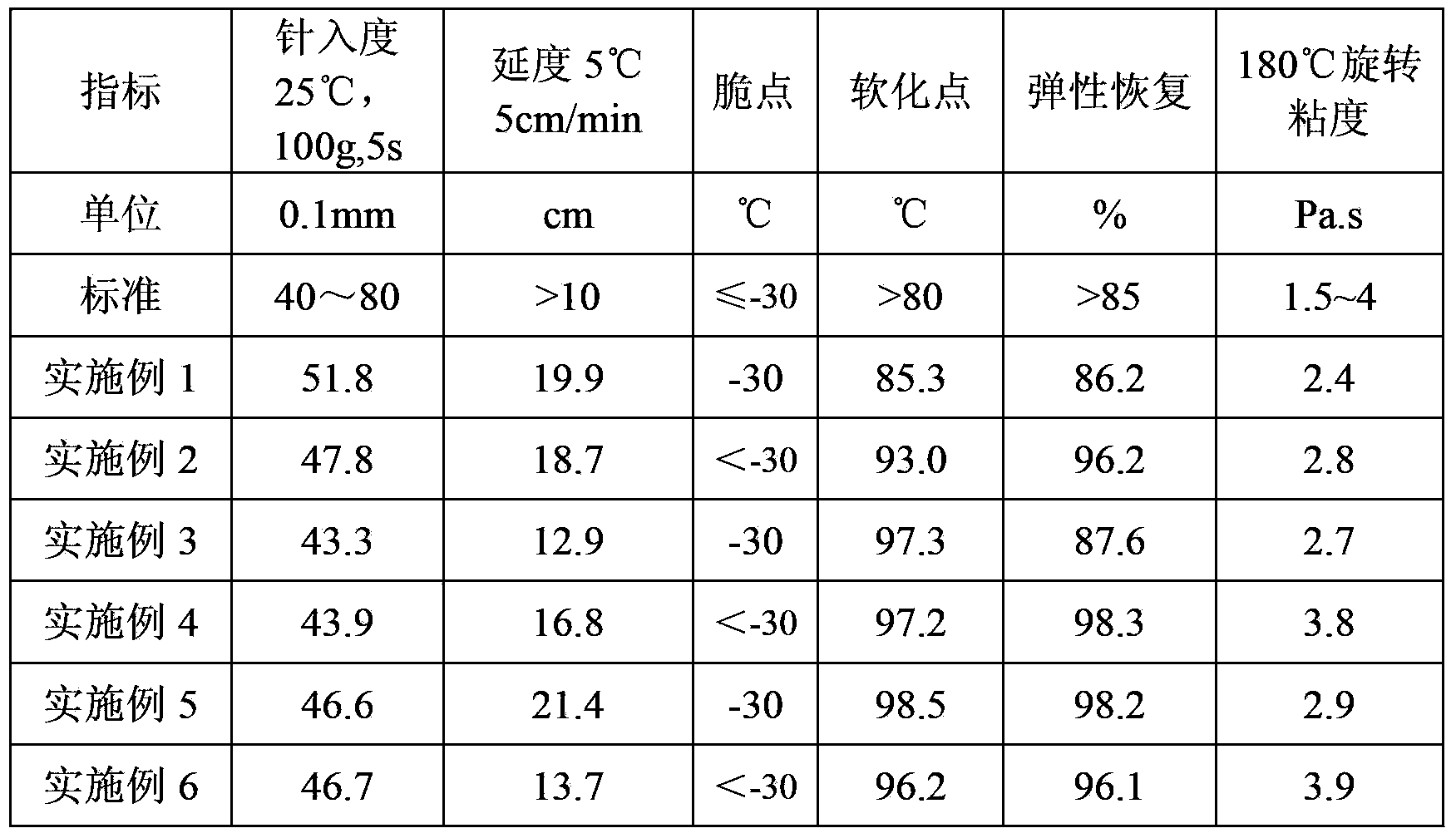

High-performance modified asphalt and preparation method thereof

InactiveCN103408956AImprove high temperature stabilityGood low temperature stabilityBuilding insulationsPolymer scienceButadiene-styrene rubber

The invention relates to high-performance modified asphalt. The high-performance modified asphalt is prepared from the following ingredients: asphalt, thermoplastic rubber, glue powder, an additive and a stabilizer, wherein the asphalt is heavy-traffic-road petroleum asphalt or cycloalkyl petroleum asphalt, the thermoplastic rubber is styrene-isoprene-styrene block copolymer (SIS) or styrene-butadiene-styrene (SBS), the glue powder is rubber powder which is formed through grinding waste and old tires prepared through normal temperature methods, the additive is volcanic ash or silicon powder or fly ash, and the stabilizer is rosin or rosin resin. The high-performance modified asphalt has better high-temperature stability, the softening point capable of reaching above 80 DEG C, better low-temperature stability, the brittle point being below -30 DEG C, relatively high elasticity, the elasticity recovery reaching over 90% and better adhesivity reaching over the level IV. The waste of energy and resources is reduced through using industrial and domestic wastes as much as possible, so that the preparation method has the advantages of energy saving, emission reduction, simple production process and low cost.

