High-temperature-resistant adhesive tape and high-temperature-resistant adhesive used by high-temperature-resistant adhesive tape

A technology of high temperature resistance and adhesives, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc. It can solve the problems of general heat resistance, reduced tape peel strength, and poor heat and oxygen aging resistance. To achieve good shock resistance, improve the ability to change the micro-conformation freely, and improve the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

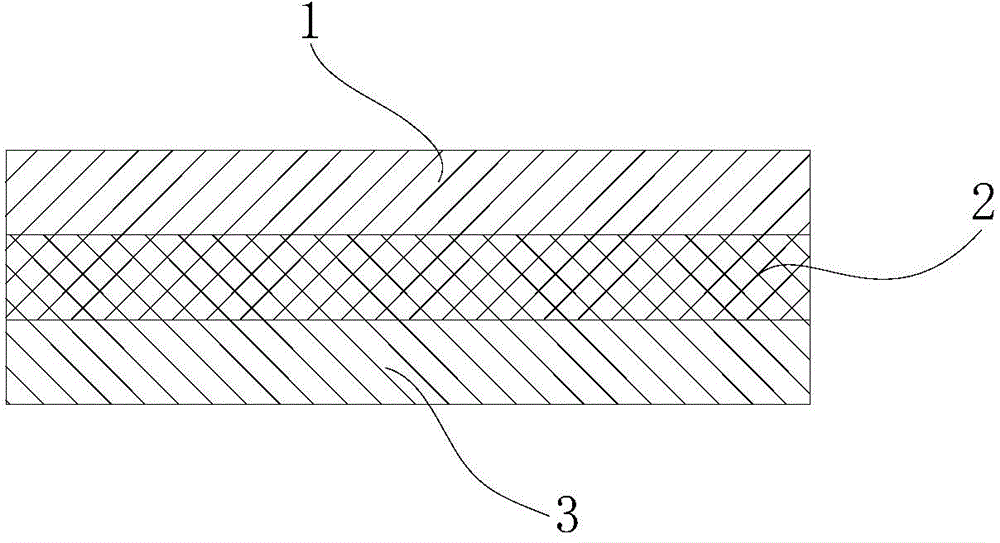

Image

Examples

Embodiment 1

[0041] Embodiment 1: a high temperature resistant adhesive tape and the high temperature resistant adhesive used therefor;

[0042] A high-temperature-resistant adhesive, the raw material formula of the high-temperature-resistant adhesive includes the following materials by weight:

[0043] 35 parts of silicone resin;

[0044] 25 parts of methyl vinyl silicone rubber;

[0045] 5 parts of benzoyl peroxide;

[0046] 15 parts of hydrogenated styrene-isoprene-styrene block copolymer;

[0047] 20 parts of polybutylene terephthalate;

[0048] Add silicone resin, methyl vinyl silicone rubber, hydrogenated styrene-isoprene-styrene block copolymer, and polybutylene terephthalate into a beaker filled with toluene according to the proportion, and heat to Dissolve at 70°C, add benzoyl peroxide dropwise, and continue to heat up to 90°C-120°C for polycondensation reaction for 1 hour to obtain the desired product, which is a light yellow transparent liquid.

[0049] The raw material formu...

Embodiment 2

[0052] Embodiment 2: a high temperature resistant adhesive tape and the high temperature resistant adhesive used therefor;

[0053] A high-temperature-resistant adhesive, the raw material formula of the high-temperature-resistant adhesive includes the following materials by weight:

[0054] 45 parts of silicone resin;

[0055] 25 parts of methyl vinyl silicone rubber;

[0056] 4 parts of benzoyl peroxide;

[0057] 16 parts of hydrogenated styrene-isoprene-styrene block copolymer;

[0058] 10 parts of polybutylene terephthalate;

[0059] Add silicone resin, methyl vinyl silicone rubber, hydrogenated styrene-isoprene-styrene block copolymer, and polybutylene terephthalate into a beaker filled with toluene according to the proportion, and heat to Dissolve at 70°C, add benzoyl peroxide dropwise, and continue to heat up to 90°C-120°C for polycondensation reaction for 1 hour to obtain the desired product, which is a light yellow transparent liquid.

[0060] The raw material for...

Embodiment 3

[0063] Embodiment 3: A high temperature resistant adhesive tape and the high temperature resistant adhesive used therefor;

[0064] A high-temperature-resistant adhesive, the raw material formula of the high-temperature-resistant adhesive includes the following materials by weight:

[0065] 25 parts of silicone resin;

[0066] 40 parts of methyl vinyl silicone rubber;

[0067] 3 parts of benzoyl peroxide;

[0068] 17 parts of hydrogenated styrene-isoprene-styrene block copolymer;

[0069] 15 parts of polybutylene terephthalate;

[0070] Add silicone resin, methyl vinyl silicone rubber, hydrogenated styrene-isoprene-styrene block copolymer, and polybutylene terephthalate into a beaker filled with toluene according to the proportion, and heat to Dissolve at 70°C, add benzoyl peroxide dropwise, and continue to heat up to 90°C-120°C for polycondensation reaction for 1 hour to obtain the desired product, which is a light yellow transparent liquid.

[0071] The raw material for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com