Patents

Literature

85results about How to "Controllable porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

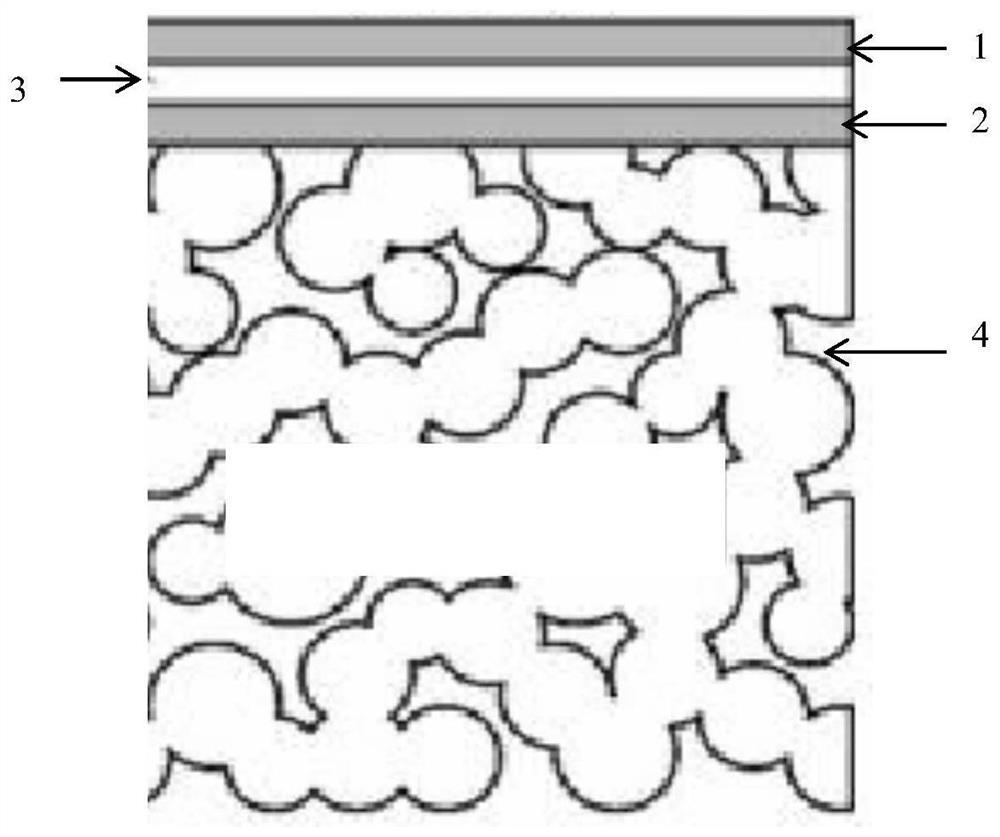

Porous medical device and method for its manufacture

ActiveUS7964206B2Thickness of device can be variedControllable porosityBiocideGenetic material ingredientsFiberBioceramic

