Patents

Literature

191results about "Medical patches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

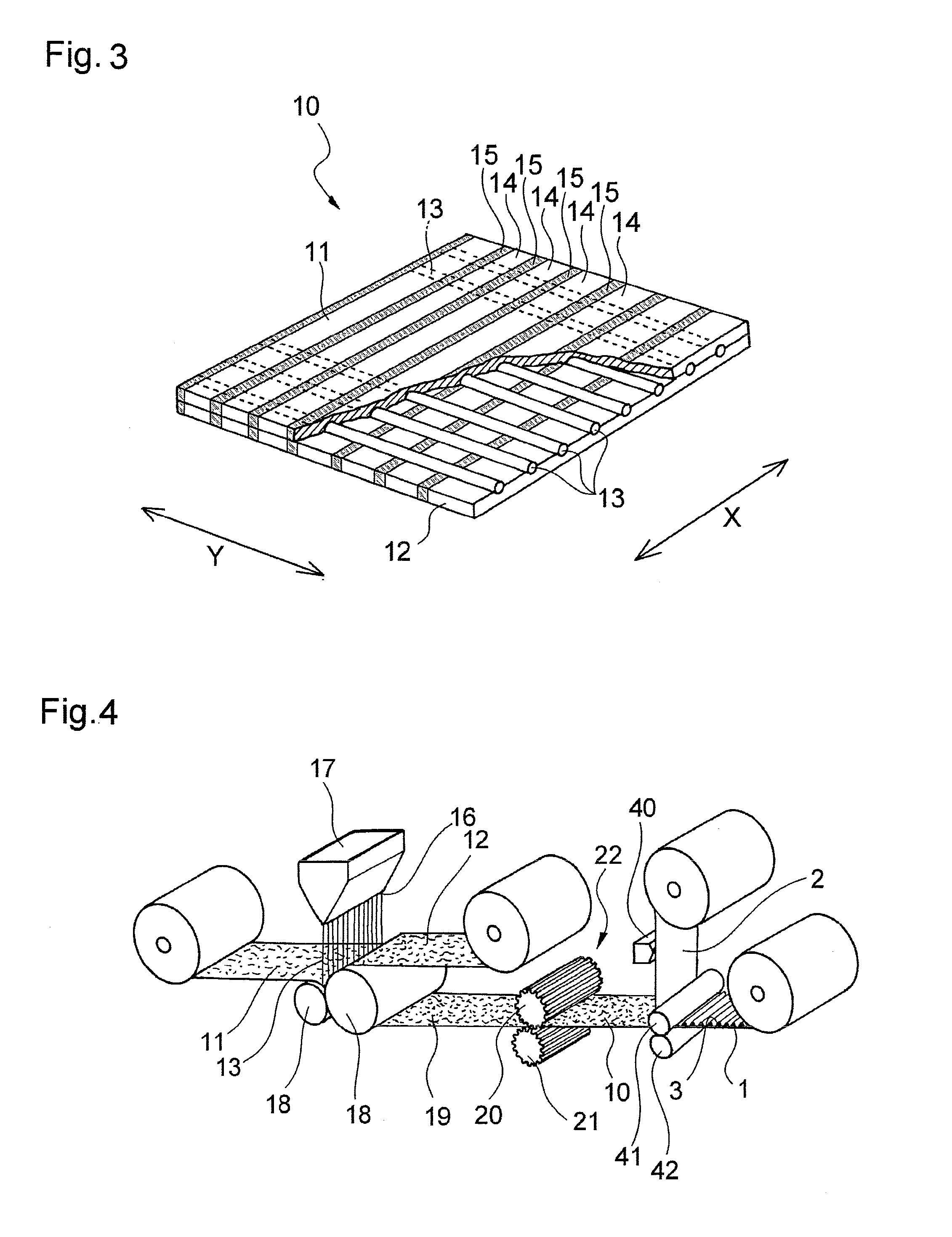

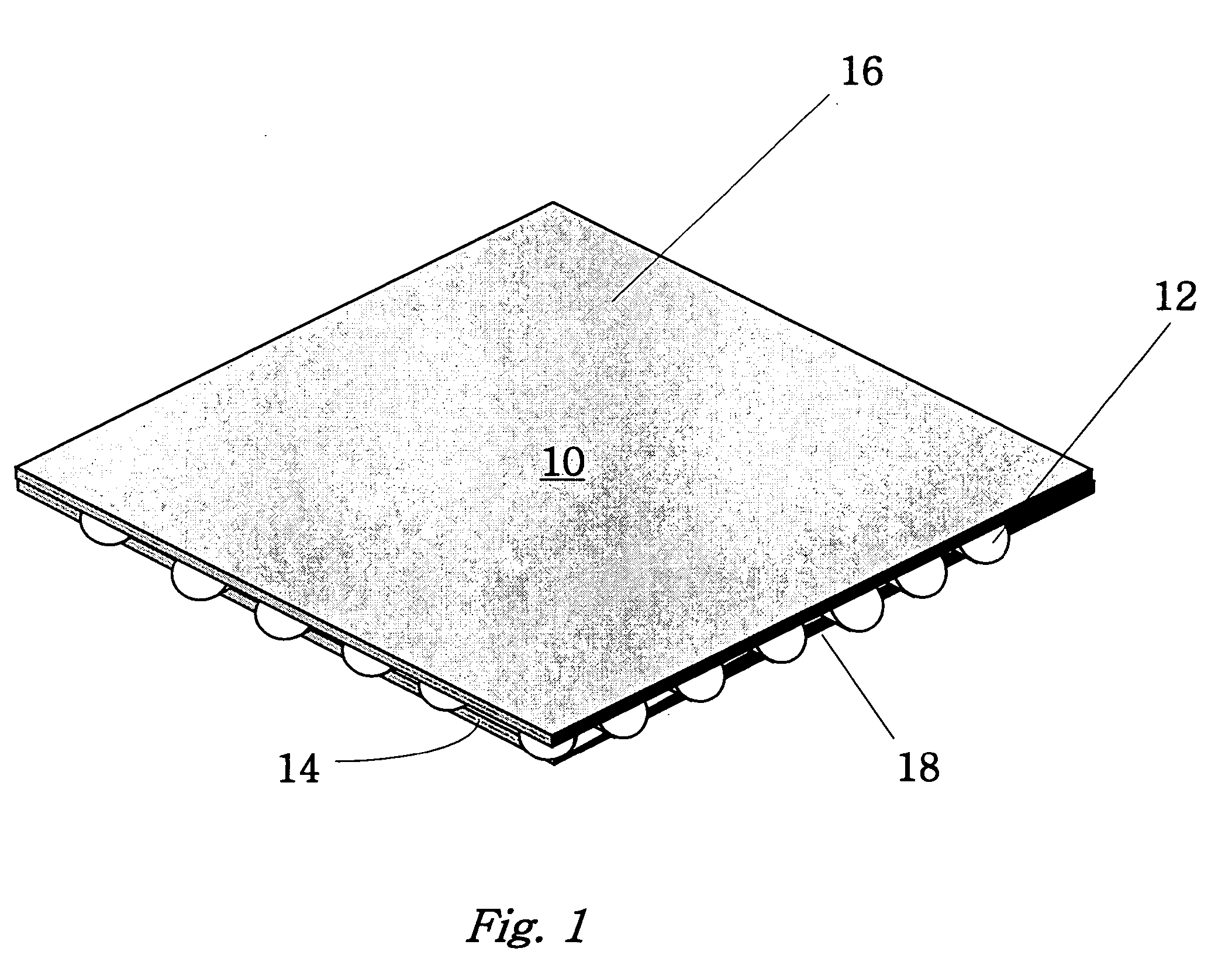

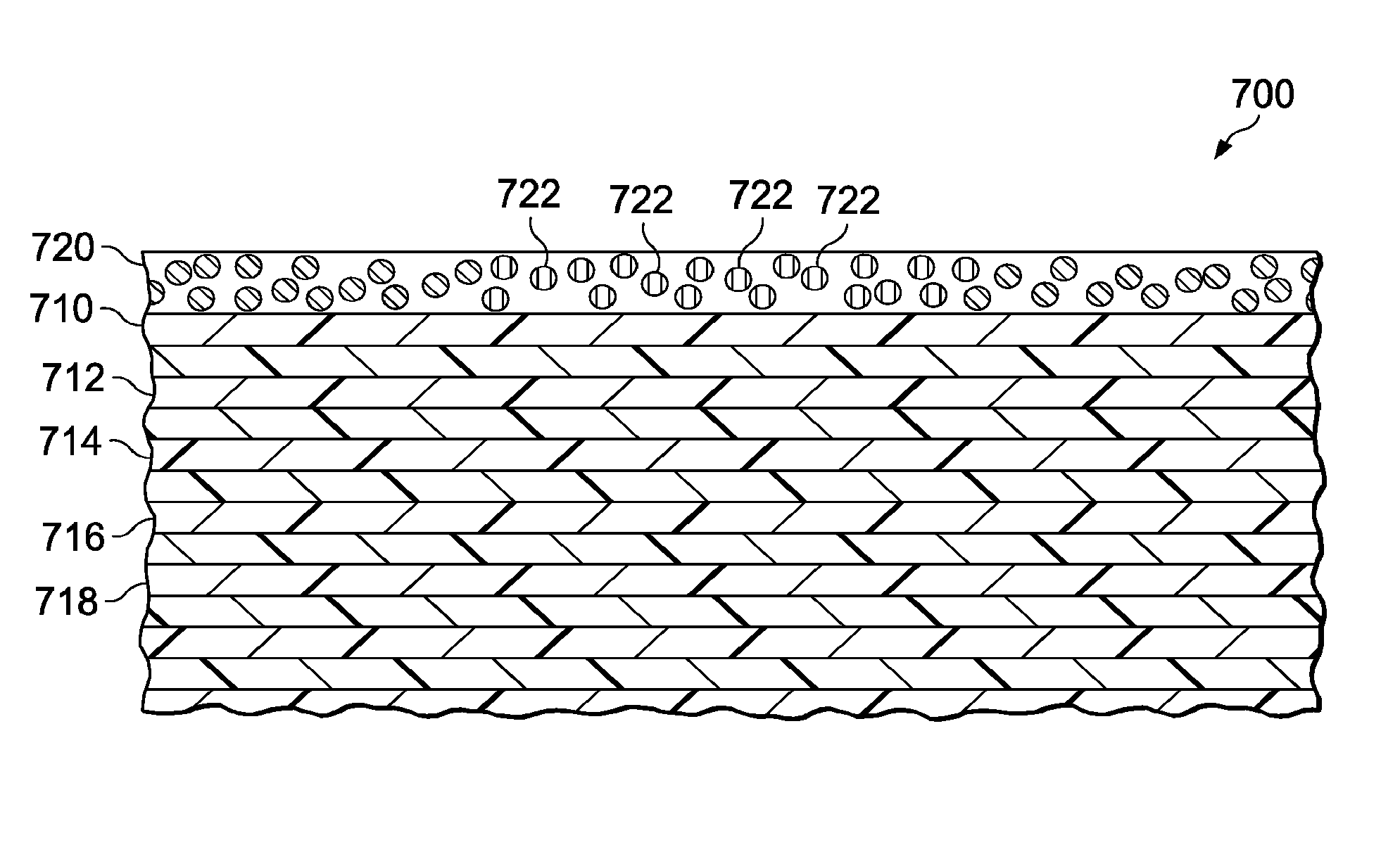

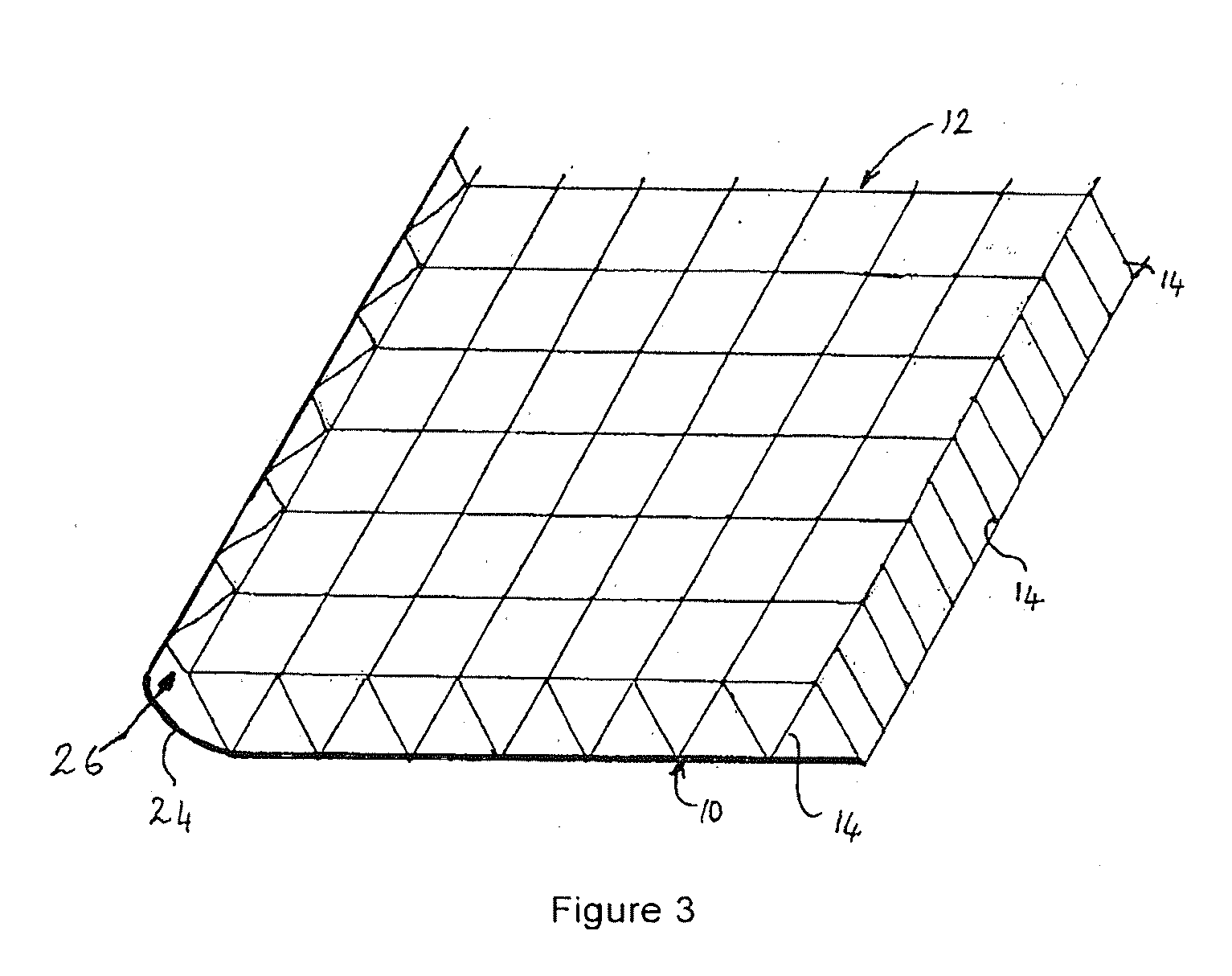

Porous medical device and method for its manufacture

ActiveUS7964206B2Thickness of device can be variedControllable porosityBiocideGenetic material ingredientsFiberBioceramic