Owner:周乃承

High performance ballistic composites having improved flexibility and method of making the same

ActiveUS7919418B2Increase flexibilityComfortable to wearArmourSynthetic resin layered productsFiberStyrene-isoprene-styrene block copolymer

A composite material which has excellent ballistic performance and has improved flexibility. Surprisingly, it has been found that a combination of poly(alpha-olefin) fiber and matrix resin provides these desirable product features. The resin matrix is a block copolymer of a conjugated diene and a vinyl aromatic monomer, preferably a styrene-isoprene-styrene block copolymer, that is applied as an aqueous composition. The fiber has a tenacity of at least about 35 g / d and a tensile modulus of at least about 1200 g / d. The composite has a total density equal to or less than about 100 g / m2 and a stiffness of less than about 2.5 pounds (1.14 kg) for a two layer structure of the composite, and a total areal density equal to or less than about 190 g / m2 and a stiffness of less than about 3.0 pounds (1.36 kg) for a four layer structure of the composite. The Peel Strength for a two layer structure of less than about 1.0 pounds (0.45 kg) for a two layer structure of the composite, and less than about 0.7 pounds (0.32 kg) for a four layer structure of the composite. The process of this invention permits fabrication of these desirable products in a cost-effective manner. Body armor made from the composite has improved flexibility and excellent ballistic characteristics.

Owner:HONEYWELL INT INC

Thermoplastic elastomer composition

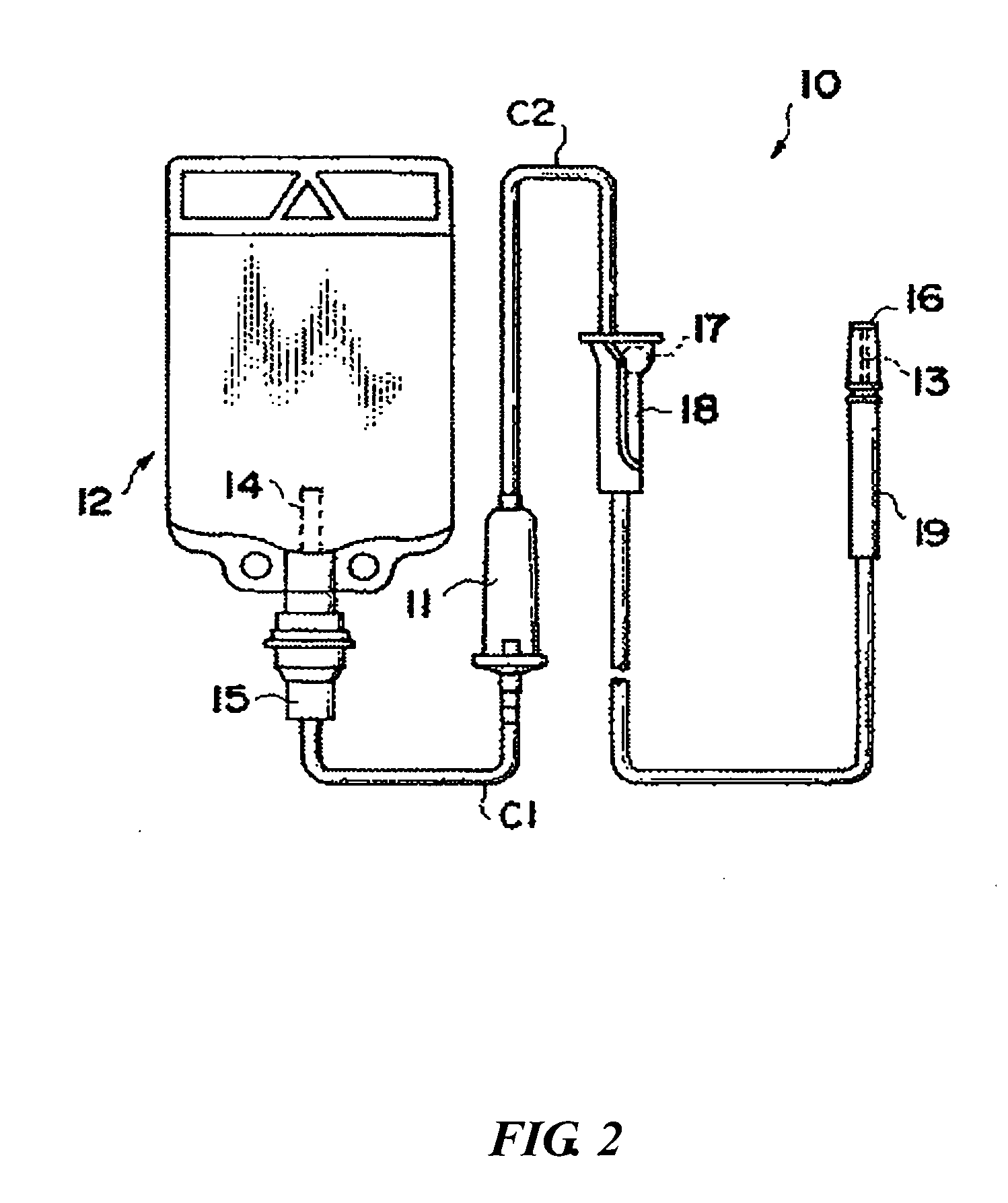

InactiveUS20070015871A1Improve adhesionHigh bonding strengthCatheterOrganic solventStyrene-isoprene-styrene block copolymer