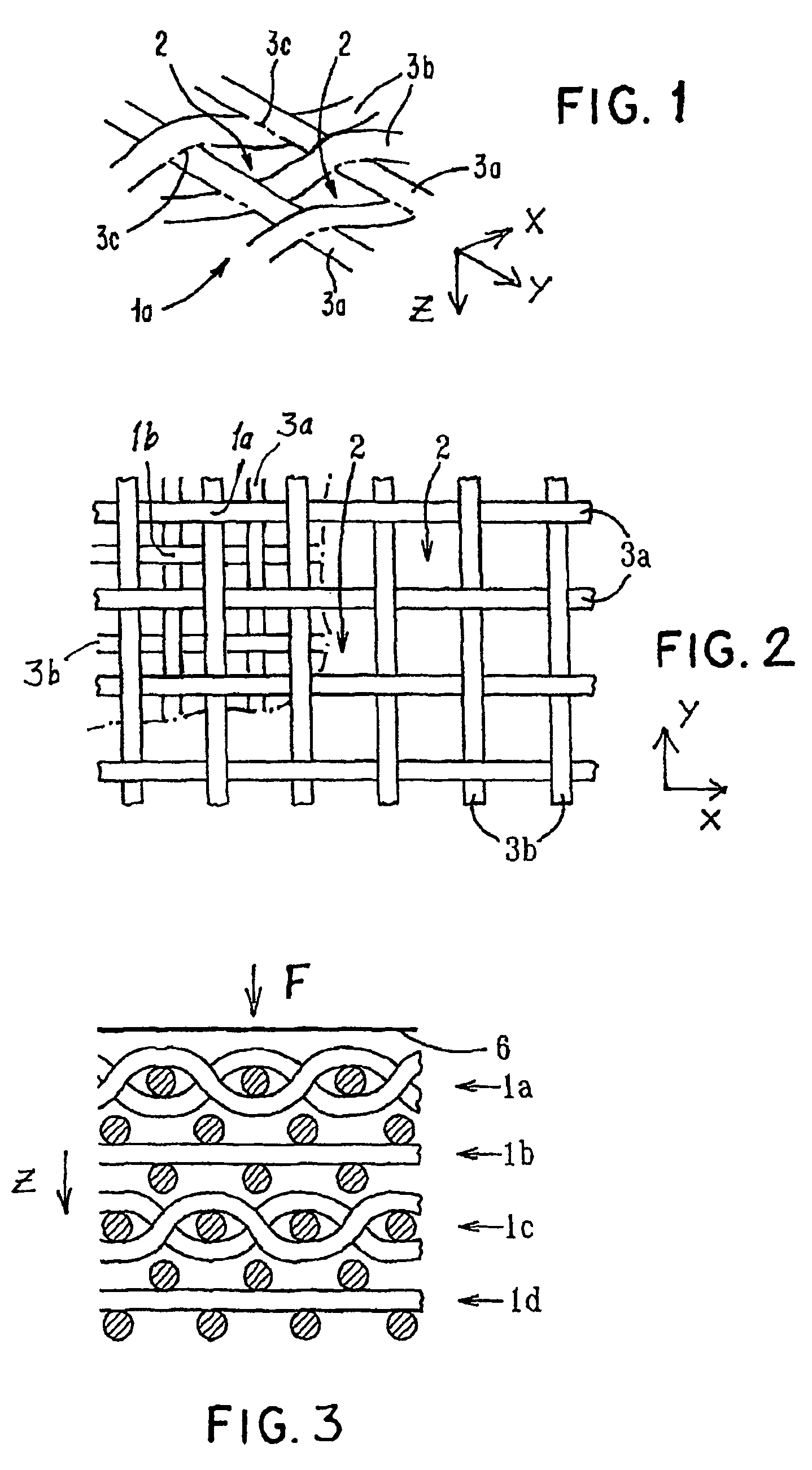

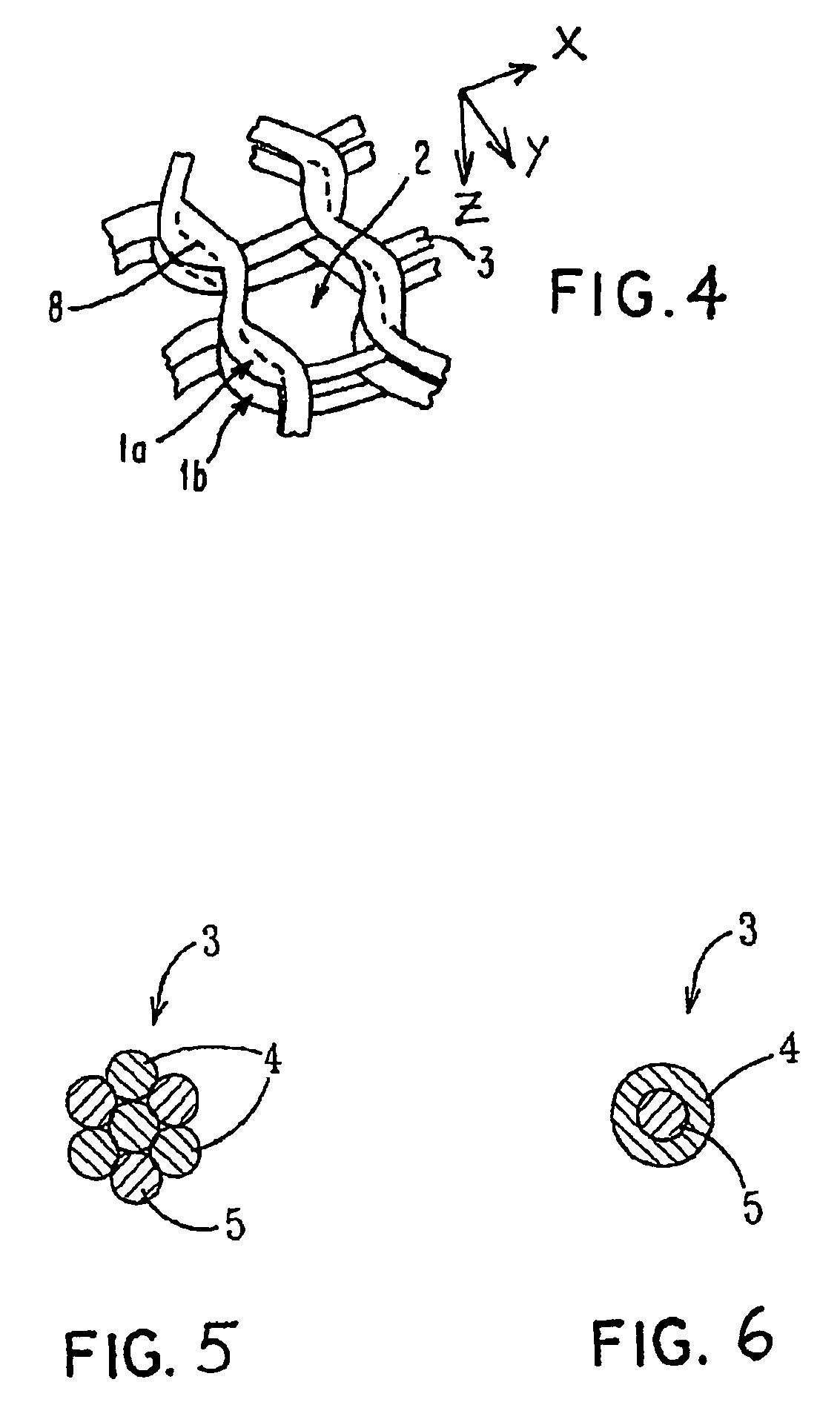

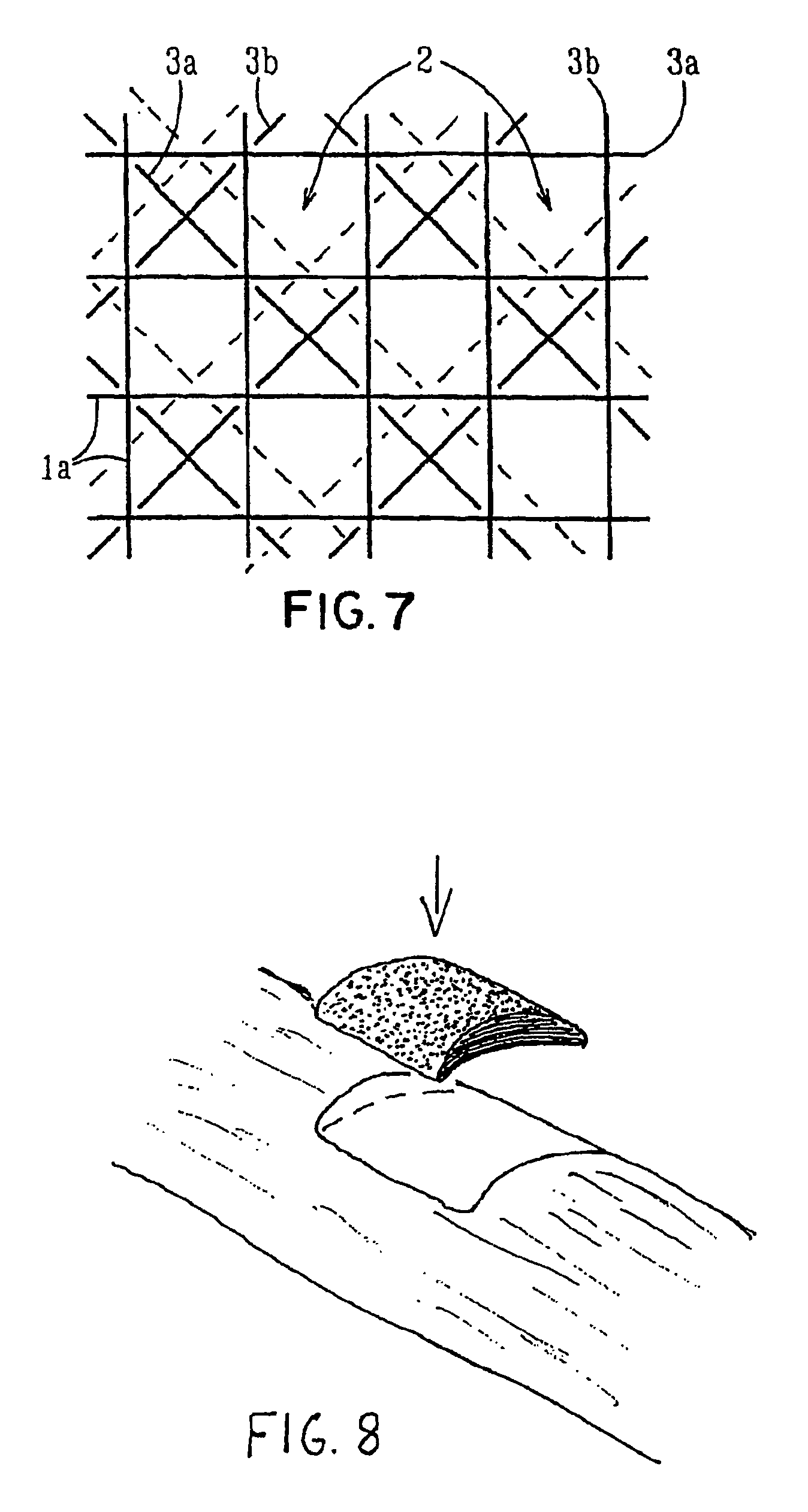

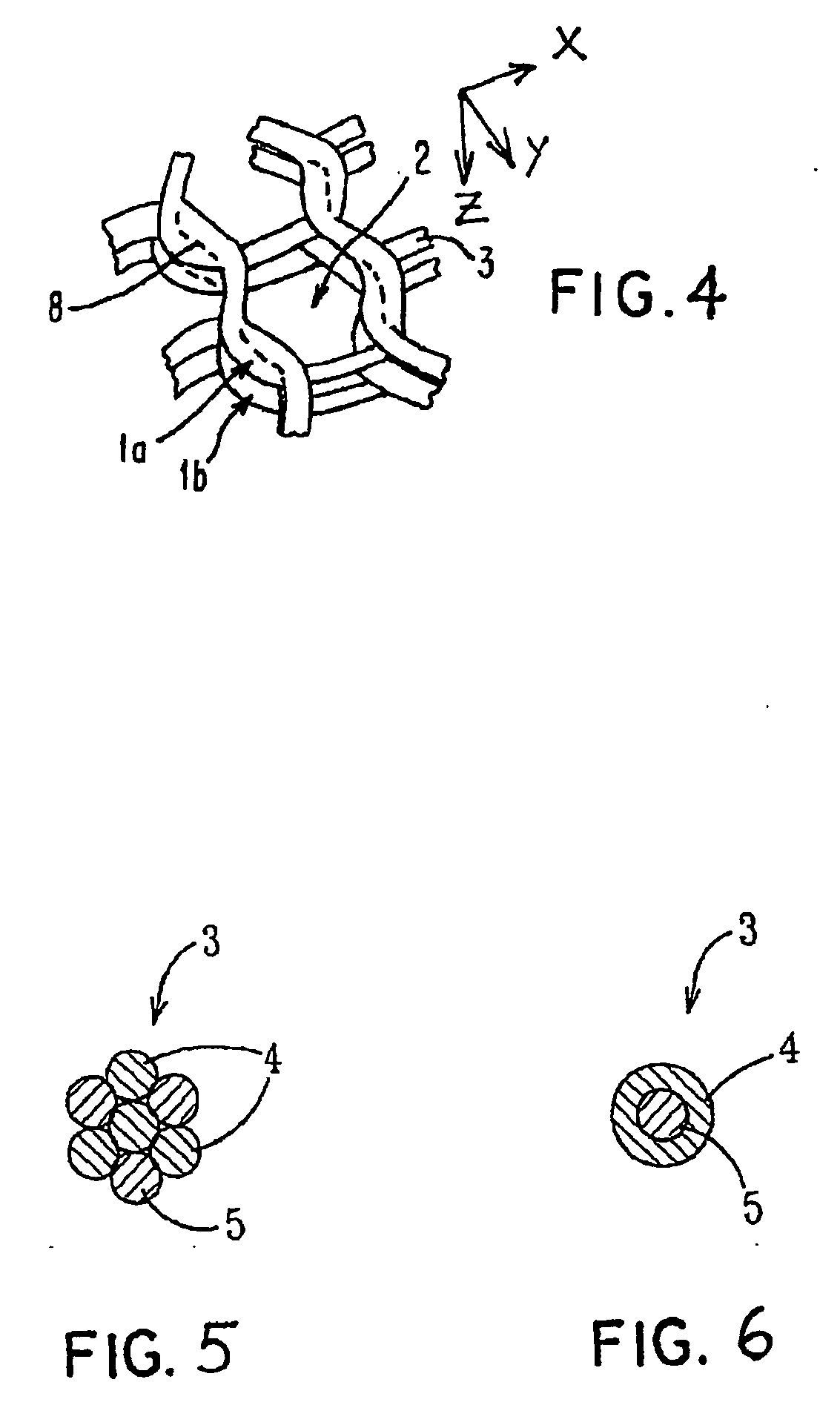

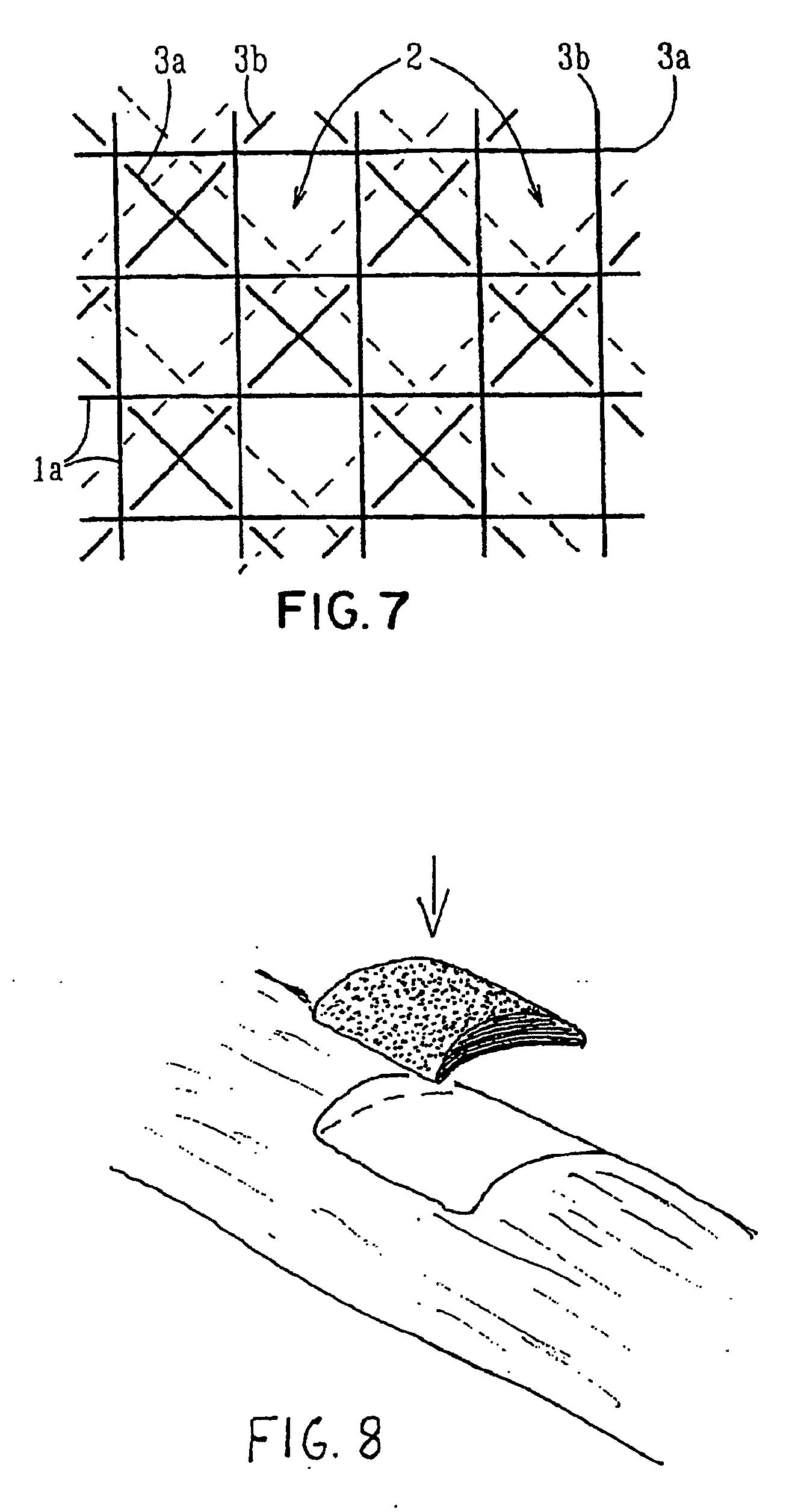

Porous bioabsorbable, bioactive and load-bearing composite medical device structure includes a plurality of regular textile planar layers (1a, 1b . . . ) formed of continuous bioabsorbable polymer matrix and bioceramic fibers acting as reinforcements, both included in continuous fibrous elements (3) forming the textile layers. The layers are placed on top of each other to form a structure having two dimensions (x, y) at right angles to each other according to the two dimensions of the textile layer and a third dimension (z) perpendicular to them and resulting from the piling of the layers. A plurality of passages extend through the layers as a result of the openings (2) defined by portions of the continuous fibrous elements (3) extending substantially in the direction of the plane. The continuous fibrous elements (3) comprise both bioactive ceramic reinforcing fibers which form a reinforcing structure and a bioabsorbable polymer matrix material which forms a matrix which binds the layers together and also binds the portions of continuous fibers defining the openings together, thereby forming the passages and stiffening the structure. This bioactive and bioabsorbable composite structure is suitable to be used as a basic structure in medical devices, especially in osteochondral applications where the load-bearing properties of implant are required.

Owner:BIORETEC

Porous medical device and method for its manufacture

ActiveUS20070141111A1Uniform distribution of poresSuppress mutationBiocideGenetic material ingredientsFiberBioceramic

Porous bioabsorbable, bioactive and load-bearing composite medical device structure includes a plurality of regular textile planar layers (1a, 1b . . . ) formed of continuous bioabsorbable polymer matrix and bioceramic fibers acting as reinforcements, both included in continuous fibrous elements (3) forming the textile layers. The layers are placed on top of each other to form a structure having two dimensions (x, y) at right angles to each other according to the two dimensions of the textile layer and a third dimension (z) perpendicular to them and resulting from the piling of the layers. A plurality of passages extend through the layers as a result of the openings (2) defined by portions of the continuous fibrous elements (3) extending substantially in the direction of the plane. The continuous fibrous elements (3) comprise both bioactive ceramic reinforcing fibers which form a reinforcing structure and a bioabsorbable polymer matrix material which forms a matrix which binds the layers together and also binds the portions of continuous fibers defining the openings together, thereby forming the passages and stiffening the structure. This bioactive and bioabsorbable composite structure is suitable to be used as a basic structure in medical devices, especially in osteochondral applications where the load-bearing properties of implant are required.

Owner:BIORETEC

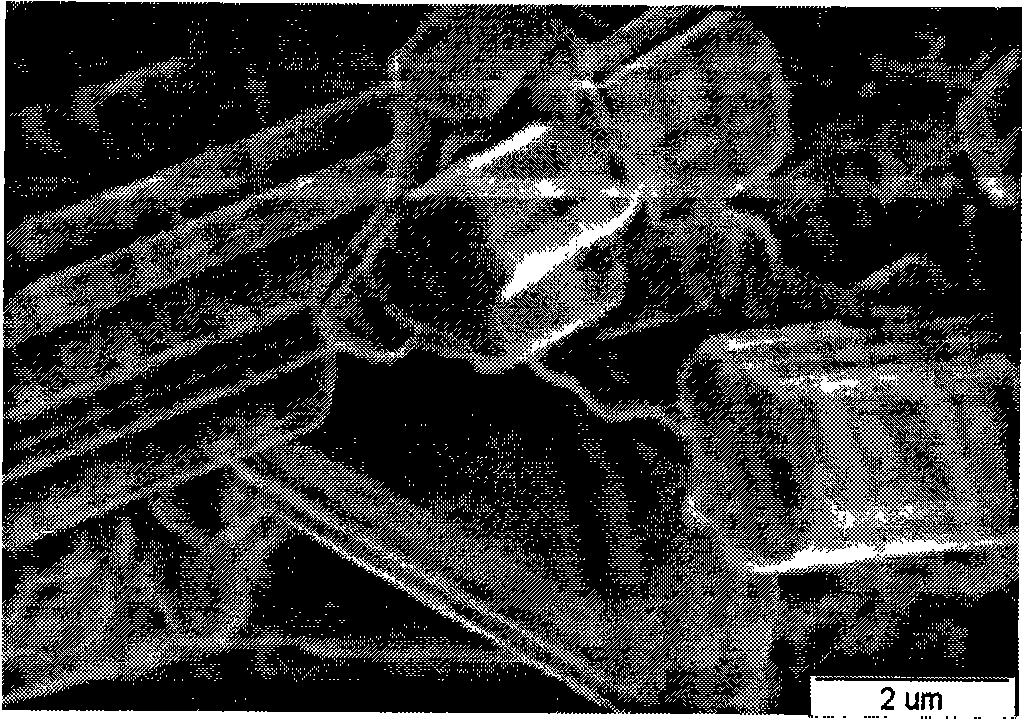

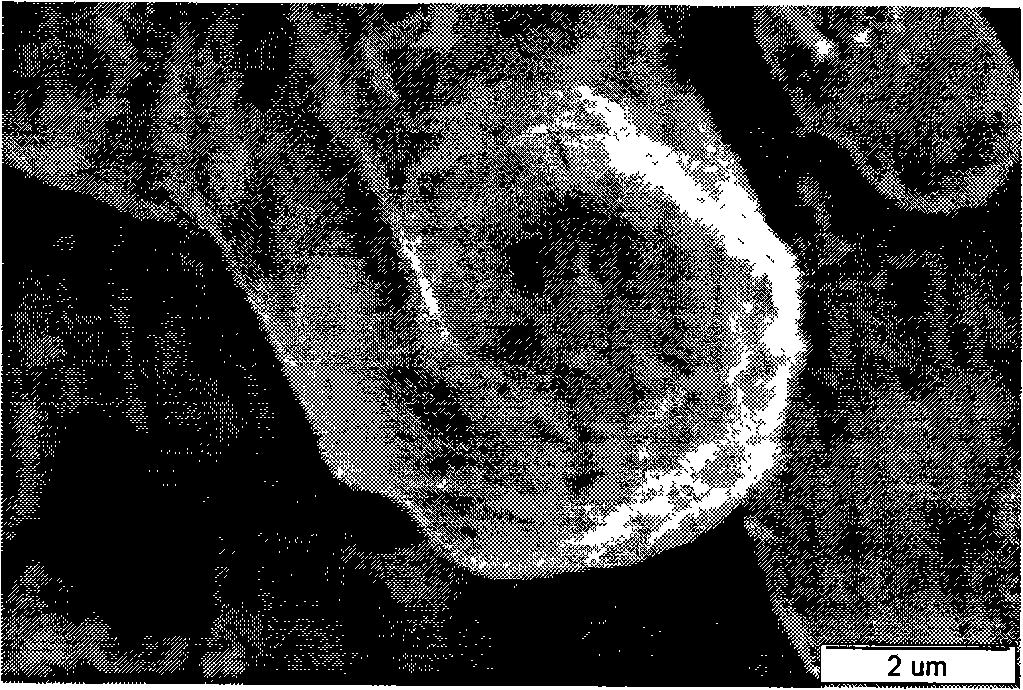

Method for preparing nanometer carbon fiber/foam coal through taking coal liquefaction residues as raw materials

The method for preparing nanometer carbon fiber / foam coal through taking coal liquefaction residues as raw materials belongs to the scientific and technological field of coal materials of the scientific and technological branch of inorganic non-metallic materials. The method takes the coal liquefaction residues as the coal source of the foam coal, and compounds metallic / foam coal compound materials through the supercritical foaming method or the formwork method, and prepares the nanometer carbon fiber / foam coal compound materials through the chemical vapor deposition of organic matter. The method fully utilizes the characteristics of metallic accelerating agent containing abundant coal organic matter, iron-contained compound and the like in the coal liquefaction residues, and prepares metallic / foam coal compound materials, and the nanometer carbon fiber completely covers on the surface of the foam coal after the chemical vapor deposition. The novel nanometer carbon fiber / foam compound materials have the structural characteristics of solid foam and hollow nanometer carbon fiber. And the method is expected to be used in the fields of catalyzer and a catalyzer carrier, a fuel battery electrode material, high-effective sorbent of a fixed bed reactor and the like.

Owner:DALIAN UNIV OF TECH

Novel clay soil polyporous materials and method of producing the same

InactiveCN101492276AControllable porositySimple processCement productionCeramicwarePorosityEnergy absorption

The invention discloses a novel clay-type porous material and a preparation method thereof. The preparation method comprises the steps of taking metakaolin (or chainotte) as a raw material, taking industrial water glass as an alkali-exciting agent and adopting a direct foaming process under a low temperature (between 120 and 200 DEG C) to prepare the porous material which takes geopolymers as a framework and has good performances. Results of performance tests on the porous materials show that the clay-type porous material has the compressive strength between 2.0 and 9.0Mpa, the apparent porosity between 30 and 70 percent and the volume density between 0.40 and 1.0 g / cm<3>, and can resist a high temperature above 800 DEG C. The porous material with different performances and pore structures can be obtained by controlling different mixture ratio and reaction conditions. The preparation method has the advantages of simple process and low cost, and is hopeful of obtaining wide application in the fields of heat preservation materials, waste-gas adsorbing materials, wastewater filtering materials, energy absorbing materials and the like.