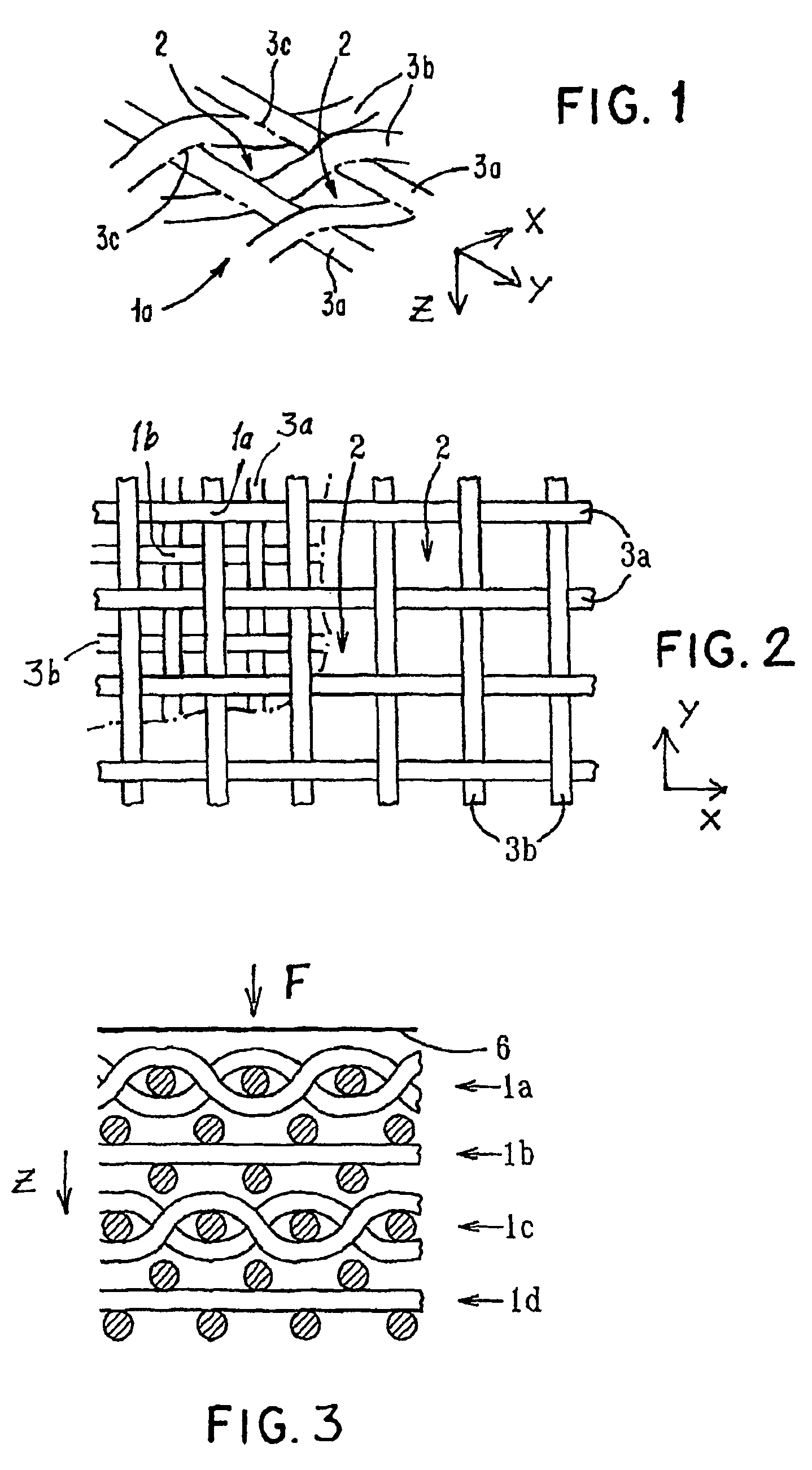

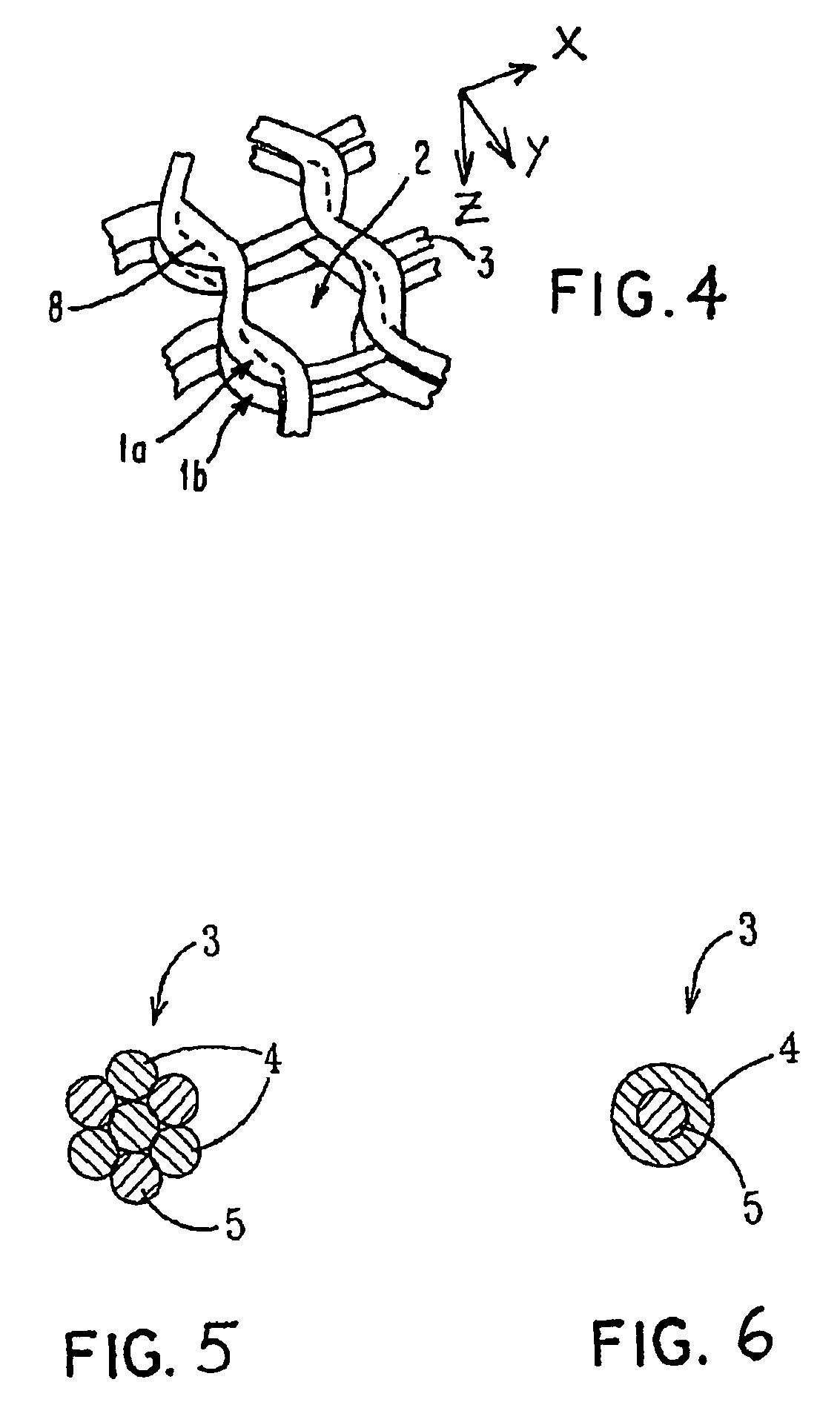

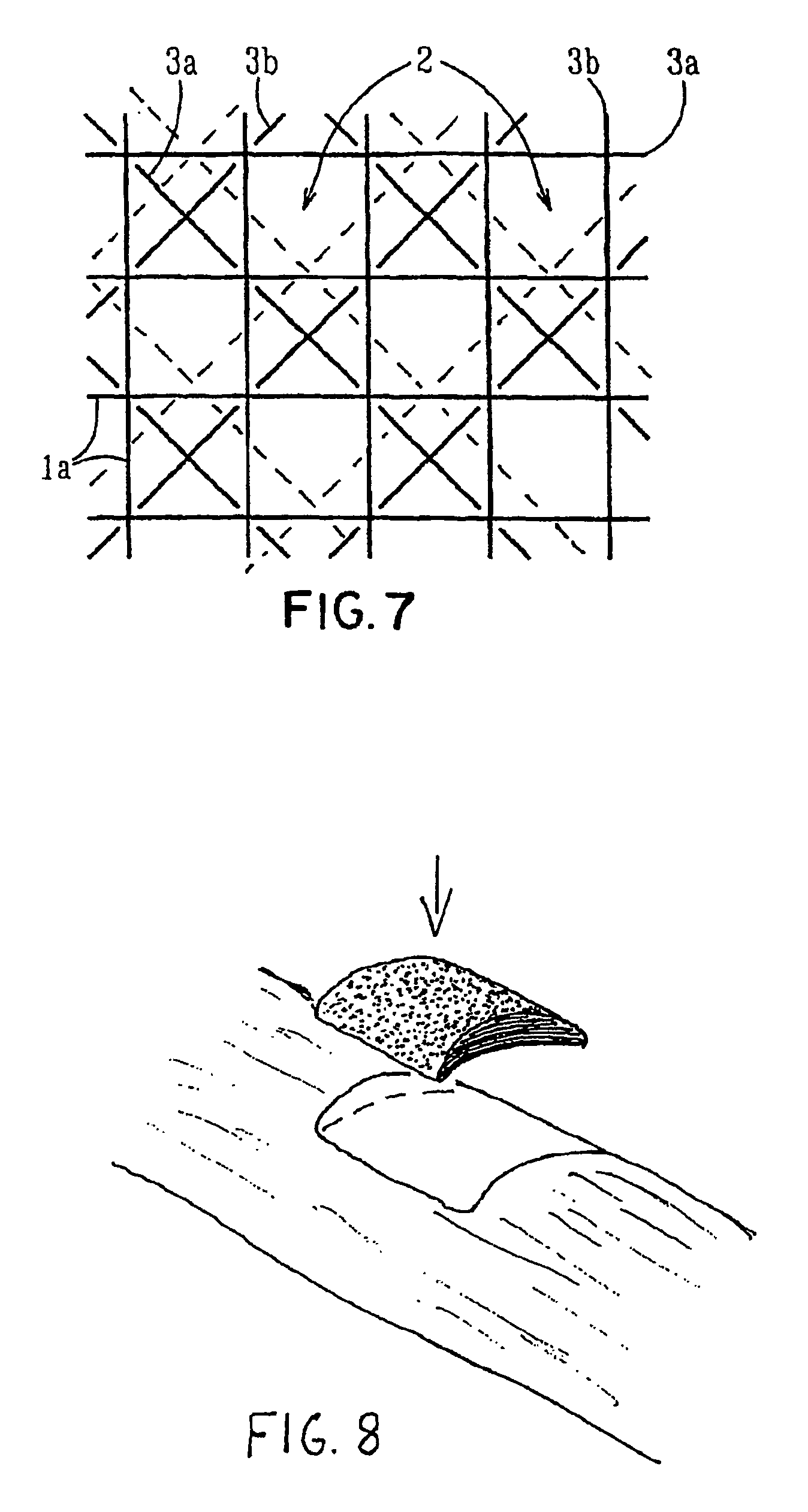

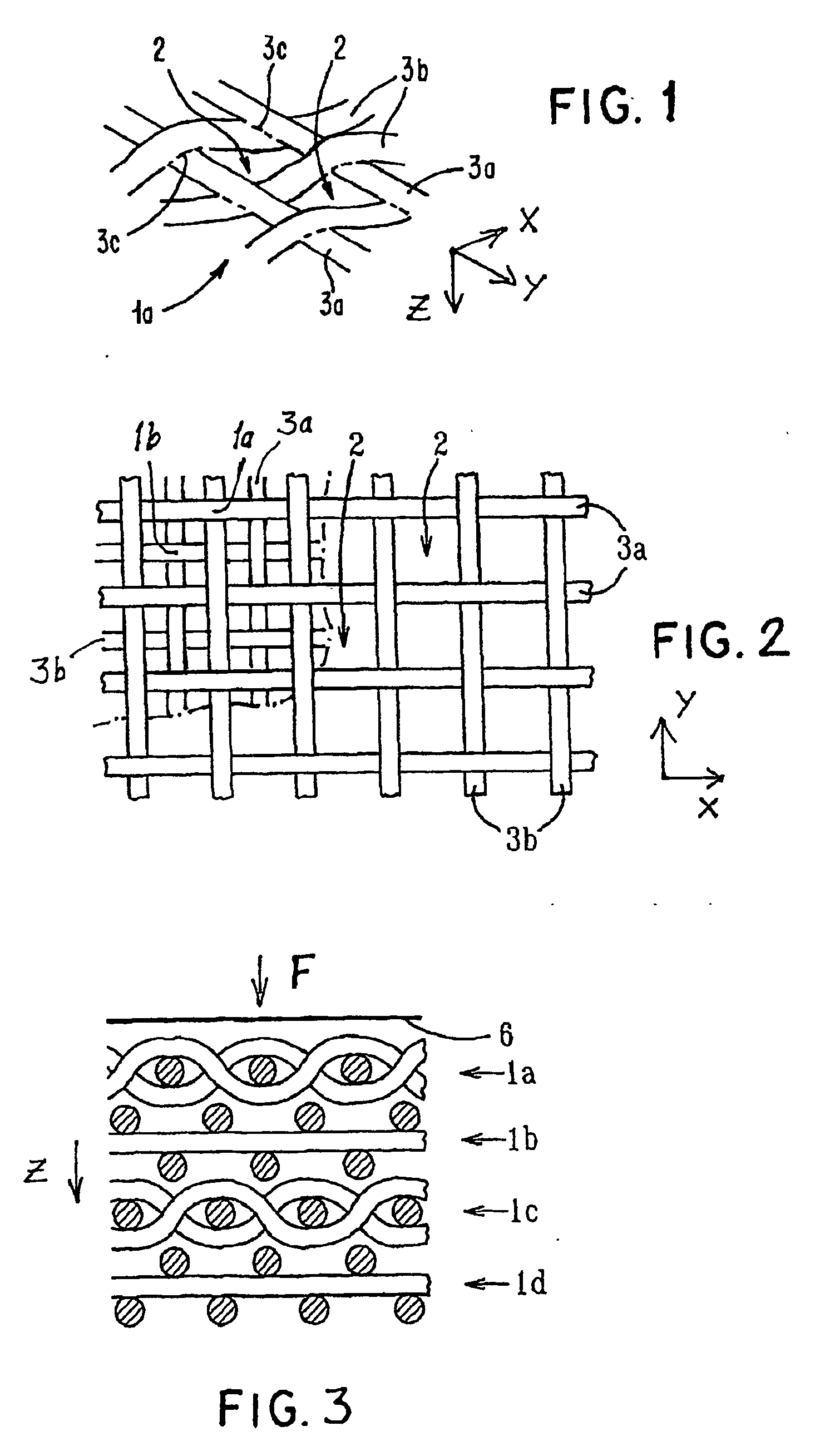

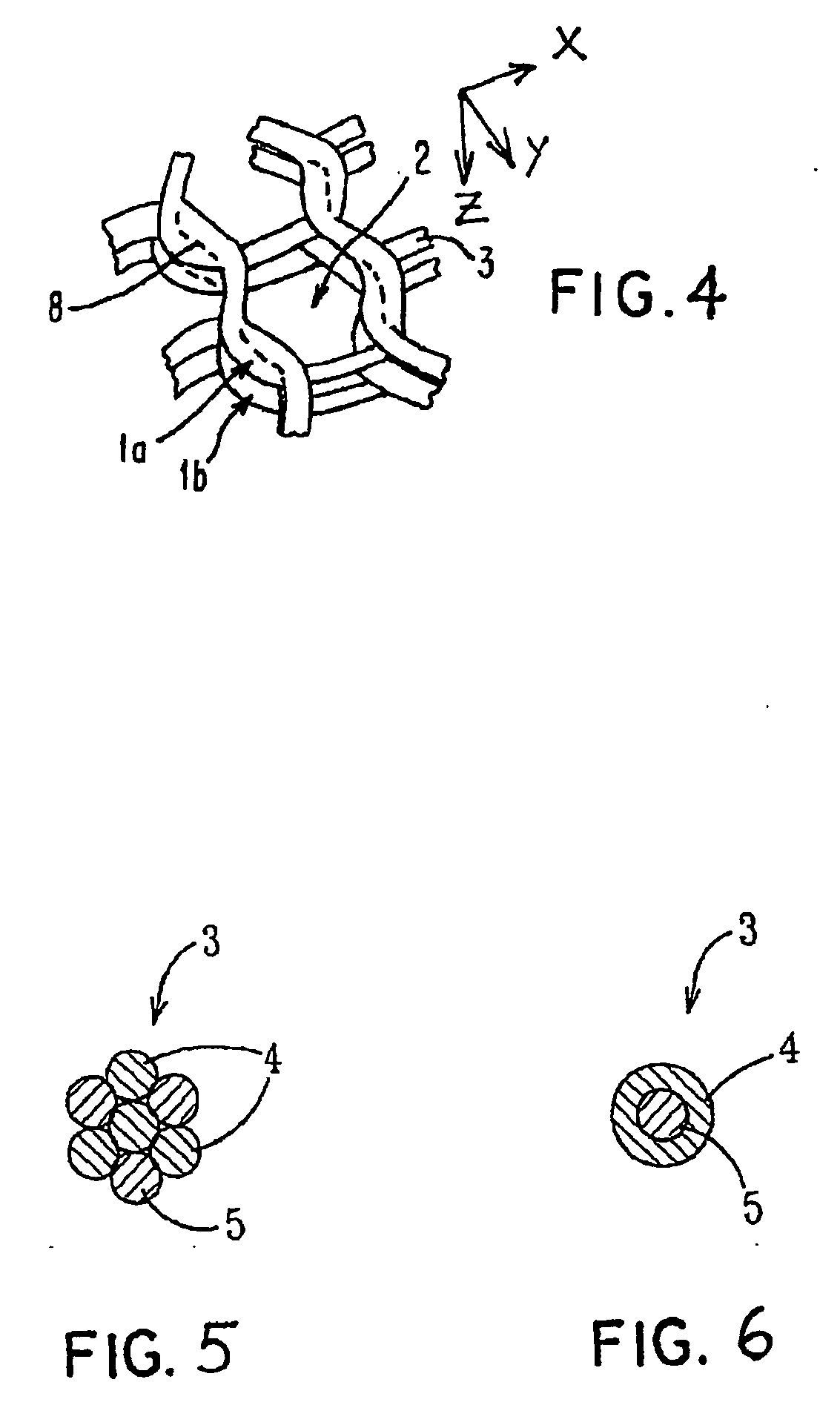

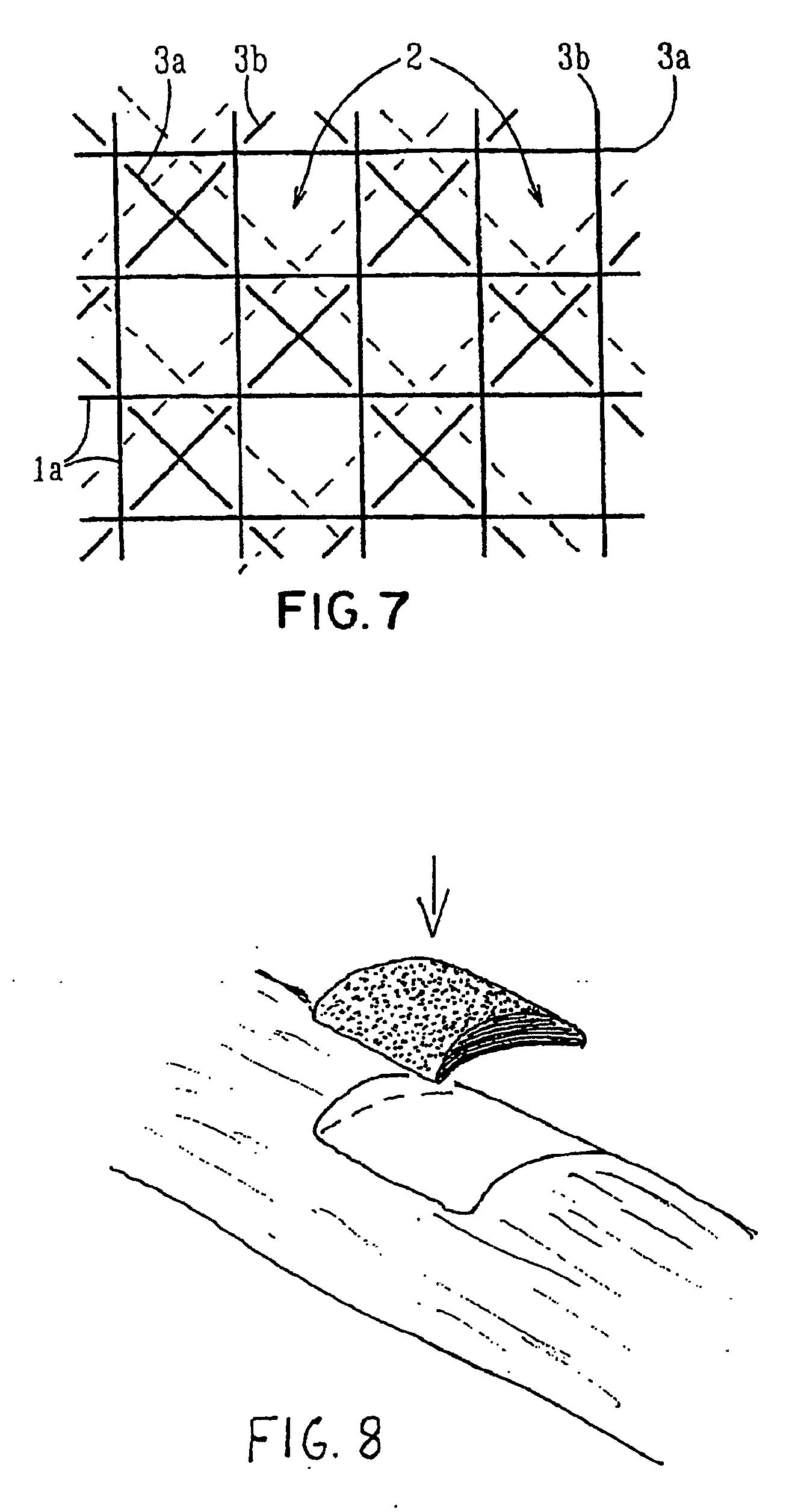

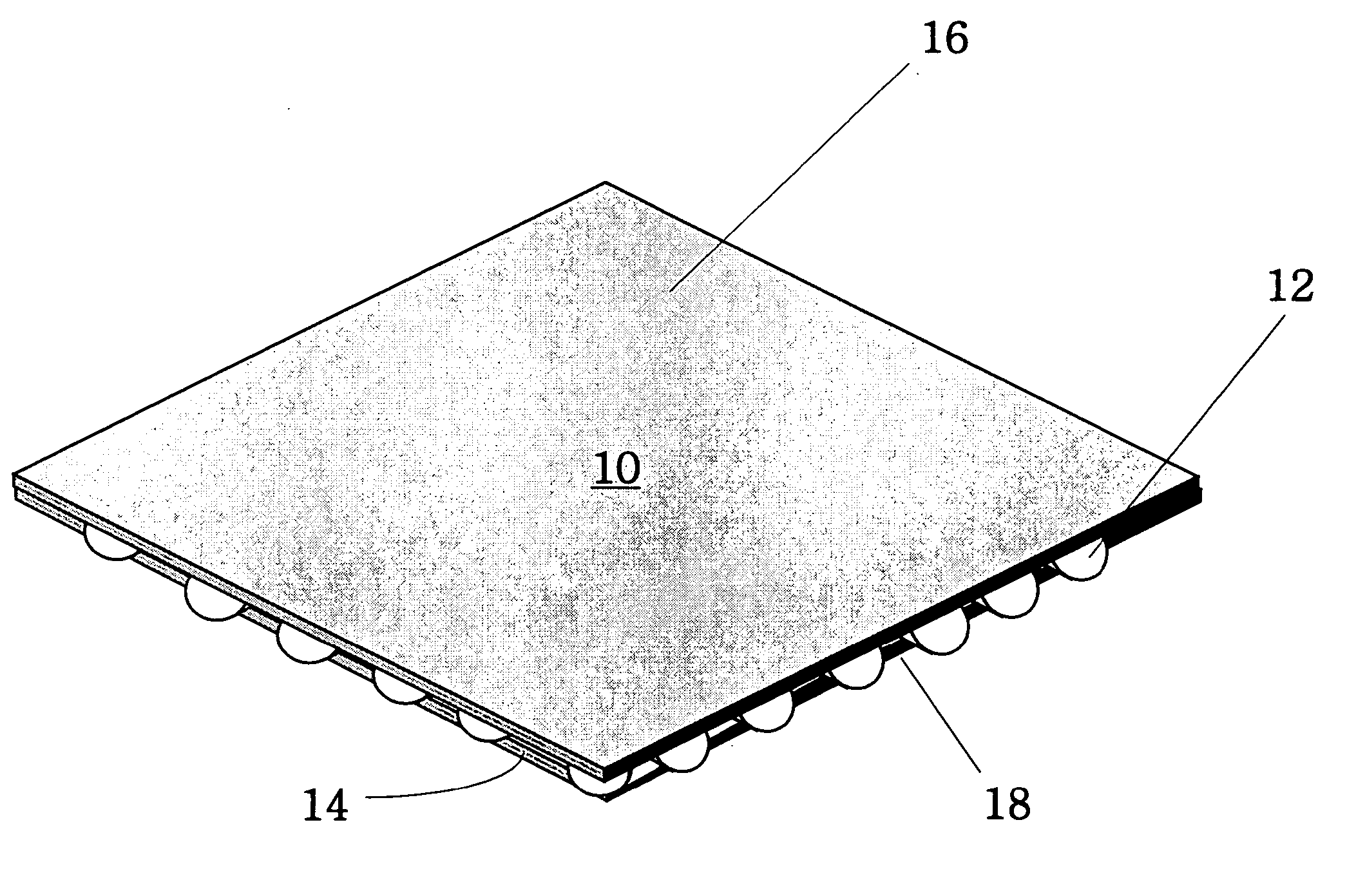

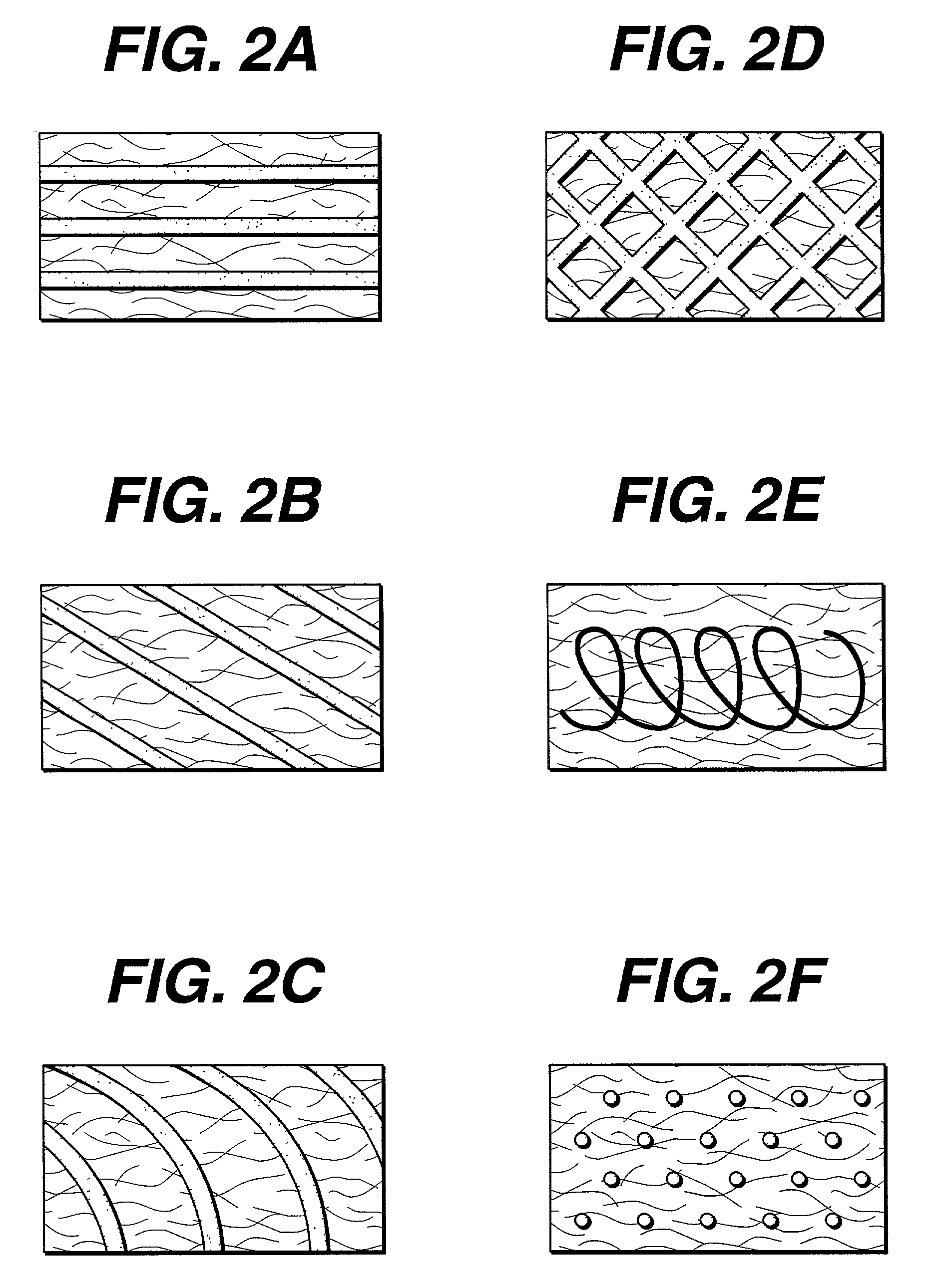

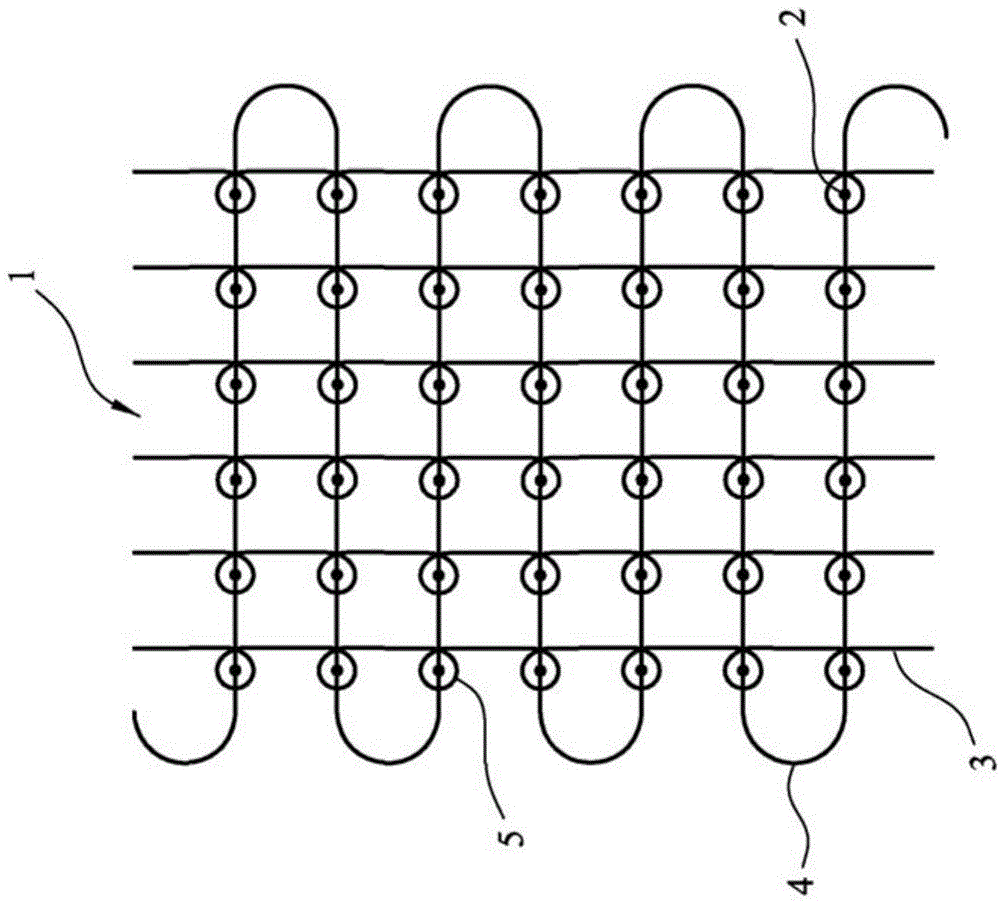

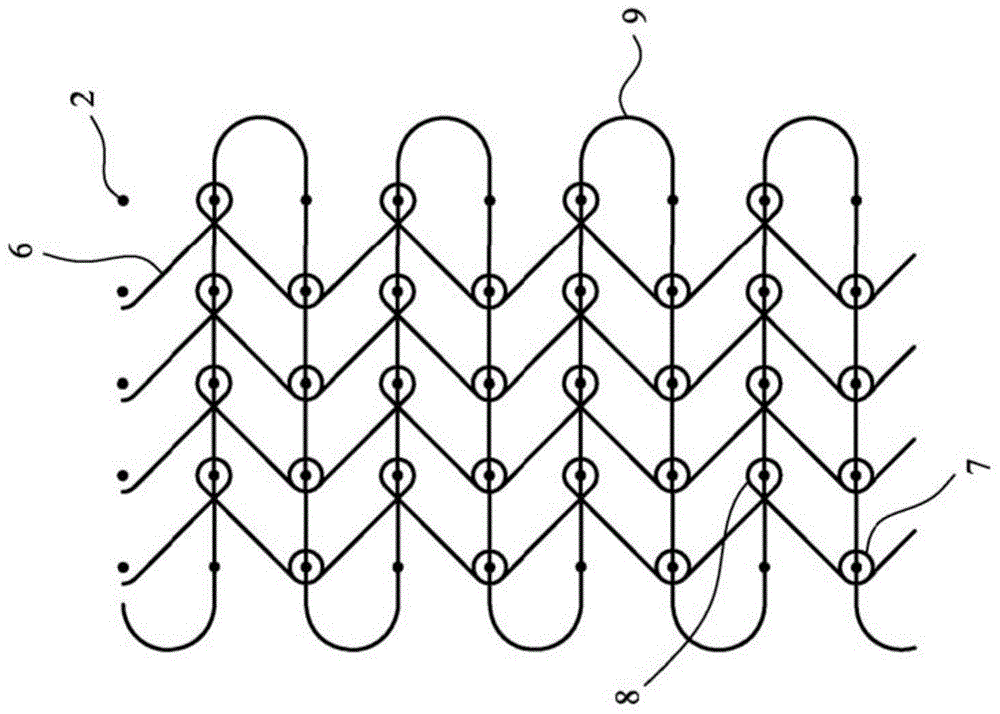

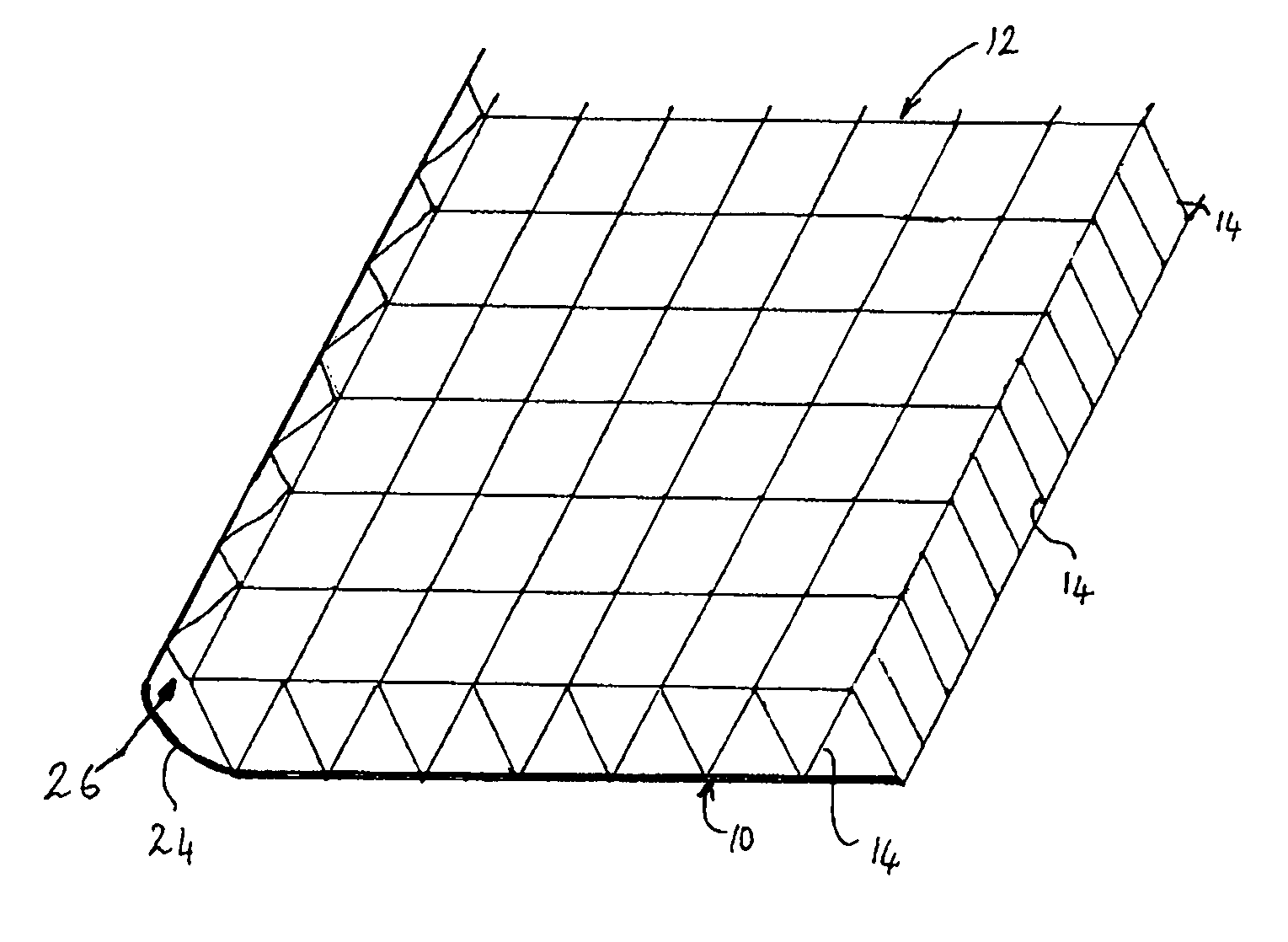

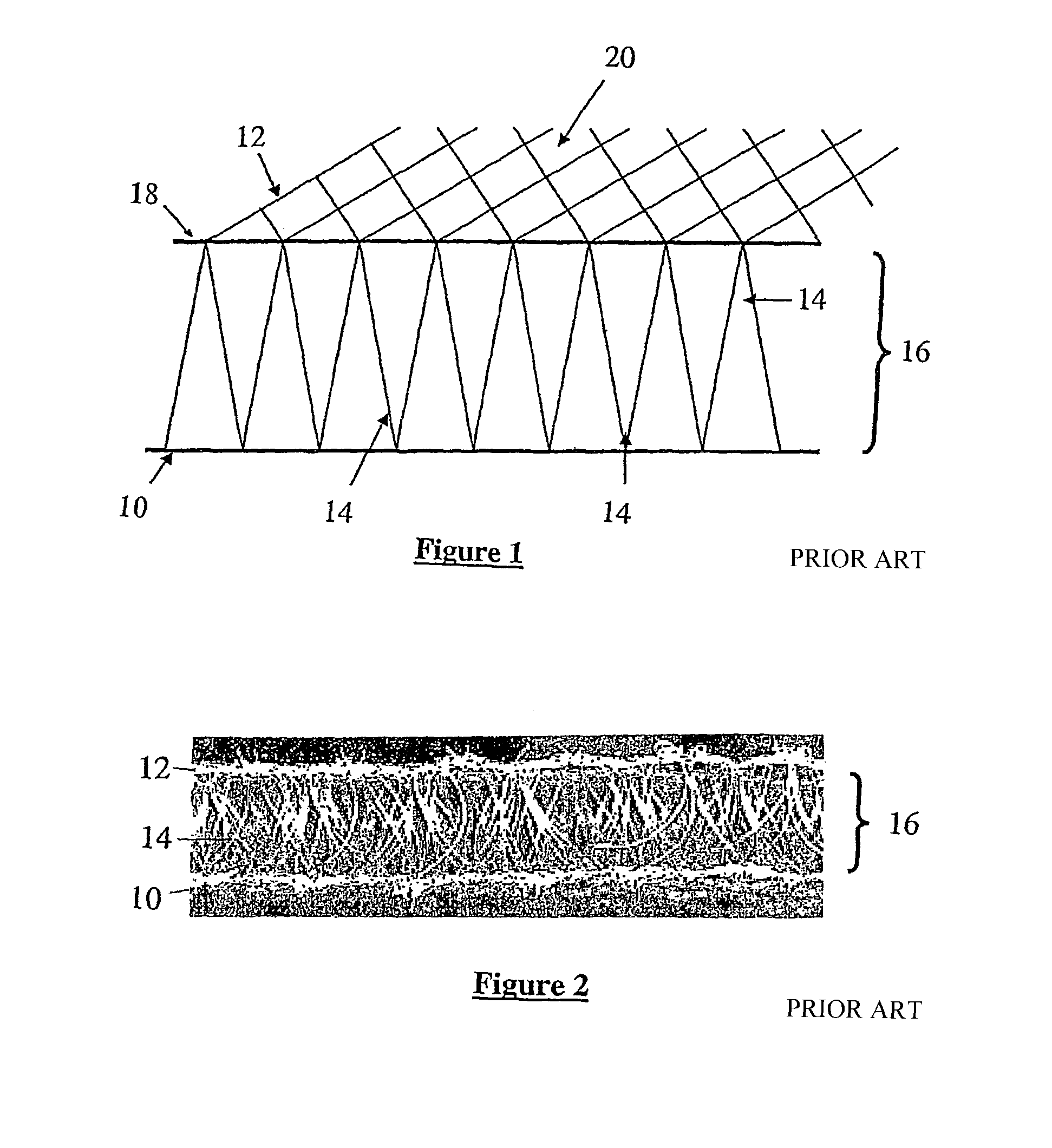

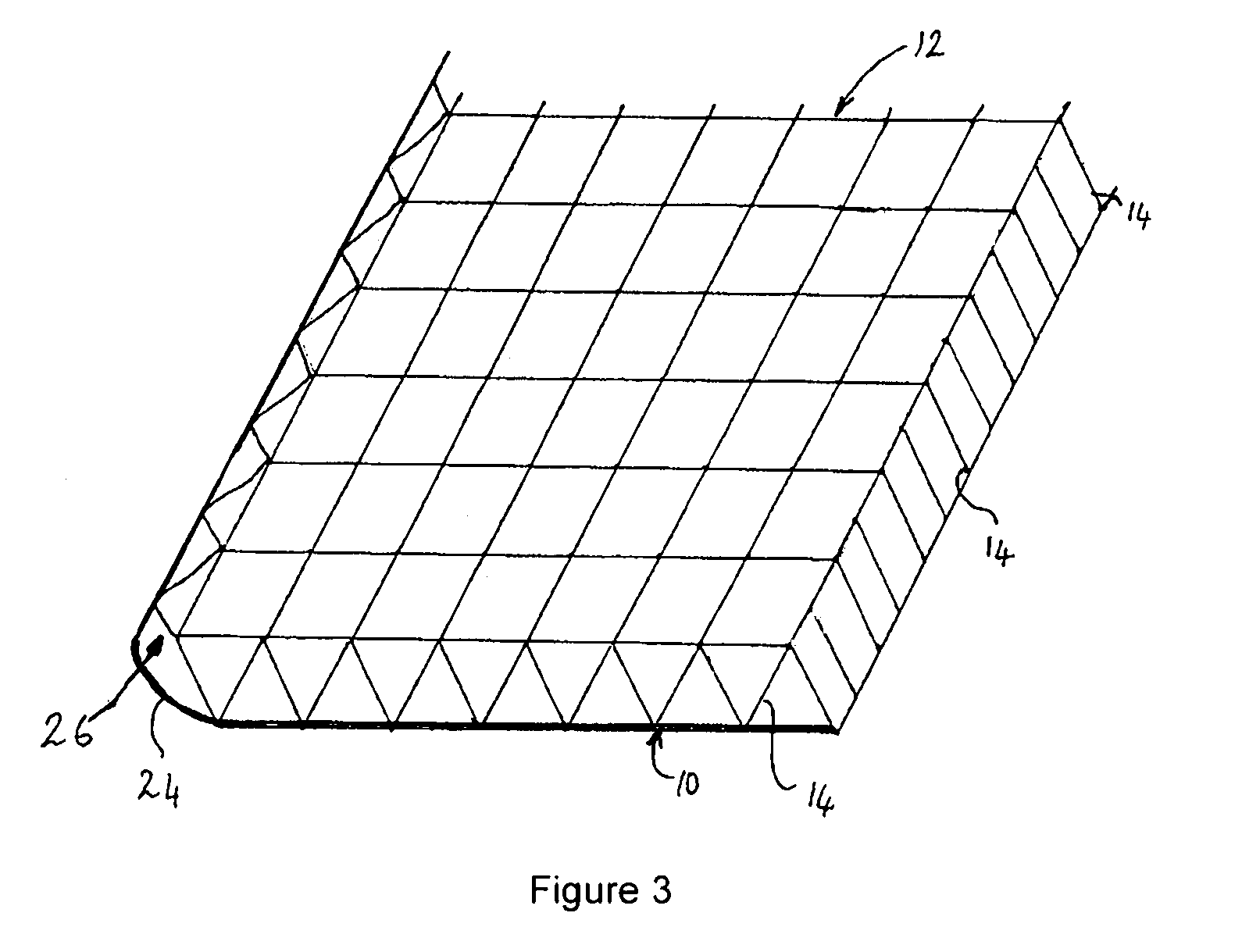

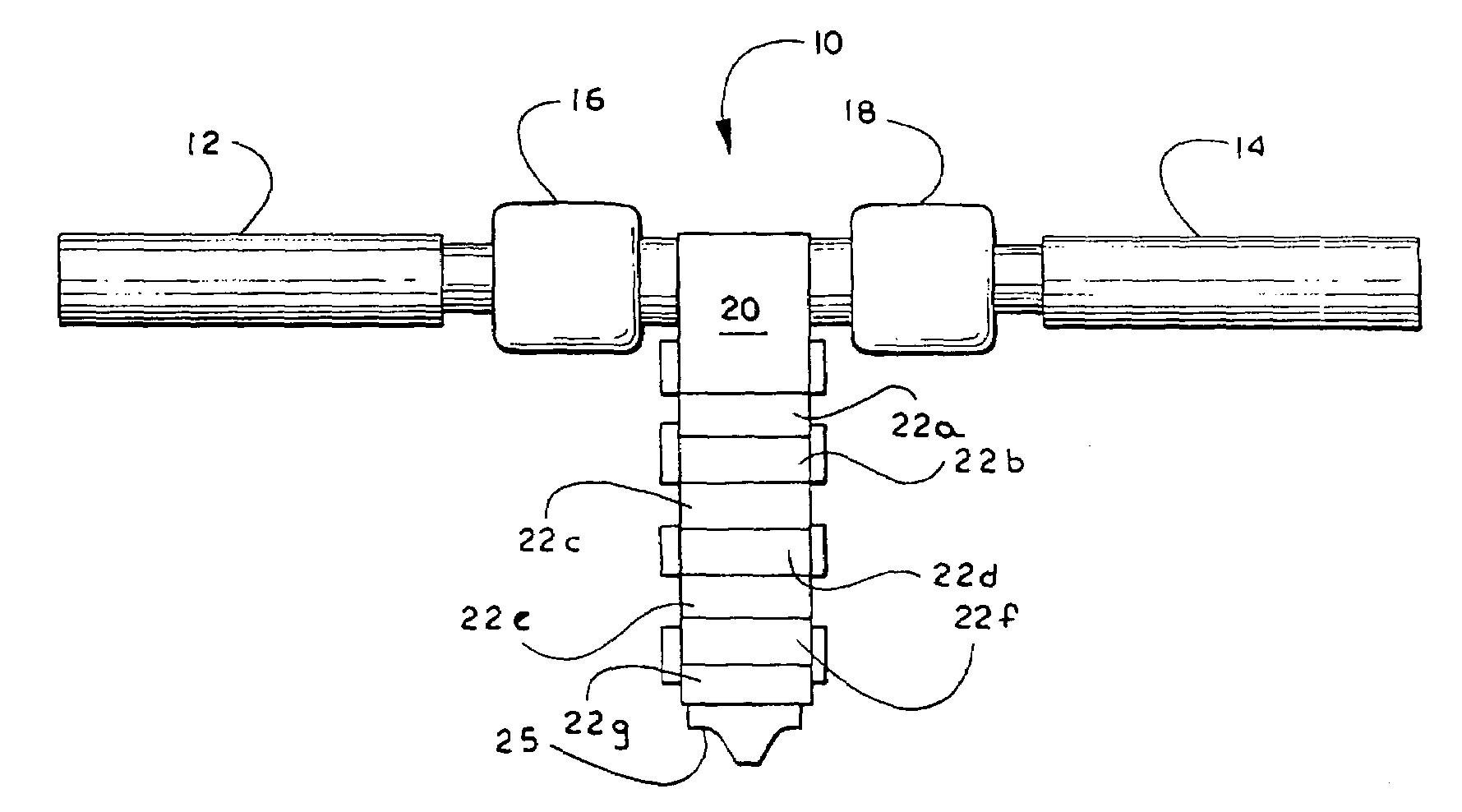

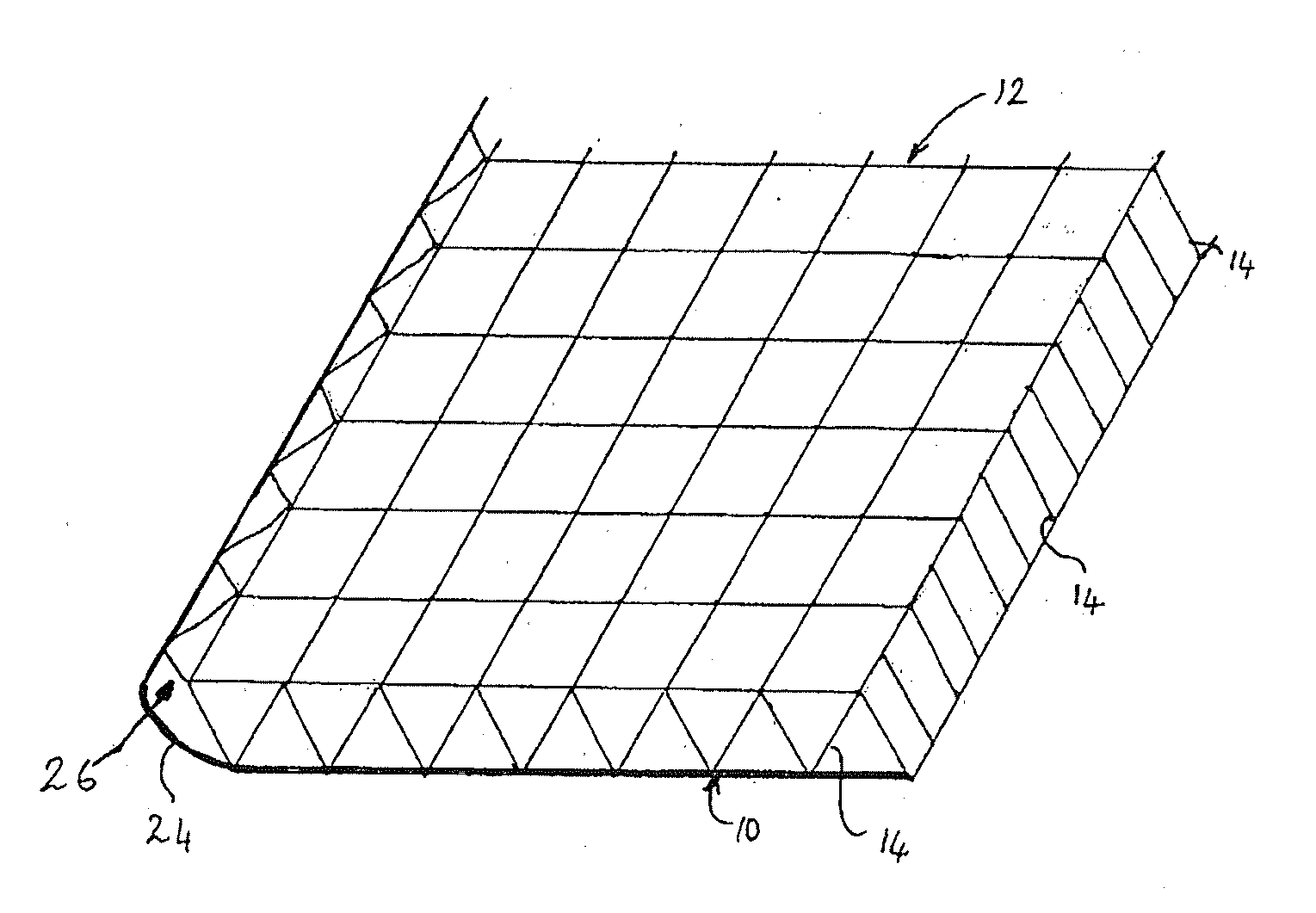

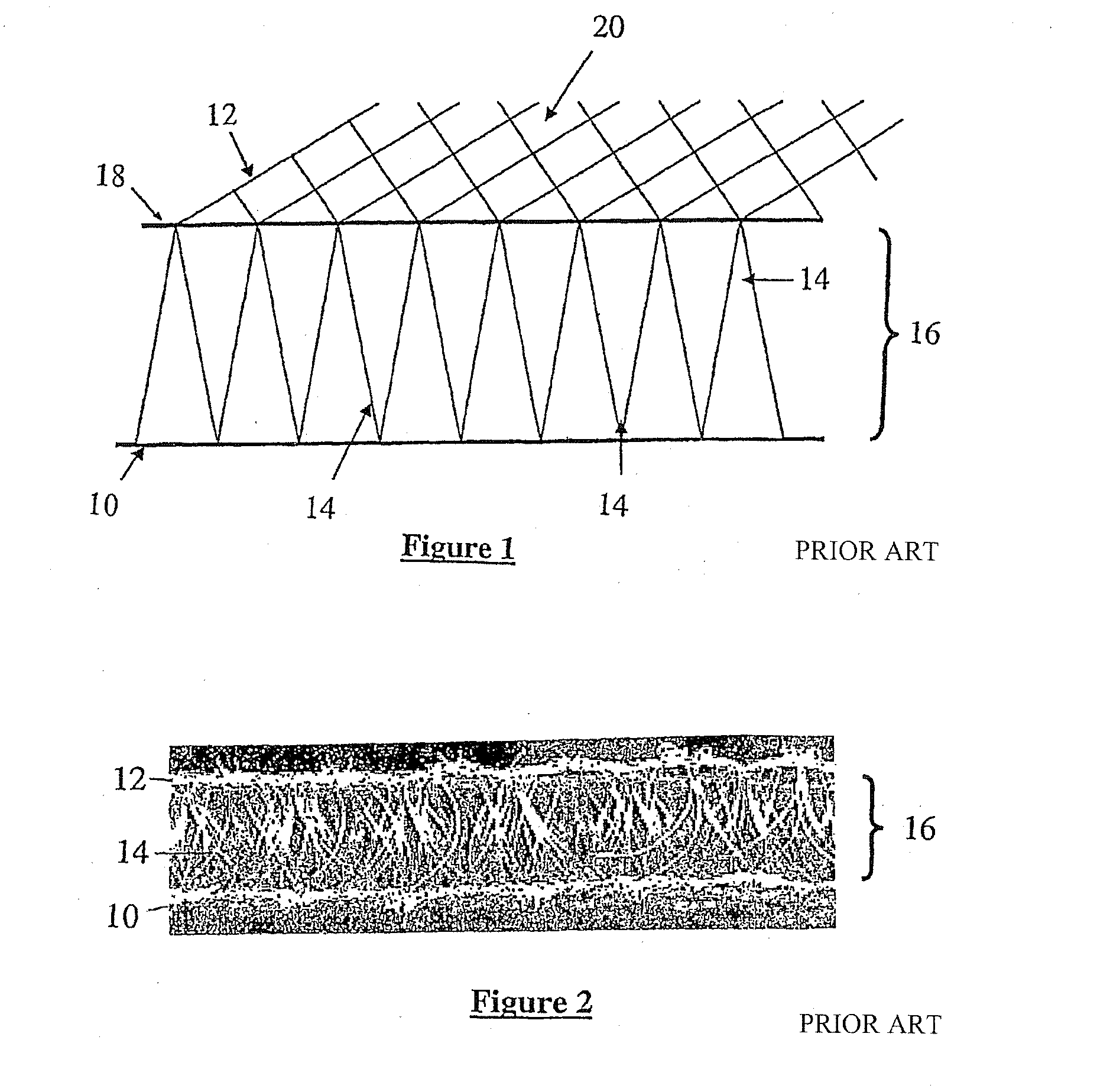

Porous bioabsorbable, bioactive and load-bearing composite medical device structure includes a plurality of regular textile planar layers (1a, 1b . . . ) formed of continuous bioabsorbable polymer matrix and bioceramic fibers acting as reinforcements, both included in continuous fibrous elements (3) forming the textile layers. The layers are placed on top of each other to form a structure having two dimensions (x, y) at right angles to each other according to the two dimensions of the textile layer and a third dimension (z) perpendicular to them and resulting from the piling of the layers. A plurality of passages extend through the layers as a result of the openings (2) defined by portions of the continuous fibrous elements (3) extending substantially in the direction of the plane. The continuous fibrous elements (3) comprise both bioactive ceramic reinforcing fibers which form a reinforcing structure and a bioabsorbable polymer matrix material which forms a matrix which binds the layers together and also binds the portions of continuous fibers defining the openings together, thereby forming the passages and stiffening the structure. This bioactive and bioabsorbable composite structure is suitable to be used as a basic structure in medical devices, especially in osteochondral applications where the load-bearing properties of implant are required.

Owner:BIORETEC

Porous medical device and method for its manufacture

ActiveUS20070141111A1Uniform distribution of poresSuppress mutationBiocideGenetic material ingredientsFiberBioceramic

Porous bioabsorbable, bioactive and load-bearing composite medical device structure includes a plurality of regular textile planar layers (1a, 1b . . . ) formed of continuous bioabsorbable polymer matrix and bioceramic fibers acting as reinforcements, both included in continuous fibrous elements (3) forming the textile layers. The layers are placed on top of each other to form a structure having two dimensions (x, y) at right angles to each other according to the two dimensions of the textile layer and a third dimension (z) perpendicular to them and resulting from the piling of the layers. A plurality of passages extend through the layers as a result of the openings (2) defined by portions of the continuous fibrous elements (3) extending substantially in the direction of the plane. The continuous fibrous elements (3) comprise both bioactive ceramic reinforcing fibers which form a reinforcing structure and a bioabsorbable polymer matrix material which forms a matrix which binds the layers together and also binds the portions of continuous fibers defining the openings together, thereby forming the passages and stiffening the structure. This bioactive and bioabsorbable composite structure is suitable to be used as a basic structure in medical devices, especially in osteochondral applications where the load-bearing properties of implant are required.