A thermoplastic elastomer composition comprising: (A) 85-98 wt % of syndiotactic 1,2-polybutadiene having a 1,2-bond content of 70% or more and a degree of crystallinity of 5-50% and (B) 2-15 wt % of a styrene-butadiene-styrene block copolymer and / or styrene-isoprene-styrene block copolymer is disclosed. Since the thermoplastic elastomer composition and a molded article made from the composition can be firmly bonded with a polar resin using an organic solvent, the composition is useful as a material of components used for medical treatment such as an infusion set for medical treatment.

Owner:JSR CORPORATIOON

Adhesive preparations

InactiveUS20070083139A1Less stimulationExcellent in long time store stabilityAntipyreticAnalgesicsMedicinePlasticizer

This invention provides a patch with less skin stimulation, excellent in long time store stability and heat stability and having favorable tack during use. The patch comprising a styrene-isoprene-styrene block copolymer, polyisobutylene, tackifier, plasticizer and pharmaceutically effective ingredient, in which two or more kinds of polyisobutylene of different average molecular weight are used in combination and the viscosity of the adhesive of the patch is between 1500 and 30,000 poise (at 60° C.) and the tack of the patch is from 5 to 200 g / 10 mm.

Owner:HISAMITSU PHARM CO INC

Medical hydrocolloid pressure-sensitive adhesive and preparation method thereof

InactiveCN104371614AGood initial adhesionFast water absorptionNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantIsoprene

The invention provides a medical hydrocolloid pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from styrene-isoprene-styrene block copolymer, ester gum, acetate starch, copal, sodium alginate, sodium carboxymethyl cellulose, phthalate, polyisobutylene, an antioxidant, an auxiliary antioxidant, ammonium persulfate, diethylene glycol vinyl ether, polytrimethyldihydroquinoline and naphthenic oil. The preparation method comprises the following steps: adding the styrene-isoprene-styrene block copolymer, acetate starch, copal, antioxidant and auxiliary antioxidant into a rheometer, and compounding; adding the ester gum, phthalate, polyisobutylene, ammonium persulfate, diethylene glycol vinyl ether and naphthenic oil into the rubber mixture, and compounding; and finally, adding the rest of components into the hot-melt pressure-sensitive adhesive, and compounding to obtain the hydrocolloid pressure-sensitive adhesive. The pressure-sensitive adhesive can be easily peeled from the skin surface, and has the advantages of high water absorptivity and high controllability on water-absorbing capacity when in use.

Owner:北京精诚通医药科技有限公司

Adhesive preparations

This invention provides a patch with less skin stimulation, excellent in long time store stability and heat stability and having favorable tack during use. The patch comprising a styrene-isoprene-styrene block copolymer, polyisobutylene, tackifier, plasticizer and pharmaceutically effective ingredient, in which two or more kinds of polyisobutylene of different average molecular weight are used in combination and the viscosity of the adhesive of the patch is between 1500 and 30,000 poise (at 60° C.) and the tack of the patch is from 5 to 200 g / 10 mm.