Owner:GUANGXI UNIV

Solid oxide fuel cell and preparation method thereof

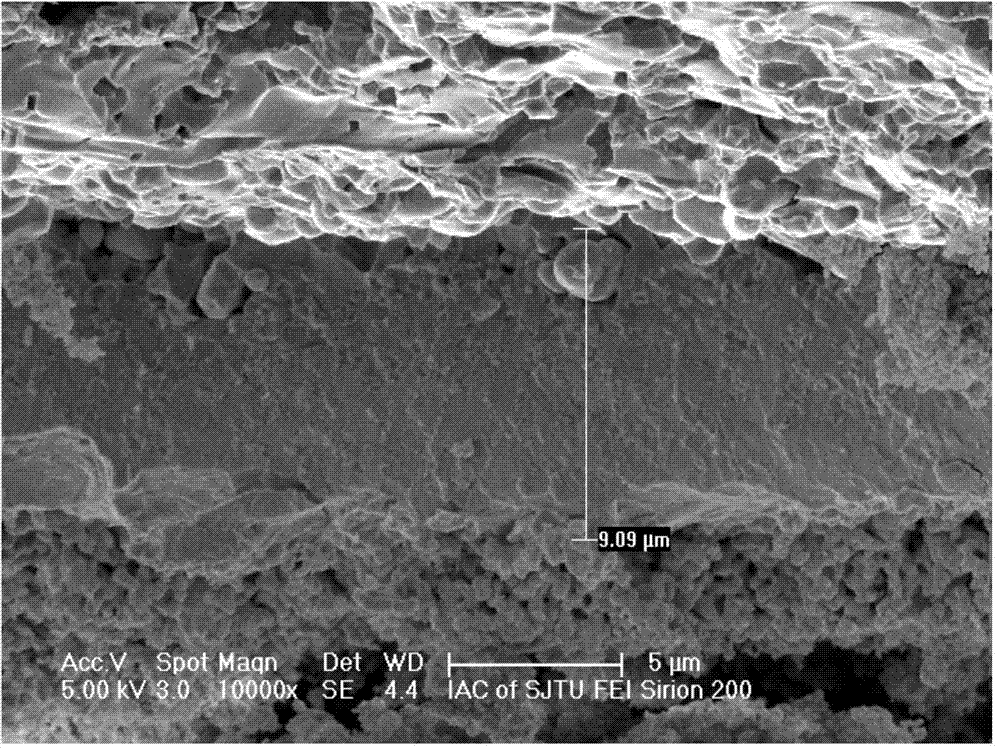

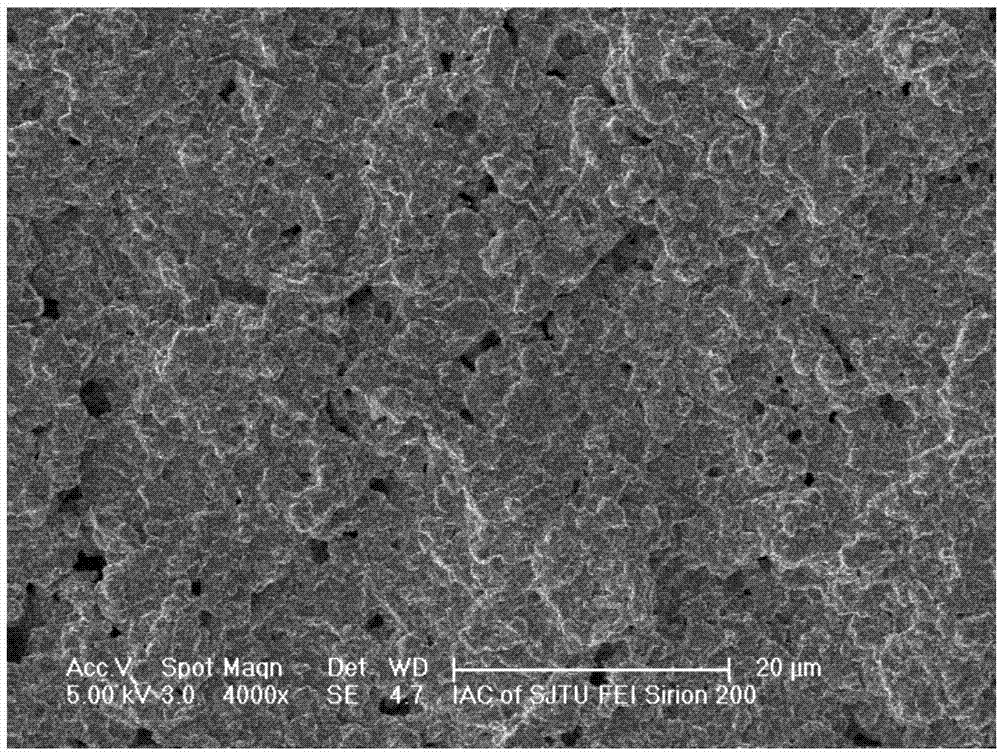

ActiveCN104779409AReduce carbon depositionThickness is easy to controlCell electrodesSolid electrolyte fuel cellsFuel cellsSulfur

The invention relates to a solid oxide fuel cell and a preparation method thereof. The cell is formed by sequentially depositing a porous anode functional layer, a dense electrolyte layer and a porous cathode functional layer on a porous anode supporting body with perovskite type oxide serving as an anode material, a porous cathode layer is deposited on the reduced porous cathode functional layer, nanometer-doped cerium oxide is deposited in the porous perovskite anode supporting body and the porous anode functional layer, and nanometer-doped cerium oxide and a nanometer cathode material are sequentially deposited in the porous cathode functional layer. The prepared solid oxide fuel cell is stable in structure for a long time and can endure oxidization-reduction circulation multiple times, carbon deposition is resisted, and the sulfur-resistant performance is achieved.

Owner:上海氢洋科技有限公司

Tantalum foam and preparation method thereof

The invention belongs to the technical field of metal material preparation, and particularly relates to a tantalum foam and a preparation method thereof. The porosity of the tantalum foam is between 20 and 80 percent, pores in the tantalum foam are intercommunicated, and the tantalum foam accounts for over 99.9 percent of the weight of the tantalum. The preparation method comprises the following steps: uniformly mixing one of iron powder, iron dust, cobalt powder or nickel powder and tantalum powder or tantalum dust, and pressing the mixture into blocks; then, putting the blocks into a vacuum furnace, sintering the blocks for 0.5 to 2 hours at the temperature of between 1,200 and 1,400 DEG C, then heating the blocks to between 1,500 and 1,800 DEG C and sintering the blocks for 2 to 6 hours, and cooling the blocks to the room temperature; taking the blocks out, soaking the blocks into aqueous solution of hydrochloric acid till the reaction is finished, then washing the blocks by deionized water till the flushing solution is neutral, drying the blocks, finally putting the blocks into the vacuum furnace for sintering, and cooling the blocks to the room temperature. The process method of the invention has the characteristics of simple equipment implementation, easy control of the porosity of the foam metal, easy realization of special shape of the foam metal, low cost and the like.

Owner:有研资源环境技术研究院(北京)有限公司

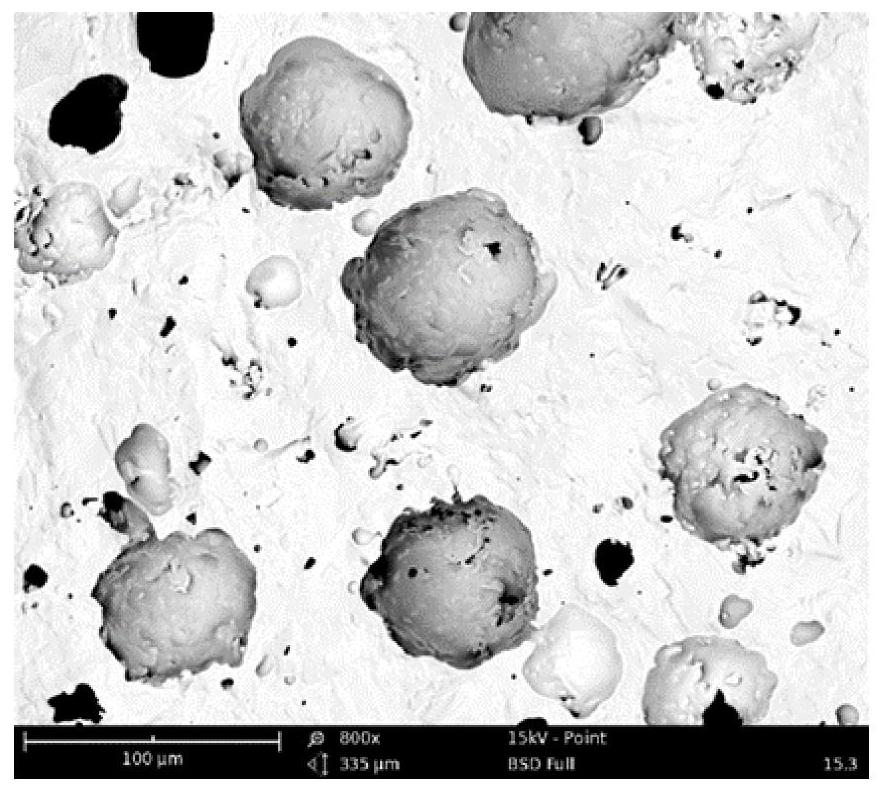

Preparation method for porous tungsten bulk material with uniform and controllable pores

The invention discloses a preparation method for a porous tungsten bulk material with uniform and controllable pores. The preparation method is characterized by comprising the following steps of: by taking tungsten powder as a raw material, obtaining spherical tungsten powder through plasma balling treatment and electric vibrating and screening treatment; and then, obtaining the porous tungsten bulk material by discharge plasma sintering. According to the preparation method, the porous tungsten bulk material with uniform and controllable pores is obtained by combining a plasma balling technology, an electric vibrating and screening technology and a discharge plasma sintering technology; the preparation method is simple and liable to realize; the control on pores of the product can be realized by regulating the process parameters, so that the porous tungsten bulk material with porosity of 17%-22.5% and pore size of 2-5 mum; the prepared porous tungsten bulk material can be used for remarkably improving the infiltration performance of the material, so that the launch stability of a barium-tungsten cathode is greatly improved, and the service life of the barium-tungsten cathode is prolonged.

Owner:HEFEI UNIV OF TECH

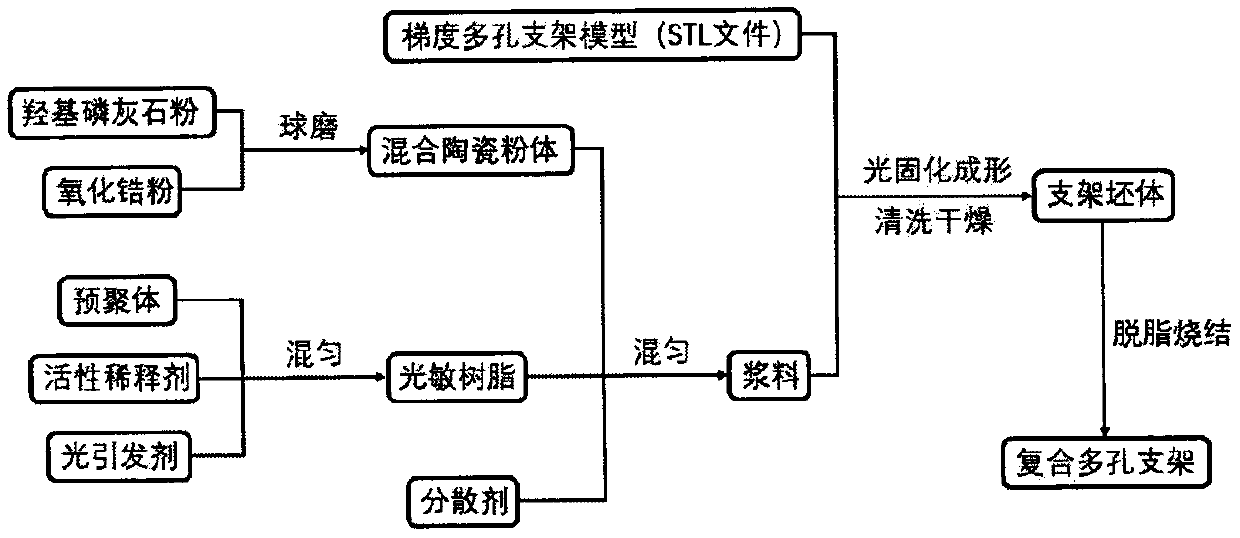

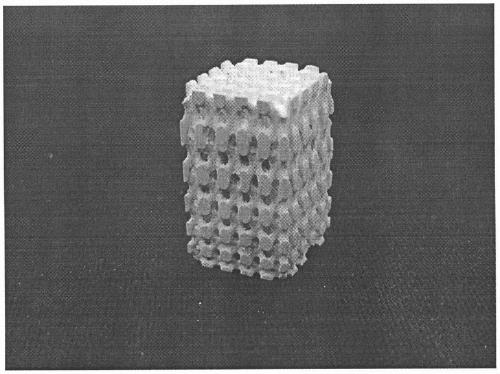

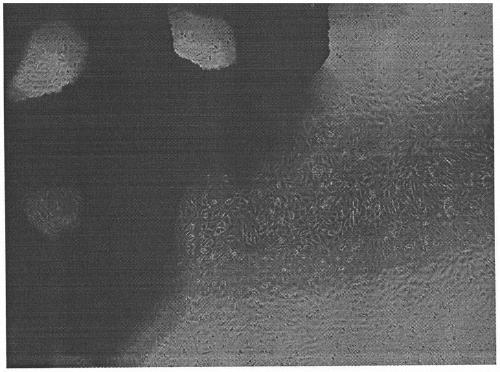

Calcium phosphate/zirconium oxide gradient porous scaffold as well as preparation method and application

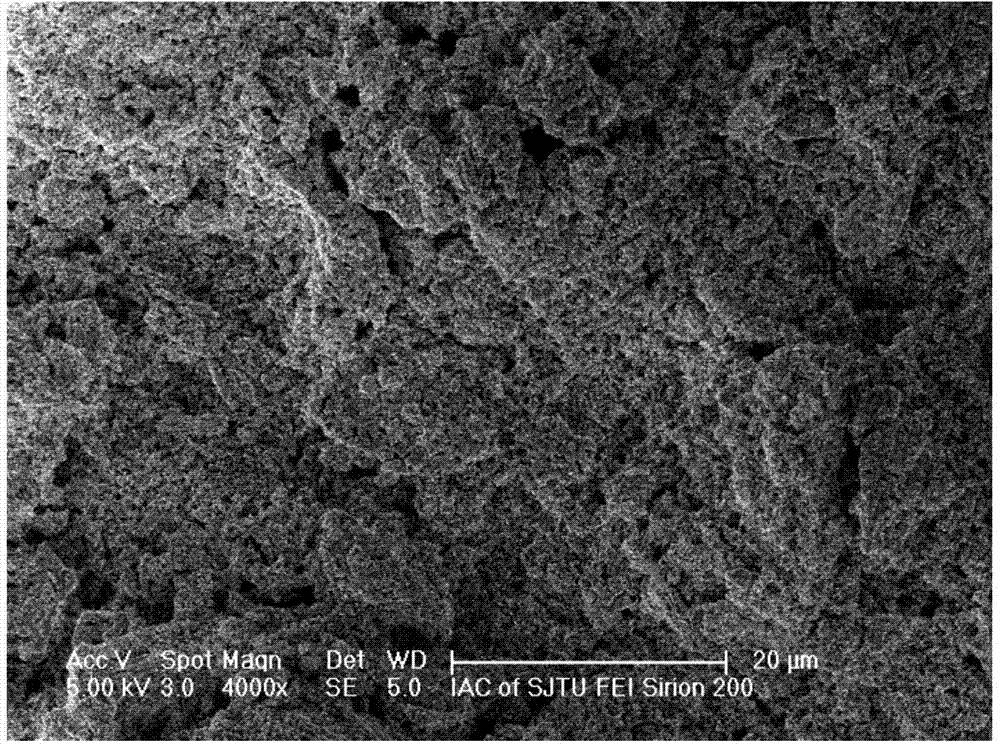

InactiveCN109912303AControllable shapeControllable porosityAdditive manufacturing apparatusBone implantZirconium hydrideDrug biological activity

The invention provides a calcium phosphate / zirconium oxide gradient porous scaffold as well as a preparation method and application. The porous scaffold takes calcium phosphate ceramic and zirconium oxide powder as raw materials, is formed through a light curing technology, and is obtained through high temperature degreasing and sintering. The pore size of the porous scaffold forms gradient changebetween 10 to 100 micrometers, the porosity is 30 to 90 percent, and the porous scaffold has relativley high penetration. The method does not need dies, can realize individualized design of scaffoldappearance and porosity and gradient change of the pore size, and can adjust the mechanical property and biological activity of the composite scaffold by controlling the ratio of ceramic powder, thereby obtaining the porous scaffold with excellent biological property and certain strength. The composite porous scaffold prepared with the method has potential application space in the field of bone tissue engineering.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of high-porosity aluminum oxide ceramic filter

The invention relates to a preparation method of high-porosity aluminum oxide ceramic filter. The preparation method comprises the following steps: preparing aluminum oxide compound powder and aluminum oxide ceramic slurry; freezing and forming the slurry; lyophilizing a frozen blank; and sintering a dried blank. The preparation method specifically comprises the following steps: respectively dissolving soluble aluminum salt, titanium salt, magnesium salt, yttrium salt, lanthanum salt and cerium salt in deionized water, gathering one or more ammonia solutions in the solution to form a mixed solution and settling, and carrying out vacuum filtration, washing by deionized water, drying and calcining to obtain aluminum oxide compound powder; uniformly mixing a tertiary butanol solvent, a dispersant and an adhesive to prepare a premixed solution, ball-milling the aluminum oxide compound powder and the premixed solution at constant temperature, and degassing in vacuum to prepare suspended slurry; freezing and forming the slurry at a temperature lower than the solification temperature of the solvent; lyophilizing the formed frozen blank to obtain a porous blank body; and firing the blank body at a low temperature and sintering the blank body at a high temperature to obtain the aluminum oxide ceramic filter. The whole process is free of any pore forming materials and pollution-free and is an ideal method for preparing the directional high-porosity and high-strength ceramic filter.