Owner:BIORETEC

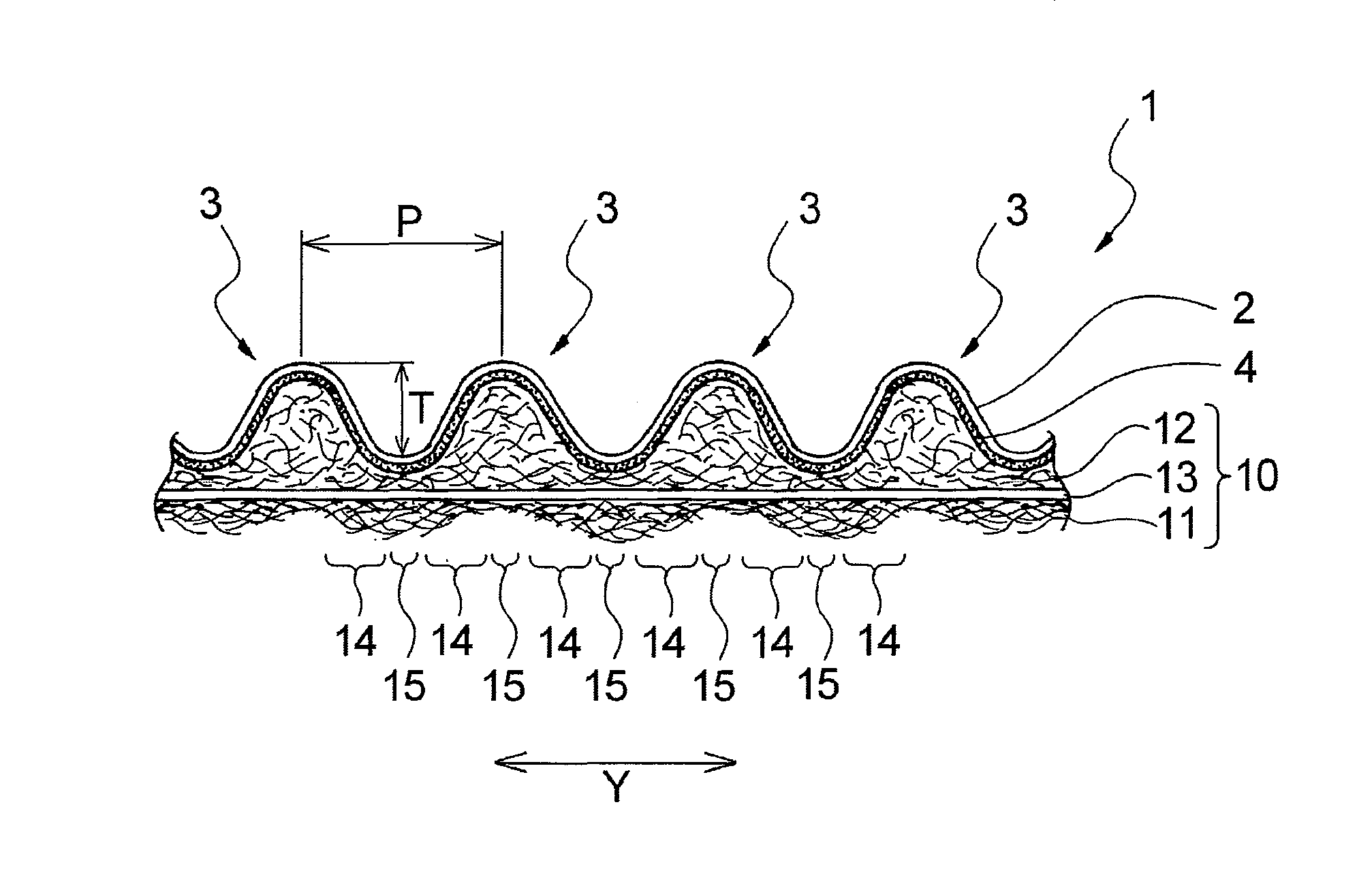

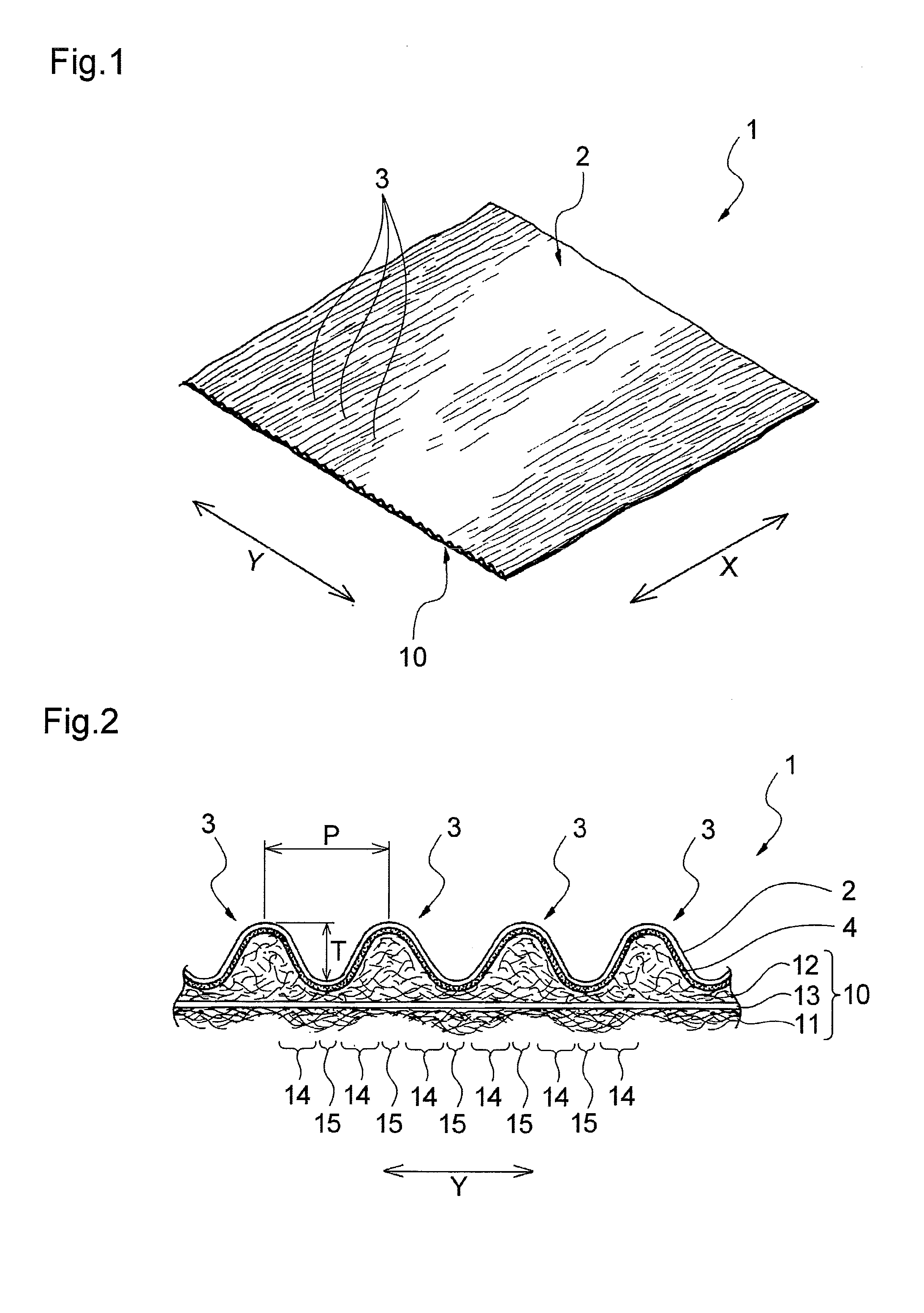

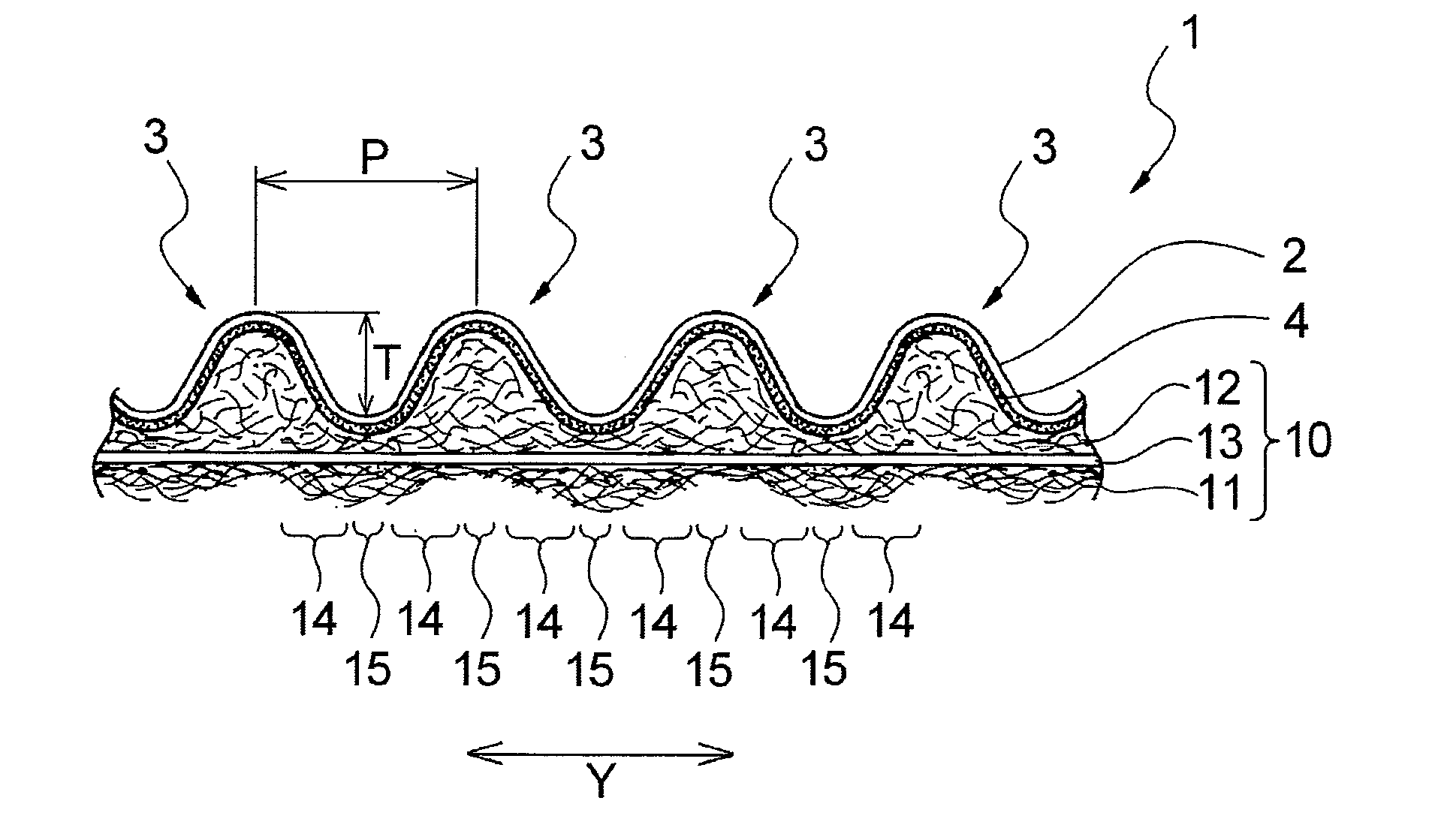

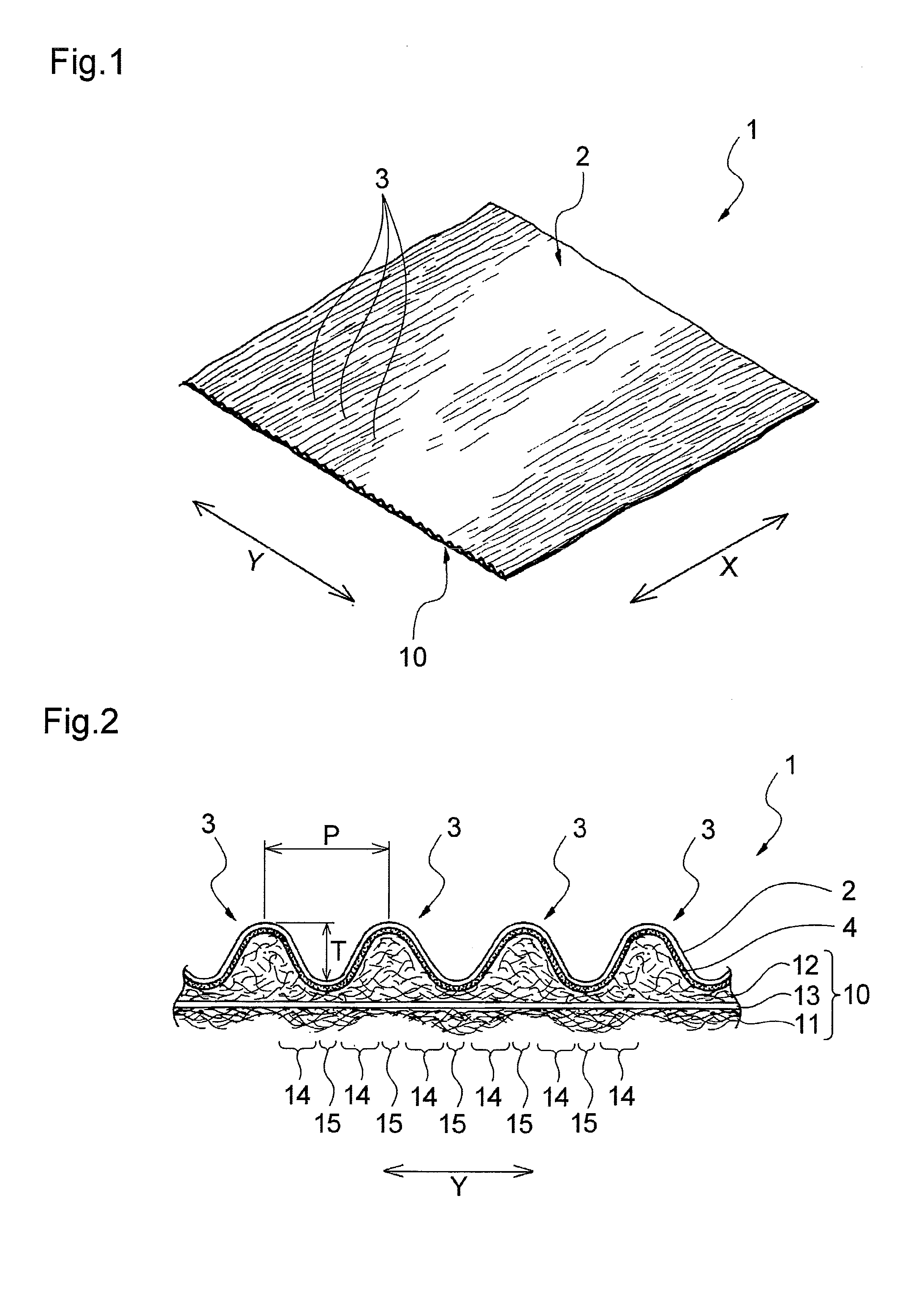

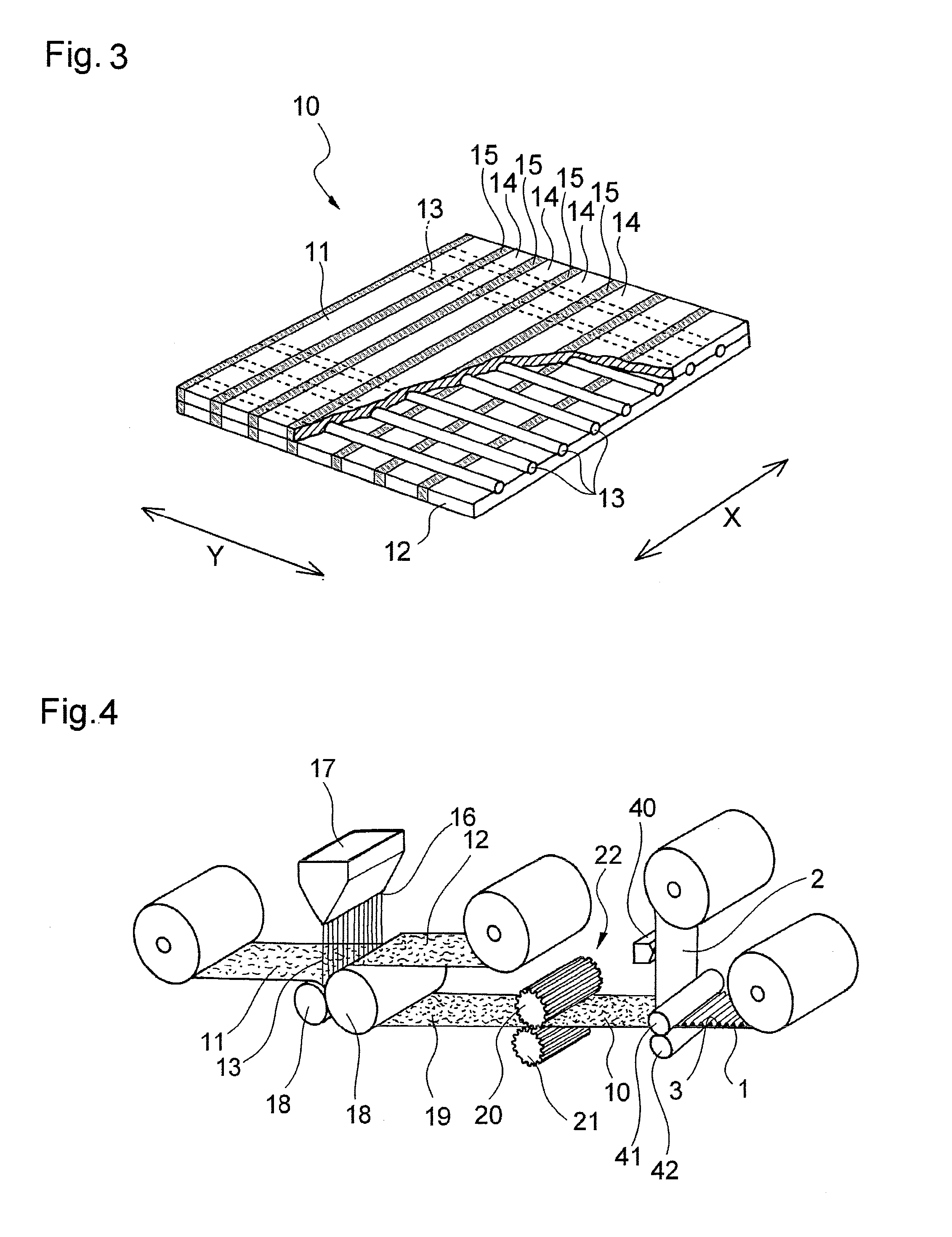

Stretchable composite sheet

Owner:KAO CORP

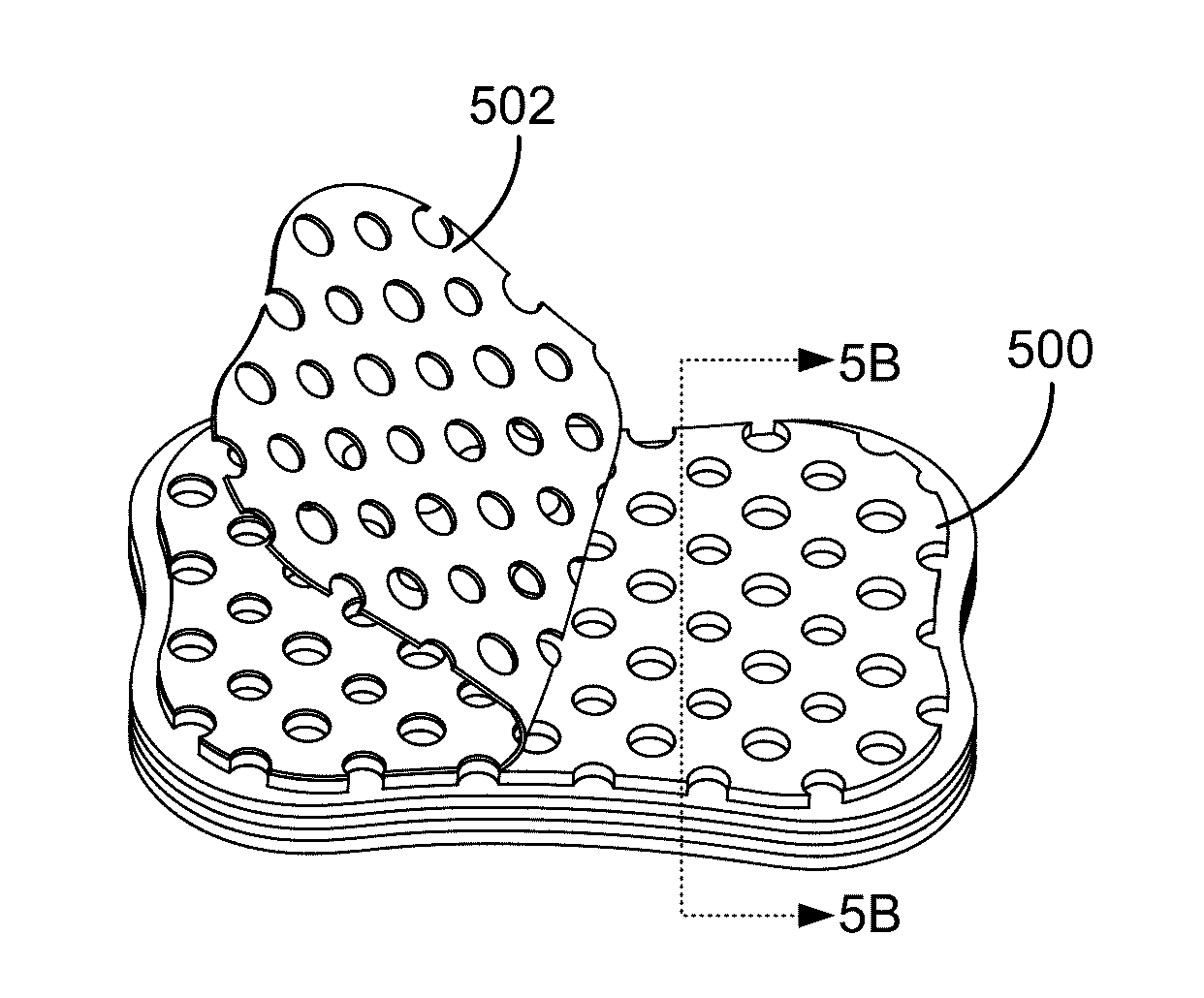

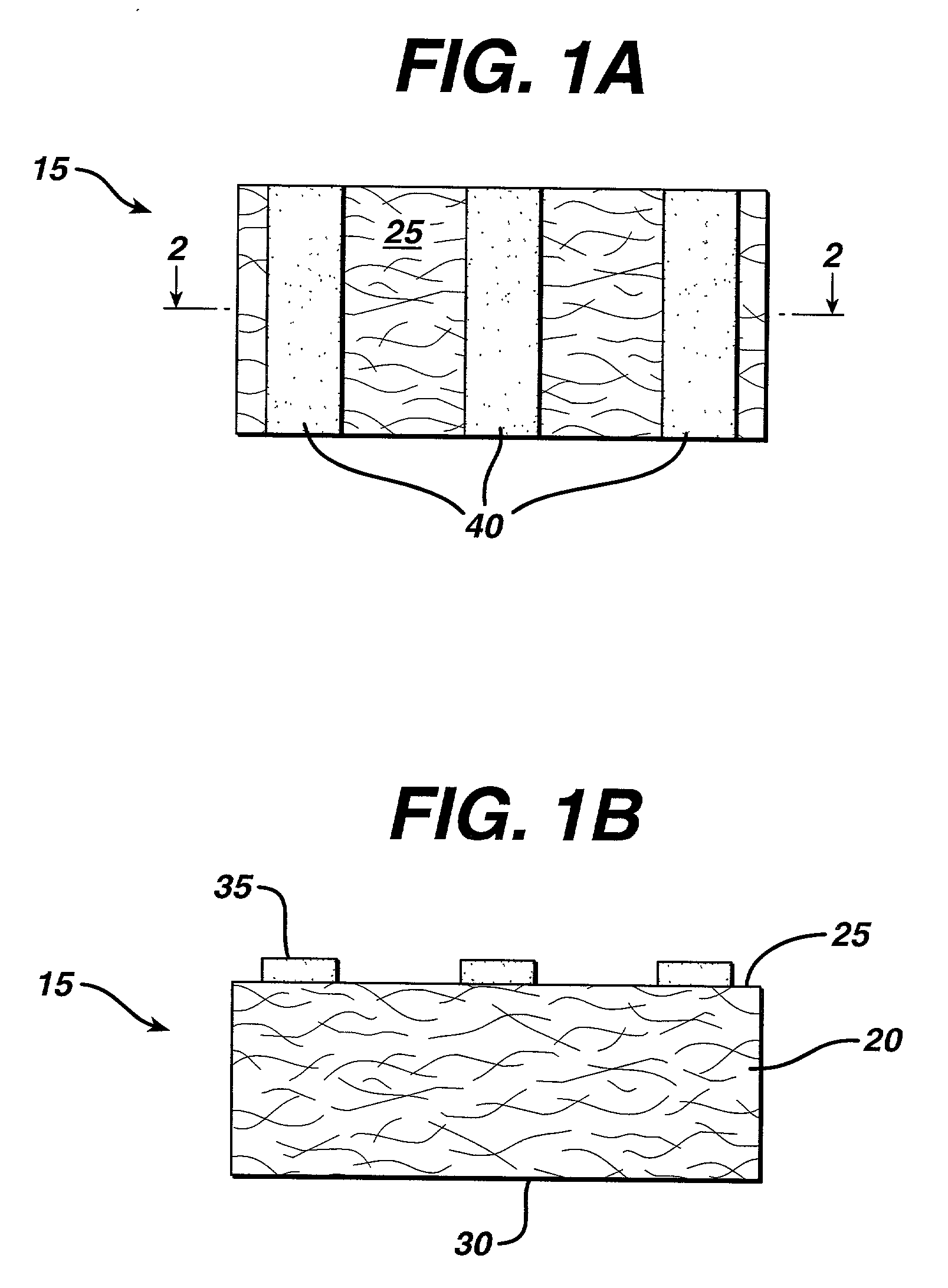

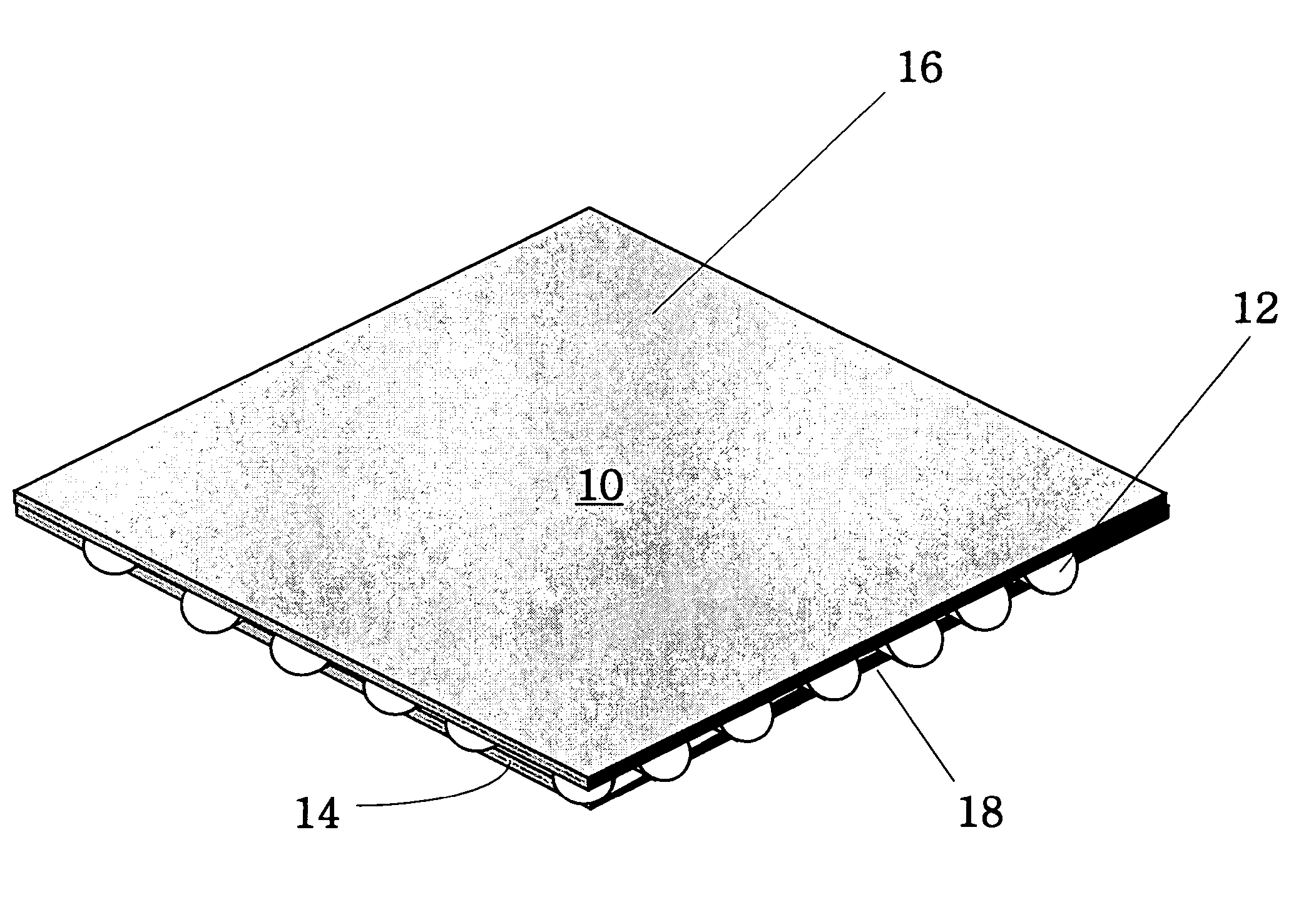

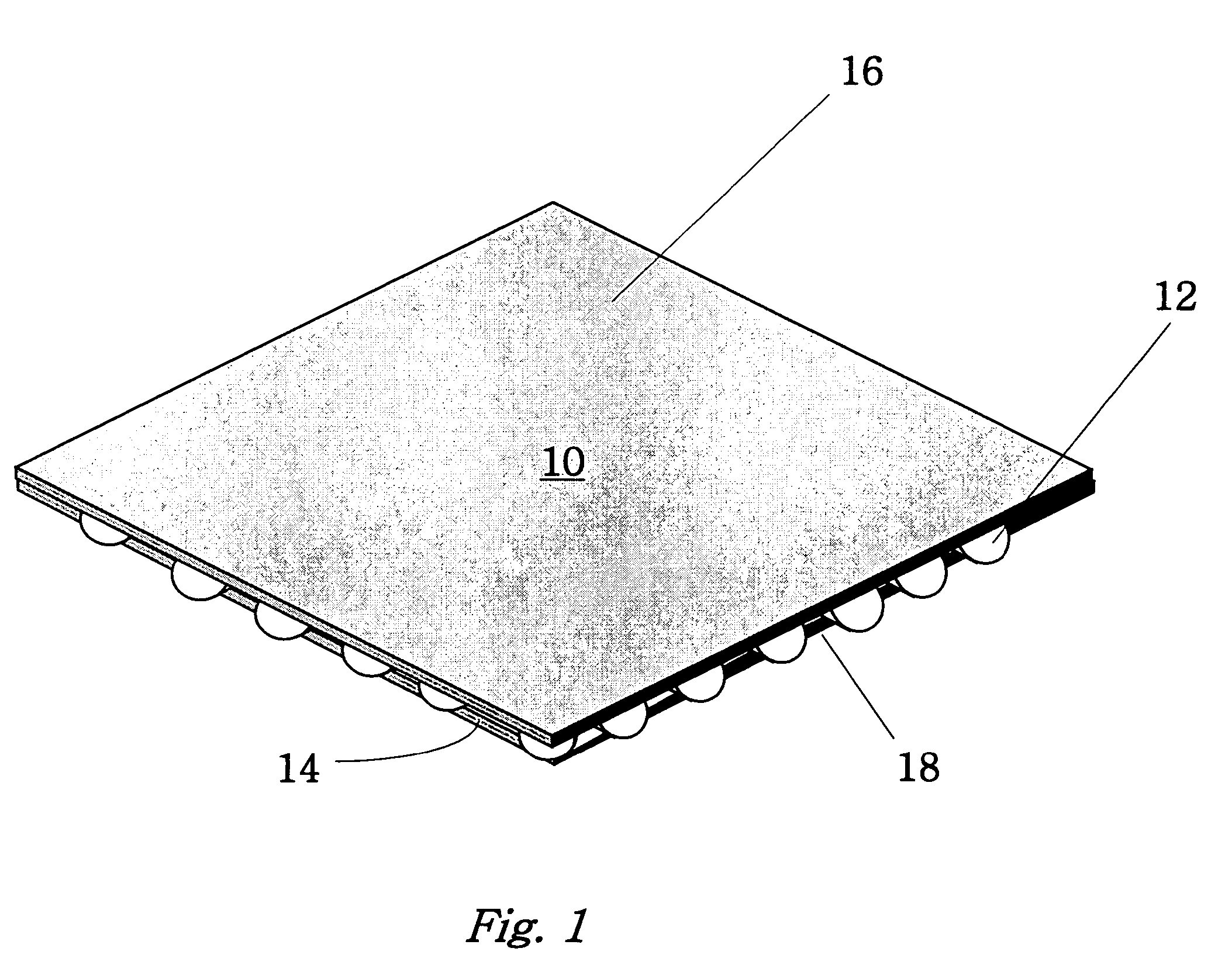

Moisture wicking adhesives for skin-mounted devices

InactiveUS20160361015A1Improve breathabilityReduce the likelihood of injuryMedical patchesFilm/foil adhesivesSkin InjuryAdhesive

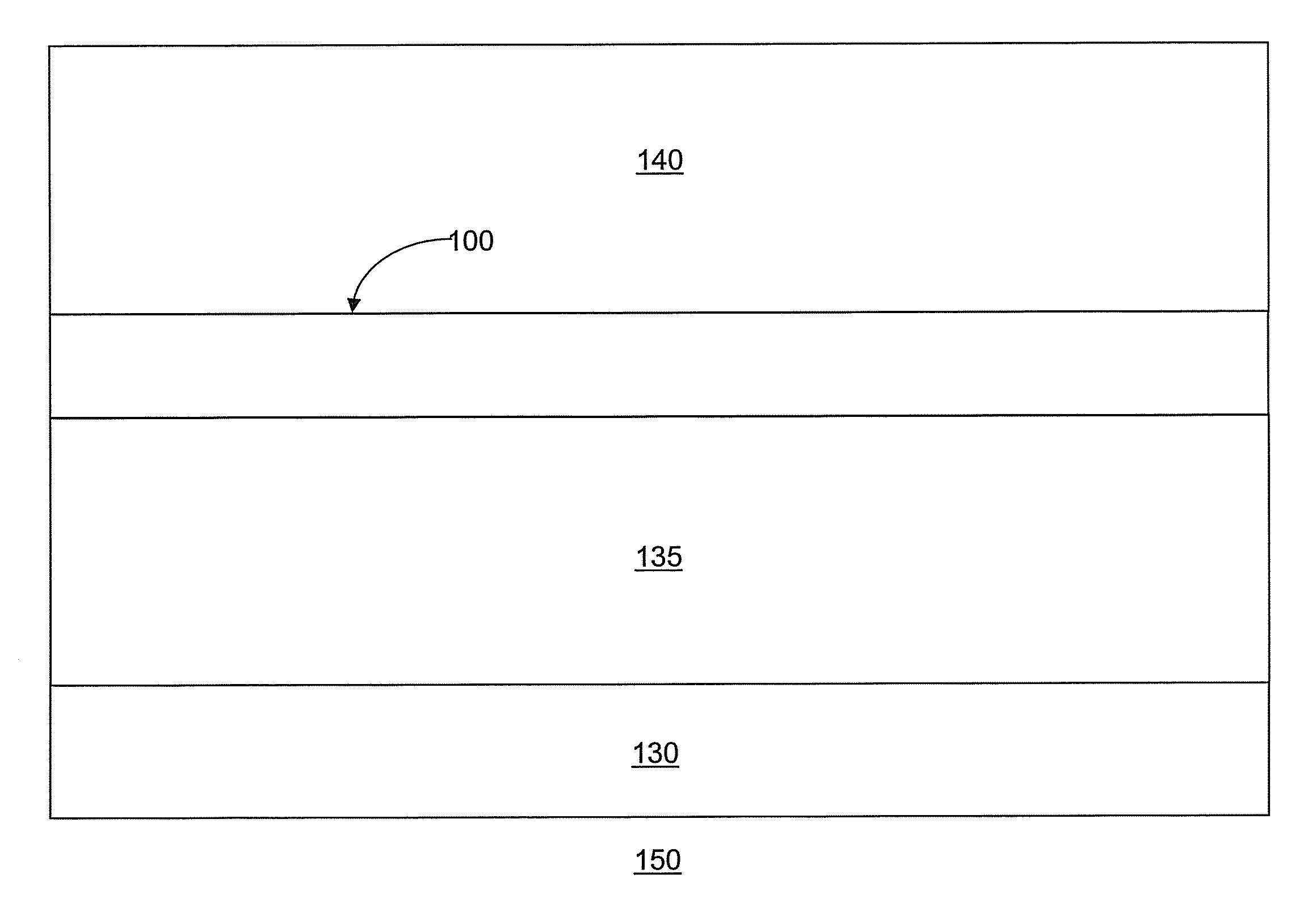

The present invention describes breathable multilayered adhesive structures that can be used as adhesives to mount devices onto the skin. The breathable multilayered adhesive structures can comprise moisture-wicking layers adhered to the skin by a porous adhesion layer. The pores allow moisture released from the skin to be transferred away through the moisture-wicking layer. The adhesive structures permit the devices to be skin-mounted for an extended period of time (e.g., a few hours or days) without causing moisture-associated skin injuries such as erythema, maceration, and irritation or inflammation.