Owner:HISAMITSU PHARM CO INC

Transdermal Absorption Preparation

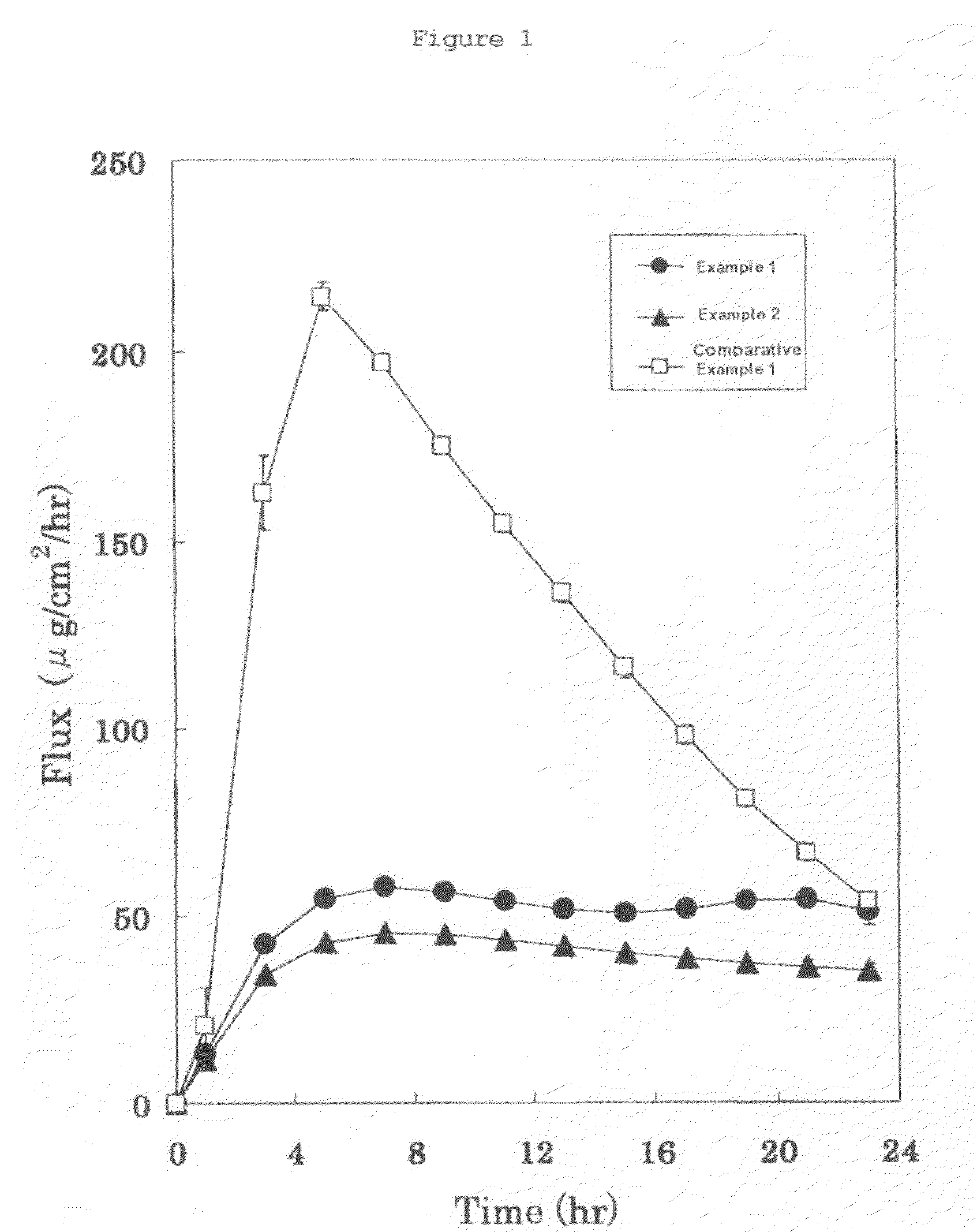

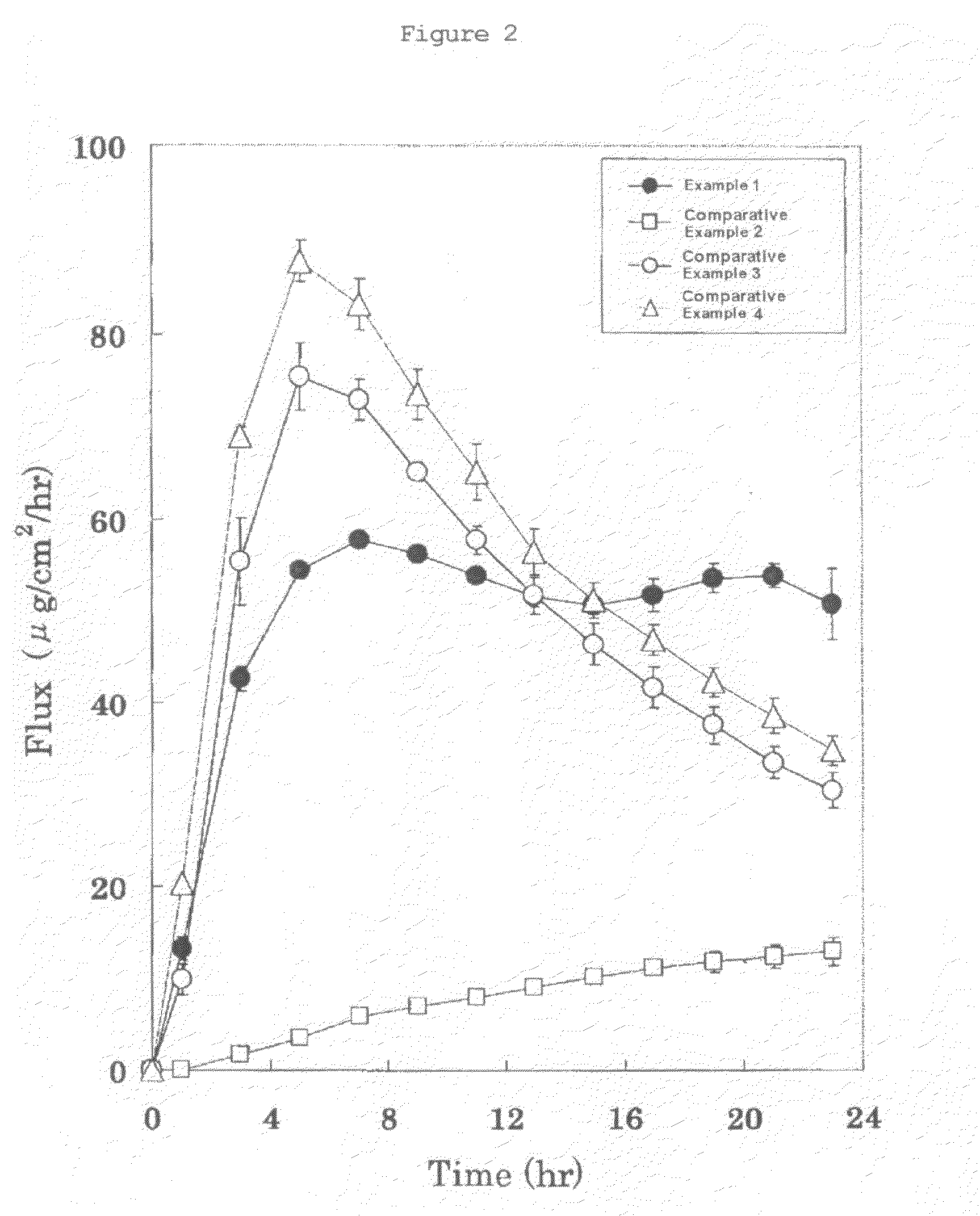

ActiveUS20090068252A1Easy to produceStable skin permeation ratePowder deliveryOrganic active ingredientsStyrene-isoprene-styrene block copolymerMultiple layer

A transdermal absorption preparation having a support and a pressure-sensitive adhesive layer consisting of multiple layers, wherein the pressure-sensitive adhesive layer comprises a drug-retaining layer containing a drug and an acrylic pressure-sensitive adhesive and a skin adhesion layer containing a styrene-isoprene-styrene block copolymer. This preparation can continuously release bisoprolol at a constant concentration. Moreover, it can be easily produced.

Owner:HISAMITSU PHARM CO INC

High impact polystyrene sheath material for power cords and preparation method thereof

InactiveCN103992608AImprove insulation performanceHigh mechanical strengthPlastic/resin/waxes insulatorsDi-tert-butyl peroxidePolybutylene

The invention discloses a high impact polystyrene sheath material for power cords and a preparation method thereof. The sheath material is prepared from the following raw materials in part by weight: 45-65 parts of high impact polystyrene, 20-30 parts of polypropylene, 10-15 parts of ethylene propylene diene monomer, 5-10 parts of styrene-isoprene-styrene block copolymer, 4-8 parts of paraffin oil, 3-6 parts of ethylene bis oleamide, 1-2 parts of isopropyl tri(dioctyl pyrophosphate acyloxy) titanate, 10-15 parts of talc powder, 3-5 parts of nano beryllia, 1-2 parts of zinc stearate, 4-6 parts of calcium hydroxide, 2-5 parts of low molecular polybutylene, 15-25 parts of carbon black N550, 2-3 parts of di-tert-butyl peroxide, 1.5-2.5 parts of trihydroxypropane trimethylacrylate, 10-15 parts of acetyl triethyl citrate, 5-10 parts of diphenyl-isooctyl phosphite and 15-20 parts of aid. The sheath material is good in electric insulating property, high in mechanical strength, good in toughness and high in impact resistance, has the characteristics of excellent heat, corrosion, oil and water resistance and the like and is durable, so that the sheath material has a wide application prospect.

Owner:TIANCHANG FUXIN ELECTRONICS

Elastic methacrylate compositions

InactiveUS20070155899A1Ester polymer adhesivesOrganic non-macromolecular adhesiveSulfonyl chlorideMethacrylate