Owner:辽宁法库陶瓷工程技术研究中心

Method for fabricating porous TiO2 thin film by utilizing nano-crystalline TiO2 hydrosol

ActiveCN101585552AShape is easy to controlHigh degree of crystallizationTitanium dioxideDispersityPhotodetector

The invention relates to a method for a fabricating porous TiO2 thin film by utilizing nano-crystalline TiO2 hydrosol, belonging to the technical field of fabrication process of inorganic metal oxide porous thin film. The fabricating steps of the method are as follows: (1), preparation of nano-crystalline TiO2 hydrosol: titanium salt used as raw material is complexed with ammonia water, extraction filtered, washed, and dissolved in different solvents, and then H2O2 is added thereinto to dissolve colloid to obtain different crystallization results; the sol is transferred to a high-pressure reaction kettle, crystallized for 8-15 hours at temperature of between 100 and 200 DEG C, and extraction filtered and ultrasonic dispersed in water to obtain nano-crystalline TiO2 hydrosol; (2), fabrication of the porous TiO2 thin film: the porous thin film is obtained by directly coating the hydrosol onto a matrix at low temperature. The TiO2 hydrosol prepared by the invention has high crystallization degree, good dispersity, and controllable sol shape; surface of the porous thin film is flat and even with good adhesion. The porous TiO2 thin film can be applied to fields of photocatalysis, photodetector and solar battery and the like.

Owner:SHANGHAI UNIV

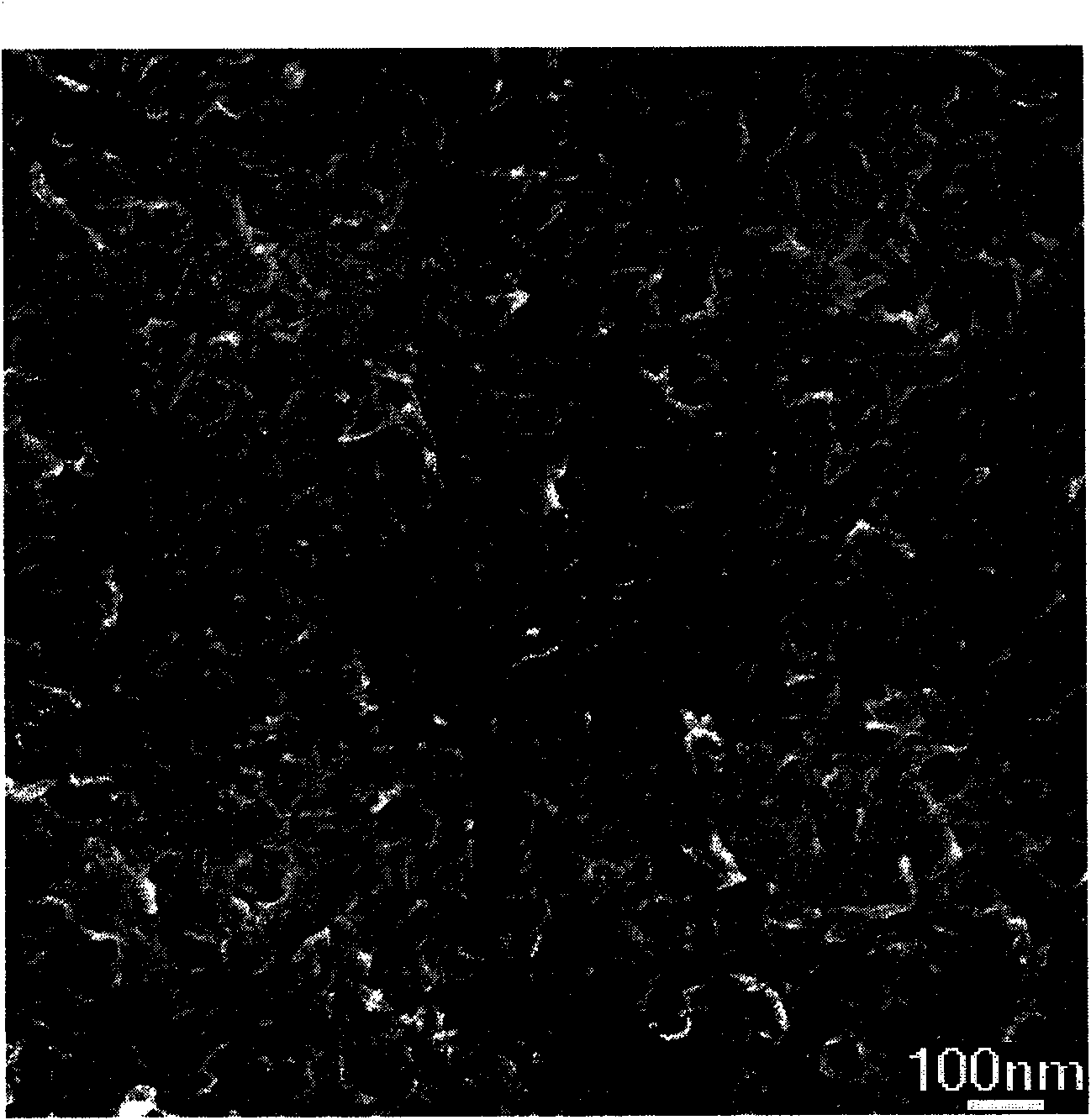

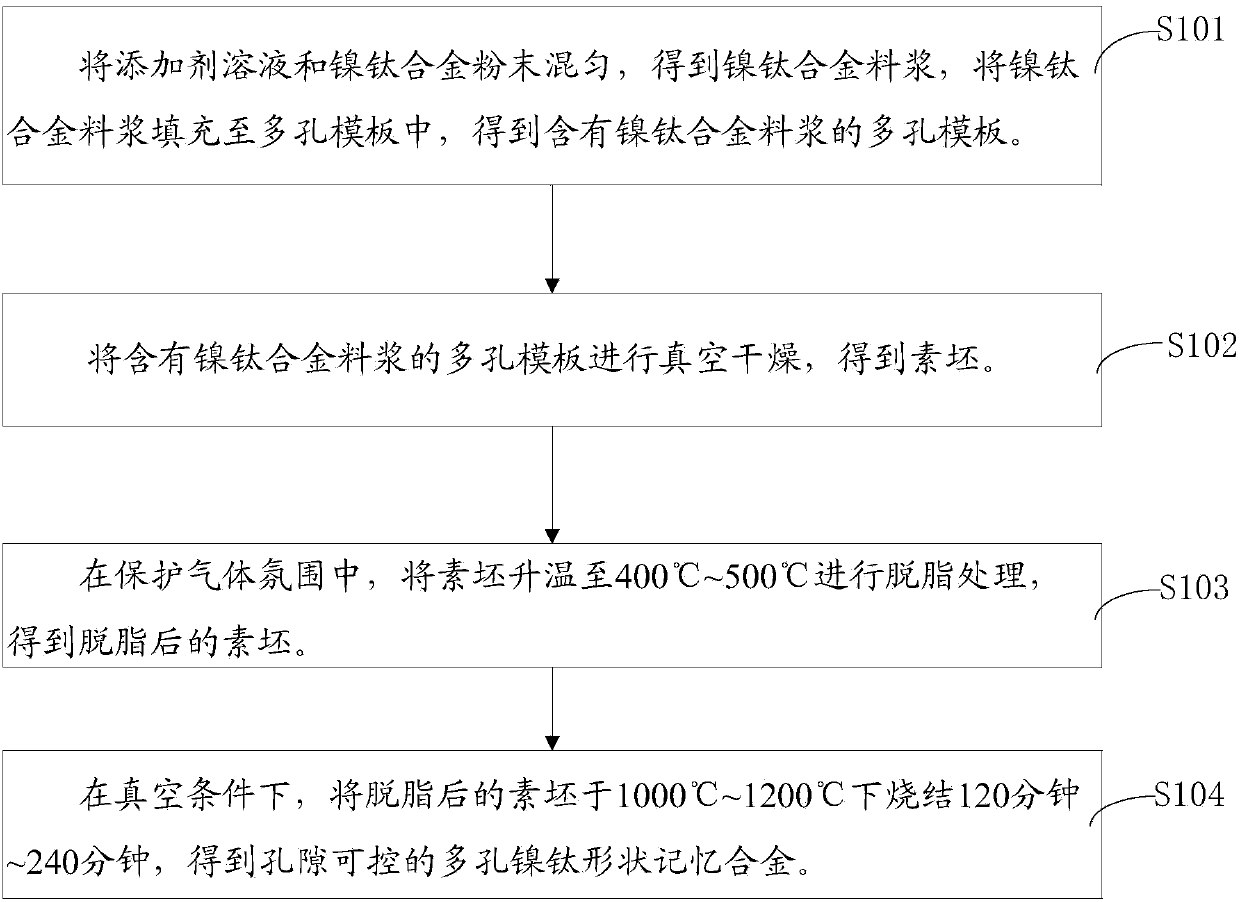

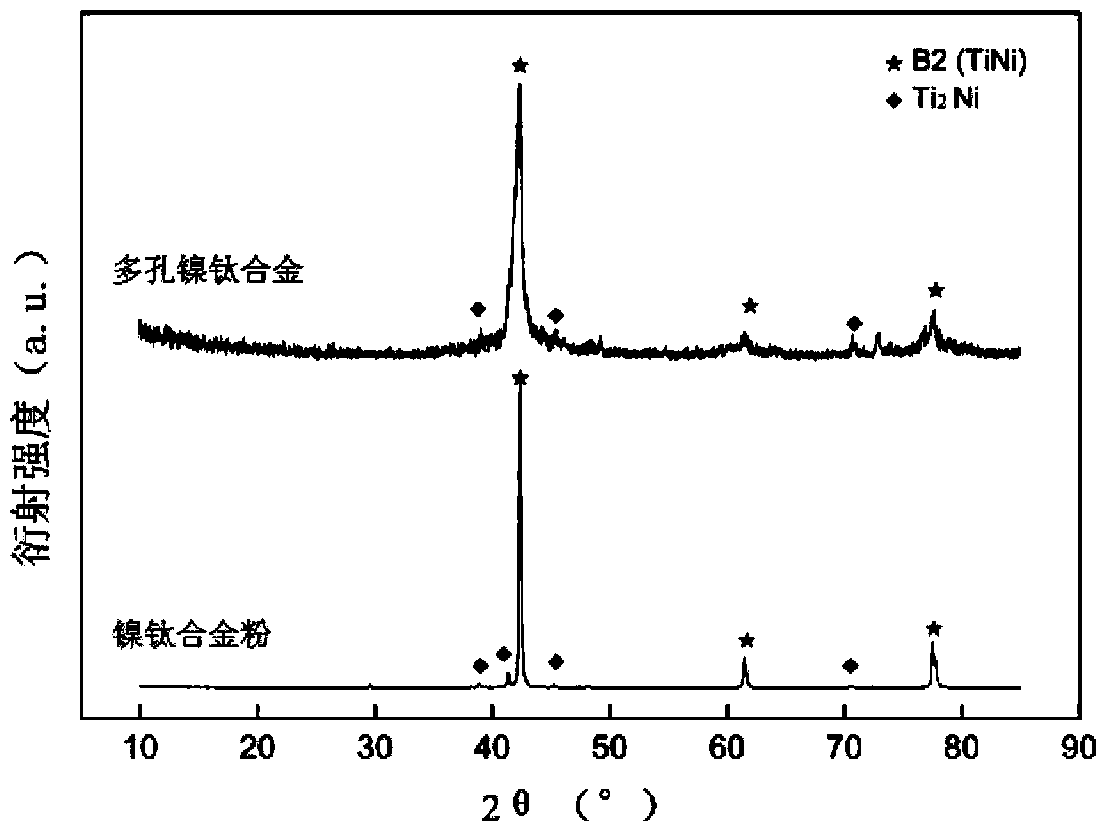

Preparation method of pore-controllable porous nickel-titanium shape memory alloy

The invention discloses a preparation method of a pore-controllable porous nickel-titanium shape memory alloy, and the preparation method comprises the following steps: uniformly mixing an additive solution and nickel-titanium alloy powder to obtain nickel-titanium alloy slurry; filling a porous template with the nickel-titanium alloy slurry to obtain a porous template containing nickel-titanium alloy slurry; performing vacuum drying on the porous template containing nickel-titanium alloy slurry to obtain a biscuit; in a protective gas atmosphere, heating the biscuit to 400-500 DEG C and performing degreasing treatment to obtain degreased biscuit; in a vacuum condition, sintering the degreased biscuit at 1,000-1,200 DEG C for 120-240 minutes so as to obtain the pore-controllable porous nickel-titanium shape memory alloy. In the preparation method, the preparation process is simple, the equipment is simple, the cost is low, the pore performance of the porous nickel-titanium shape memory alloy can be adjusted, and the prepared pore-controllable porous nickel-titanium shape memory alloy has high porosity and uniform pores and a three-dimensional communication structure.

Owner:CENT SOUTH UNIV

Self Standing Nanoparticle Networks/Scaffolds with Controllable Void Dimensions

InactiveUS20110244003A1Easy to controlControllable porosityMaterial nanotechnologyNanomagnetismCross-linkNanoparticle

The present invention discloses a self standing network or scaffold of nanoparticles with controllably variable mesh size between 500 nm and 1 mm having particle volume fraction between 0.5 to 50%. The network comprises nanoparticles, a surfactant capable of forming ordered structured phases and a cross linking agent, wherein the surfactant is washed off leaving the self standing scaffold. The invention further discloses the process for preparing the self standing scaffolds and uses thereof.

Owner:COUNCIL OF SCI & IND RES

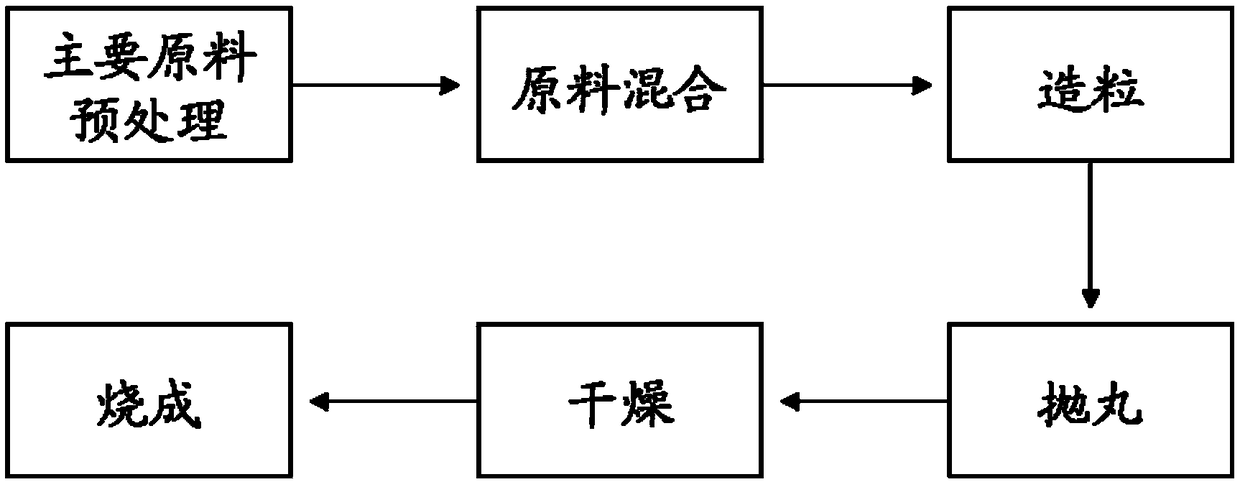

Preparation method of porous ceramic particle

ActiveCN109503196AParticle size controllableMeet apertureGrowth substratesCulture mediaMetallurgyPulverized fuel ash

The invention provides a preparation method of a porous ceramic particle. The preparation method comprises the following steps of adopting pulverized fuel ash, construction waste, mine mud, clay and feldspar as main raw materials, adopting pulverized coal and the like as foaming agents, pretreating, mixing, pelleting, drying, and firing to obtain the porous ceramic particle. The porous ceramic particle prepared through the invention has the characteristics of high strength, long service life, low density, good liquidity, high water absorption, good nutrient preserving capability, high water-retaining property, good air permeability, easiness in controlling particle size, high in reusability, excellent in anti-hardening performance and the like; without the need of other soil, a matrix canbe directly applied to plant cultivation, can be widely applied to greening an outer wall, a roof, a square, a park, a desert and the like, and can be further widely applied to a soil conditioner, a fertilizer efficiency conditioner, an anti-hardening agent and the like. The preparation method of the porous ceramic particle provided by the invention is simple in process, high in production efficiency, low in cost, and suitable for large-scale industrial production.