Owner:MC 10 INC

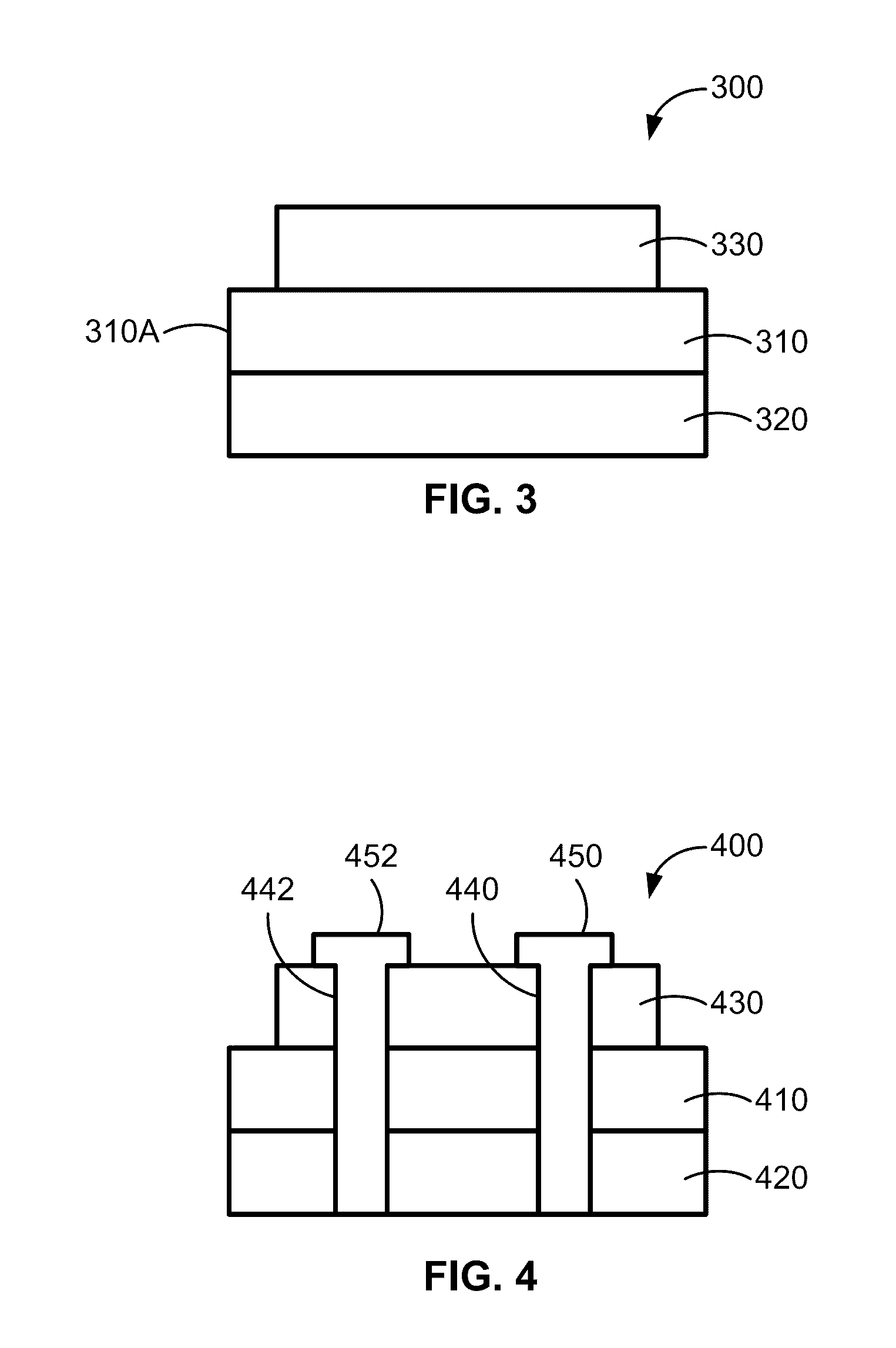

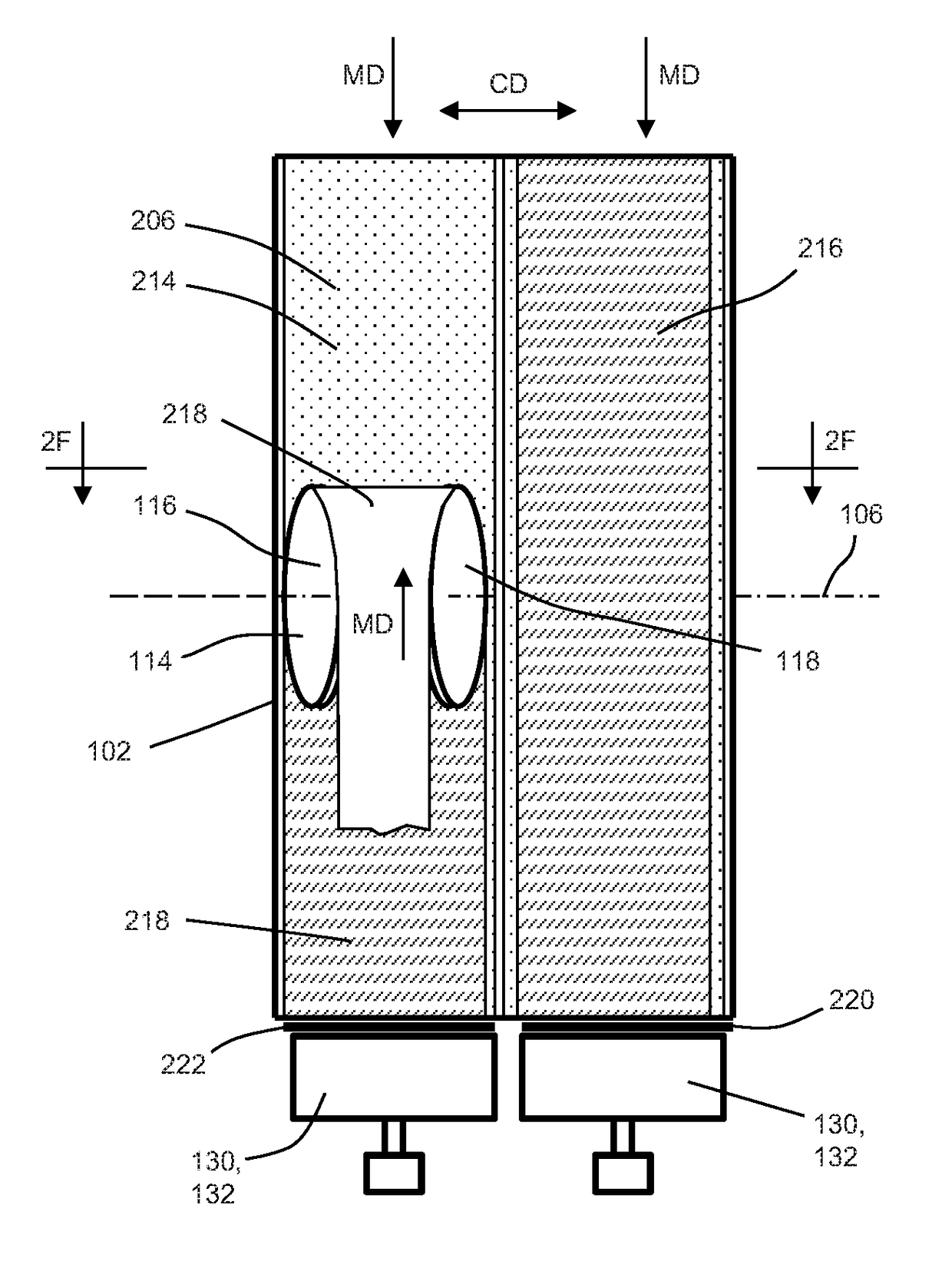

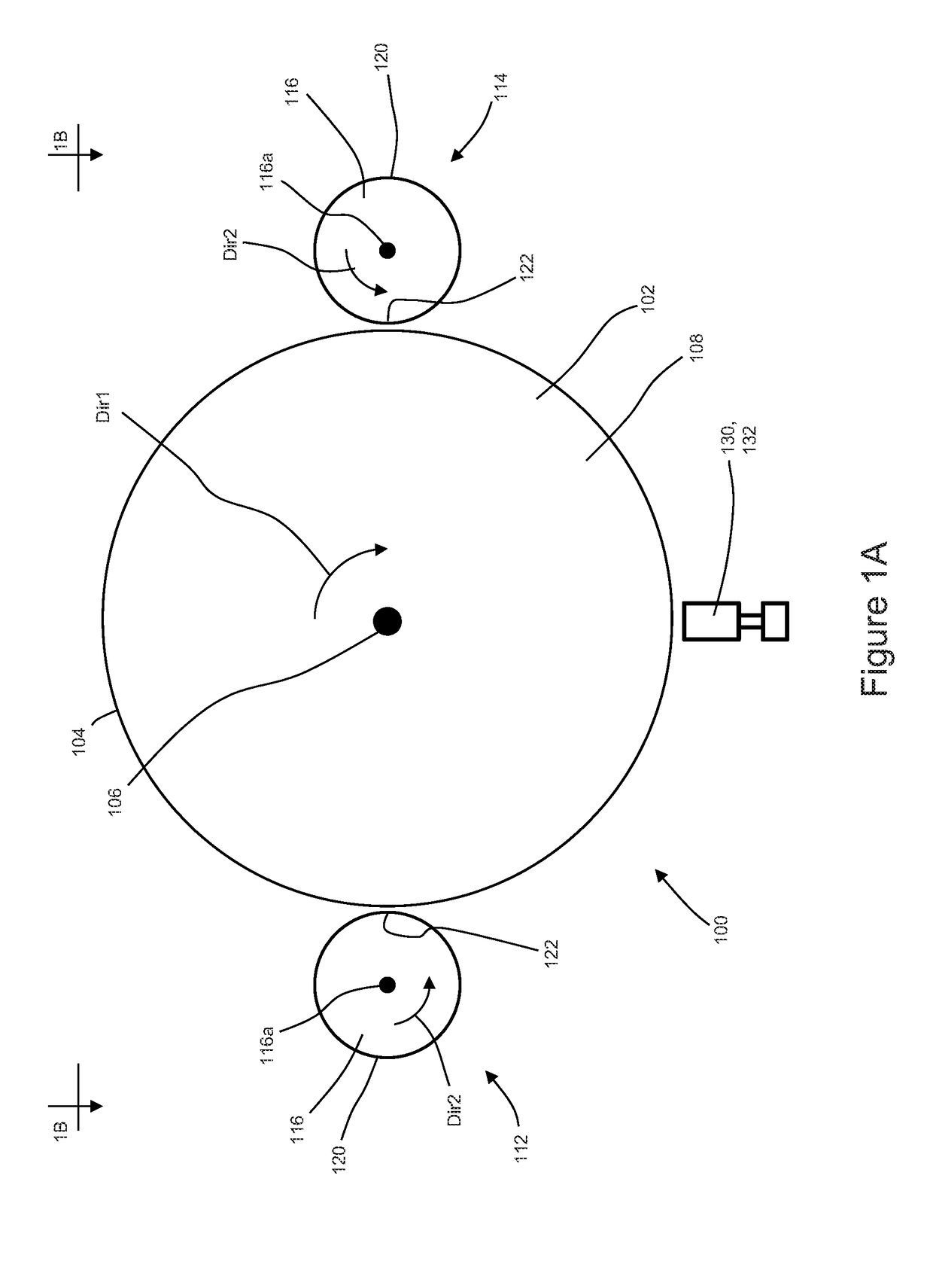

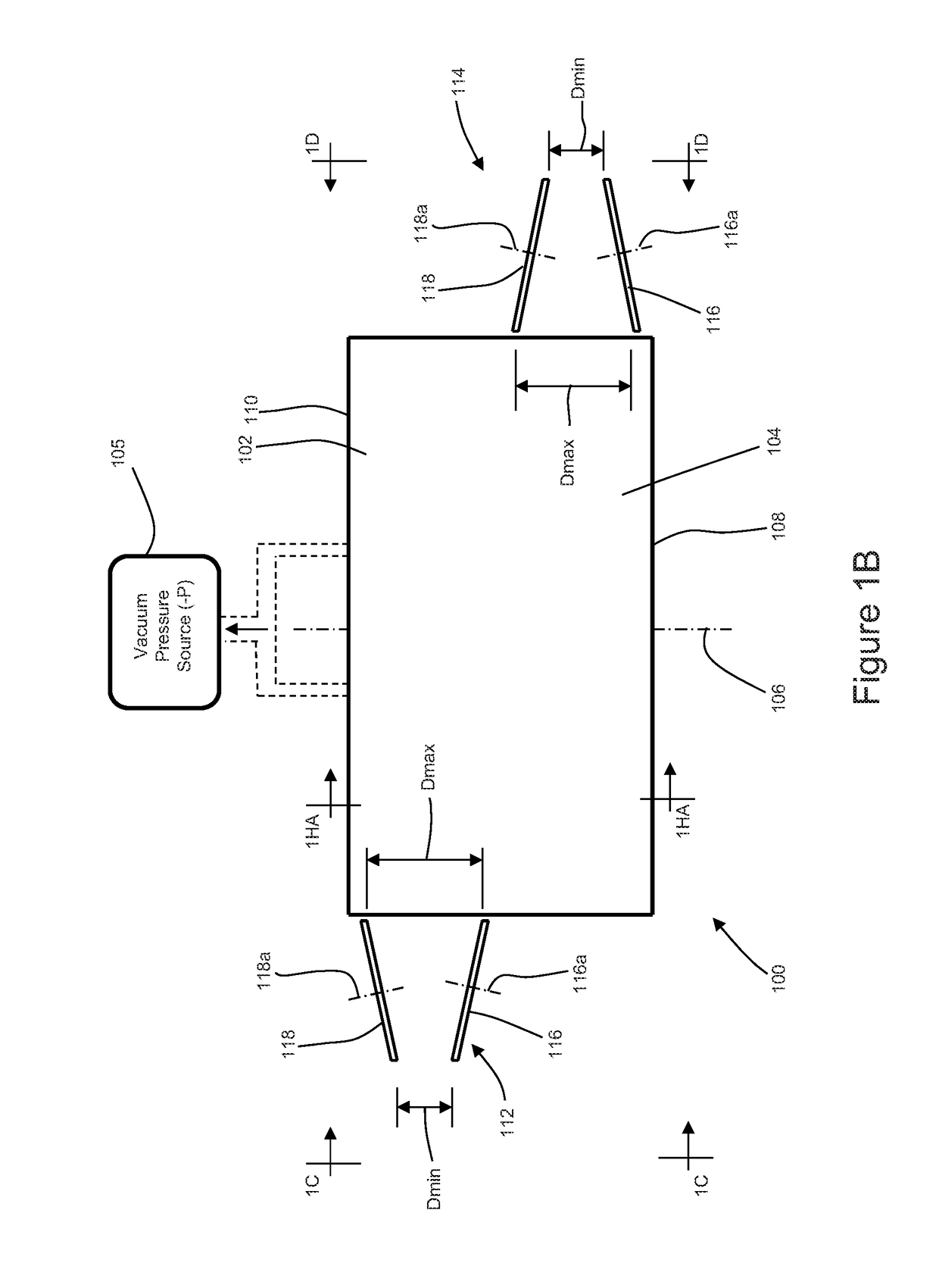

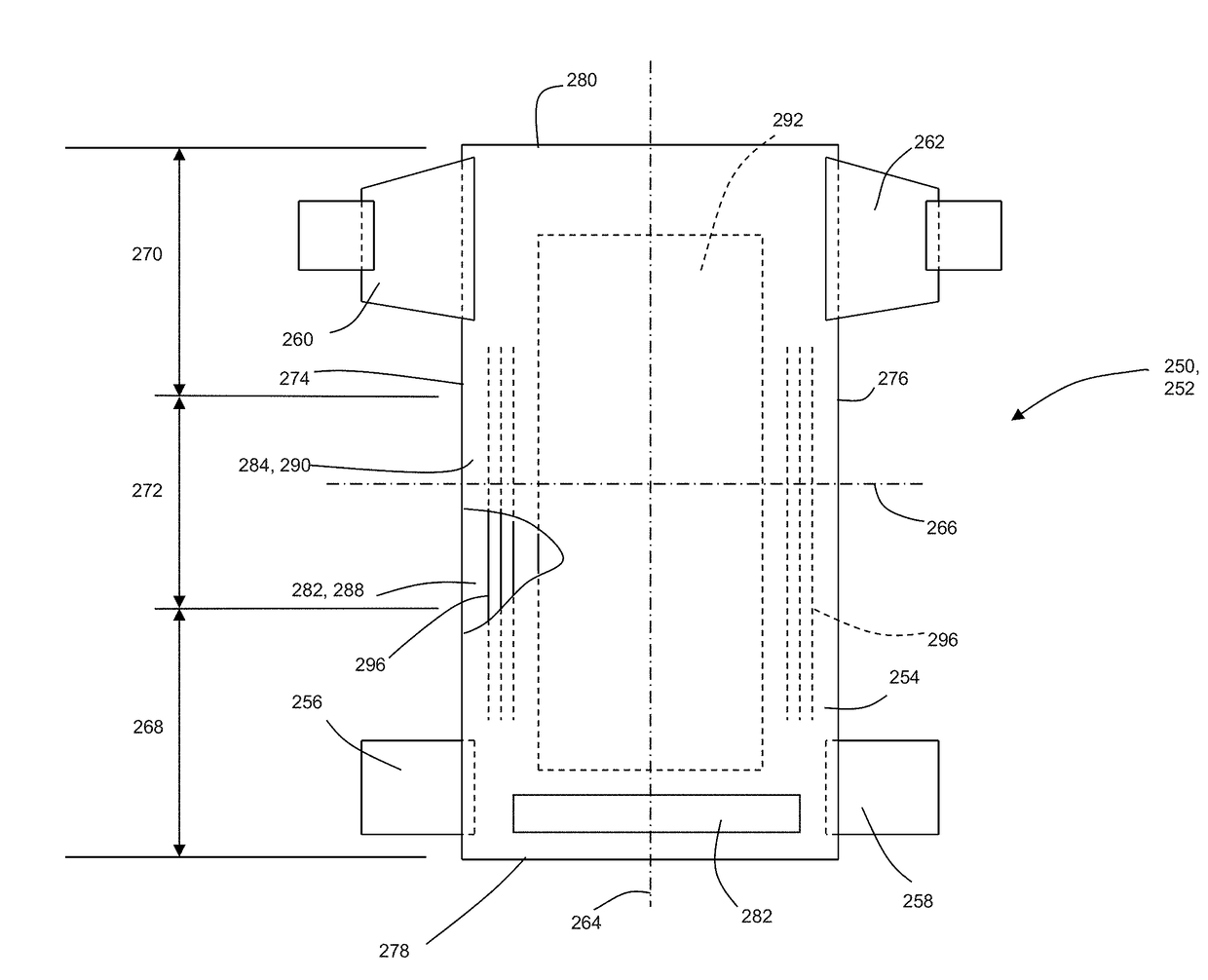

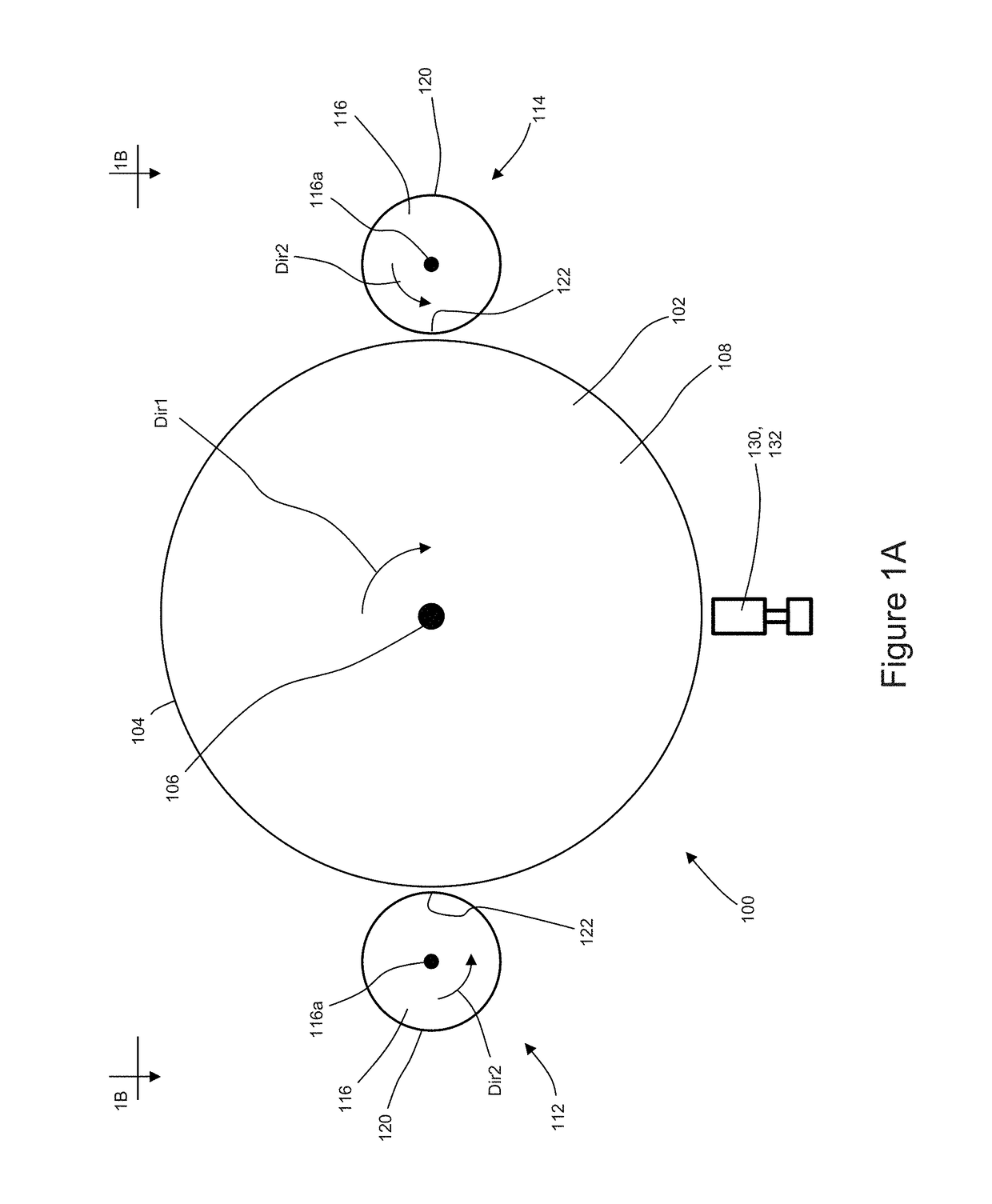

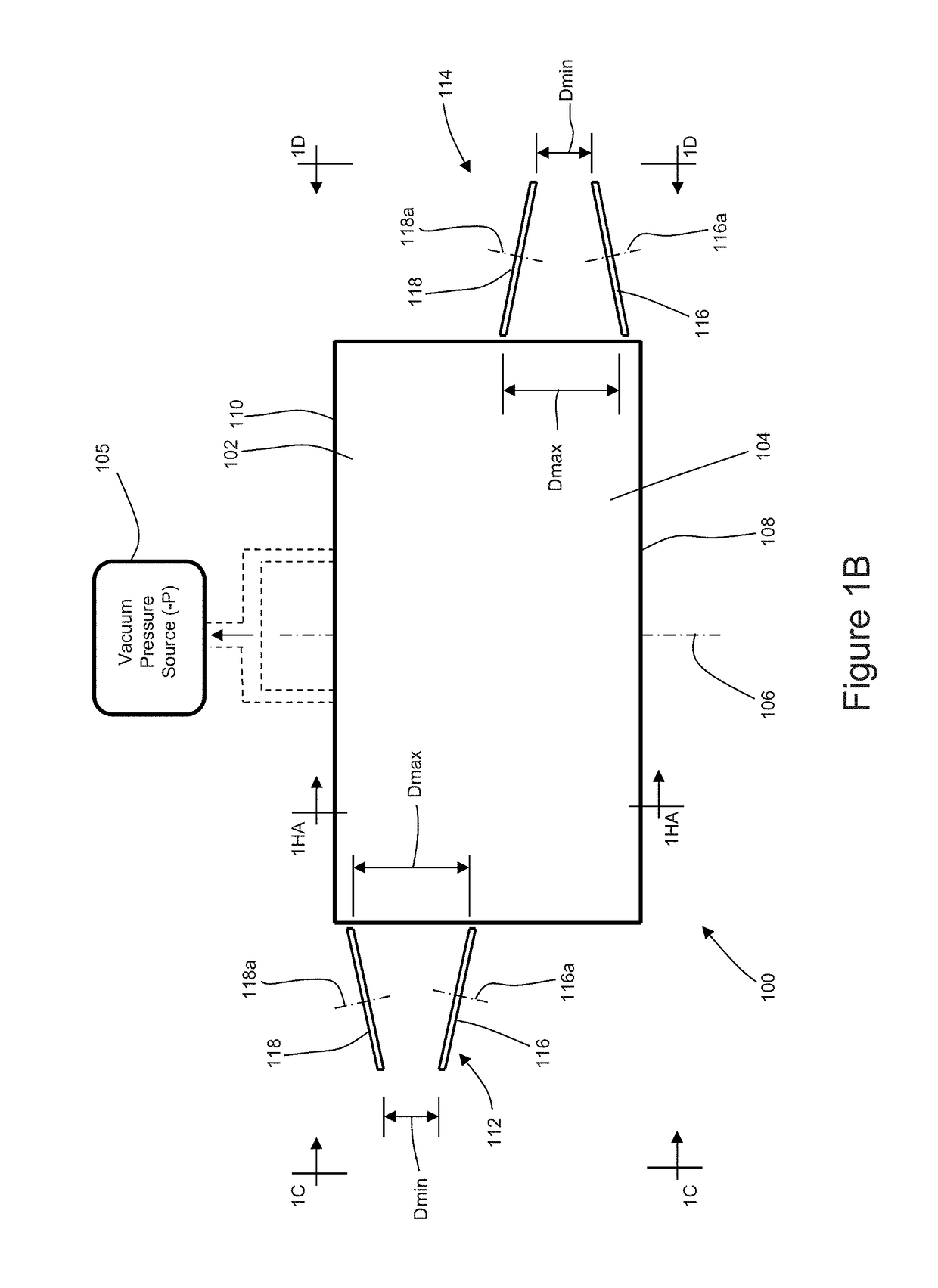

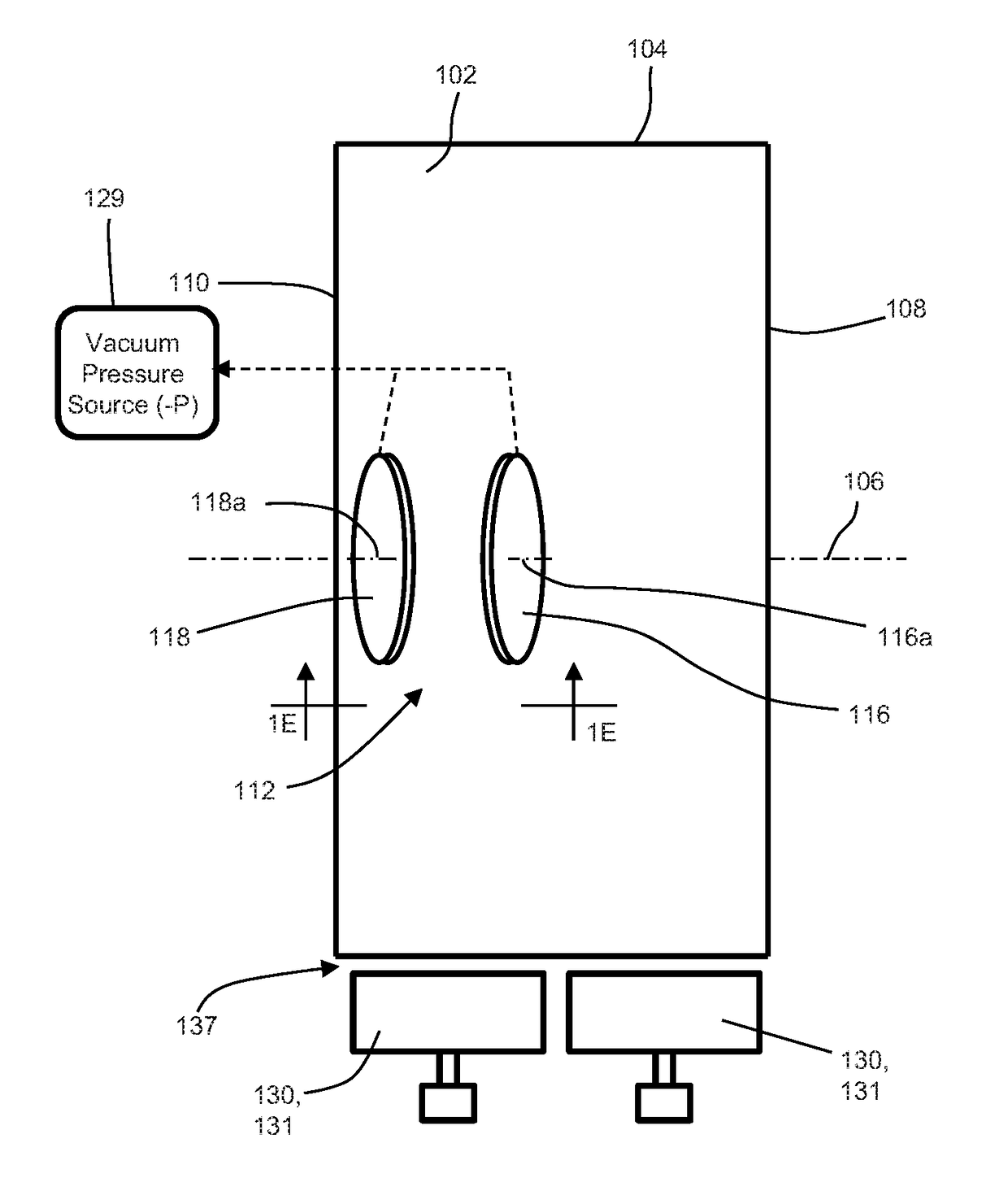

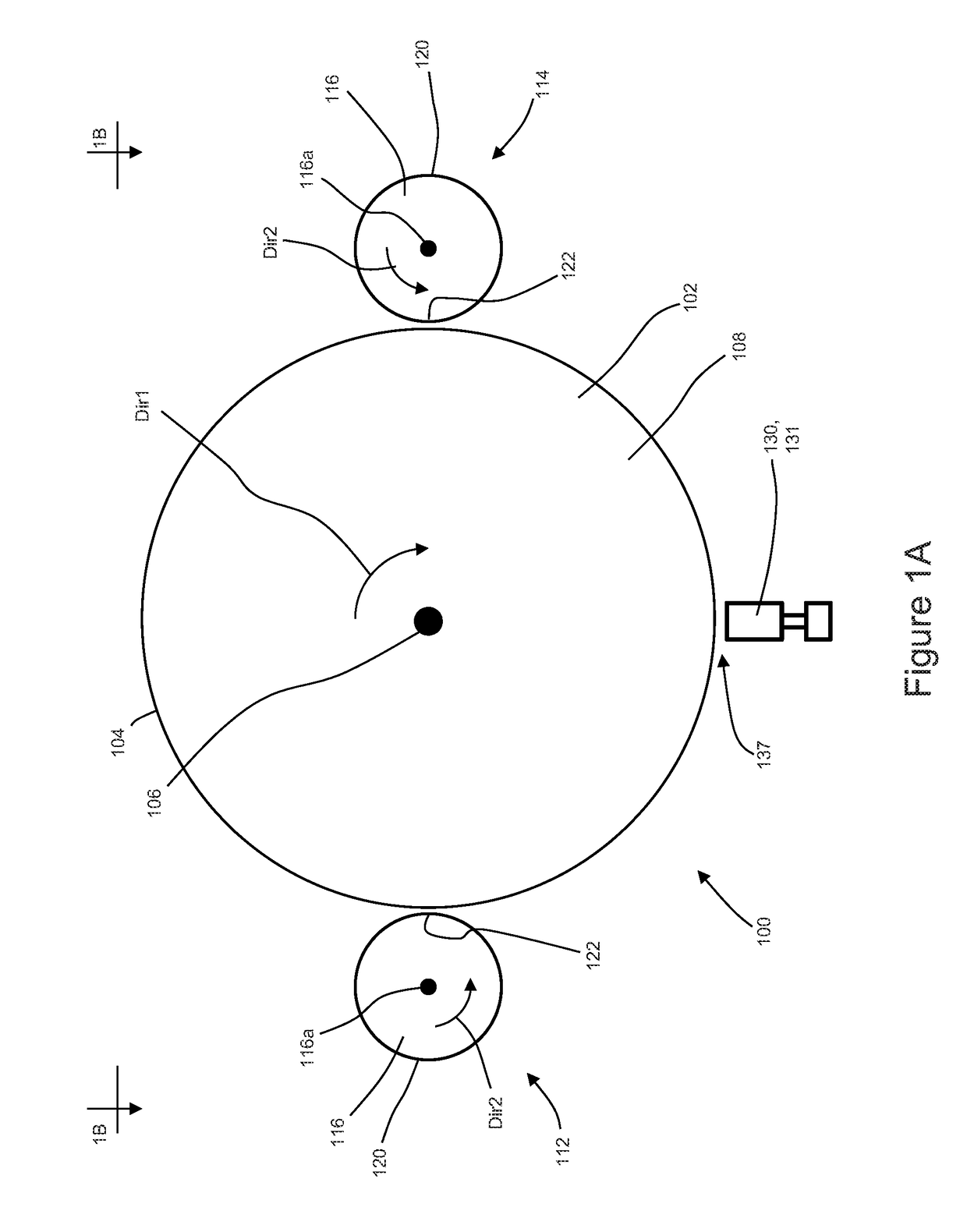

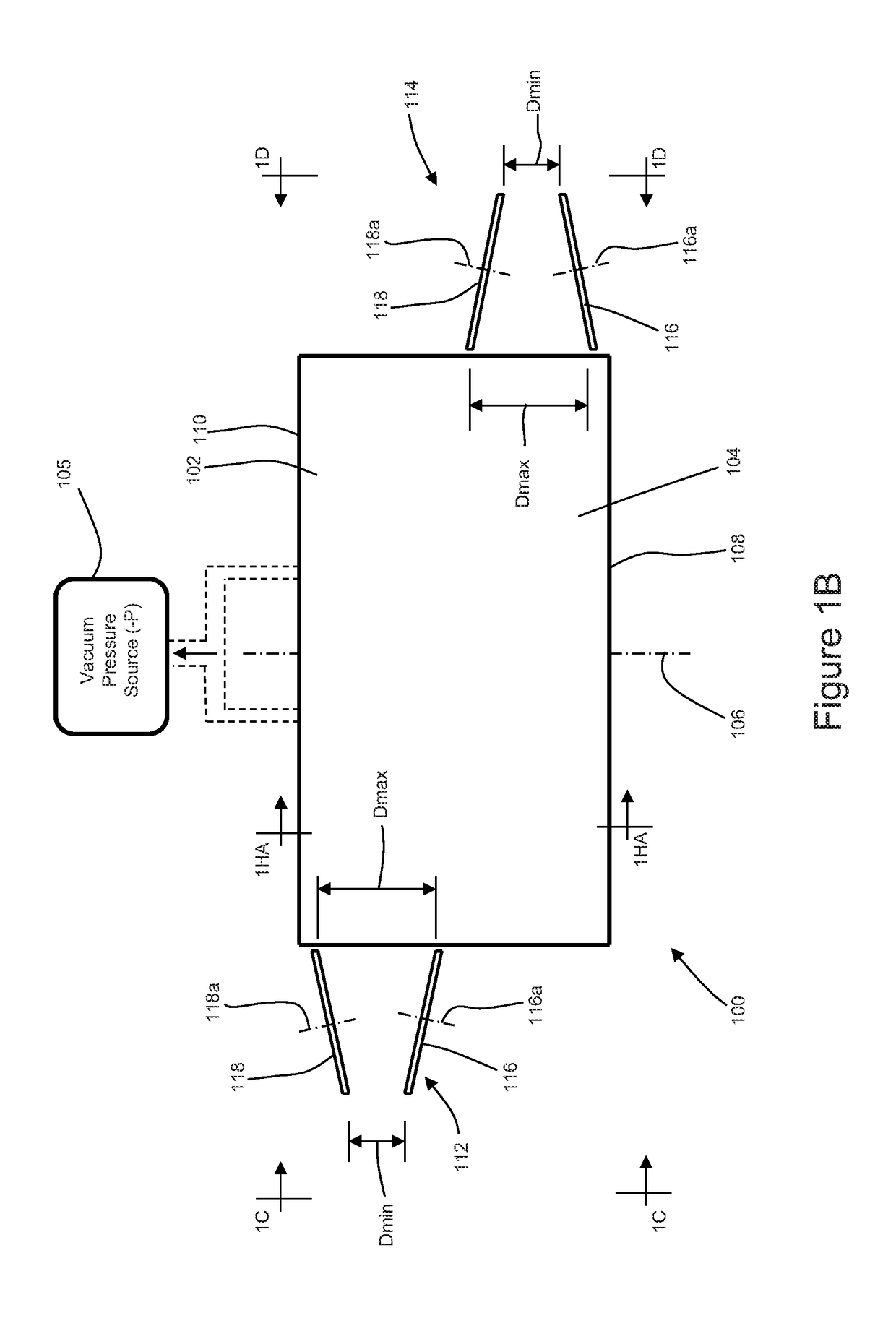

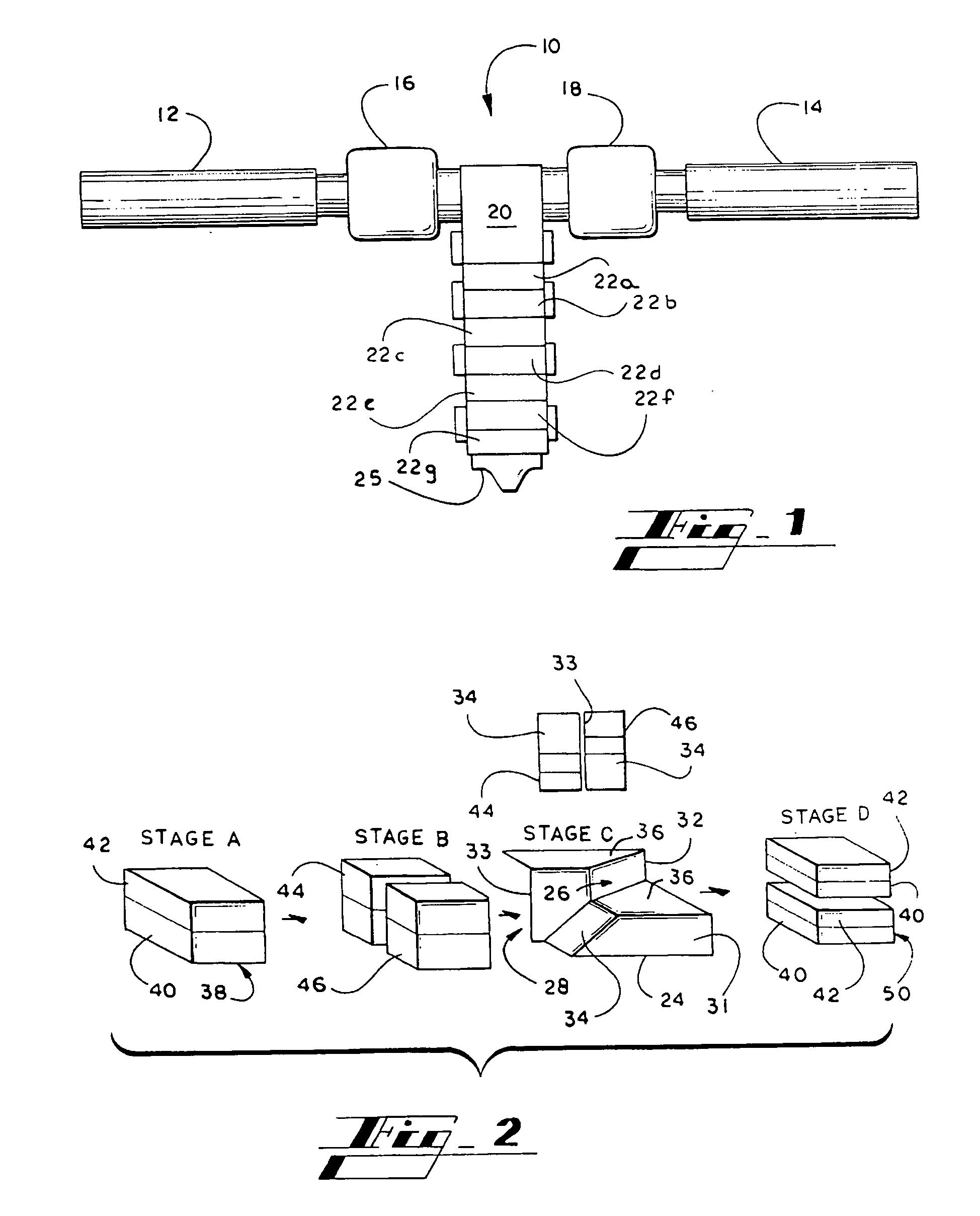

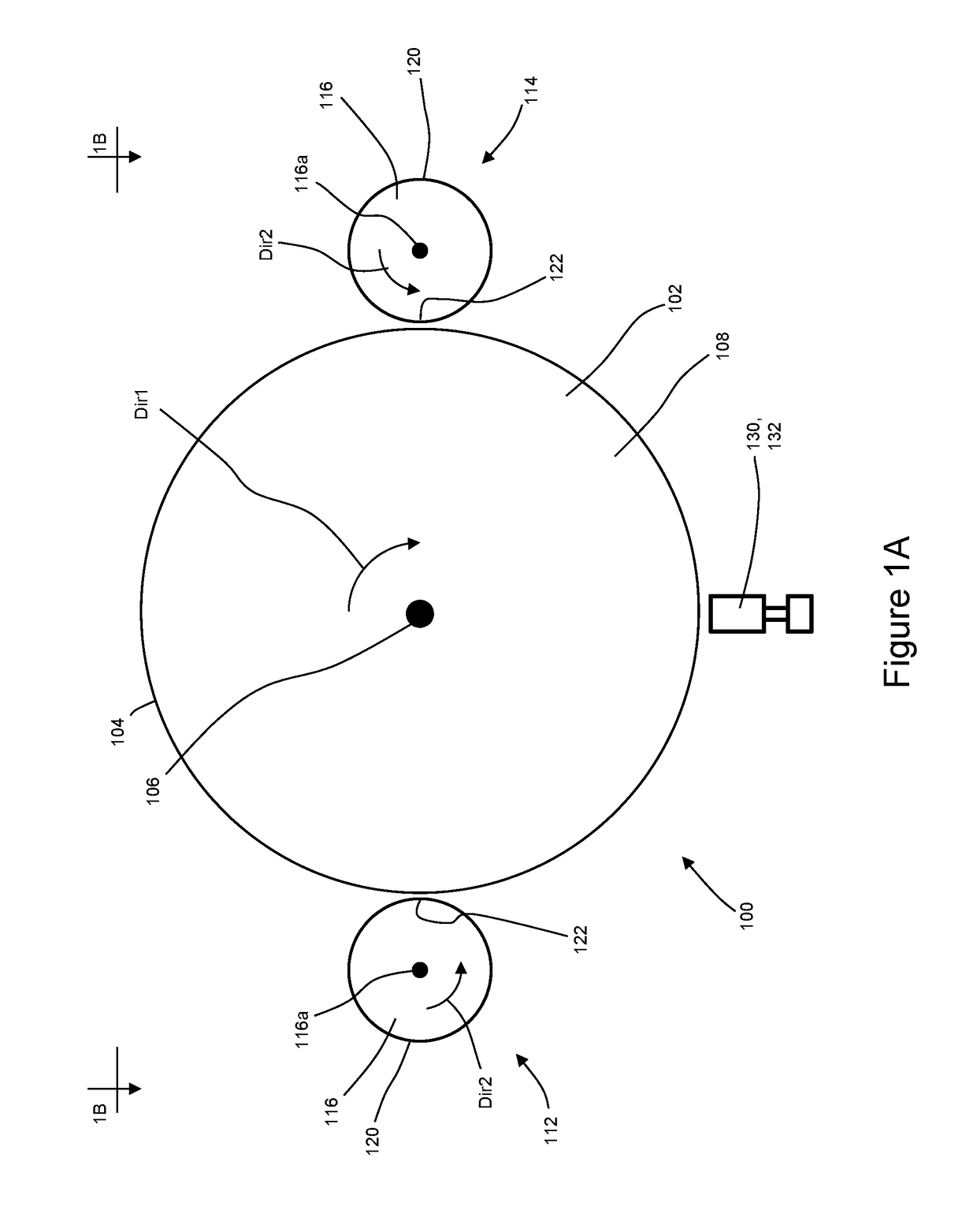

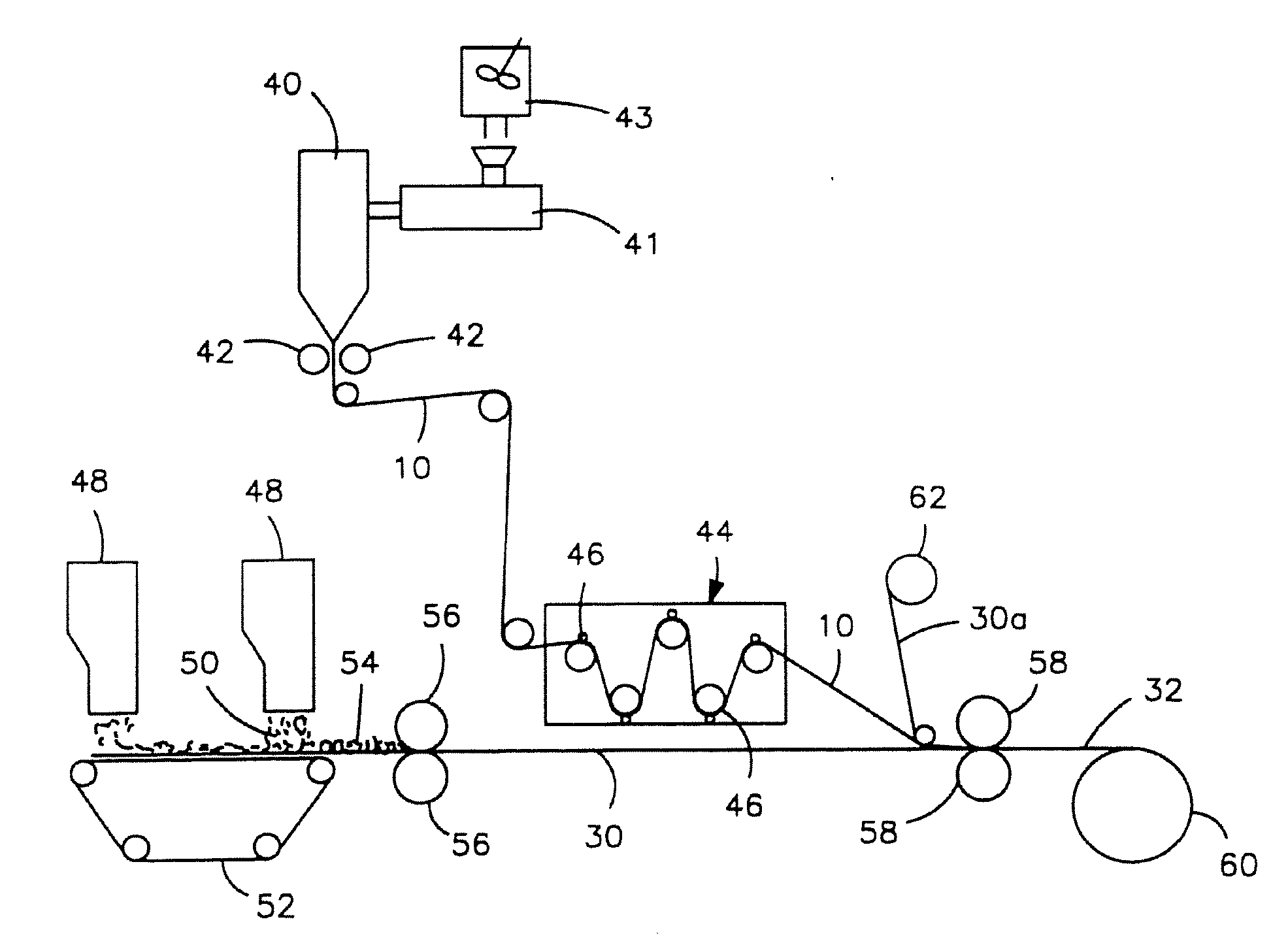

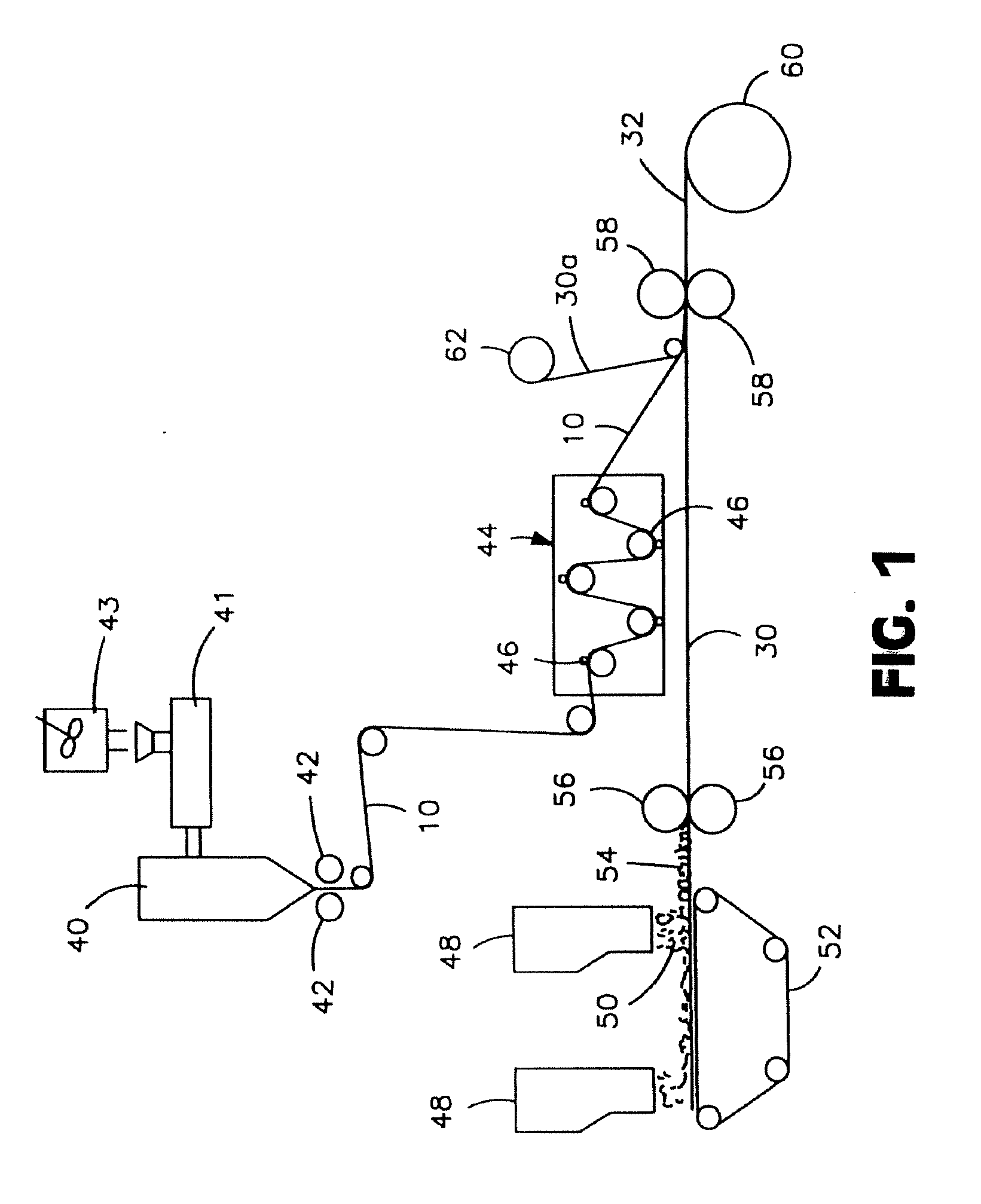

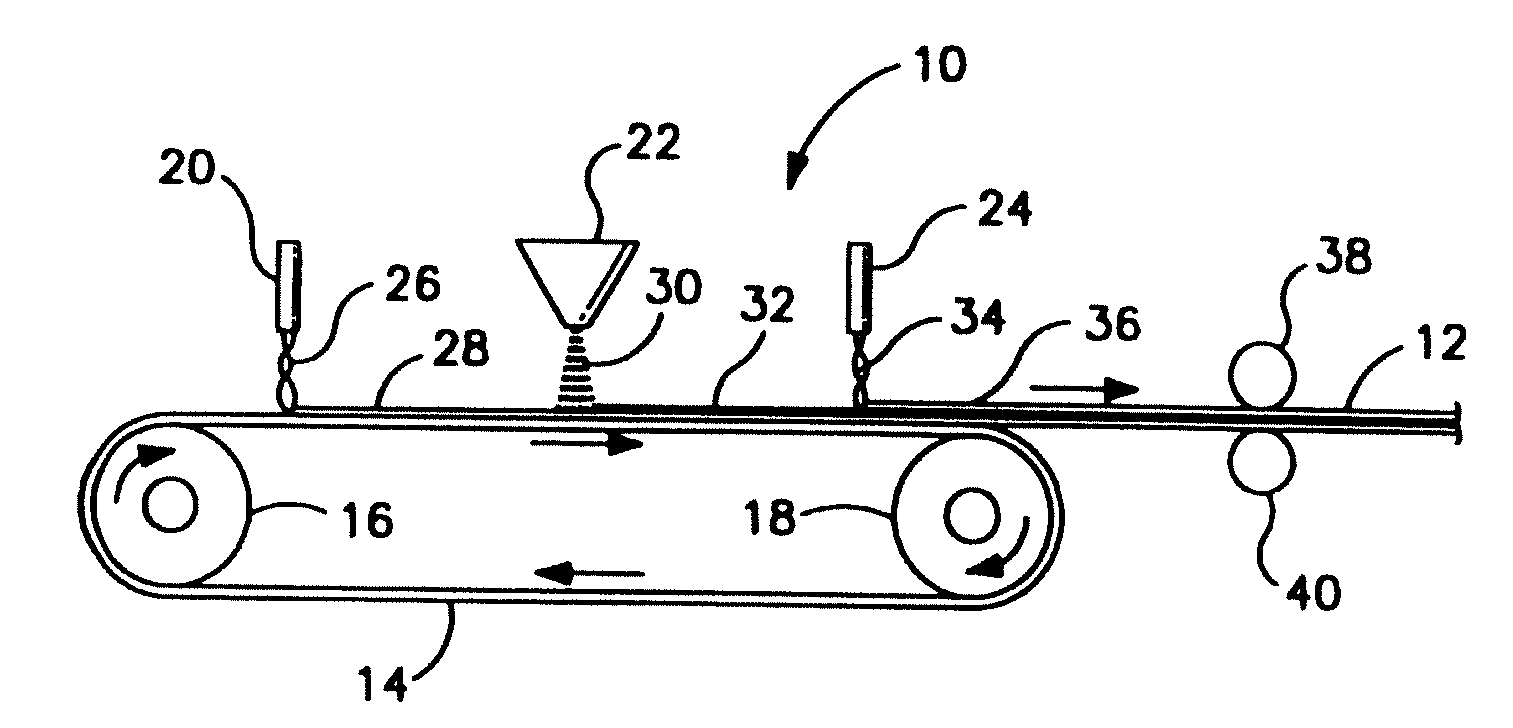

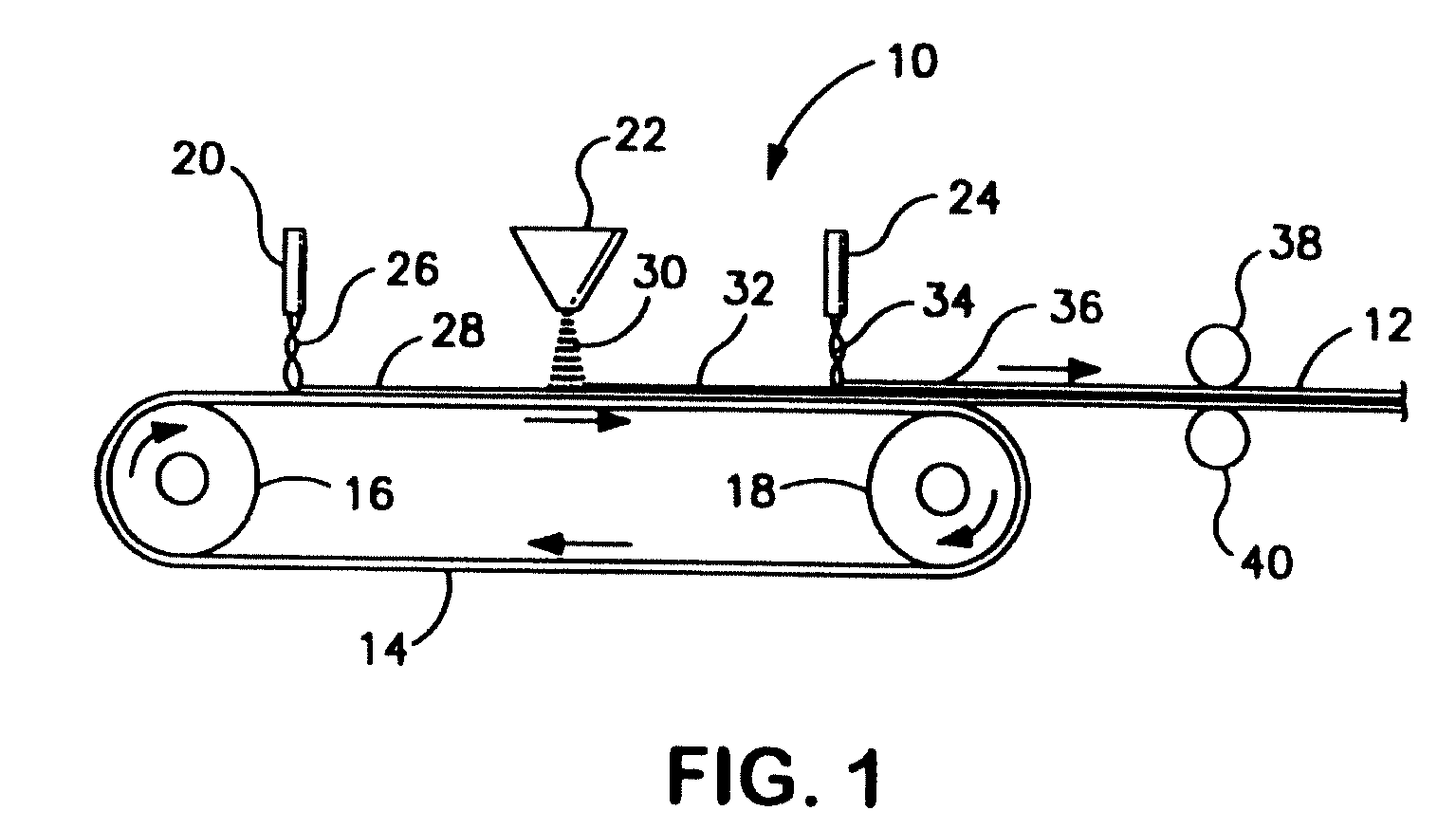

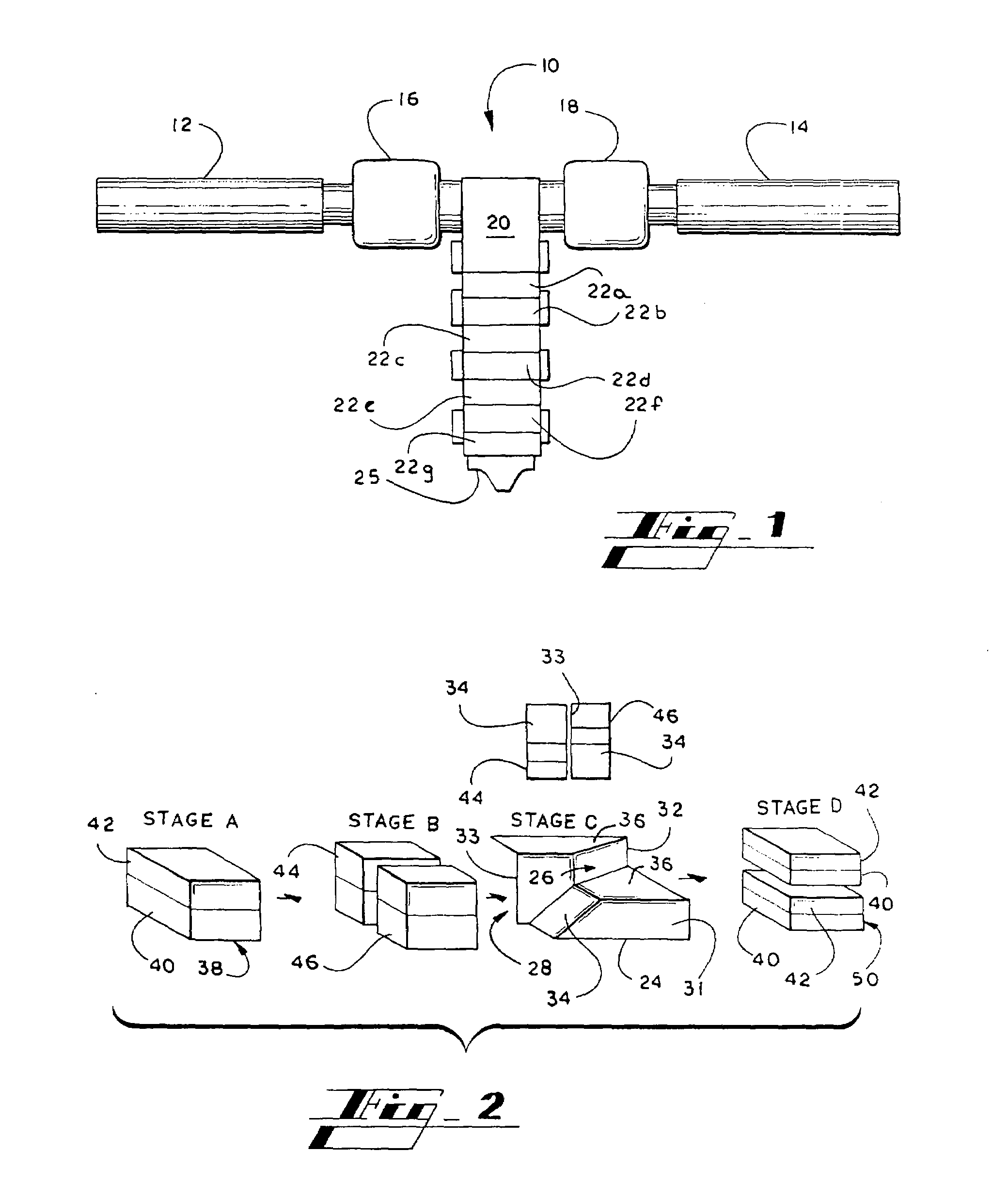

Method and Apparatus for Assembling Absorbent Articles

The present disclosure relates to assembling elastic laminates that may be used to make absorbent article components. Methods and apparatuses herein may include an anvil adapted to rotate about an axis of rotation, wherein first and second spreader mechanisms adjacent the anvil roll are axially and angularly displaced from each other with respect to the axis of rotation. During the assembly process, a substrate may be advanced in a machine direction onto the rotating anvil. The first spreader mechanism stretches a first elastic material in the cross direction, and the second spreader mechanism stretches a second elastic material in the cross direction. The stretched first and second elastic materials advance from the spreader mechanisms and onto the substrate on the anvil roll. The combined and elastic materials may then be ultrasonically bonded together on the anvil to form at least one elastic laminate.

Owner:THE PROCTER & GAMBLE COMPANY

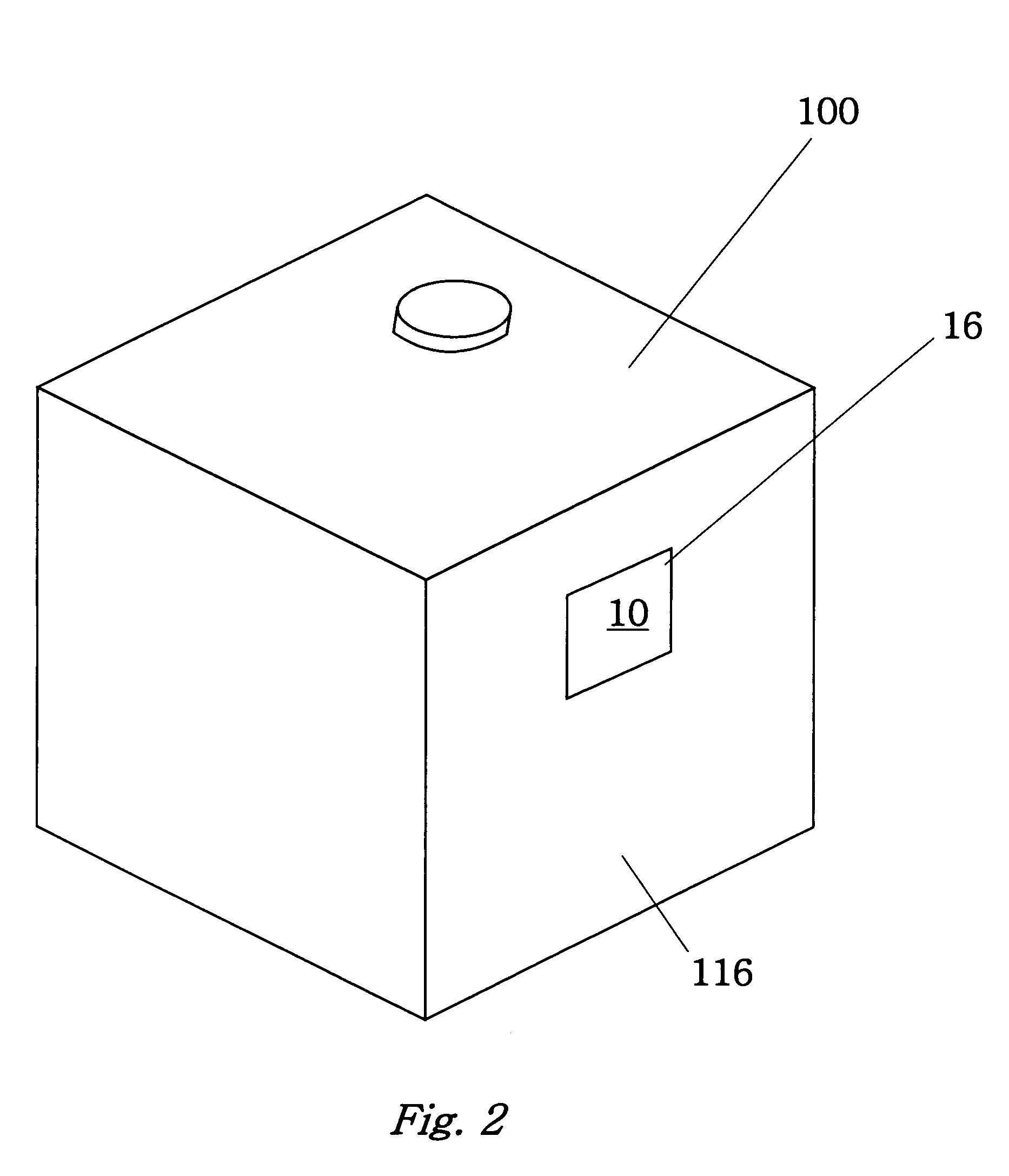

Patch repair system for collapsible fuel and water tanks

InactiveUS20050112968A1High crystallinityHighly elasticMedical patchesPolyureas/polyurethane adhesivesPolyesterElastomer

The invention is a patch system for repairing collapsible fuel tanks, water tanks, inflatable boats, and other articles fabricated from a flexible structural fabric coated with a polymer. The coated structural fabric is made of nylon or polyester synthetic fibers or a blend thereof, which are coated with a thermoplastic elastomer. The structural coated fabric is coated with a thermoplastic elastomer that is a urethane (TPU), or a TPU alloy polymer. Likewise, the patch is a urethane adhesive having a latent cure coated on a TPU film. The patch can also have an integral reinforcing fabric for applications requiring a higher tensile patch. In the invention, the urethane adhesive of the patch is solvent activated by the application of a thin coating of a volatile, substantially low odor, fugitive solvent like acetone or MEK. While in the activated state, the adhesive has much less cyrstallinity and a lot more tack. The solvent activated adhesive has good wetting, and aggressively wets out and adheres to the surface of the TPU coating on the tank. The activated adhesive side of the patch is pressed against the surface of the tank. The solvent will also partially etch the thermoplastic urethane polymer coating on the tank fabric, and rapidly diffuses therein, ultimately evaporating to the surroundings. The cross-linkable urethane adhesive contains a blocked isocyanate and, preferably, an uretdione. The reduced cyrstallinity in the adhesive imparts greater freedom to the blocked isocyanate that can, depending on the equilibrium of the system, begin to cross-link the adhesive. The curing process can be accelerated through the application of heat, albeit will slowly progress to a cured state at ambient conditions.

Owner:COOLEY

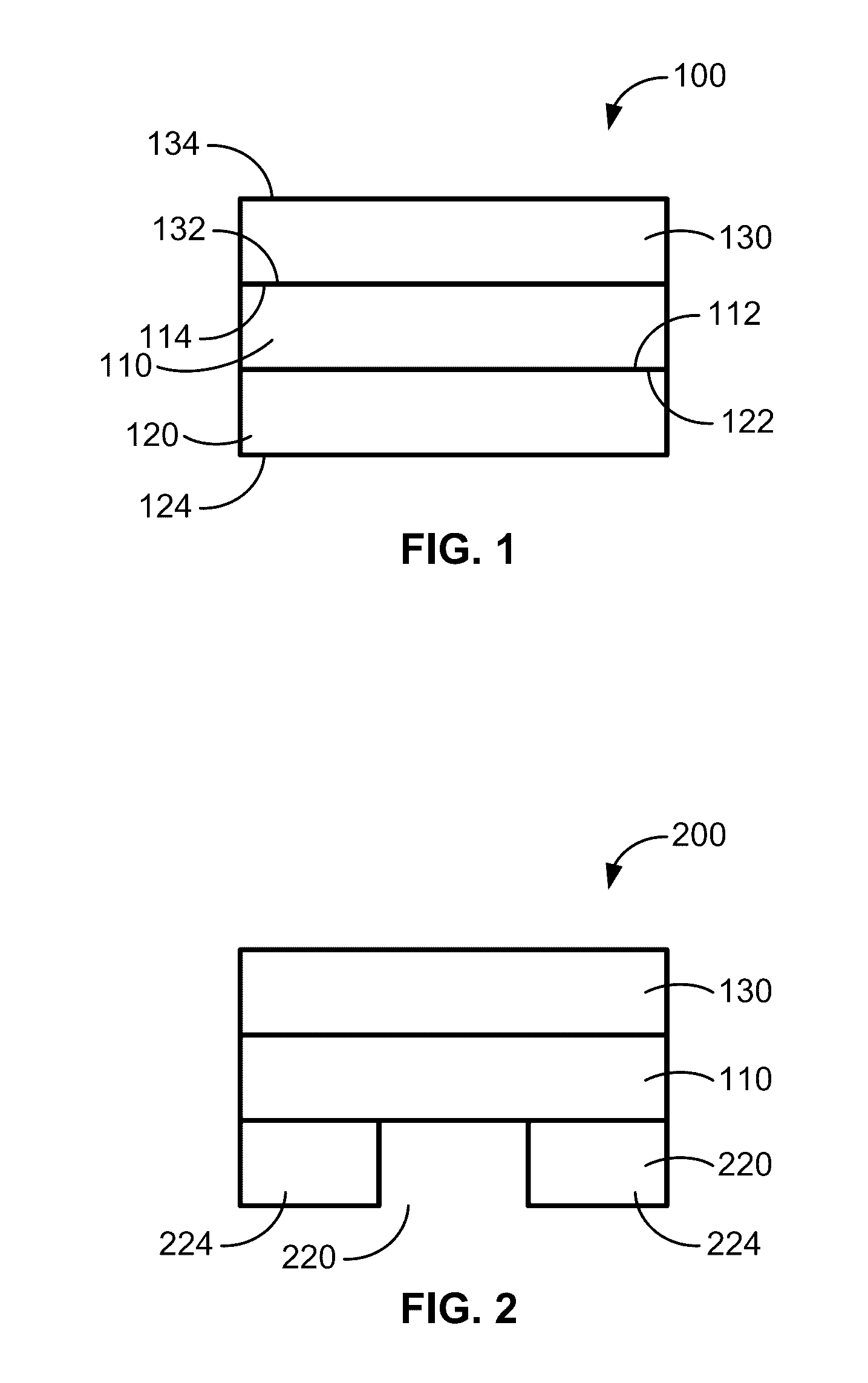

Elastic Laminates and Methods for Assembling Elastic Laminates for Absorbent Articles

The present disclosure relates to elastic laminates and methods for assembling elastic laminates that may be used to make absorbent article components. Elastic laminates may include one or more reinforcement layers positioned between unstretched portions of elastic materials and substrates to which the elastic materials are bonded.