A two-part adhesive composition exhibiting improved elasticity wherein its composition includes one or more acrylate or methacrylate ester monomers, a sulfur bearing compound, preferably a sulfonyl chloride, an amine promoter, preferably, an amine aldehyde reaction product, and a thermoplastic block copolymer component selected from the group consisting of a. a linear styrene-butadiene-styrene copolymer b. a radial styrene-butadiene-styrene block copolymer with a plasticizer, c. a linear or radial styrene-isoprene-styrene block copolymer, and d. a linear or radial styrene-butadiene-isoprene-styrene block copolymer, and mixtures thereof.

Owner:IPS

External plaster containing flurbiprofen

ActiveCN101119716APrevent crystallizationHigh dose releaseOrganic active ingredientsAntipyreticAdditive ingredientStyrene-isoprene-styrene block copolymer

The present invention provides a transdermal external patch, which is an external patch in which an adhesive layer is laminated on a support, wherein the adhesive layer contains styrene-isoprene-benzene as an essential component. An ethylene block copolymer (SIS), a tackifying resin, and a softener, and flurbiprofen as an active ingredient are mixed therein. The external patch containing flurbiprofen makes possible the long-term stable release of the flurbiprofen contained, and the preparation has high stability and very high drug release.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

High-temperature-resistant adhesive tape and high-temperature-resistant adhesive used by high-temperature-resistant adhesive tape

ActiveCN104789185AImprove cohesionImprove insulation performanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolytetramethylene terephthalateAdhesive

The invention relates to a high-temperature-resistant adhesive tape and a high-temperature-resistant adhesive used by the high-temperature-resistant adhesive tape. The high-temperature-resistant adhesive tape comprises a polyimide film layer, a methyl vinyl phenyl polysiloxane rubber layer and a high-temperature-resistant adhesive layer which are sequentially stacked. A raw material formula of the high-temperature-resistant adhesive comprises the following components: 20-50 parts of organosilicon rubber resin, 15-40 parts of methyl vinyl silicone rubber, 2-8 parts of organic peroxides, 5-20 parts of a hydrogenated styrene-isoprene-styrene segmented copolymer and 2-20 parts of polybutylene terephthalate. The high-temperature-resistant adhesive tape prepared by the invention still has good peel strength and retentivity even if being exposed to a high-temperature condition.