Owner:SHENZHEN CUILU TECH GREENING ENG CO LTD

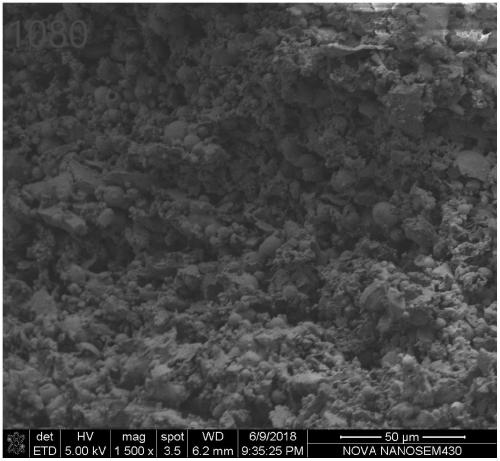

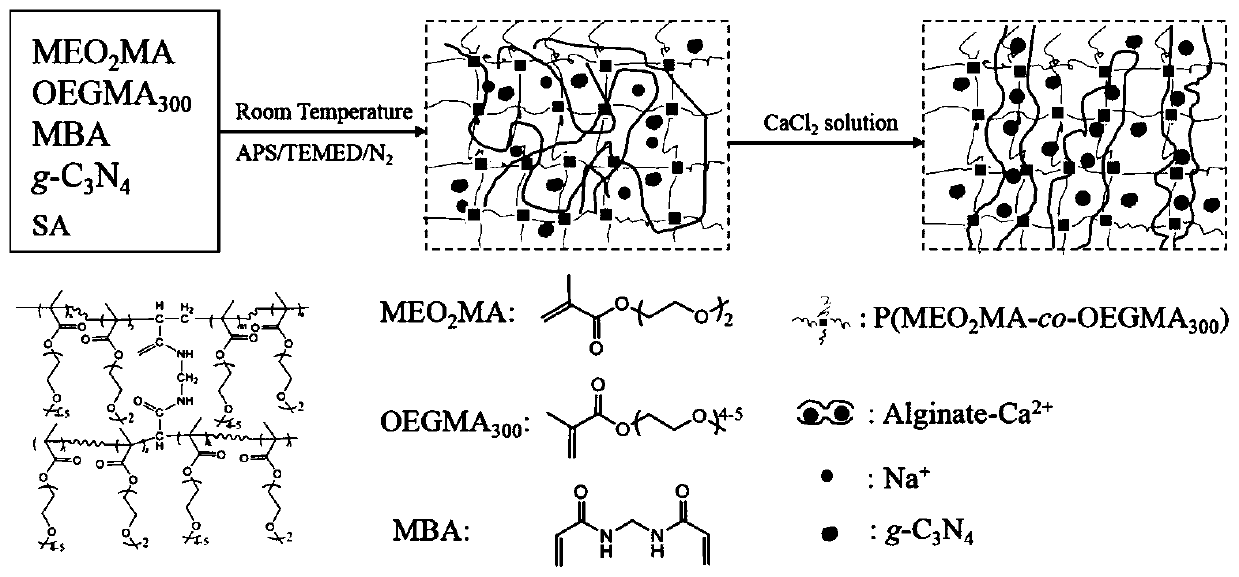

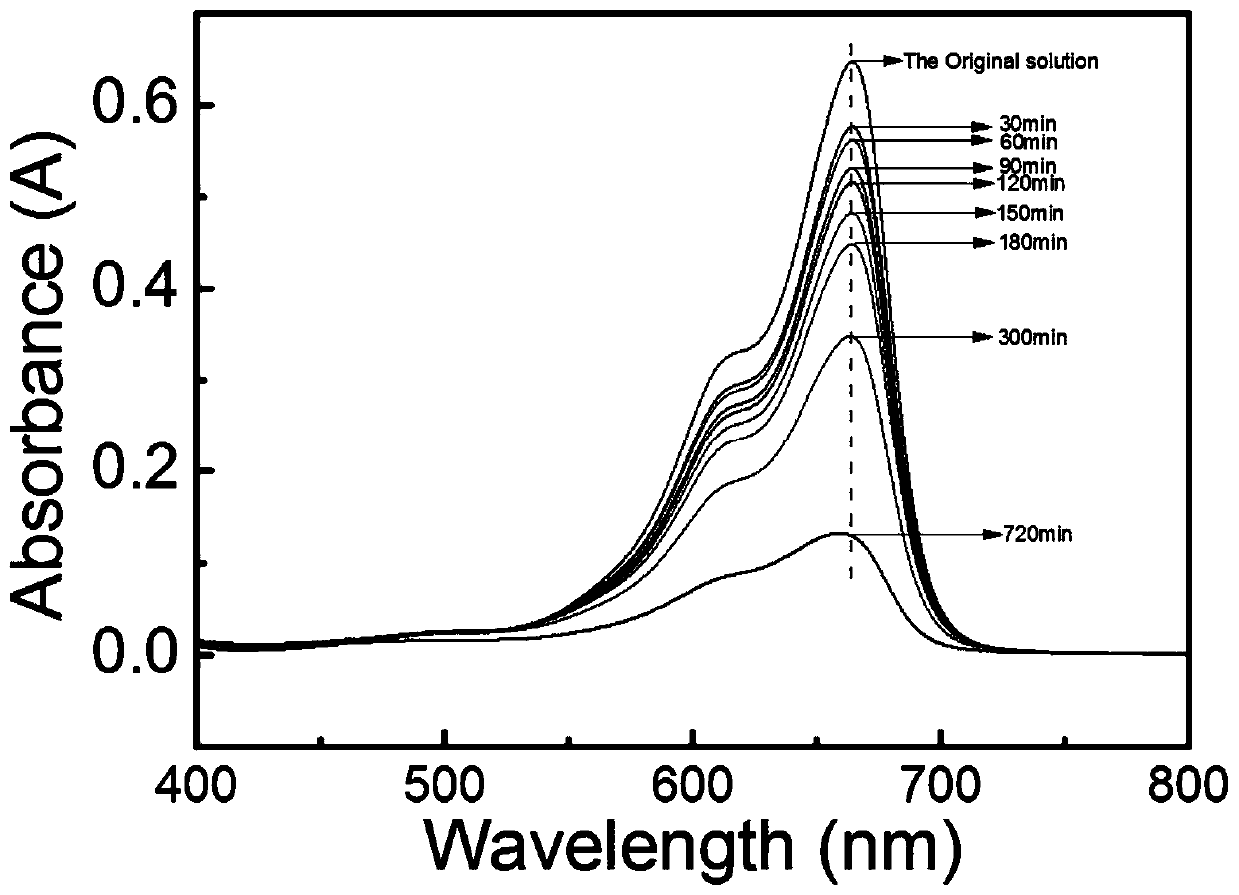

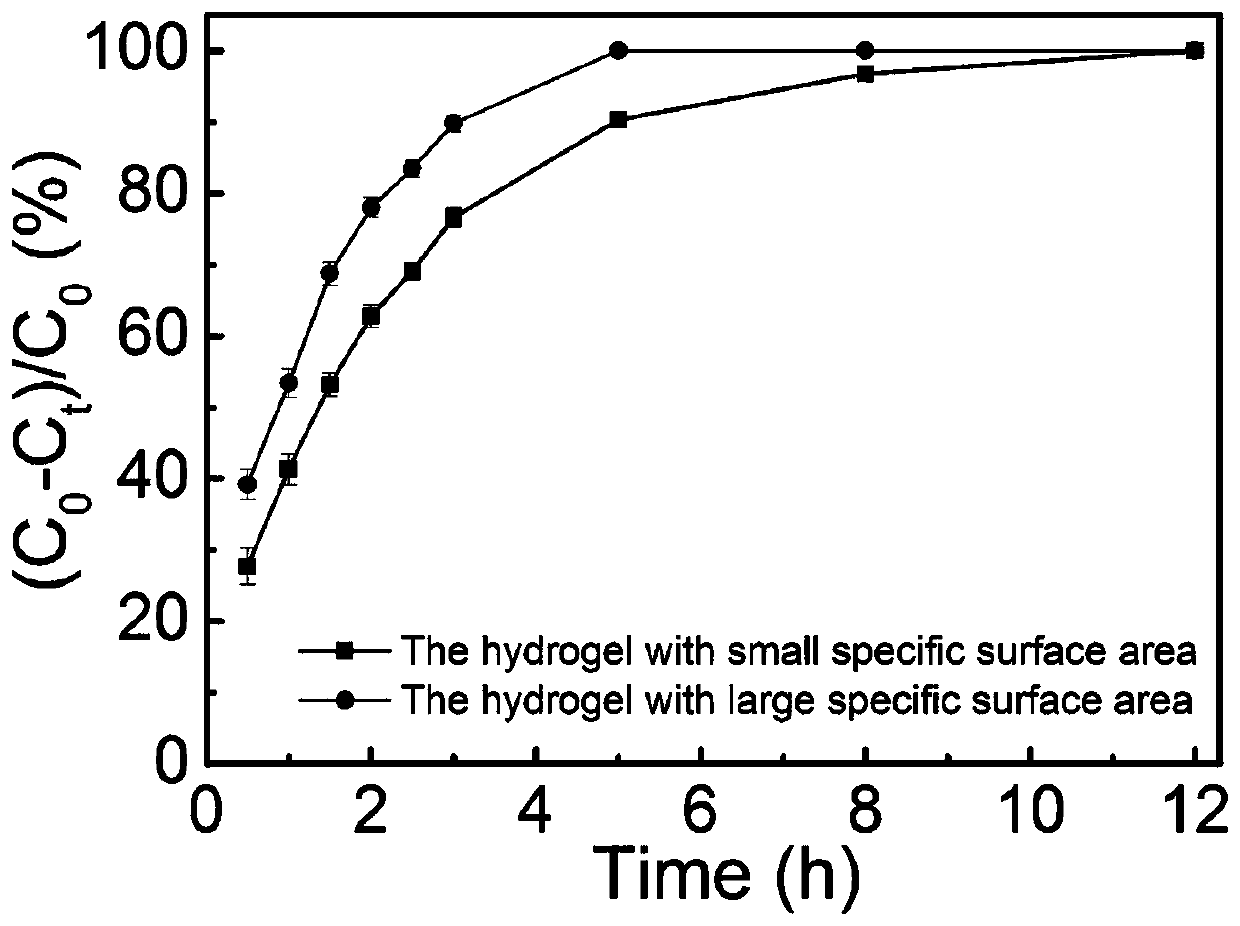

Preparation method and application of temperature-sensitive composite hydrogel by utilizing synergistic effect of photocatalysis and temperature sensitivity

ActiveCN111154027AHigh porosityImprove efficiencyOther chemical processesAlkali metal oxides/hydroxidesPtru catalystDyeing wastewater

The invention relates to the technical field of printing and dyeing wastewater treatment. The invention discloses a preparation method and application of temperature-sensitive composite hydrogel by utilizing a synergistic effect of photocatalysis and temperature sensitivity. The temperature-sensitive composite hydrogel disclosed by the invention is prepared by the steps: introducing a temperature-sensitive copolymer and a photocatalyst into alginate hydrogel; the porosity of the hydrogel is adjustable in the temperature change process, a dye can be adsorbed and degraded under the illuminationcondition, and the adsorption capacity of the composite hydrogel to the dye is improved by virtue of the synergistic effect of a porous structure in the hydrogel caused by adding a catalyst and a loose structure formed by a temperature-sensitive copolymer at the temperature higher than the conversion temperature. And by virtue of the photocatalyst embedded in the hydrogel, the degradation of the adsorbed dye and the cyclic utilization of the composite hydrogel can be realized, and the composite hydrogel can be applied to the fields of printing and dyeing sewage treatment and the like.