Owner:THE PROCTER & GAMBLE COMPANY

Methods and apparatuses for assembling elastic laminates with different bond densities for absorbent articles

The methods herein relate to assembling an elastic laminate with a first elastic material and a second elastic material bonded between first and second substrates. During assembly, an elastic laminate may be formed by positioning the first and second substrates in contact with stretched central regions of the first and second elastic materials. The elastic laminates may include two or more bonding regions that may be defined by the various layers or components of the elastic laminate that are laminated or stacked relative to each other. In some configurations, a first plurality of ultrasonic bonds are applied to the elastic laminate to define a first bond density in the first bonding region, and a second plurality of ultrasonic bonds are applied to the elastic laminate to define a second bond density in the second bonding region, wherein the second bond density is not equal to the first bond density.

Owner:THE PROCTER & GAMBLE COMPANY

Stretchable composite sheet

Owner:KAO CORP

Dressings and bandages comprising same

InactiveUS20020015726A1Effect woundMedical patchesSynthetic resin layered productsSemi solidBULK ACTIVE INGREDIENT

The dressings of the invention comprise at least two components: an absorbent substrate having a first skin-facing surface and a second opposing surface; and a discontinuous coating of a semi-solid composition having an ointment-like feel overlying a portion of the first surface of said absorbent substrate. The absorbent substrate is useful as a passive dispenser of at least one active ingredient that may be contained therein. The discontinuous coating is essentially non-adherent to the skin and is useful as an active dispenser of at least one active ingredient that may be contained therein. In preferred embodiments the dressing of the invention contains at least one and more preferably at least two active ingredients intended to provide therapeutic benefit to the skin.

Owner:SCAMILLA ALEDO MARIA APARECIDA DE CARVALHO +3

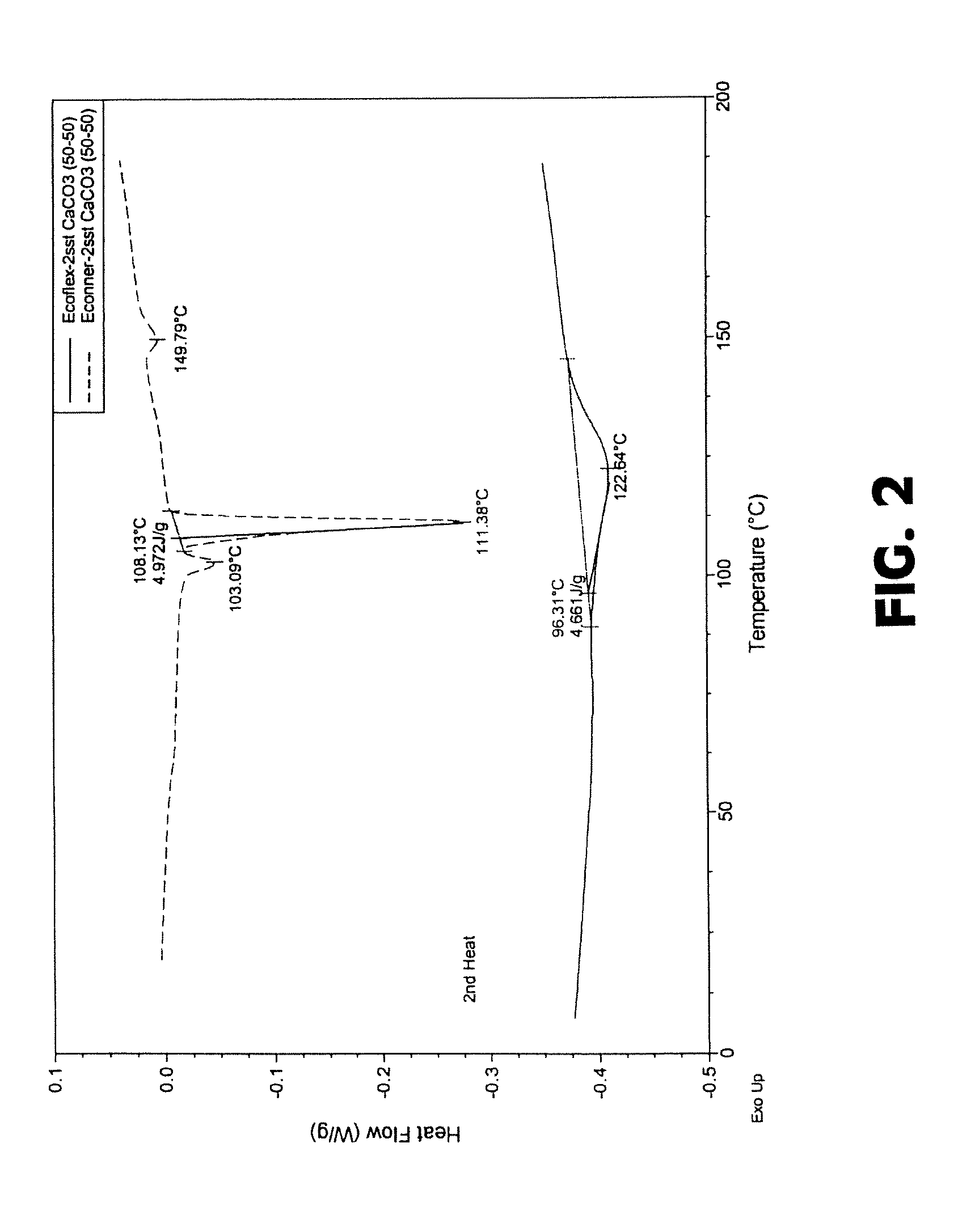

Degradable breathable multilayer film with improved properties and method of making same

A multilayer film includes a plastic layer and an elastomeric layer. The plastic layer and / or the elastomeric layer can contain filler particles, and may be present as a well bonded bilayer laminate. The plastic layer and a filled elastomeric layer can also be combined with an unfilled elastomeric layer to form a tri-layer laminate. The film has an average roughness of about 500 to about 1,000 nanometers. The multilayer films can provide breathable films with improved degradability, stretchability and recoverability, and tactile feel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

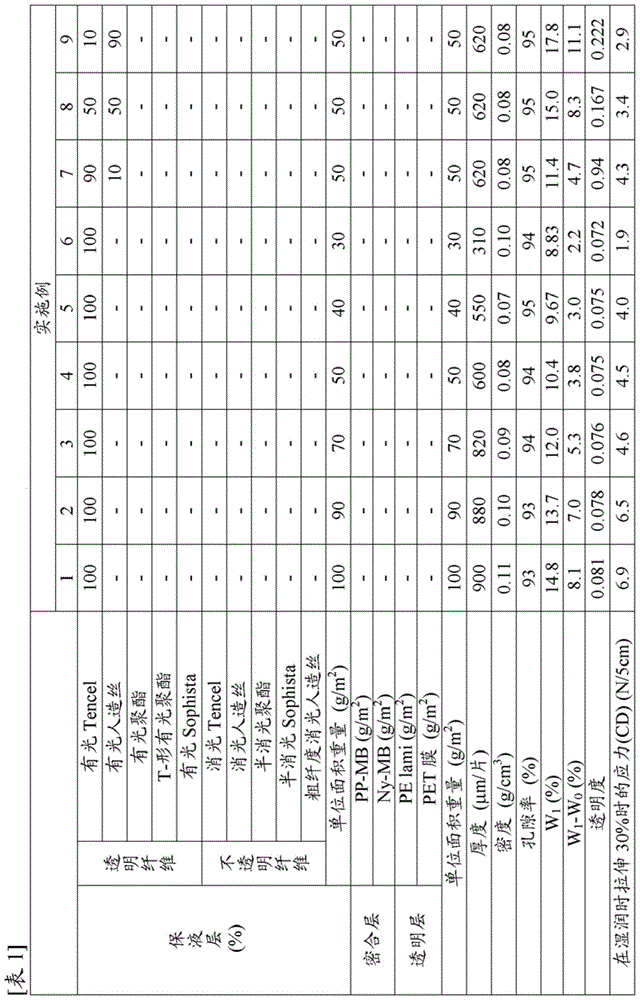

Liquid-retaining sheet and face mask

ActiveCN104487629AHigh transparencyImprove fitCosmetic preparationsMedical patchesPolymer scienceCellulose fiber

A liquid-retaining sheet formed from a nonwoven fiber aggregate comprising a liquid-retaining layer capable of absorbing a liquid component, in which the liquid-retaining layer comprises transparent fibers, wherein the degree of transparency as defined below is adjusted to 0.27 or less. Transparency = degree of white (%) / basis weight (g / m2) when the water content per sheet mass has been set at 700 mass%. The transparent fibers can comprise cellulose fibers that are essentially free of carboxyl groups. Even though the liquid-retaining sheet comprises a nonwoven fiber aggregate, it is possible to improve transparency in a wet state and to realize optimal strength in a wet state. This sheet is used in a skin care sheet or face mask impregnated by a liquid component containing a cosmetic.