Owner:苏州市新广益电子股份有限公司

Hot melt adhesives and disposable products using the same

InactiveUS20180100091A1Improve adhesion strengthTemperature in roomNon-macromolecular adhesive additivesAbsorbent padsPolymer sciencePlasticizer

The present invention provides hot melt adhesives. A hot melt adhesive according to the present invention contains a styrenic block copolymer (A) containing a styrene-butadiene-styrene block copolymer (A1); and at least one styrenic block copolymer (A4) selected from the group consisting of a styrene-butadiene-styrene block copolymer (A2) and a styrene-isoprene-styrene block copolymer (A3), wherein the styrenic block copolymer (A) contains a predetermined amount of the styrene-butadiene-styrene block copolymer (A1) relative to the total amount of the styrene-butadiene-styrene block copolymer (A1) and the styrenic block copolymer (A4); a tackifier (B); and a plasticizer (C), wherein the hot melt adhesive has a melt viscosity of 6000 mPa s or lower.

Owner:SEKISUI FULLER

Elastic methacrylate compositions

A two-part adhesive composition exhibiting improved elasticity wherein its composition includes one or more acrylate or methacrylate ester monomers, a sulfur bearing compound, preferably a sulfonyl chloride, an amine promoter, preferably, an amine aldehyde reaction product, and a thermoplastic block copolymer component selected from the group consisting ofa. a linear styrene-butadiene-styrene copolymerb. a radial styrene-butadiene-styrene block copolymer with a plasticizer,c. a linear or radial styrene-isoprene-styrene block copolymer, andd. a linear or radial styrene-butadiene-isoprene-styrene block copolymer,and mixtures thereof.