Owner:ZHEJIANG SCI-TECH UNIV

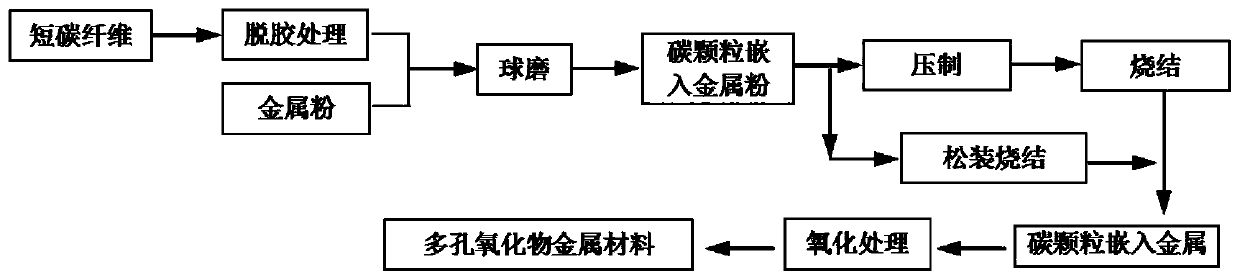

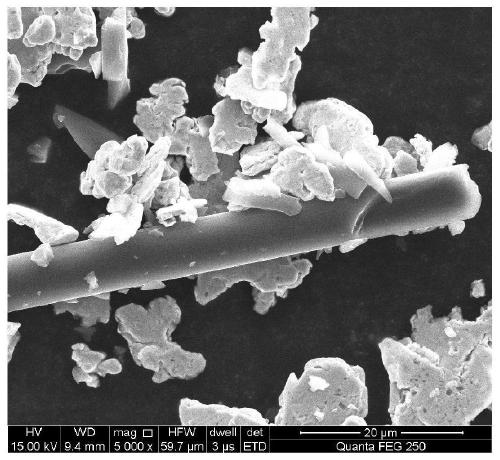

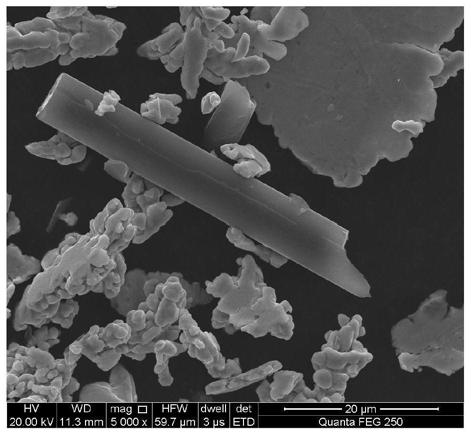

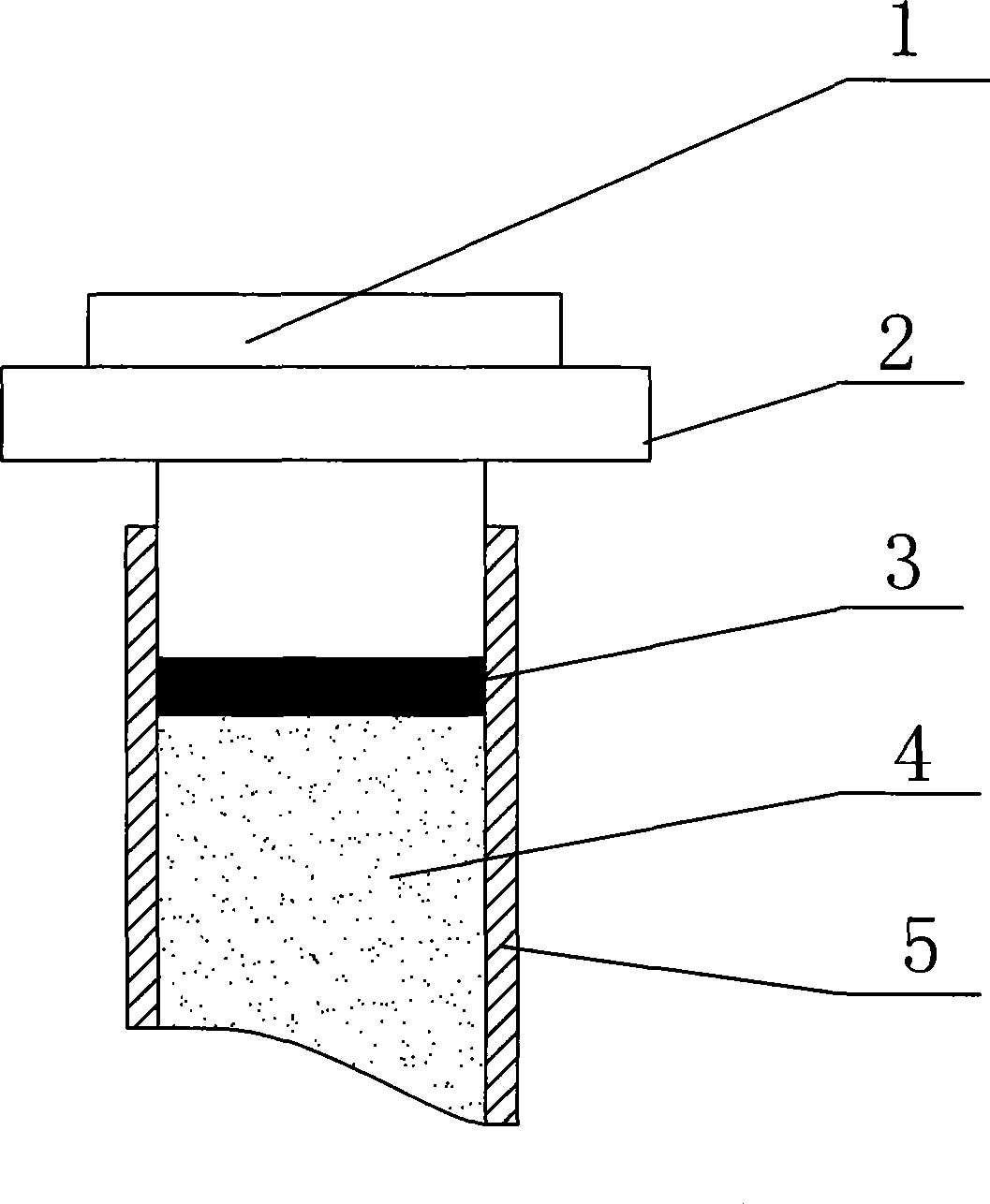

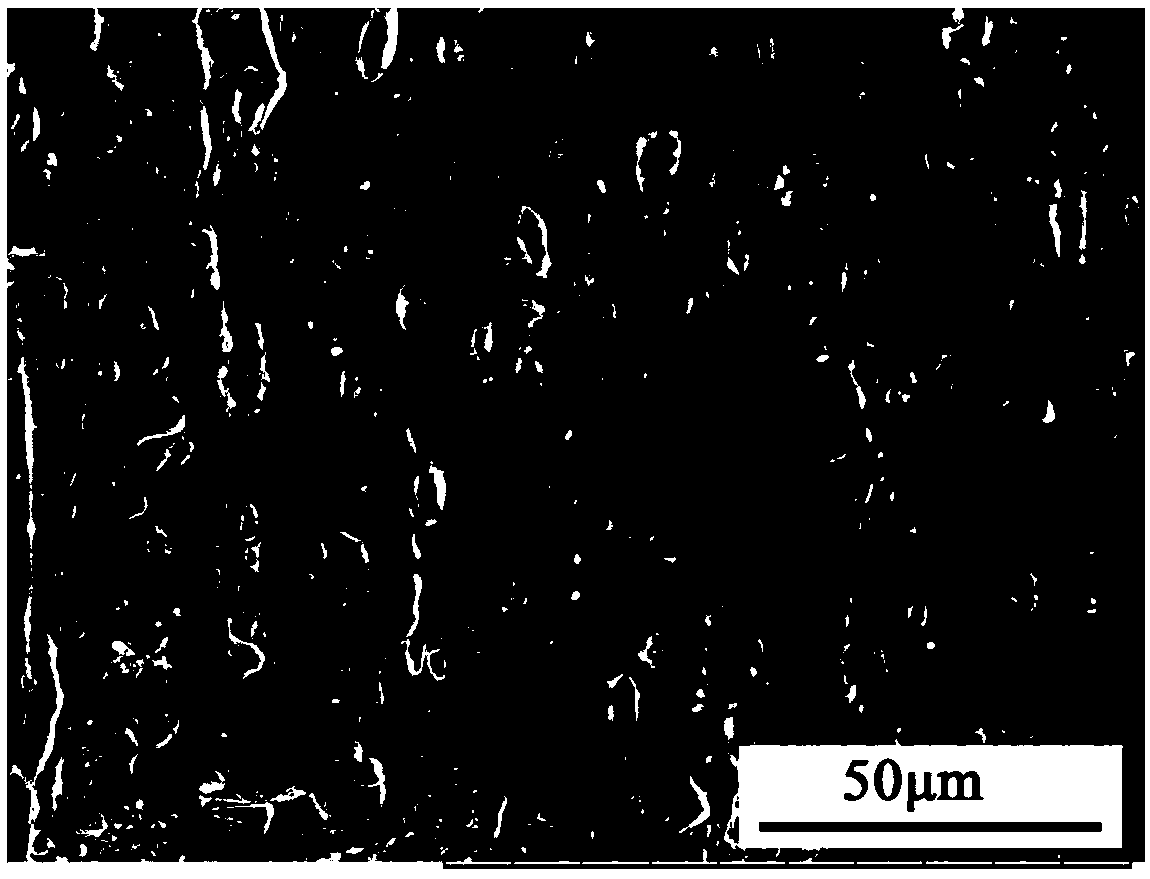

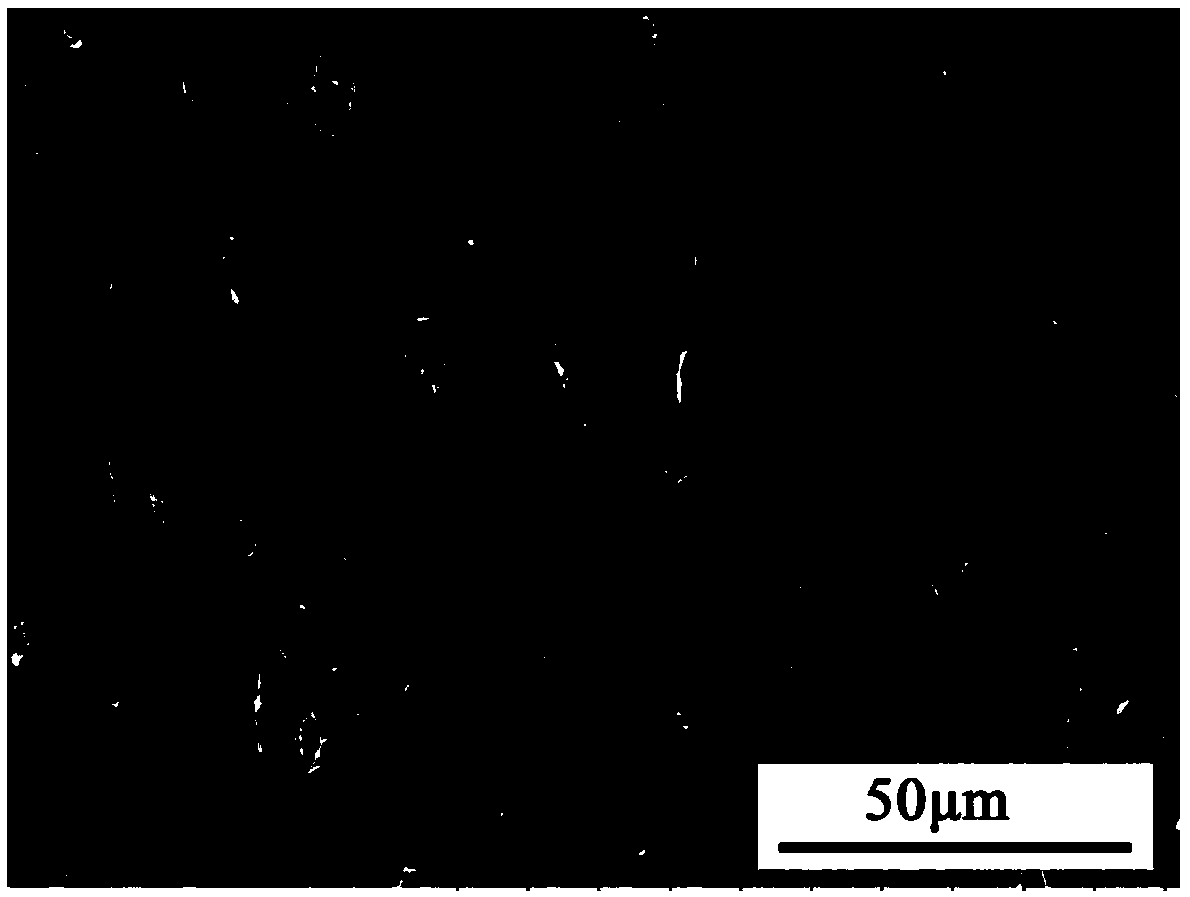

Preparation method of porous metal oxide

The invention relates to a preparation method of a porous metal oxide, and belongs to the crossing field of metal powder technology and metal material surface treatment. The preparation method comprises the following steps: firstly degumming short carbon fibers, then performing a suitable ball milling process on the degummed short carbon fibers and a metal powder to obtain a metal powder embeddedwith ultrafine carbon particles, performing sintering after press-forming in a protective atmosphere or vacuum, or directly performing loose sintering, finally performing short-time annealing treatment in oxygen-containing air to remove the carbon particles in the metal powder and partially oxidize the surface of metal particles to obtain the porous metal whose surface is partially oxidized. The porous metal oxide prepared by the method exhibits good oil storage, hydrogen storage, paraffin wax storage, lithium storage performances, and catalytic performance, and the porous metal oxide has simple preparation process and low cost.

Owner:CENT SOUTH UNIV

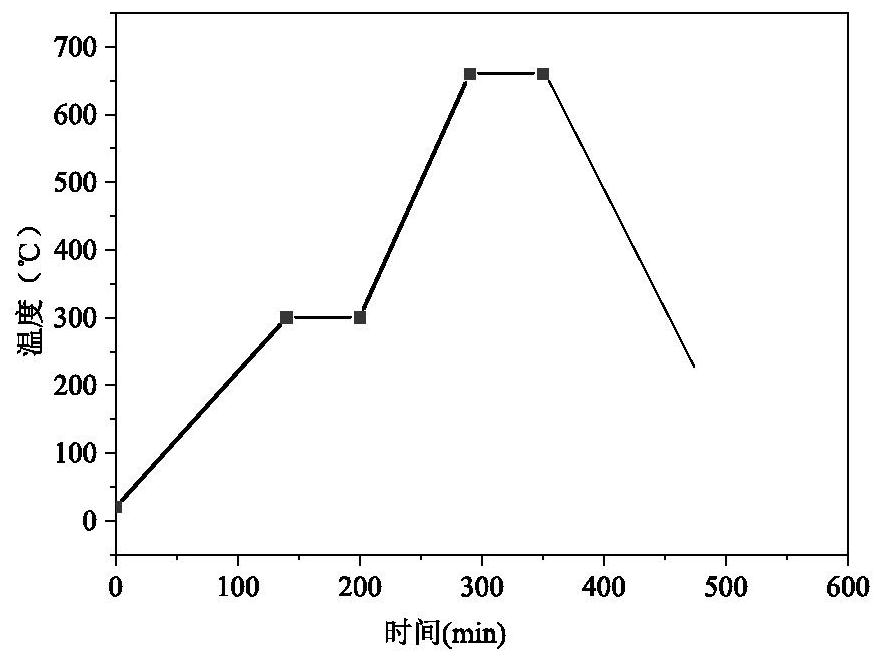

Low temperature dynamic constraint load sintering method for preparing metal polyporous material

The invention discloses a low-temperature dynamic constraint loading-sintering method for preparing metal porous materials. A preparation process is as follows: to-be-sintered metal blank or powder is directly put into a sintering mold; a heat-resistant loading weight with a limiting stopper is placed on the to-be-sintered metal blank or powder; the gravity of the loading weight is utilized to apply pressure to the to-be-sintered metal blank or powder; then the sintering mold is placed in a vacuum sintering furnace; and low-temperature dynamic constraint loading-sintering is performed under the condition lower than a common metal porous material sintering temperature, so as to prepare the metal porous materials. The low-temperature dynamic constraint loading-sintering method adopted by the invention comprises the following steps of adopting a loading mold with simple structure in a common powder-metallurgy vacuum sintering furnace, utilizing the deadweight phenomenon of the mold to mutually bond metal particles thermally softened and finishing sintering the metal porous materials at a low temperature, which avoids the phenomenon that metal high-temperature grains grow up. The metal porous materials are adjustable in size and controllable in porosity. The method has the advantage of greatly reducing production cost, along with simple process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Process for cold pressing-solving-vacuum sintering preparation of foamed aluminum

The invention designs a kind of cold-press - dissolved - vacuum to agglutinate the preparation froth aluminum method, is the froth aluminum the preparation technology. The method including below process: In the 180~~200 goal aluminite powder, compared to is 40~~70% joins the average grain diameter according to the quality is 0.45~~1.00mm NaCl makes the hole medicinal preparation, and compared to joins 5% absolute ethyl alcohol according to the aluminite powder and the NaCl quality to carry on the intensive mixing; Above will match the good mix aluminite powder to lay aside in will rub has, will suppress the semifinished product under the 250~~350MPa pressure, then will set at the semifinished materials in the 75~~85deg.C water bath soaks causes NaCl to dissolve, again will use the deionized water repeatedly to wash eliminates remaining NaCl; After will go to NaCl the pressure semifinished product to agglutinate as for the vacuum oven, maintains in the stove vacuum degree 1*10 -3 power of exponent ~~1*10 -4 power of exponent Pa, will control 8-10deg.C / min to heat up the speed temperature rise and keeps warm 2-3h the stove to 540~~560deg.C, then will cool along with the stove to the room temperature system results in the froth aluminum. The invention merit lies in, technological process simple, the manufacture froth aluminum blowhole size even, the opening wall intensity is high controllably factor of porosity.