Owner:LENZING AG

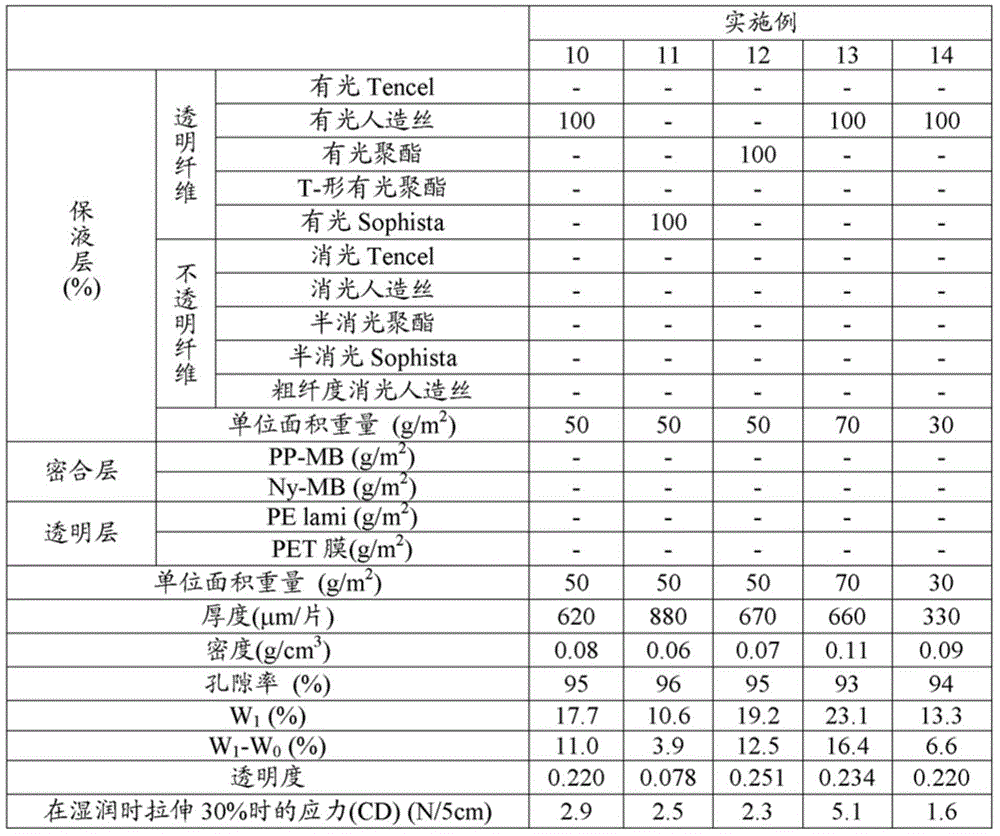

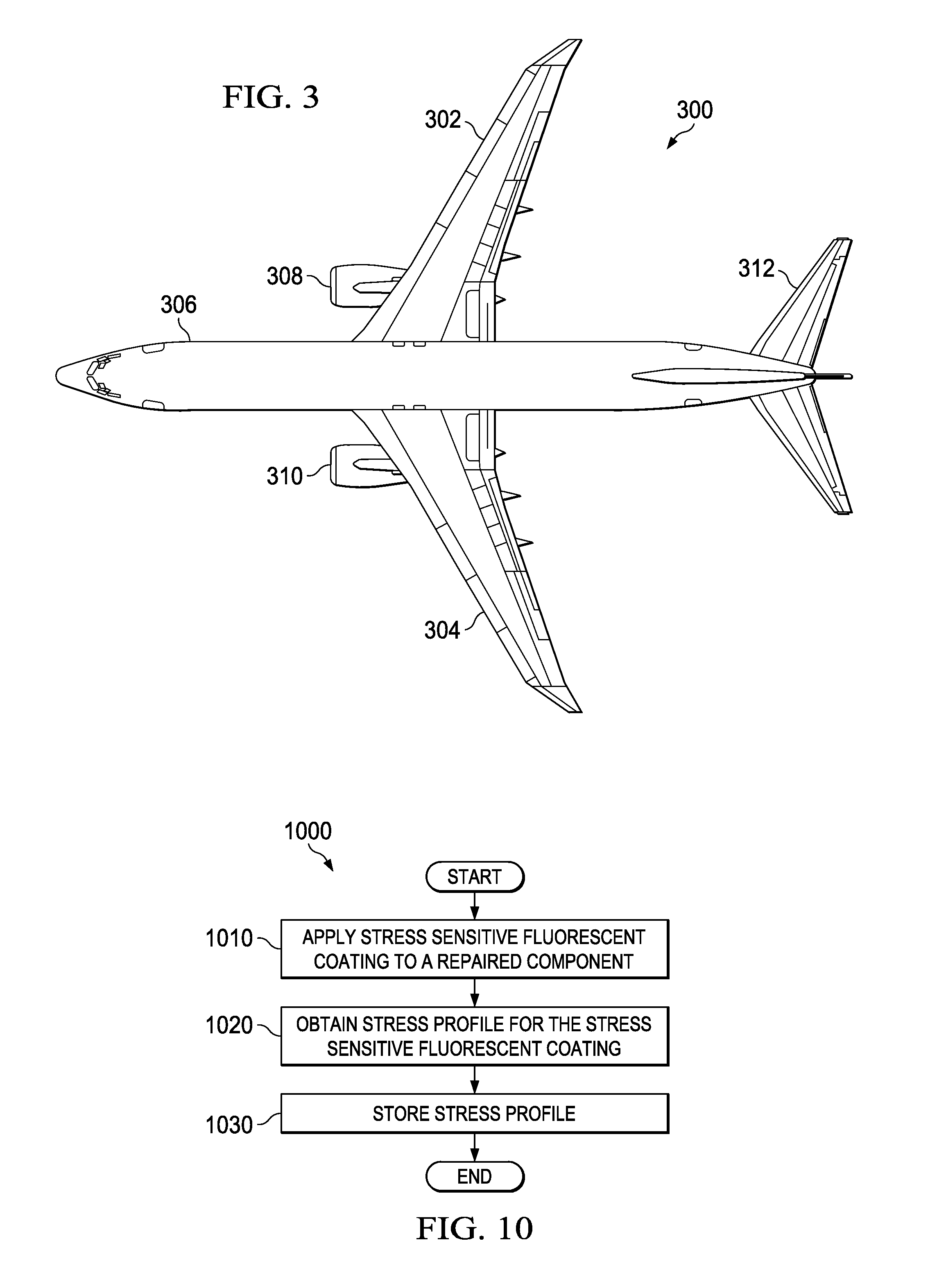

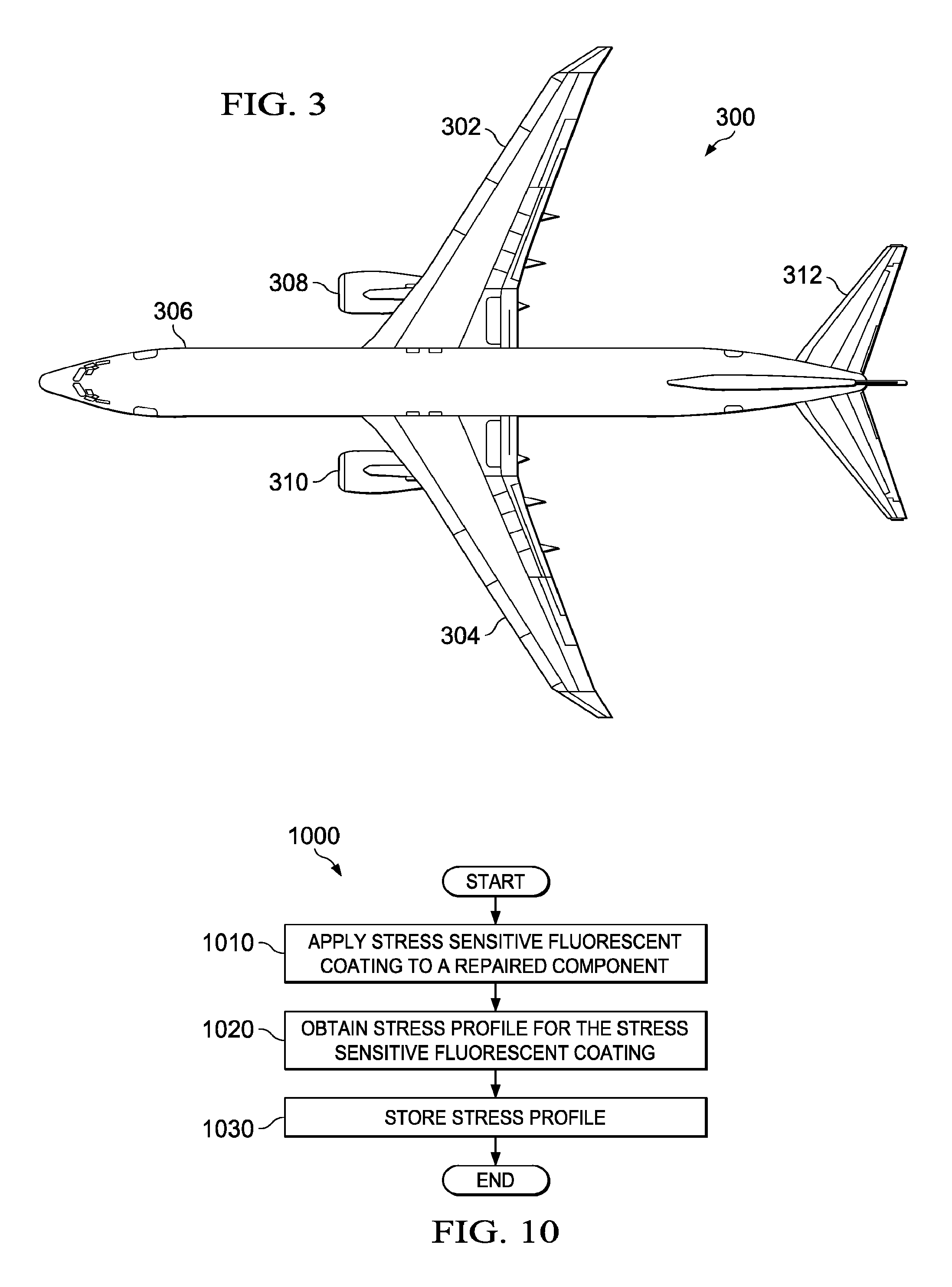

Structural repair having optical witness and method of monitoring repair performance

ActiveUS9085052B1Performance can be quickly and easyAvoid weightMedical patchesControlling laminationFluorescenceLength wave

A structural repair includes a tell-tale optical witness that allows the health of the repair to be visually monitored. The optical witness includes a stress sensitive fluorescent dye that shows changes in local strain / stress patterns when the repair is subjected to electromagnetic energy of a particular wavelength. The dyes fluoresce more or less strongly as a function of the local stress / strain.

Owner:THE BOEING CO

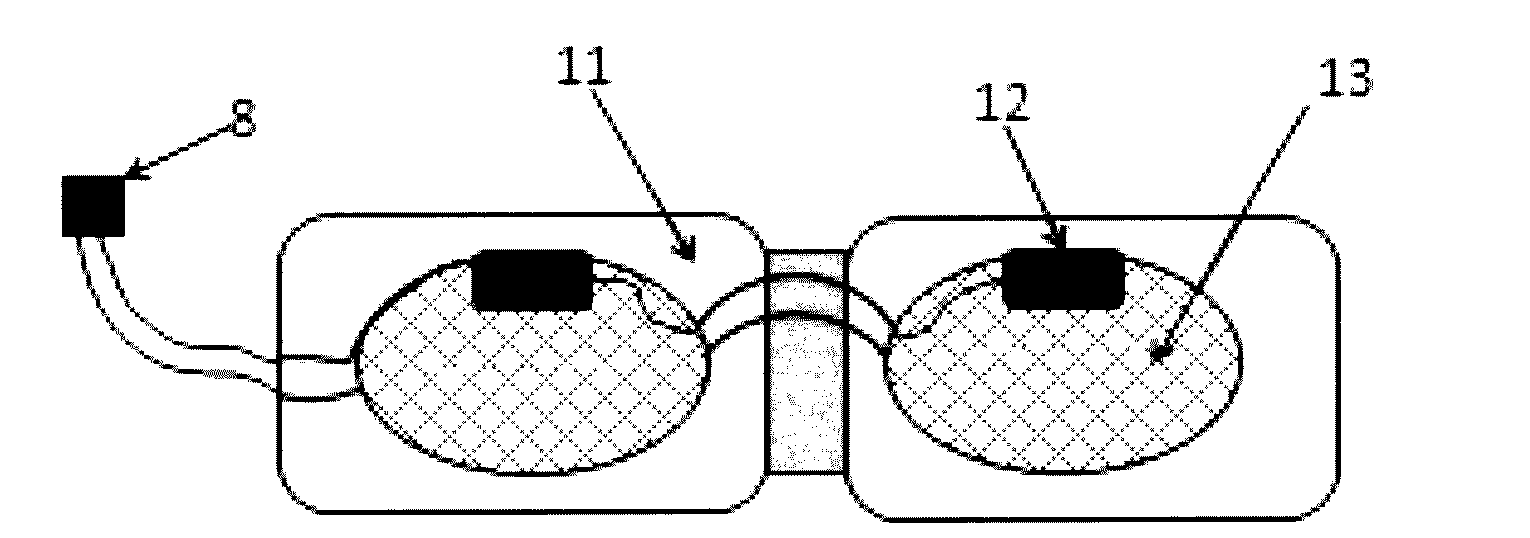

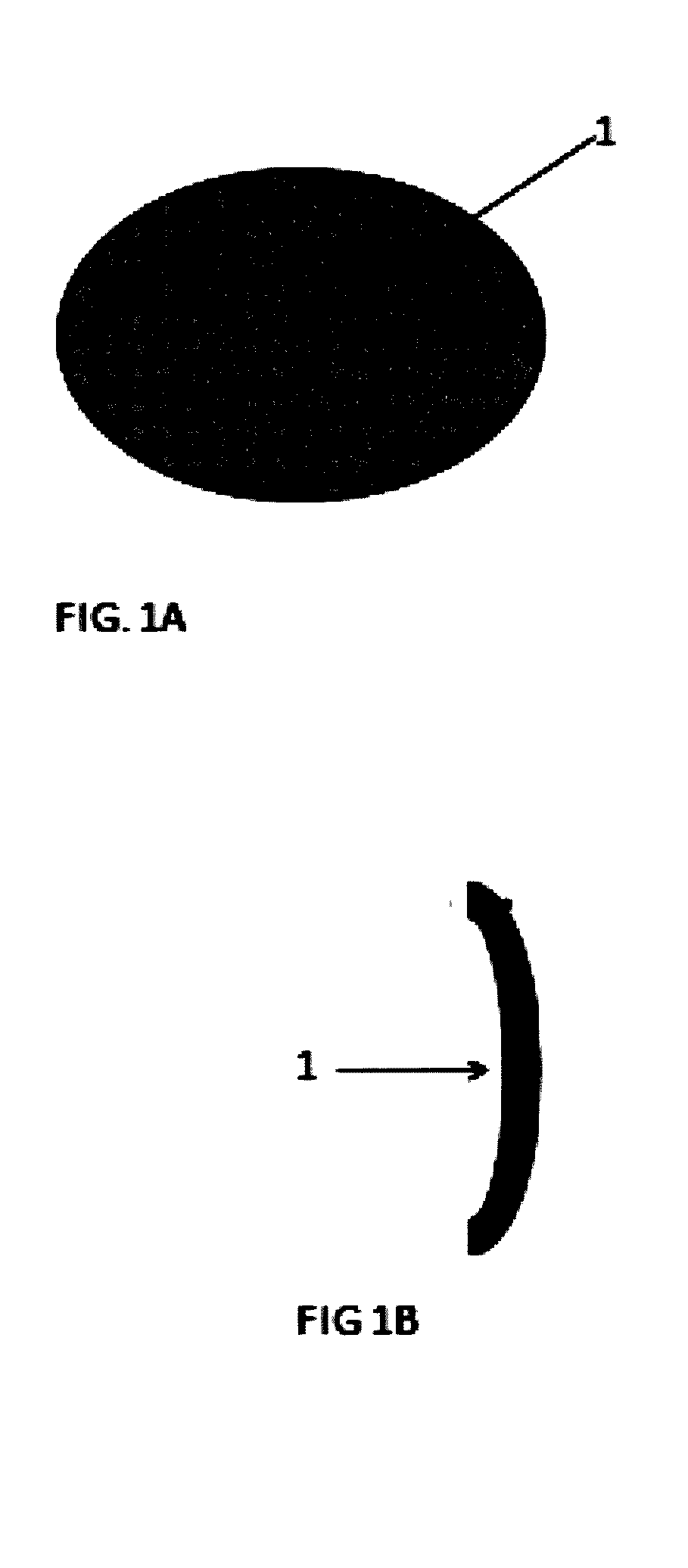

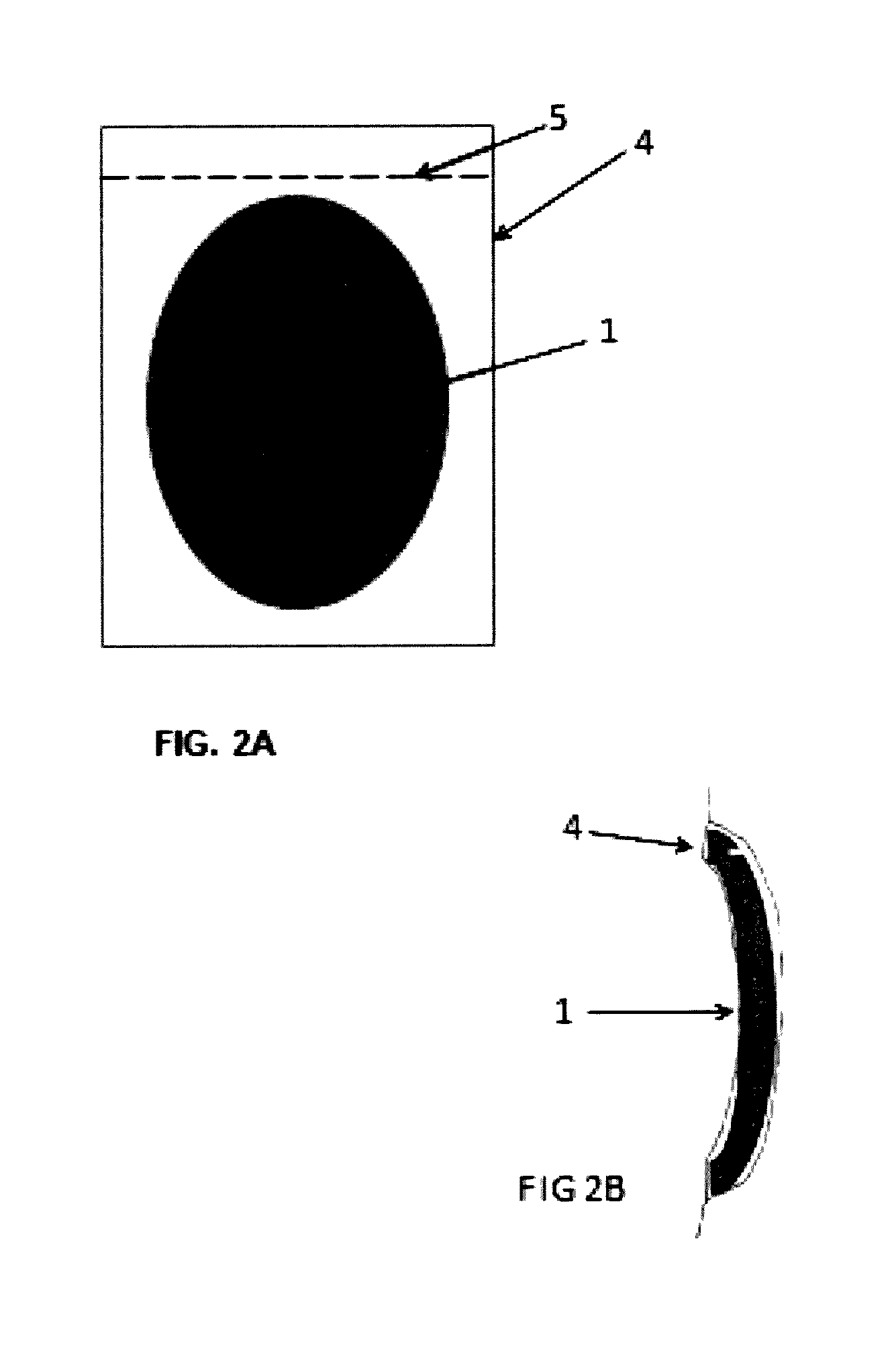

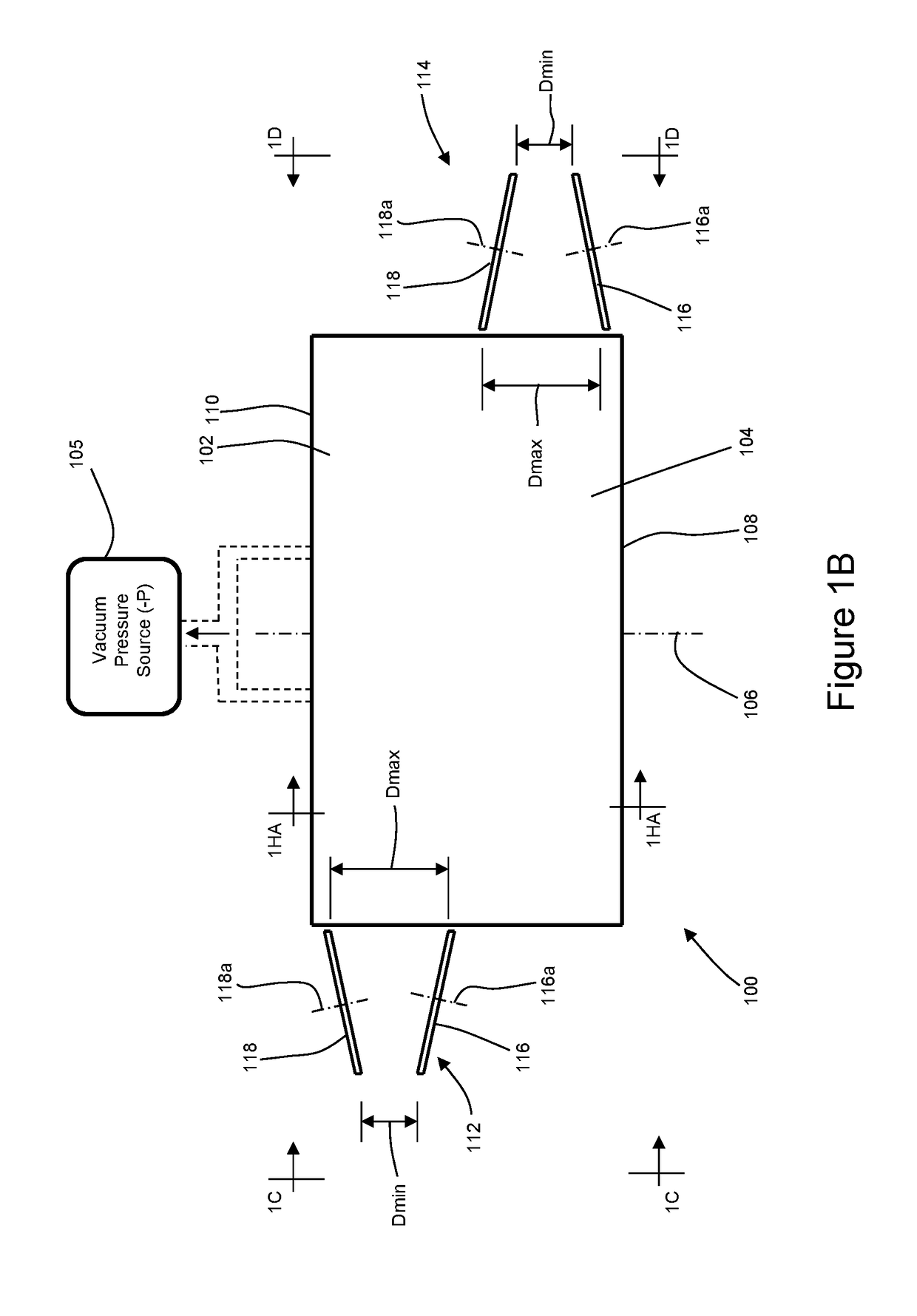

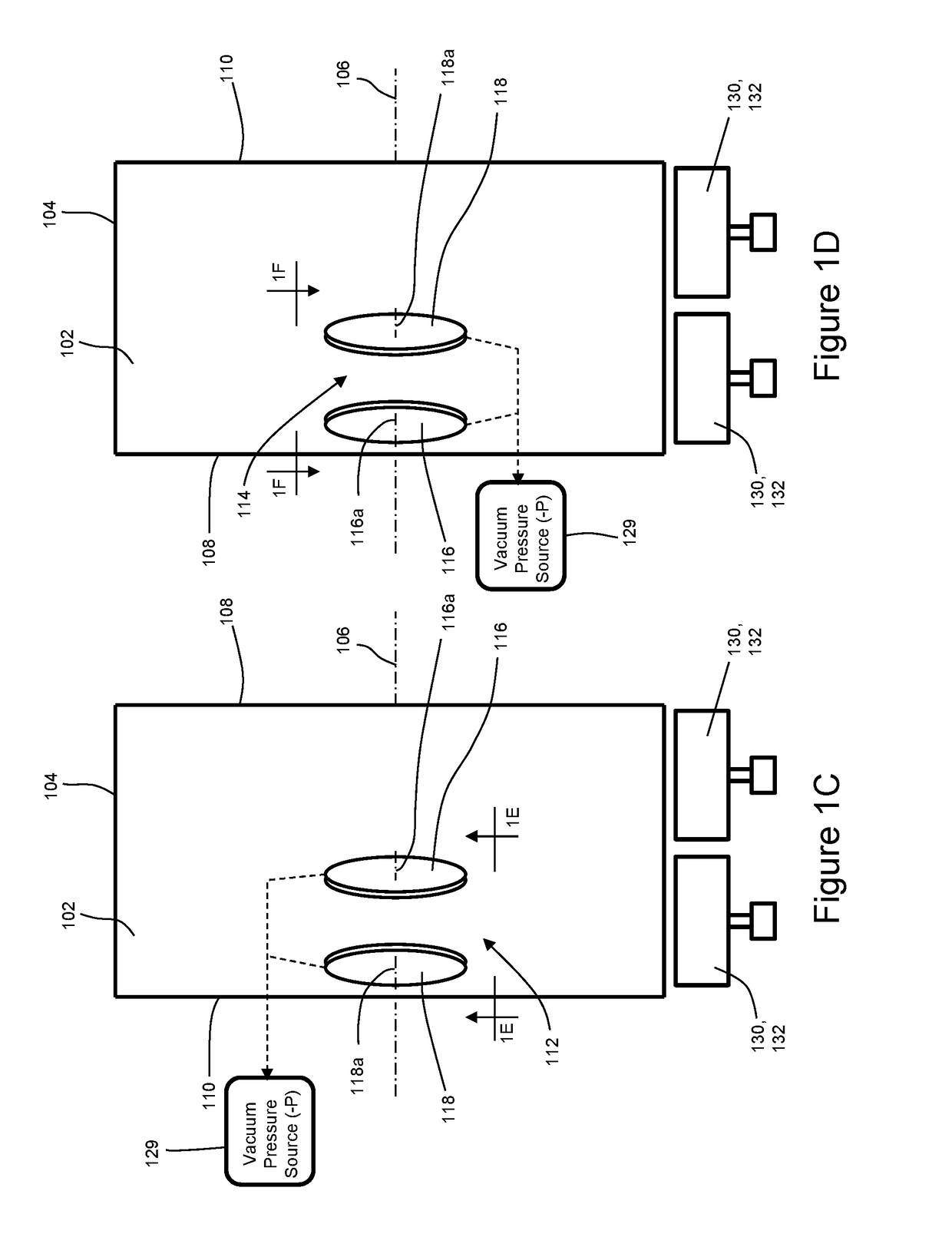

Moldable heater with Miniature Resonant Frequency Vibration Generator for Ophthalmic Eyelid Therapy

PendingUS20170014300A1Precise deliveryEncourage flowMedical patchesProtective equipmentExternal energyMedicine

A combined eyelid warming device, resonance frequency generator, coupling device, and tissue response sensor are disclosed in the field of use in dry eye treatment. These combined devices are used to ensure that the entire eyelid surface and periorbital structures receive defined therapeutic warmth and appropriately tuned harmonic resonance frequency for a required period of time to stimulate flow from the Meibomian glands. The combined elements of the invention include an easily moldable heating disc, targeted formulation of the heating material, miniaturized resonant frequency vibrating generator combined with a properly designed reusable mask, to ensure precise location of the heat. Vibration may be delivered continuously or intermittently, and may be delivered according to one or more patterns. A chemical sensor is included to characterize flow as vibration is varied. The external energy source allows for circuitry in the external power module to act as a sweep range device, targeting the specific optimally tuned point or sweep frequency the individual patients body reacts to during initial use. The initial testing device supplied to the Doctor for treatment would include sensing elements to determine the optimal harmonic resonance frequency. Once the frequency is defined, the patient would receive a kit with custom harmonic resonant frequency vibrating generators set to their optimum parameters. This configuration would be amenable to both single use and reusable heater approaches.