Owner:IPS

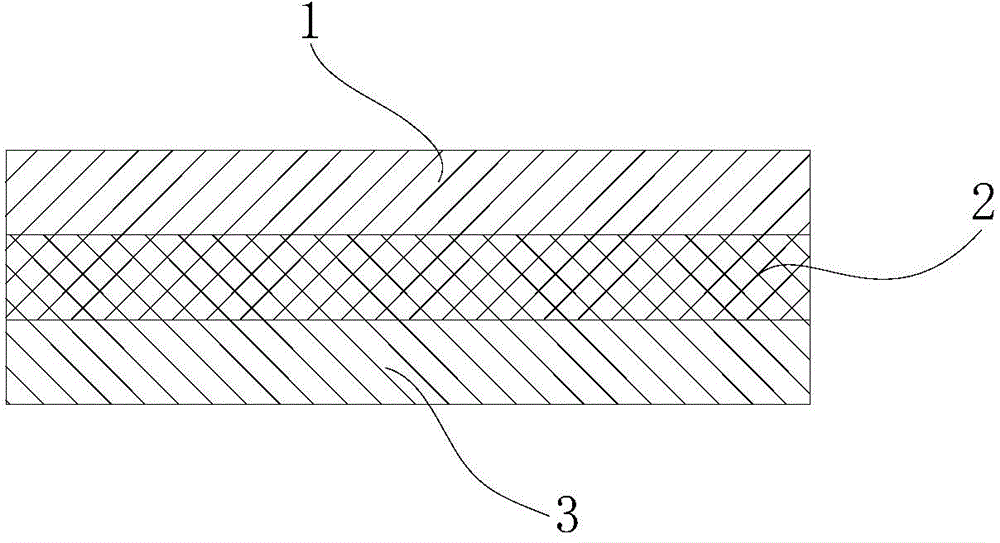

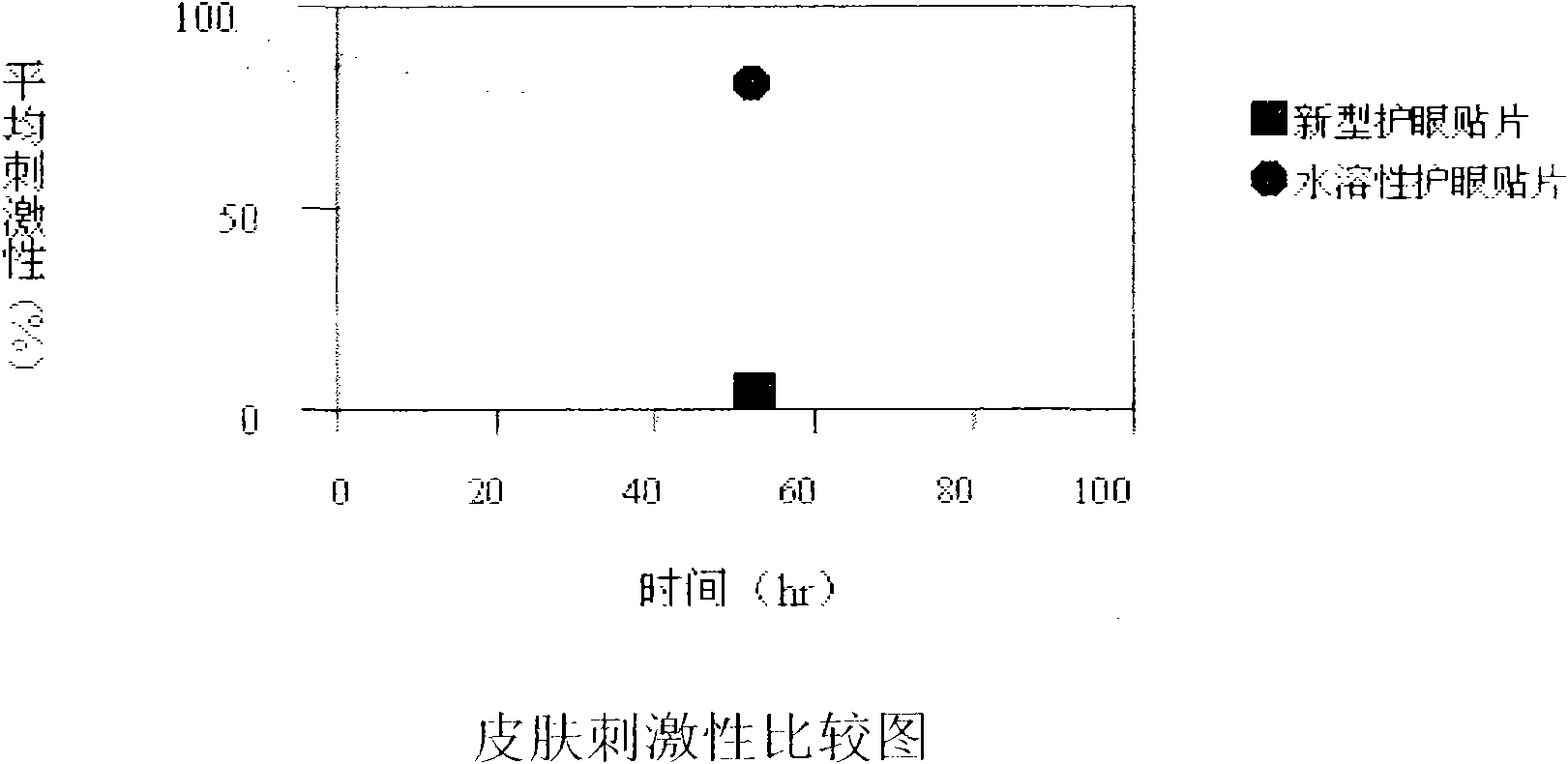

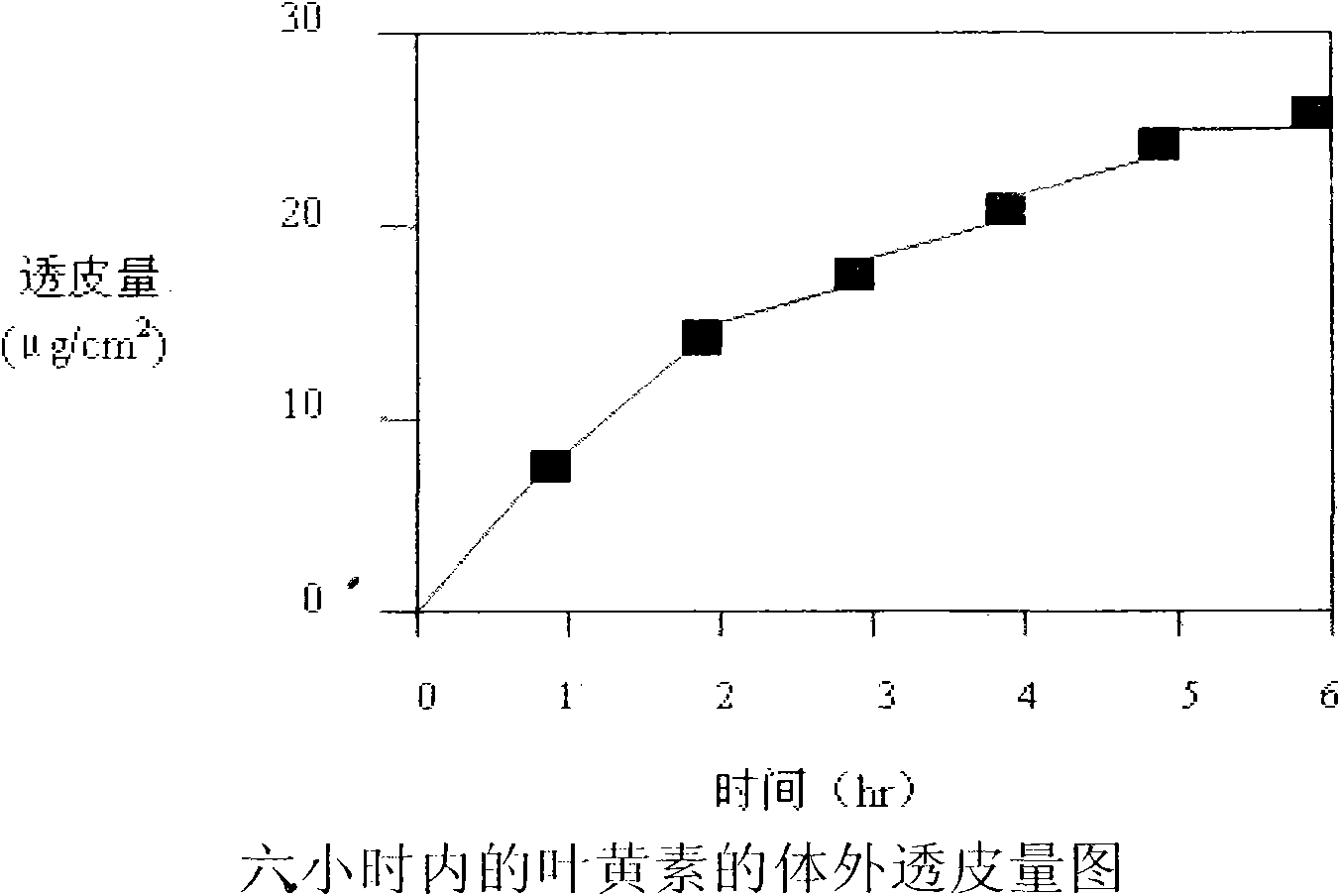

Eye protection patches and preparation process thereof

InactiveCN102133209ANo allergiesHigh affinitySenses disorderHydroxy compound active ingredientsElastomerLutein

The invention discloses external patches which adapt to eye nutrition and health care of people in different ages and contain abundant nutrient components required by eyes such as lutein and the like. A novel elastomer material, namely styrene-isoprene-styrene block copolymer (SIS) is taken as a framework material. Various external eye patches for the people in the different ages are prepared by a low temperature on-line melting molding technology. Patented products are external eye nutrient patches which have specific components, exact functions and soft texture, easily penetrate skin, are highly elastic, and can be persistently released.

Owner:候玉庆 +1

Reworkable thermal deadhesion adhesive tape for manufacture procedure and preparation method of adhesive tape

InactiveCN109913141AImprove peel forceEasy to peelNon-macromolecular adhesive additivesFilm/foil adhesivesDiaminodiphenyl ether(Hydroxyethyl)methacrylate

The invention discloses a reworkable thermal deadhesion adhesive tape for manufacture procedure. The adhesive tape comprises a substrate layer and a thermal deadhesion adhesive layer coating the surface of the substrate layer, wherein the thermal deadhesion adhesive layer comprises components as follows: butyl acrylate, 2-ethylhexyl acrylate, methyl methacrylate, hydroxyethyl methylacrylate, a styrene-isoprene-styrene block copolymer, thermoplastic phenolic resin, methylbenzotriazole, N,N-diethylaniline, azodiisobutyronitrile, 4,4'-diaminodiphenyl ether, polyethylene wax, gamma-methacryloxy propyl trimethoxyl silane, an antioxidant and a solvent. The reworkable thermal deadhesion adhesive tape for the manufacture procedure has notably reduced adhesion after being heated, can be easily stripped from an attached object and is convenient to rework, the adhesion of the adhesive layer can recover after the adhesive tape recovers the normal temperature, therefore, the adhesive tape can be recyclable, and the economic cost is saved.