Owner:TIANJIN UNIV

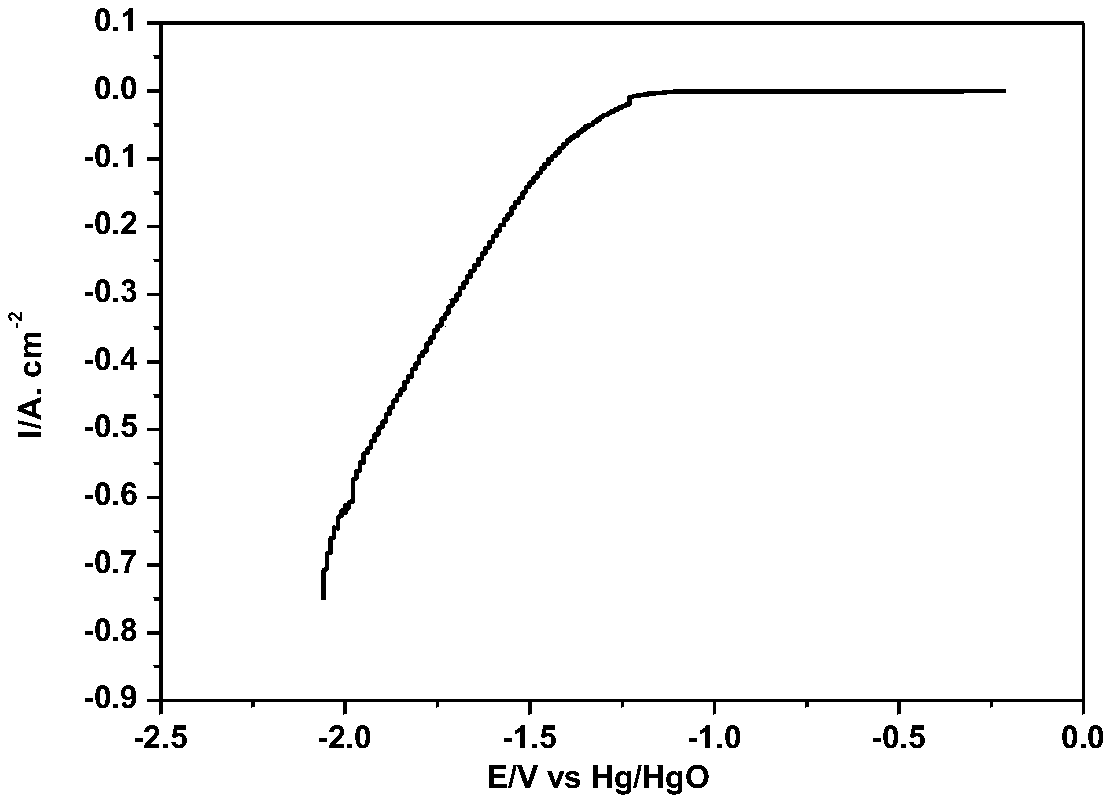

Preparation method of pre-alloyed porous nickel-based electrolytic hydrogen evolution cathode material

InactiveCN109267084AStable physical and chemical propertiesLarge specific surface areaElectrode shape/formsIron powderHydrogen

The invention provides a Ni-Fe-Mo-Mn porous material. The Ni-Fe-Mo-Mn porous material is prepared by the steps of accurately weighing 15 to 21 percent of ferro-molybdenum, 11 to 16 percent of ferro-manganese, 7 to 9 percent of iron powder the balance of nickel, preparing pre-alloyed powder by adopting an atomization technology and sintering in vacuum. The porous material prepared by the inventionhas abundant, uniform and controllable pores and has the advantages of large specific surface area, low hydrogen evolution overpotential, good catalytic performance, good corrosion resistance, stableworking performance, simple and environment-friendly preparation technology and the like; the preparation cost is low and the technology is simple and easy to realize. The porous material prepared bythe invention can be used as the electrolytic hydrogen evolution cathode material.

Owner:XIANGTAN UNIV +1

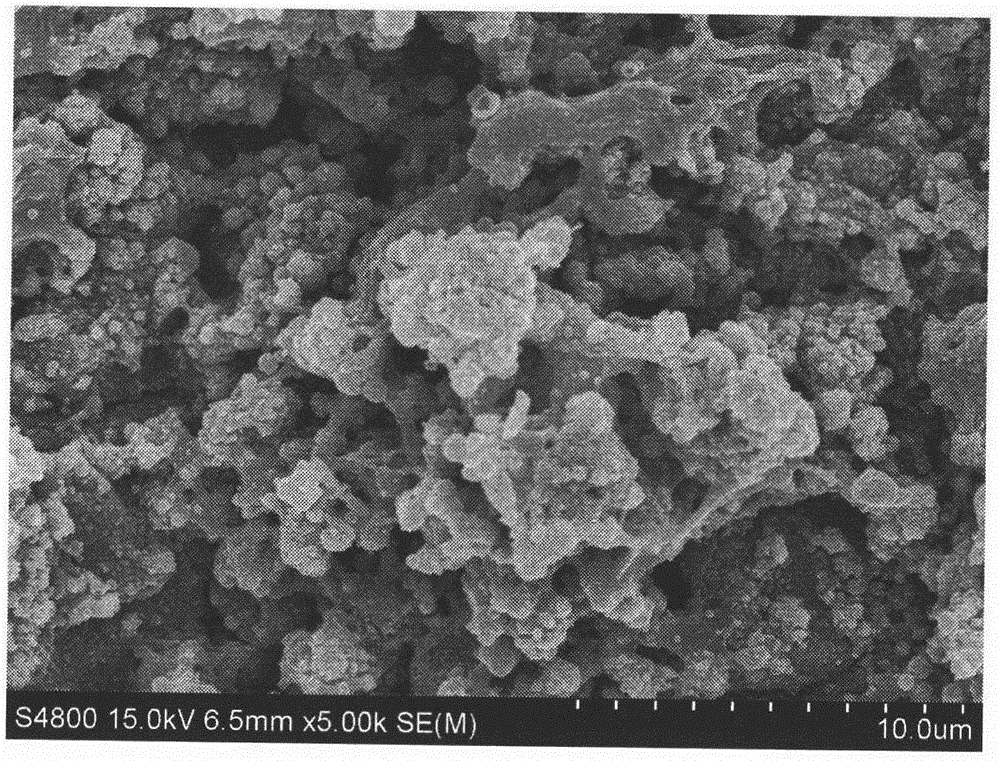

Preparation method for prefabricated SiC component used for SiC-reinforced Al-based composite material

The invention discloses a preparation method for a prefabricated SiC component used for a SiC-reinforced Al-based composite material. The preparation method comprises the following steps: (1) adding pore forming agent starch into the binder analytically pure Al(H2PO4)3, carrying out uniform mixing so as to obtain a uniform mixture, adding the uniform mixture into an alpha-SiC raw material, carrying out uniform mixing again and drying and sieving an obtained mixture so as to obtain a material for the prefabricated component; (2) filling the material for the prefabricated component obtained in step (1) into a die and carrying out compression molding by using a hydraulic press so as to obtain a wet blank of the prefabricated SiC component; and (3) sintering the wet blank of the prefabricated SiC component obtained in step (2) so as to obtain the prefabricated SiC component. The preparation method provided by the invention has the advantages of strong operationality, easiness, practicability, low cost and easy control; and the prefabricated SiC component prepared by using the method has appropriate porosity, uniform pore distribution and high mechanical strength and is easy to control and sufficient to meet demands for subsequent liquid phase infiltration of Al.

Owner:SOUTH CHINA UNIV OF TECH

Polyperfluorinated ethylene propylene hollow fiber membrane preparation formula and preparation method

InactiveCN109351209AHigh porosityImprove permeabilitySemi-permeable membranesMembranesPolymer scienceDecomposition

The invention discloses a polyperfluorinated ethylene propylene hollow fiber membrane preparation formula and preparation method. The formula comprises 50-75wt% of polyperfluorinated ethylene propylene, 20-40wt% of a pore-forming agent, 5-15wt% of a plasticizer and 0-10wt% of auxiliary additives, wherein the sum of the components is 100wt%, and the pore-forming agent refers to calcium carbonate. The method includes: well mixing the components in the formula, granulating, quantitatively extruding particles, and after curing of spinning melt in an air bath, performing online stretching and winding to obtain a primary hollow fiber membrane; subjecting the primary hollow fiber membrane to after stretching and heat setting, and soaking membrane fibers into acid solution to leach out calcium carbonate; sequentially performing extraction washing and water washing to obtain a polyperfluorinated ethylene propylene hollow fiber membrane in a multi-hole structure with a stretching hole, a dissolution hole and an interface hole. By adoption of calcium carbonate as the pore-forming agent in the formula, decomposition in a high-temperature spinning process is avoided, and the calcium carbonate can be completely leached out by the acid solution after spinning forming is finished.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing ceramic filters with hot pressure casting process

InactiveCN108178654ALower sintering temperatureControllable porosityDischarging arrangementFeeding arrangmentsPorosityMagnesium salt

The invention relates to a method for preparing ceramic filters with a hot pressure casting process. The method comprises steps as follows: alumina powder with proper grain size distribution and paraffin are mixed in a certain ratio, one or more pore-forming agents such as carbon powder, wood chips, aluminum salt, titanium salt, magnesium salt, sodium salt, lanthanum salt, cerium salt and the likeare added according to the size and distribution of required pores, and alumina slurry is configured. Under certain pressure, the slurry is injected into a mold meeting the shape requirement for forming, and various special-shaped filter bodies meeting the requirements are prepared; the bodies are subjected to removal burning, the pore-forming agents are removed, and porous bodies are obtained; the porous bodies are sintered at the high temperature, and the special-shaped alumina ceramic filters are obtained. In the whole process, no special mechanical equipment is required, the pore size anddistribution and the shapes of the filters are controllable, and the method is an ideal process for preparing high-porosity, high-strength and special-shaped ceramic filters.

Owner:辽宁法库陶瓷工程技术研究中心

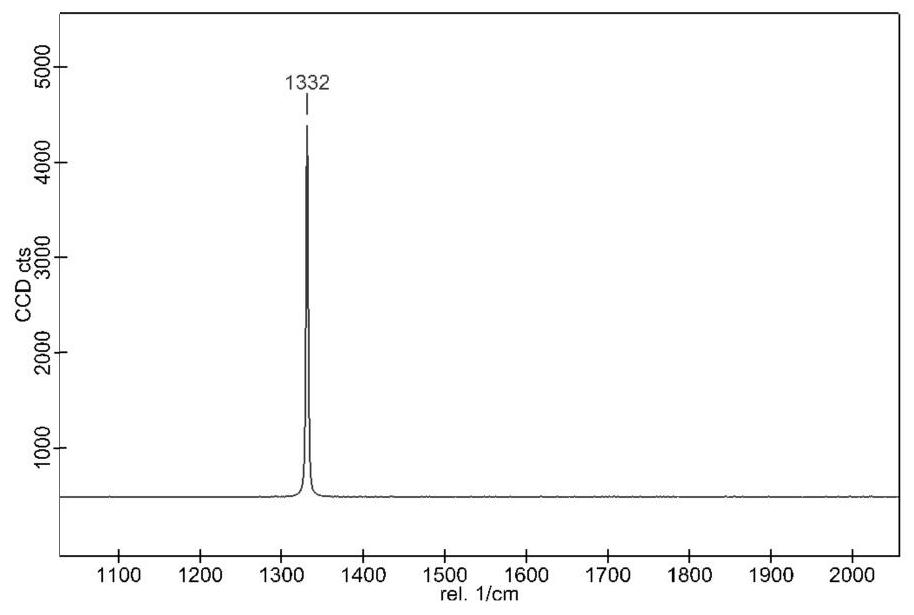

Slurry direct writing forming method of diamond tool

ActiveCN112723902APromote self-sharpeningUniform stomataAdditive manufacturing apparatusAbrasion apparatusPolymethyl methacrylateNanoceramic

The invention discloses a slurry direct writing forming method of a diamond tool, which comprises the following steps: (1) fully mixing nano ceramic powder, PMMA (polymethyl methacrylate) and diamond microparticles to obtain mixed powder; (2) fully dispersing xanthan gum in deionized water to obtain a xanthan gum solution; (3) uniformly mixing the mixed powder prepared in the step (1) with the xanthan gum solution obtained in the step (2) to obtain slurry; (4) adding the slurry prepared in the step (3) into a needle cylinder of slurry direct writing forming equipment, and printing into a designed shape in a layer-by-layer overlapping manner to obtain a green body; and (5) drying the green body prepared in the step (4) to constant weight, and then sintering to obtain the diamond tool. The diamond tool with a complex structure can be manufactured at a time through slurry direct writing forming, and the diamond tool has high consistency, proper mechanical property, controllable porosity and high shape precision.

Owner:HUAQIAO UNIVERSITY

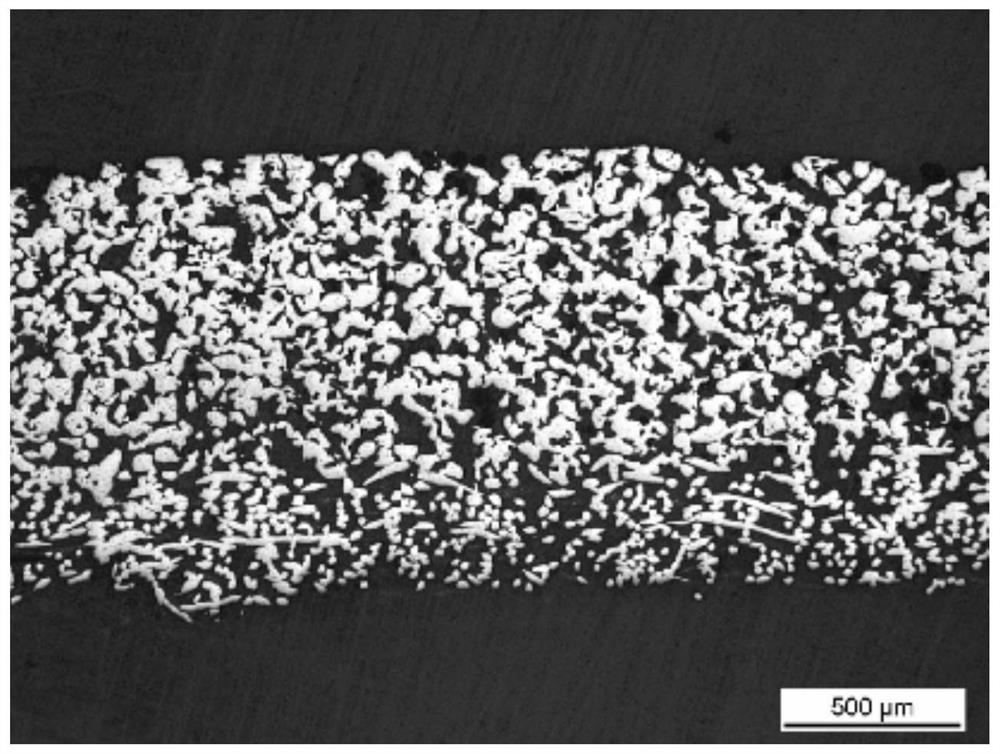

Manufacturing method of metal supporting plate for fuel cell

PendingCN113054215AReduce sintering deformationElimination of sintering deformationFinal product manufactureFuel cellsFuel cellsSlurry

The invention relates to a manufacturing method of a metal supporting plate for a fuel cell. The manufacturing method sequentially comprises the following steps: 1) adopting one of sintered stainless steel, heat-resistant steel, nickel-based alloy, cobalt-based alloy, titanium alloy and chromium-based alloy; 2) screening the powder in the step 1), wherein the particle size of the selected powder is 13-250 microns; 3) placing the powder in an inner hole of a measuring vessel, removing a redundant powder, and placing the measuring vessel on a load bearing plate; 4) sintering the load bearing plate on which the measuring vessel is placed; 5) coating an anode slurry on the upper surface of a metal substrate so as to form an anode layer on the upper surface of the metal substrate; 6) coating an electrolyte slurry on the upper surface of the anode layer to form an electrolyte coating on the surface of the anode layer; and 7) coating the cathode slurry on the upper surface of the electrolyte coating to form a cathode layer on the upper surface of the electrolyte coating so as to produce a metal support plate. Sintering deformation is eliminated, and the combination tightness between the anode layer and the metal substrate is improved.

