Preparation method of porous ceramic particle

A technology of porous ceramics and manufacturing methods, which is applied in the field of preparation of porous ceramic particles, can solve the problems of free design, unsatisfactory free-form building greening, low porosity of porous ceramics, and high requirements for raw material powders, so as to achieve preferential growth and development, The effect of good liquidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

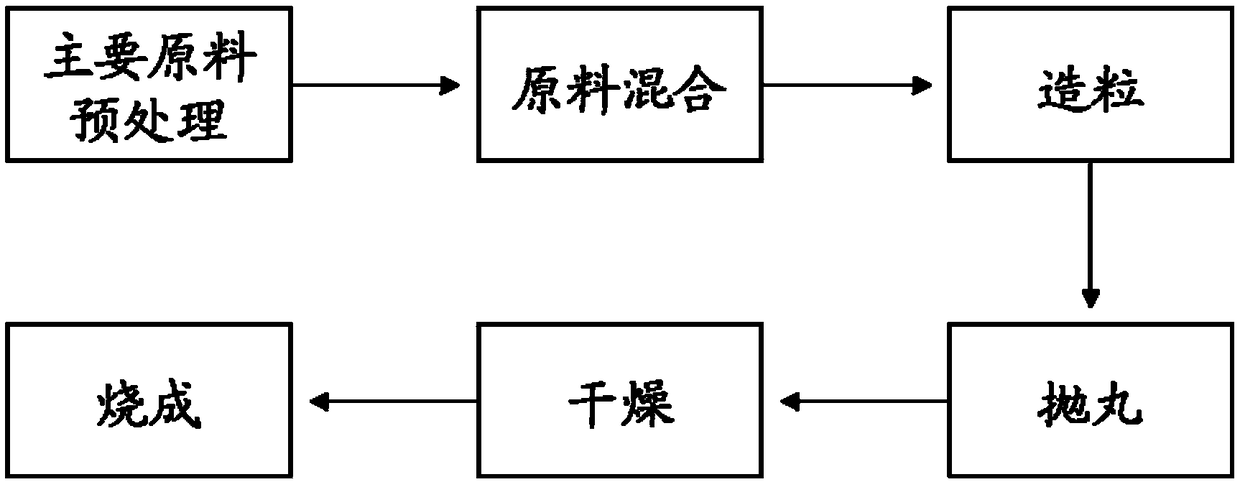

[0033] A kind of preparation method of porous ceramic particles, its technological process is as follows figure 1 As shown, the detailed method steps are as follows:

[0034] (1) The main raw materials are pretreated. The pretreatment is drying and pulverization. In parts by mass, 30 parts of fly ash, 20 parts of construction waste, 25 parts of mine mud, 15 parts of clay, 10 parts of Potassium feldspar, 30 parts of coal powder, and 1 part of polyvinyl alcohol are dry mixed in a high-speed mixer for 3 minutes, after dry mixing, add 15 parts of water, and continue mixing for 5 minutes;

[0035] (2) After the wet mixing is completed, the wet material is added to the rotary granulator for granulation to obtain strip-shaped granules;

[0036] (3) Put the strip-shaped particles granulated in step (2) into a shot blasting machine, and pelletize under high-speed centrifugal force to obtain spherical particles, then put them into an oven, and bake at 100°C for 150 minutes;

[0037] (...

Embodiment 2

[0041] A preparation method of porous ceramic particles, the detailed method steps are as follows:

[0042] (1) The main raw materials are pretreated. The pretreatment is drying and pulverization. In parts by mass, 40 parts of fly ash, 30 parts of construction waste, 10 parts of clay, 10 parts of albite, 0.1 Dry mix 1 part of SiC, 10 parts of coal powder, 1 part of polyvinyl alcohol, and 4 parts of pregelatinized starch in a high-speed mixer for 60 minutes, add 20 parts of water after dry mixing, and continue mixing for 30 minutes;

[0043] (2) After the wet mixing is completed, the wet material is added to the rotary granulator for granulation to obtain strip-shaped granules;

[0044] (3) Put the strip-shaped particles granulated in step (2) into a shot blasting machine, and pelletize under high-speed centrifugal force to obtain spherical particles, then put them into an oven, and bake at 30°C for 240 minutes;

[0045] (4) firing the spherical particles dried in step (3) at ...

Embodiment 3

[0049] A preparation method of porous ceramic particles, the detailed method steps are as follows:

[0050] (1) The main raw materials are pretreated. The pretreatment is drying and pulverization. In terms of parts by mass, 100 parts of construction waste, 1 part of SiC, and 1 part of Fe 2 o 3 , 20 parts of coal powder, 18 parts of CaCO 3 , 2 parts of polyvinyl alcohol and 6 parts of pregelatinized starch were dry mixed in a high-speed mixer for 5 minutes, after dry mixing, 15 parts of water were added, and the mixture was continued for 10 minutes;

[0051] (2) After the wet mixing is completed, the wet material is added to the rotary granulator for granulation to obtain strip-shaped granules;

[0052] (3) Put the strip-shaped particles granulated in step (2) into a shot blasting machine, and pelletize under high-speed centrifugal force to obtain spherical particles, then put them into an oven, and bake at 200°C for 5 minutes;

[0053] (4) Spherical particles dried in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com