Owner:苏州义铠轩电子科技有限公司

Low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention and preparation method of low-temperature 3PE dry film hot melt adhesive

InactiveCN110028915AMeet construction needsSolve the needs of joint anticorrosion constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention. The low-temperature 3PE dry film hot melt adhesive is prepared by kneading a rubber elastomer, bonding resin, tackifying resin, a plasticizer, an antioxidant and a filler and conducting extruding, wherein the rubber elastomer is two or more of a styrene-isoprene-styrene block copolymer, a styrene-ethylene-butene-styrene block copolymer, butyl rubber and ethylene propylene diene monomer; the bonding resin is one or two of an ethylene-vinyl acetate maleic anhydride grafted modified material and an ethylene-acrylate-maleic anhydride terpolymer; the tackifying resin is one or more of terpene resin, C5 petroleum resin and rosin glyceride; and the plasticizer is polyisobutene or naphthenic oil. The low-temperature dry film hot melt adhesive disclosed by the invention is used for pipeline joint coating and corrosion prevention, meets the construction requirements in an extremely cold environment, and meets the pipeline joint coating and corrosion prevention construction requirements in cold regions; and the adhesive has the advantages of excellent adhesion and sealing property, good low-temperature flexibility, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

A mono-component moisture-curing polyolefin hot-melt adhesive and a preparing method thereof

ActiveCN106520017AEasy constructionGood first stickMineral oil hydrocarbon copolymer adhesivesPolyolefinAntioxidant

Owner:重庆中科力泰高分子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com