Method for preparing porous ceramic by coating beta-Si3N4 granule with oxide

A technology of porous ceramics and composite oxides, applied in the field of silicon nitride series ceramics, can solve the problems of complex sintering process, deterioration of material properties, etc., and achieve the effects of low dielectric constant, excellent dielectric properties, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

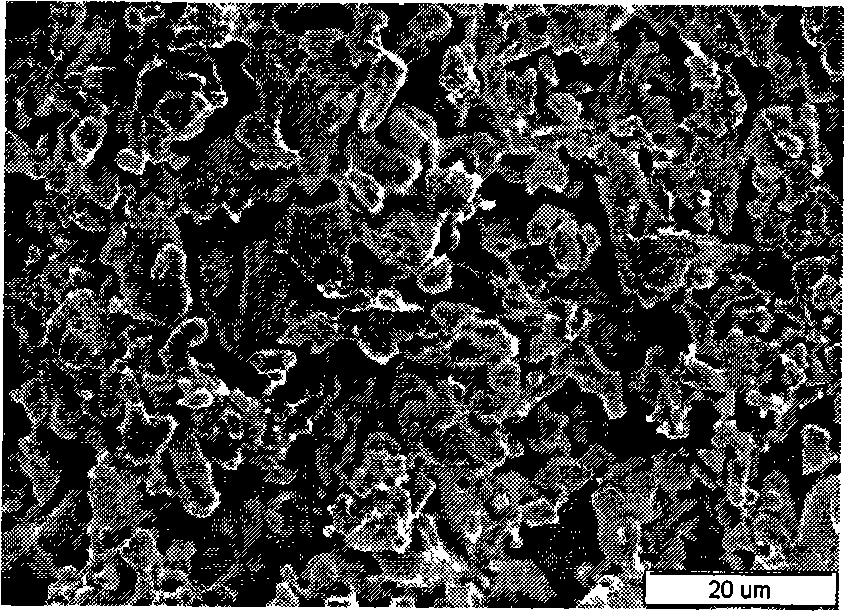

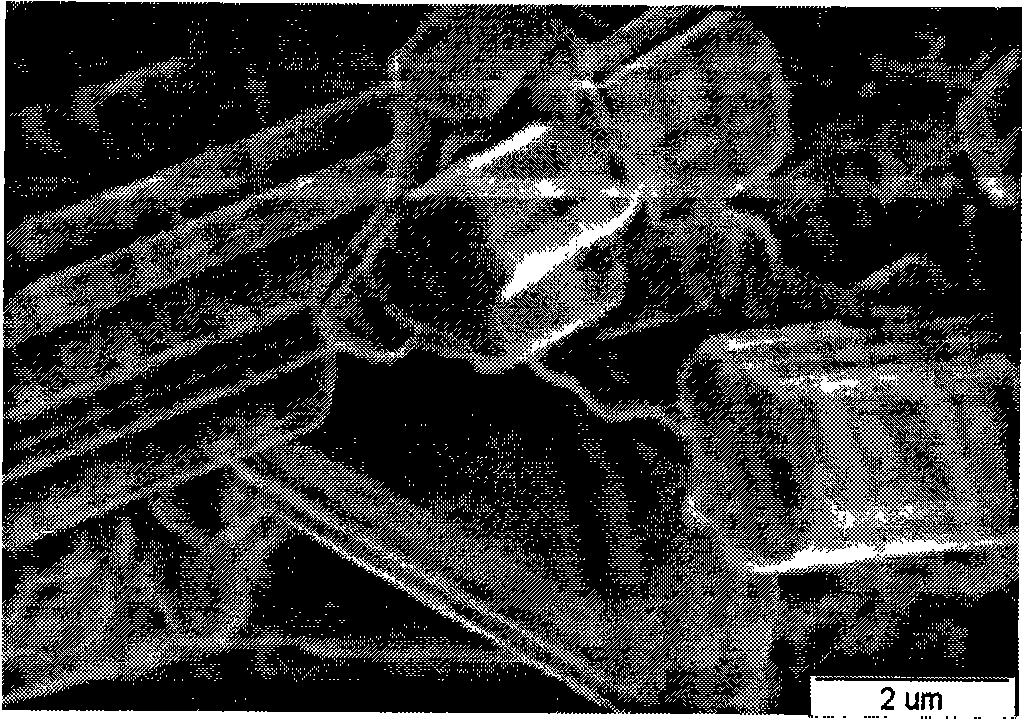

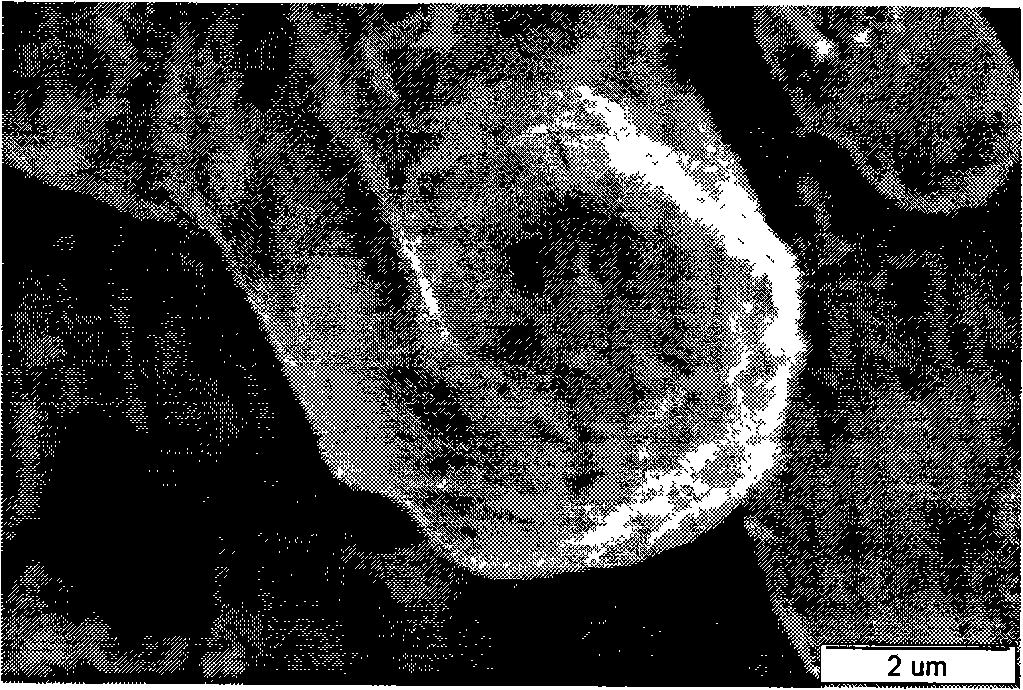

[0048] Preparation of composite oxide CaO-B 2 o 3 -SiO 2 coated β-Si 3 N 4 The granular porous ceramic has the following preparation steps:

[0049] Step 1: Prepare the Base

[0050] long columnar β-Si 3 N 4 The powder is ground to 200 mesh;

[0051] The second step: making CaO-B 2 o 3 -SiO 2 sol

[0052] Deionized water, ethanol, ethyl orthosilicate, boric acid, calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and citric acid are added in the heating reflux vessel;

[0053] When the temperature is raised to 70°C under stirring, after 60 minutes in a constant temperature water bath, the container is cooled to 25°C with heating and reflux to prepare CaO-B 2 o 3 -SiO 2 Sol; stirring speed 300r / min;

[0054] Dosage: Add 200ml of absolute ethanol, 160ml of tetraethyl orthosilicate, 16g of boric acid HBO to 100ml of deionized water 3 , 130g of Ca(NO 3 ) 2 4H 2 O and 27 g of citric acid;

[0055] The third step: making slurry

[0056] The 200-mesh long columnar β-Si prep...

Embodiment 2

[0074] Preparation of composite oxide CaO-B 2 o 3 -SiO 2 coated β-Si 3 N 4 The granular porous ceramic has the following preparation steps:

[0075] Step 1: Prepare the Base

[0076] long columnar β-Si 3 N 4 The powder is ground to 80 mesh;