Owner:NBTM NEW MATERIALS GRP

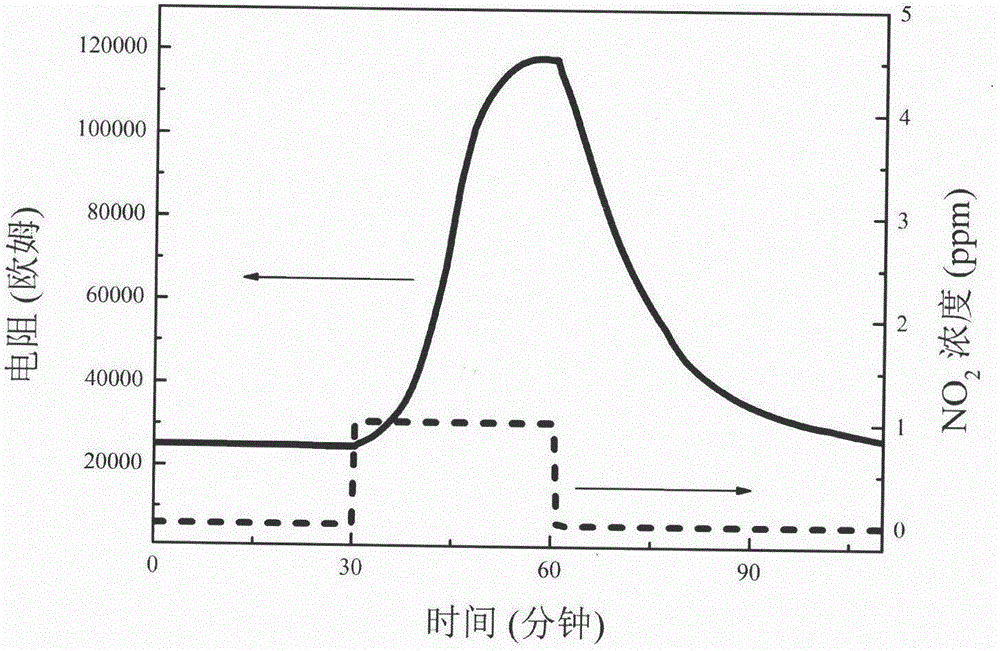

Preparation method of homotype heterojunction based semiconductor nitrogen dioxide gas sensitive layer

InactiveCN106546636AHigh sensitivityQuick responseMaterial resistanceHeterojunctionSemiconductor materials

The invention relates to a preparation method of a homotype heterojunction based semiconductor nitrogen dioxide gas sensitive layer. The method includes: taking oxidation treated monocrystalline silicon wafer Si as the insulation substrate, preparing an interdigitated electrode and a terminal on the front of the insulation substrate, dissolving mixed powder of zinc nitrate and tin chloride in deionized water or an organic solvent, and performing stirring to obtain a homogeneous solution to serve as a precursor, sending the precursor into flame flow generated by a plasma spray gun through a non-atomizing nozzle, carrying out evaporation, decomposition, nucleation, heating and acceleration series reaction, and letting molten particles bombard the position right above the interdigitated electrode so as to obtain a semiconductor gas sensitive coating. The method provided by the invention overcomes the defects of complex steps, long experiment time, low efficiency, basically no repeatability and the like in previous methods. According to the invention, the homotype heterojunction semiconductor gas sensitive layer can realize compounding of a variety of homotype semiconductor materials, and the prepared gas sensitive material has the advantages of high sensitivity to low concentration NO2, fast response speed and the like.

Owner:YANGZHOU UNIV

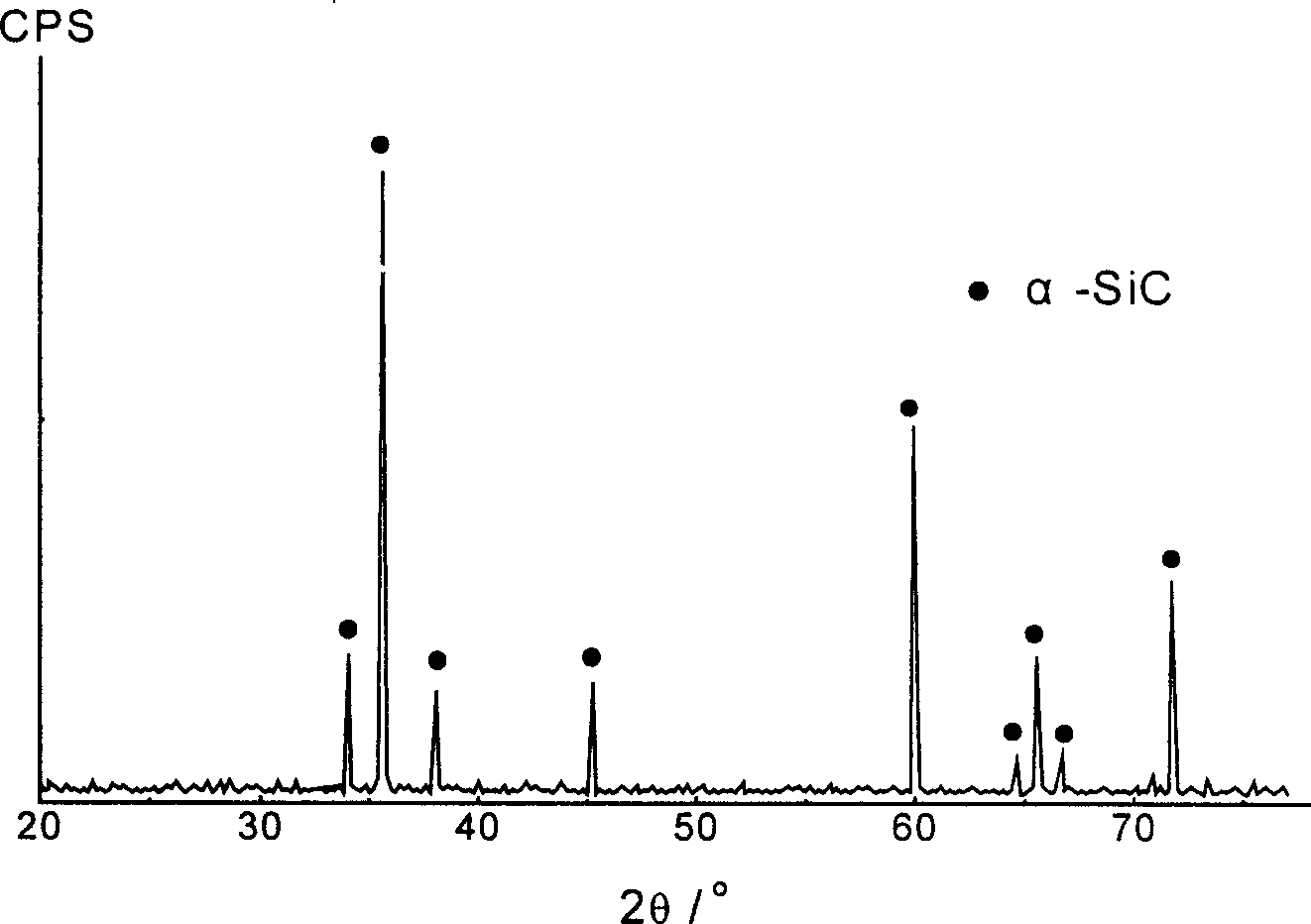

Preparation technique for silicon carbide heating element

The invention relates to the preparation technique for silicon carbide heating ceramic material, wherein the material is prepared from silicon carbide, petroleum coke, graphite, activated charcoal, silicon powder by the mass fraction of 0.3-0.9, 0.05-0.5, 0-0.2, 0-0.1, 0-0.3 through conventional processes which comprises 12 steps and specific technological conditions, the obtained principal crystalline phase is alpha-SiC with porosity.

Owner:XI AN JIAOTONG UNIV

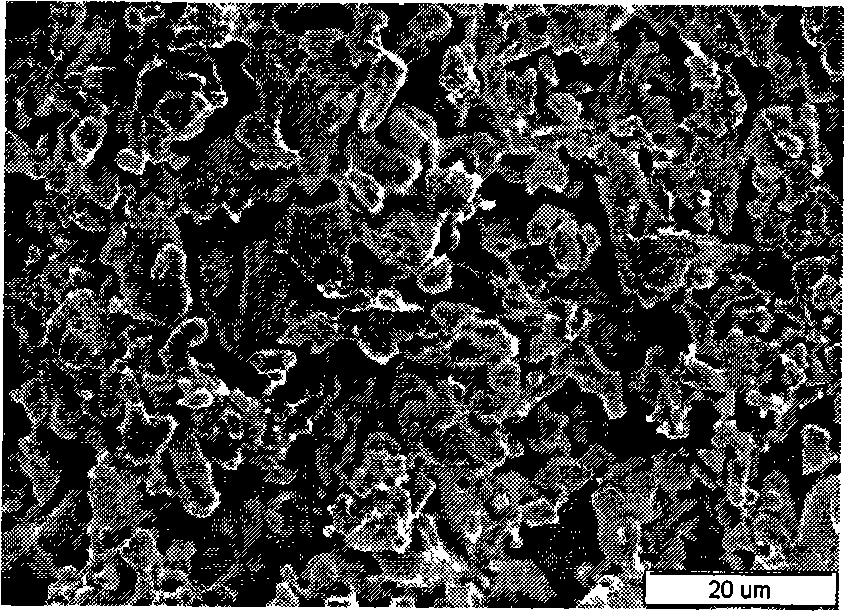

Method for preparing porous ceramic by coating beta-Si3N4 granule with oxide

The invention discloses a method for preparing porous ceramic by coating beta-Si3N4 particles with a composite oxide CaO-SiO2-B2O3, which is a porous body preparation technology comprising the following steps: the beta-Si3N4 particles are put into a CaO-SiO2-B2O3 sol made from tetraethoxysilane, boric acid, calcium nitrate, citric acid, absolute ethyl alcohol and deionized water, and the vacuum filtration method is adopted to form the porous body by self porous structure of the columnar beta-Si3N4 crystalline particles. The surface of the sintered beta-Si3N4 particles is coated with a modification layer of CaO-SiO2-B2O3 oxide interface, and the modification layer effectively connects the beta-Si3N4 particles and prevents the beta-Si3N4 particles from oxidation at high temperature. The porous ceramic prepared by the method can be used as a radome and a catalyst carrier material.

Owner:BEIHANG UNIV

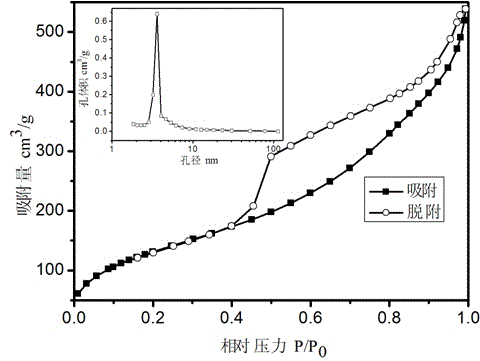

Method for preparing porous nickel-based amorphous alloy material

The invention provides a method for preparing porous nickel-based amorphous alloy material. The method combines a chemical reduction method with an in-situ precipitation pore-forming agent generation method. The prepared alloy material is in porous structure, has the specific surface area of 300-700 m<2> / g and the pore volume of 0.5-1.5 cm<3> / g, and the prepared amorphous alloy consists of Ni and B or Ni, B and element M; and the element M is one or multiple elements of Cu, Mo, P and Co. The method comprises the following steps: (1) solution is prepared; (2) alloy and pore-forming agent precipitation are produced through in-situ generation; and (3) prickling pore-forming is carried out, and the porous nickel-based amorphous alloy material is finally obtained. The amorphous alloy material prepared by the method has the characteristics that the aperture ratio is controllable, the pore structure and pore distribution are uniform, and the specific surface area is large. According to the amorphous alloy material prepared by the method, the specific surface area can reach more than 650 m<2> / g, the pore volume can be more than 1 cm<3> / g, the pore diameter distribution is uniform (3-4 nm), and the pore diameter is controllable.

Owner:HEBEI UNIV OF TECH

Low-VOC lubricating agent doped with self-assembly core-shell inorganic particles and used for polyolefin and preparation method of low-VOC lubricating agent

The invention relates to a low-VOC lubricating agent doped with self-assembly core-shell inorganic particles and used for polyolefin and a preparation method of the low-VOC lubricating agent and belongs to the field of production and processing of novel high polymer materials. The preparation method aims to solve the problems that high-shear friction occurs and volatile pollutants are easily decomposed due to high-temperature heating during the high-temperature forming process of the lubricating agent for the polyolefin and is characterized in that the electrostatic layer-by-layer self-assembly technique is used to prepare the core-shell inorganic particles with high adsorption performance, shell layer thickness and shell layer particle pores can be controlled, and the core-shell inorganic particles are compounded with other auxiliaries to prepare the low-VOC efficient lubricating agent. The lubricating agent prepared by the method has the advantages that the lubricating agent can greatly improve processing rheological properties and lubricating properties during the high-temperature forming of polymer polyolefin materials, and VOC content can be lowered to below 120 microgram C / g.

Owner:可赛成功(浙江)新材料科技有限公司

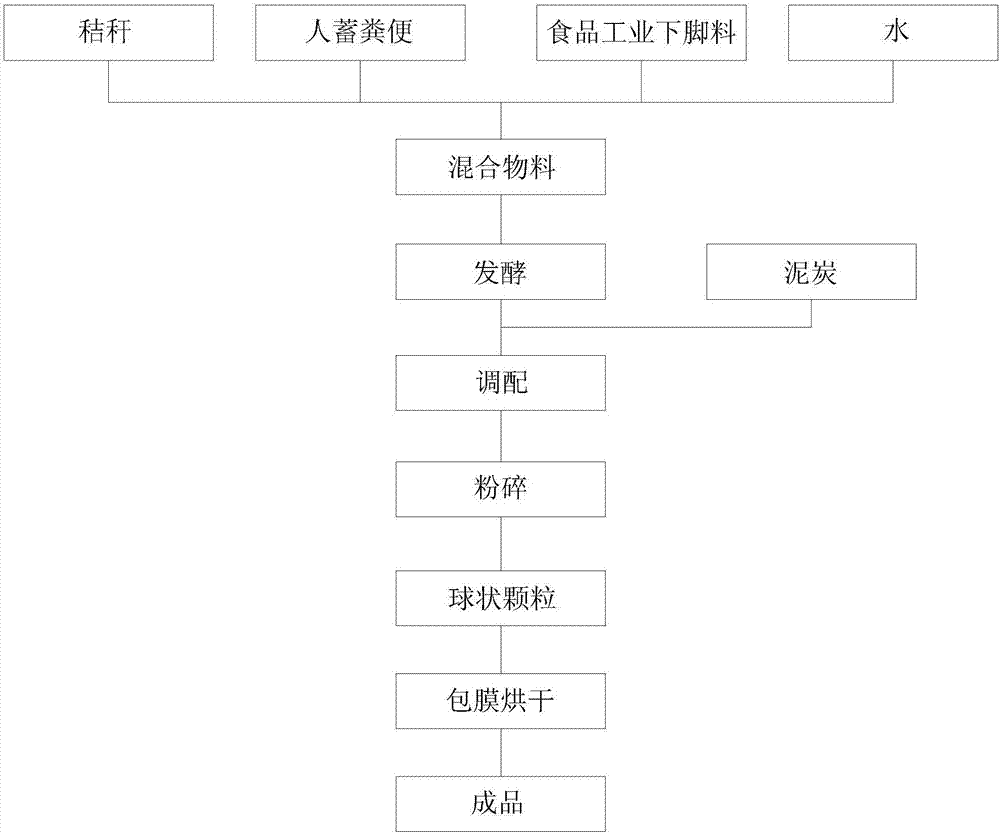

Making method for particle substrate

InactiveCN107047118AHigh in fertilizerControllable porosityExcrement fertilisersBioloigcal waste fertilisersPeatMixed materials

The invention discloses a making method for a particle substrate. The making method comprises the following steps: step one, mixing straws, excrement of people and livestock and food industrial leftovers according to the volume ratio of 2:1:1, adding water and preparing a mixed material, wherein the mass of the water in the mixed material is 60%, adding fermentation strains to the mixed material and sending to a fermentation tank after adequately stirring; step two, detecting the material temperature in the fermentation tank, while the material temperature in the fermentation tank is only reduced and is not ascended, finishing the material fermentation, wherein the total mass content of nitrogen phosphorus and potassium in the fermented material is greater than 5.0%, and the carbon nitrogen ratio thereof is less than 30:1; step three, adding 30% of peat by volume ratio to the fermented material, so that the total mass content of the nitrogen phosphorus and potassium is 2%-3%, PH is 6.5-7.5, and conductivity rate EC is less than 2.5 ms / cm; and step four, smashing the prepared material to be 1-3 mm of powder, making 4-10 mm of spherical particles by the powder, and conveying the spherical particles to an enveloping machine, adding xanthan gum, enveloping and drying, finally packaging and storing.

Owner:嘉兴市归源农业技术开发有限公司

Porous titanium-aluminum-based alloy material, preparation method and application thereof

The invention discloses a porous titanium-aluminum-based alloy material, a preparation method and application thereof. According to the porous titanium-aluminum-based alloy material, titanium powder and aluminum powder are adopted as raw materials, and the porous titanium-aluminum-based alloy material is prepared and acquired by adopting a metal powder injection molding technology. No pore formingagent is added in the preparation process of the porous material; instead, difference of the diffusion coefficient between aluminum and titanium is utilized; and aluminum diffuses in titanium, and ahigh-porosity material is acquired. The porous titanium-aluminum-based alloy material prepared by adopting the method is molded in a near-net manner; the interior of pores is clean and environment-protective; and the material can be applied to fields such as medical implantation and the like as an implanted material.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com