Owner:EYEDETEC MEDICAL

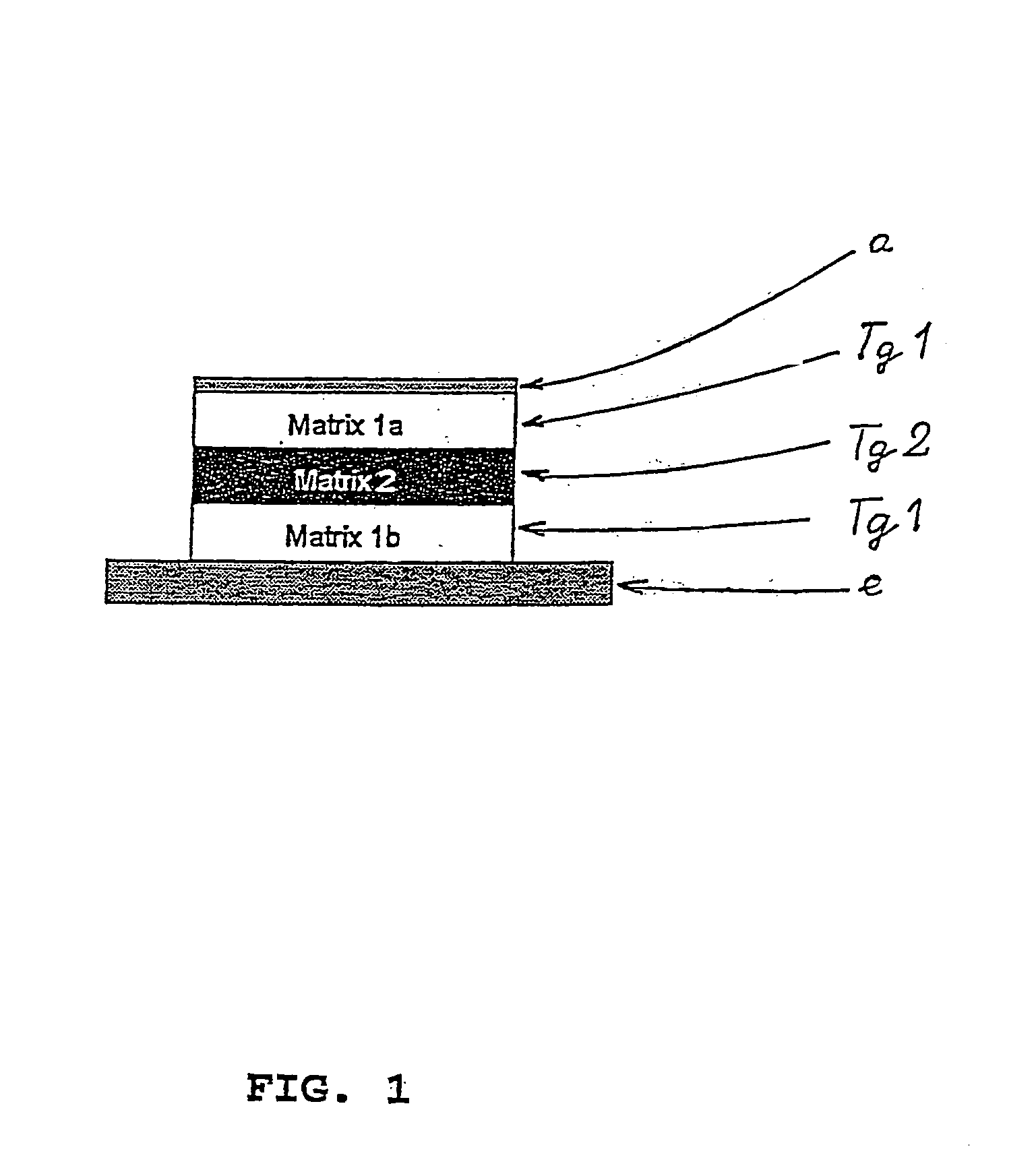

Therapeutic system containing an active substance for the application on the skin which contains at least two polymerous layers

InactiveUS20050136101A1Improve cohesionReduce cold flowPowder deliveryMedical patchesVitrificationGlass transition

Owner:LTS LOHMANN THERAPIE-SYST AG

Reinforced fiber mats for use in paved surfaces

InactiveUS20130156501A1Easy to shapeGood for scrollingIn situ pavingsMedical patchesFiberEngineering

A reinforcement mat that can be used to improve the durability and life of an asphalt paved surface. The reinforcement mat is partially or fully coated with a resin. The resin generally has a cure temperature in excess of about 140° F.

Owner:HEMPHILL WILLIAM SCOTT

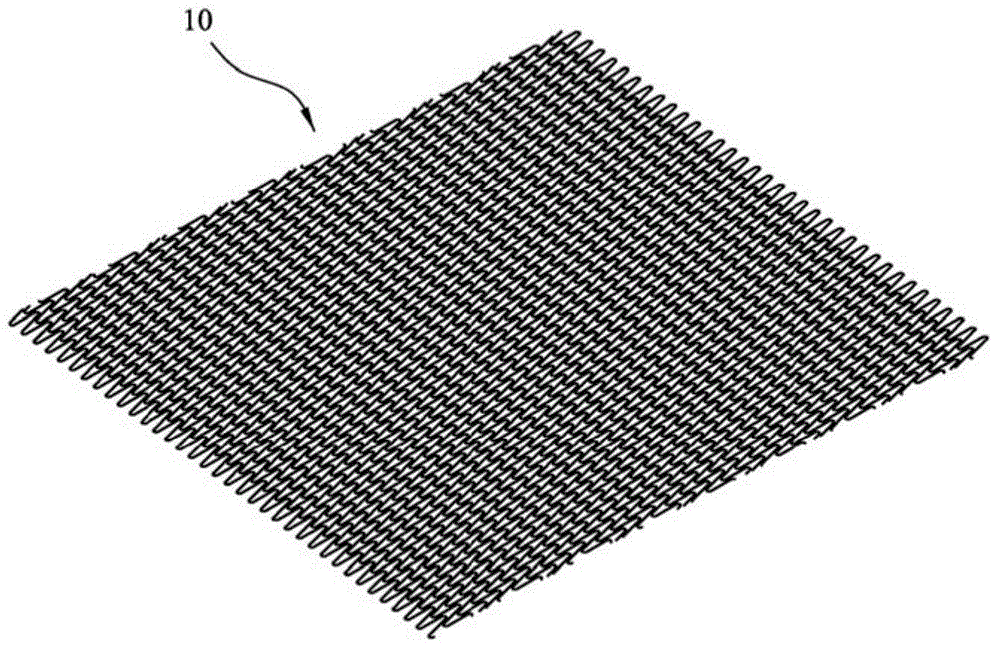

Wound dressings, and yarn useful therein

Wound dressings, methods for their production and components for use therein. A knitted structure comprising a blend of gelling fibres and non-gelling fibres wherein the yarn comprises at least 50% w / w gelling fibres, a three-dimensional textile material comprising gelling fibres, and a yarn comprising a blend of gelling and non-gelling fibres which may be used in their production, the knitted structure and three-dimensional textile material beings suitable for use as wound dressings or as components of composite wound dressings. The wound dressings may be adapted for use in negative pressure wound therapy (NPWT). It has been found that the incorporation of gel-forming fibres provides a material which has a high absorbency, enabling good transfer of exudates away from a wound, which retains structural integrity, and which is non-adherent and easily removed from the wound.

Owner:BRIGHTWAKE

Elastic Laminates and Methods for Assembling Elastic Laminates for Absorbent Articles

The present disclosure relates to elastic laminates and methods for assembling elastic laminates that may be used to make absorbent article components. Elastic laminates may include one or more reinforcement layers positioned between unstretched portions of elastic materials and substrates to which the elastic materials are bonded.

Owner:PROCTER & GAMBLE CO

Film Formed from a Blend of Biodegradable Aliphatic-Aromatic Copolyesters

A film that is formed from a biodegradable polymer blend of different aliphatic-aromatic copolyesters is provided. More specifically, the blend contains a first copolyester formed from a terephthalic acid monomer. The use of a terephthalic acid monomer results in a polymer chain containing 1,4-(para-) terephthalate units linked in a generally linear configuration (e.g., ˜180°). The blend also contains a second aliphatic-aromatic copolyester formed from a phthalic acid and / or isophthalic acid monomer. The use of such a monomer results in a polymer chain containing 1,2-(ortho-) and / or 1,3-(meta-) linked units. The inclusion of 1,2-(ortho-) and / or 1,3-(meta-) linked units into the polymer backbone of the second copolyester introduces an angle or “kink” (e.g., ˜120° kink for a 1,3-linkage) into the otherwise linear polymer chain. The “kinks” in the second copolyester backbone reduce its melting point and degree of crystallinity, which have an influence on its physical properties (e.g., toughness, tensile strength, and crystallization rate). Thus, the physical properties of the second copolyester may differ substantially from those of the first copolyester. In this regard, the “kinked” second copolyester can provide flexibility for forming films with a wide range of properties that is superior to that which may be achieved using either of copolyesters alone.

Owner:KIMBERLY-CLARK WORLDWIDE INC

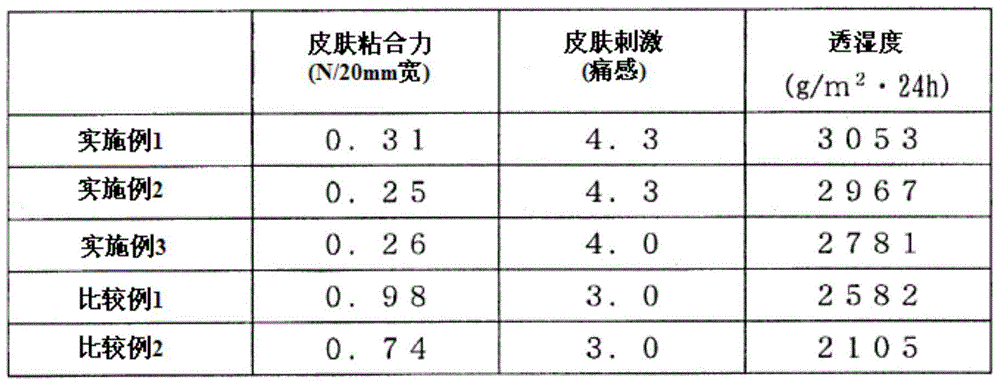

Facial Patch

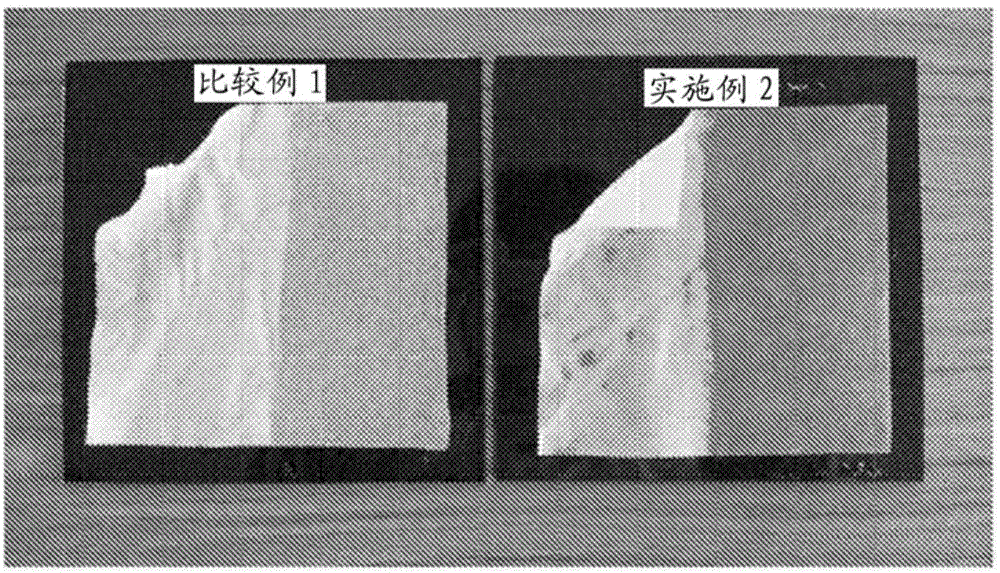

ActiveUS20150320606A1Less irritatingLess residual adhesiveHead bandagesMedical patchesMass ratioStyrene-isoprene-styrene block copolymer

Provided is a facial patch including a support, a pressure-sensitive adhesive layer, and a release layer in this order, in which (a) the pressure-sensitive adhesive layer satisfies the following conditions (a-1) to (a-3): (a-1) the pressure-sensitive adhesive layer contains a styrene-isoprene-styrene block copolymer, a tackifier resin, and a softening agent; (a-2) the ratio (mass ratio) of the styrene-isoprene-styrene block copolymer and the tackifier resin is 1:2 to 1:4; and (a-3) the content of the softening agent is 40% to 60% by mass; and (b) the support has elastic moduli with a Young's modulus of 0.01 GPa to 0.5 GPa, and also provided is a method for producing the facial patch, the method including a step of forming a pressure-sensitive adhesive layer on the upper surface of the release layer.

Owner:NICHIBAN CO LTD

Patch repair system for collapsible fuel and water tanks

InactiveUS7306851B2High crystallinityHighly elasticMedical patchesFibre treatmentCross-linkPolyester

Owner:COOLEY

Antistatic breathable nonwoven laminate having improved barrier properties

InactiveUS20090156079A1Increasing the alcohol repellency of a nonwoven webAdversely affectingMedical patchesLayered productsPolymer scienceAlcohol

A nonwoven web or laminate having improved antistatic properties and alcohol repellency properties is generally provided, along with methods of making the same. The method includes forming a nonwoven web from a thermoplastic mixture of an antistatic agent and a thermoplastic polymer. A high energy treatment is applied to a surface of the nonwoven web. Then, a fluorinated agent is grafted to the surface of the spunbond web utilizing a monomer deposition process. The monomer deposition process can generally include evaporating a liquid fluorinated agent in a vacuum chamber, followed by depositing the fluorinated agent gas on a surface of the spunbond web, and exposing the surface to radiation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

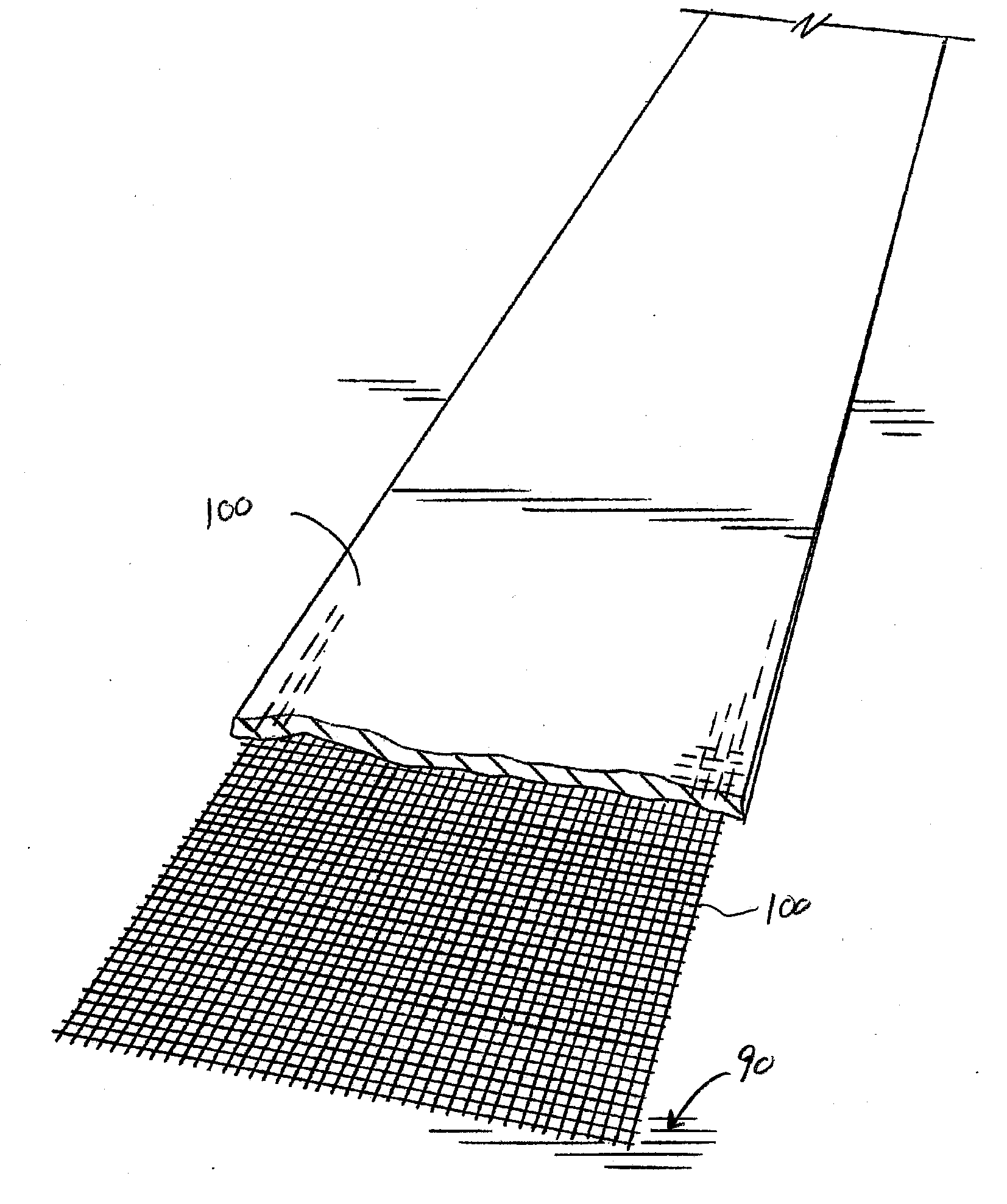

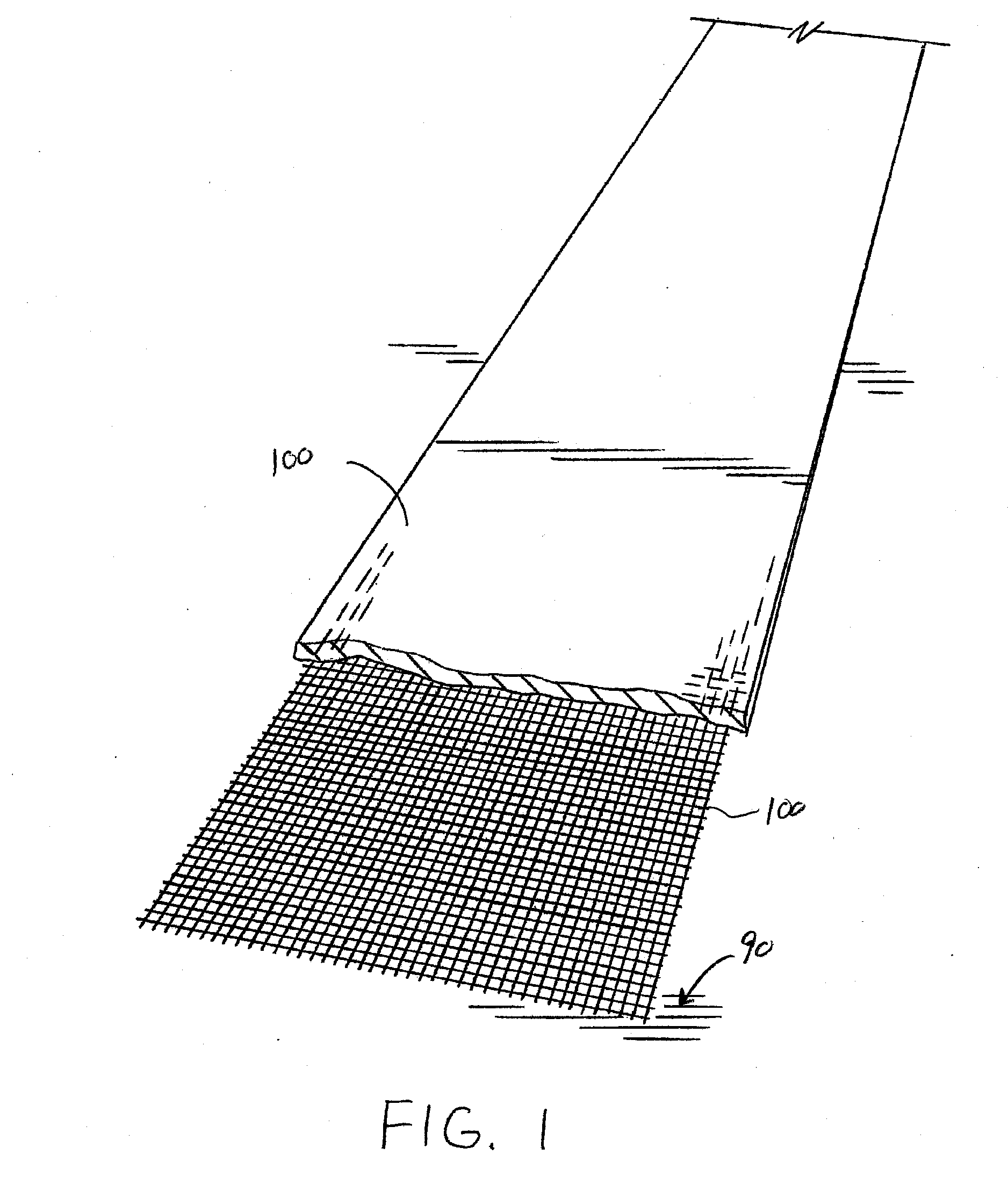

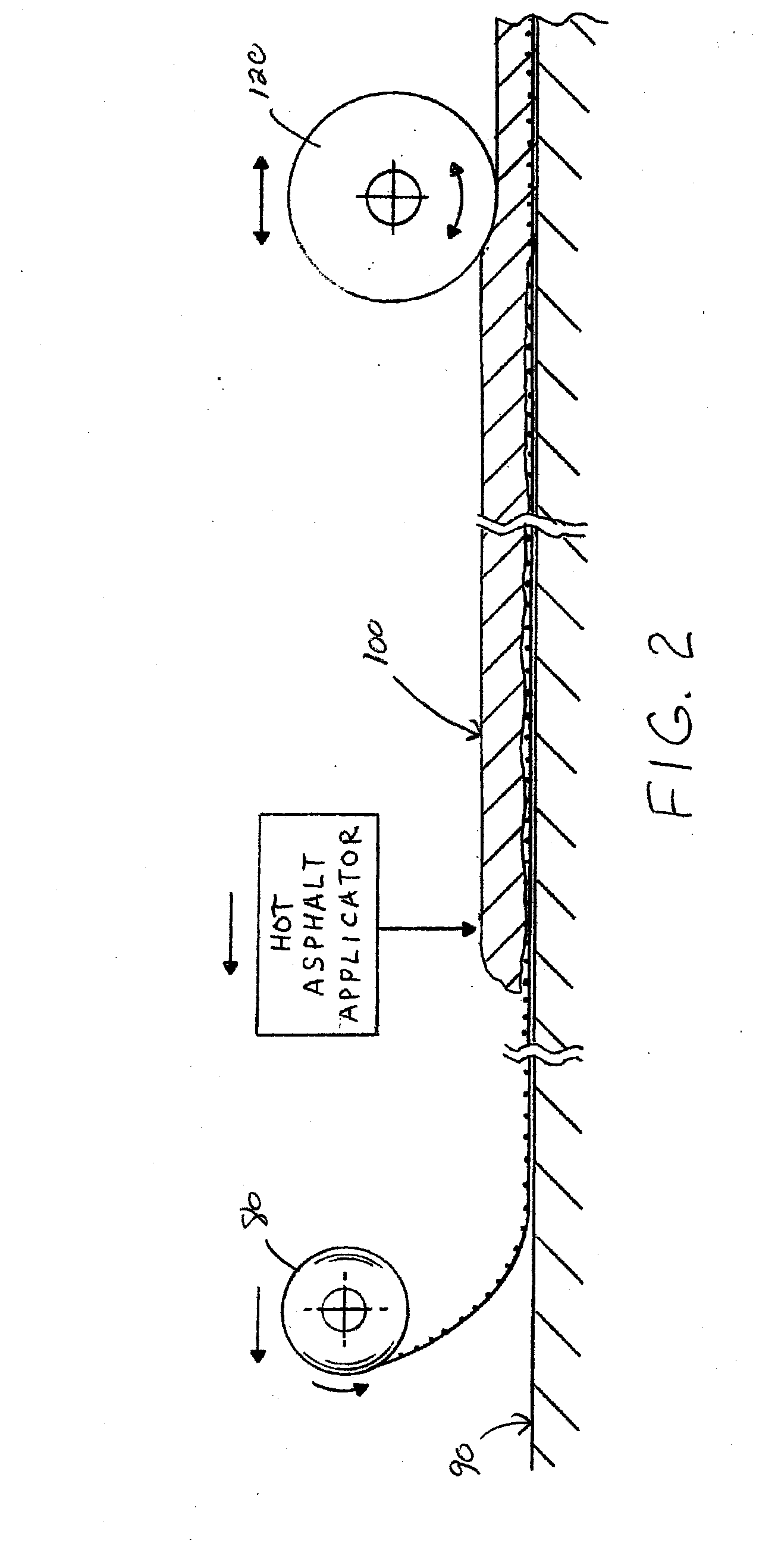

Reinforcement for asphaltic paving, method of paving, and process for making a grid with the coating for asphaltic paving

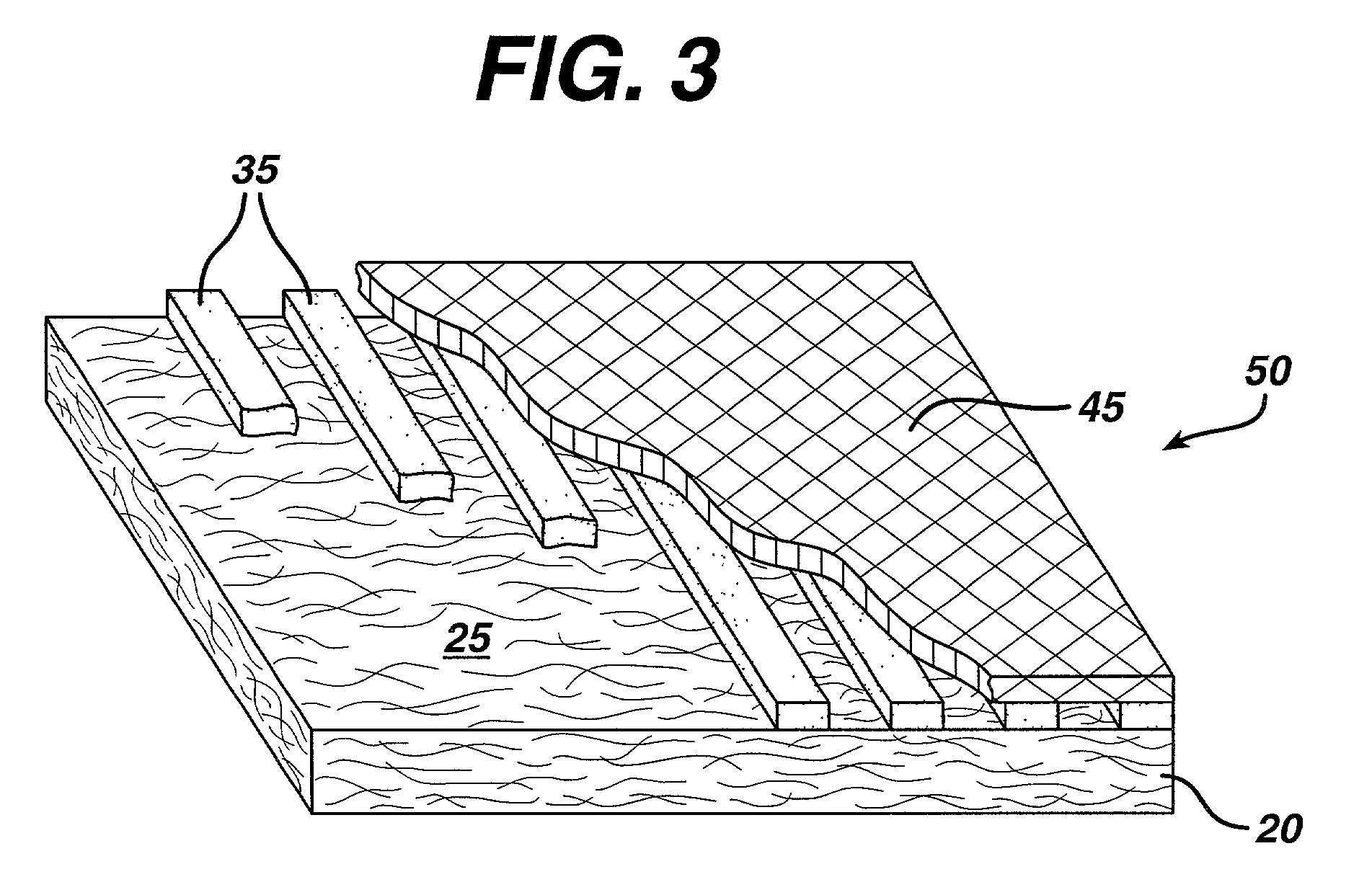

ActiveUS8038364B2Improve interlayer bonding performancePaving reinforcementsIn situ pavingsPolymer chemistryCoating

A composite material comprises: an open grid comprising at least two sets of strands. Each set of strands has openings between adjacent strands. The sets are oriented at a substantial angle to one another. A tack film is laminated to the open grid. The tack film has first and second major surfaces, such that a material of the tack film at its first and second major surfaces is a material including about 50% or more of resinous non-asphaltic component and about 50% or less of asphaltic component.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Reinforcement for asphaltic paving, method of paving, and process for making a grid with the coating for asphaltic paving

ActiveUS20090097917A1Improve interlayer bonding performancePaving reinforcementsIn situ pavingsPolymer chemistryCoating

A composite material comprises: an open grid comprising at least two sets of strands. Each set of strands has openings between adjacent strands. The sets are oriented at a substantial angle to one another. A tack film is laminated to the open grid. The tack film has first and second major surfaces, such that a material of the tack film at its first and second major surfaces is a material including about 50% or more of resinous non-asphaltic component and about 50% or less of asphaltic component.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Impregnated cloth

A knitted spacer fabric having a tightly knitted bottom layer, a more loosely knitted upper layer and linking fibres extending across the space between the lower and upper faces. Settable material, e.g. cement, is introduced into the space between the upper and lower faces and can be caused to set by the addition of a liquid, e.g. water. Until set, the fabric is flexible and can be shaped but after the material in space has set, the fabric is rigid and can be used as a structural element in a wide range of situations. The bottom layer has an extension that extends beyond the upper face and is connected to the upper face by elastic connecting fibres that draw the extension towards the other face, thereby at least partly closing the space at the edge of the cloth and preventing the settable material from spilling out.

Owner:CONCRETE CANVAS TECH LTD

Degradable breathable multilayer film with improved properties and method of making same

A multilayer film includes a plastic layer and an elastomeric layer. The plastic layer can contain a co-polyester of terepthalic acid, adipic acid and butanediol, and the elastomeric layer can contain a polyurethane elastomer. The plastic layer and / or the elastomeric layer can contain filler particles, and may be present as a bilayer laminate. The plastic layer and a filled elastomeric layer can also be combined with an unfilled elastomeric layer to form a tri-layer laminate. The multilayer films can provide breathable films with improved degradability, stretchability and recoverability, and tactile feel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Structural repair having optical witness and method of monitoring repair performance

ActiveUS20150338296A1Performance can be quickly and easyAvoid weightForce measurement by measuring optical property variationVehicle componentsFluorescenceLength wave

A structural repair includes a tell-tale optical witness that allows the health of the repair to be visually monitored. The optical witness includes a stress sensitive fluorescent dye that shows changes in local strain / stress patterns when the repair is subjected to electromagnetic energy of a particular wavelength. The dyes fluoresce more or less strongly as a function of the local stress / strain.

Owner:THE BOEING CO

Liquid-retaining sheet and facial mask

ActiveUS20150125499A1High transparencyAppropriate strengthCosmetic preparationsToilet preparationsSolventUltimate tensile strength

A liquid-retaining sheet contains a liquid-retaining layer that is able to absorb a liquid component, and the liquid-retaining layer is formed from a nonwoven structural member containing a transparent fiber. In the liquid-retaining sheet, the transparency shown below is adjusted to not more than 0.27.Transparency=Whiteness (%) of a sheet impregnated with 700% by mass of water relative to the sheet mass / Basis weight (g / m2)The transparent fiber may contain a cellulose-series fiber substantially free from a carboxyl group (in particular, a regenerated cellulose fiber such as a solvent-spinning cellulose-series fiber). The proportion of the solvent-spinning cellulose-series fiber may be not less than 30% by mass in the transparent fiber. The liquid-retaining sheet may be a skin care sheet (in particular, a facial mask) that is impregnated with a liquid component containing a cosmetic preparation. The liquid-retaining sheet has an improved transparency in a wet state in spite of a nonwoven structural member contained in the sheet and shows a suitable strength in a wet state.

Owner:LENZING AG

Impregnated Cloth

A knitted spacer fabric has a tightly knitted bottom layer, a more loosely knitted upper layer and linking fibres extending across the space between the lower and upper faces. Settable material, e.g. cement, is introduced into the space between the upper and lower faces and can be caused to set by the addition of a liquid, e.g. water. Until set, the fabric is flexible and can be shaped but after the material in space has set, the fabric is rigid and can be used as a structural element in a wide range of situations. The bottom layer has an extension that extends beyond the upper face and is connected to the upper face by elastic connecting fibres that draw the extension towards the other face, thereby at least partly closing the space at the edge of the cloth and preventing the settable material from spilling out. In addition, the packing of the settable material and maximum space between the faces are such that only a predetermined amount of liquid can be accommodated within the space and that amount is matched to the water required to set the cement.

Owner:CONCRETE CANVAS TECH LTD

Adhesive tape or sheet for application on skin

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com