[0077] The second step: making CaO-B 2 o 3 -SiO 2 sol

[0078] Deionized water, ethanol, ethyl orthosilicate, boric acid, calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and citric acid are added in the heating reflux vessel;

[0079] When the temperature is raised to 60°C under stirring, after 70 minutes in a constant temperature water bath, the container is cooled to 28°C with heating and reflux, and CaO-B is prepared. 2 o 3 -SiO 2 Sol; stirring speed 400r / min;

[0080] Dosage: Add 120ml of absolute ethanol, 100ml of tetraethyl orthosilicate, 13g of HBO to 100ml of deionized water 3 , 60g of Ca(NO 3 ) 2 4H 2 O and 13 g of citric acid;

[0081] The third step: making slurry

[0082] The 80-mesh long columnar β-Si prepared in...

Embodiment 3

[0092] Preparation of composite oxide CaO-B 2 o 3 -SiO 2 coated β-Si 3 N 4 The granular porous ceramic has the following preparation steps:

[0093] Step 1: Prepare the Base

[0094] long columnar β-Si 3 N 4 The powder is ground to 300 mesh;

[0095] The second step: making CaO-B 2 o 3 -SiO 2 sol

[0096] Deionized water, ethanol, ethyl orthosilicate, boric acid, calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and citric acid are added in the heating reflux vessel;

[0097] When the temperature is raised to 90°C under stirring, after 45 minutes in a constant temperature water bath, the container is cooled to 22°C with heating and reflux to prepare CaO-B 2 o 3 -SiO 2 Sol; stirring speed 300r / min;

[0098] Dosage: Add 250ml of absolute ethanol, 200ml of tetraethyl orthosilicate, 35g of HBO to 100ml of deionized water 3 , 180g of Ca(NO 3 ) 2 4H 2 O and 40 g of citric acid;

[0099] The third step: making slurry

[0100] The 300-mesh long columnar β-Si prepared in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com