High impact polystyrene sheath material for power cords and preparation method thereof

A polystyrene, high-impact technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of cracking, affecting the normal operation of the power cord, poor impact resistance, etc., to achieve good toughness, high impact resistance, Excellent heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

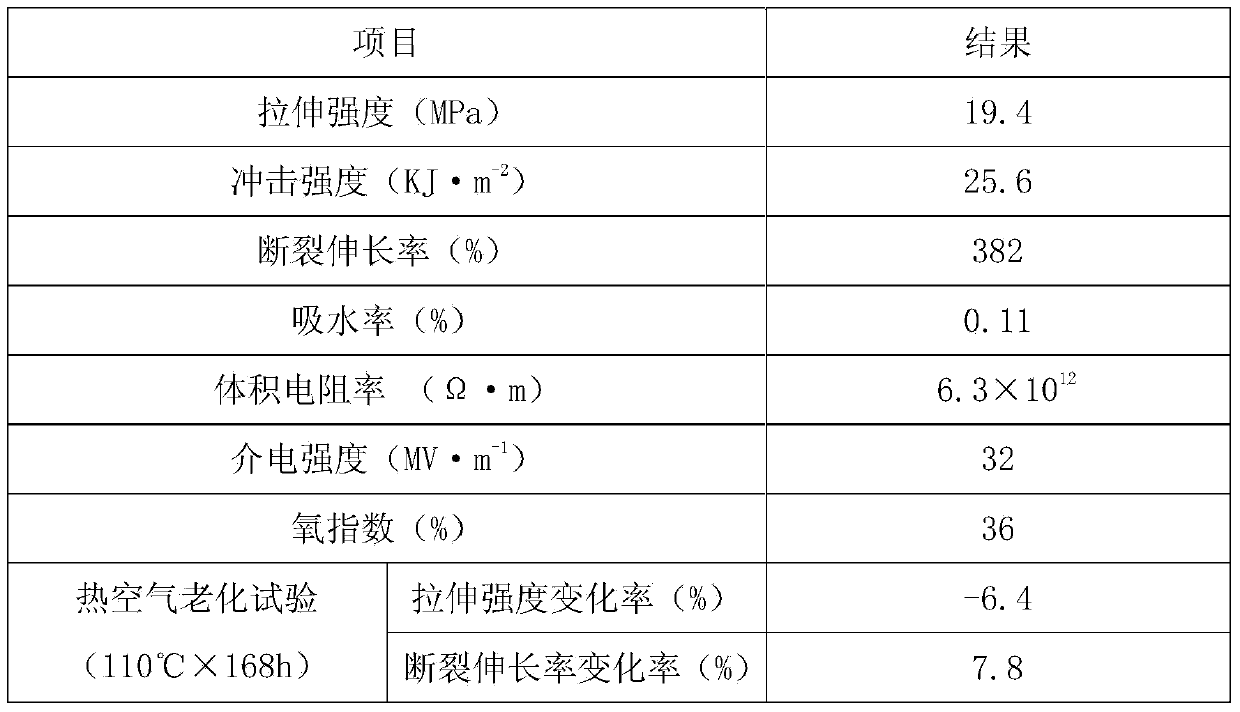

Examples

Embodiment Construction

[0010] A high-impact polystyrene sheath material for power cords, made of the following raw materials in parts by weight: high-impact polystyrene 55, polypropylene 20, EPDM rubber 15, styrene-isoprene - Styrene block copolymer 10, paraffin oil 6, ethylene bisoleic acid amide 4, isopropyl tris (dioctyl pyrophosphate acyloxy) titanate 1.5, talcum powder 12, nano beryllium oxide 4, hard Zinc fatty acid 1.5, calcium hydroxide 5, low molecular weight polybutene 4, carbon black N55020, di-tert-butyl peroxide 2, trihydroxypropane trimethacrylate 2, acetyl triethyl citrate 12, diphosphite Benzene-isooctyl 8, auxiliary agent 16;

[0011] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight portion: wollastonite 28, illite 16, blast furnace slag 14, fly ash 7, polyethylene wax 5, cadmium oxide 2.5, epoxy stearic acid Butyl ester 4, 2-mercaptobenzimidazole 1.5, benzoic acid 2, borax 3.5, pentaerythritol 2, melamine phosphate 5, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com