Preparation method of pre-alloyed porous nickel-based electrolytic hydrogen evolution cathode material

A pre-alloyed, porous cathode technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of poor corrosion resistance, high electrocatalytic activity, and low catalytic efficiency, and achieve short sintering cycle and electrocatalytic activity. Large, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preparation method and process performance of the present invention are illustrated by specific specific examples below, and those skilled in the art can fully understand other advantages and functions of the present invention from the content disclosed in this specification.

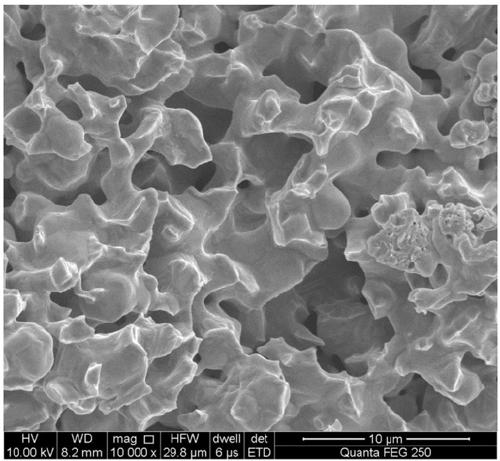

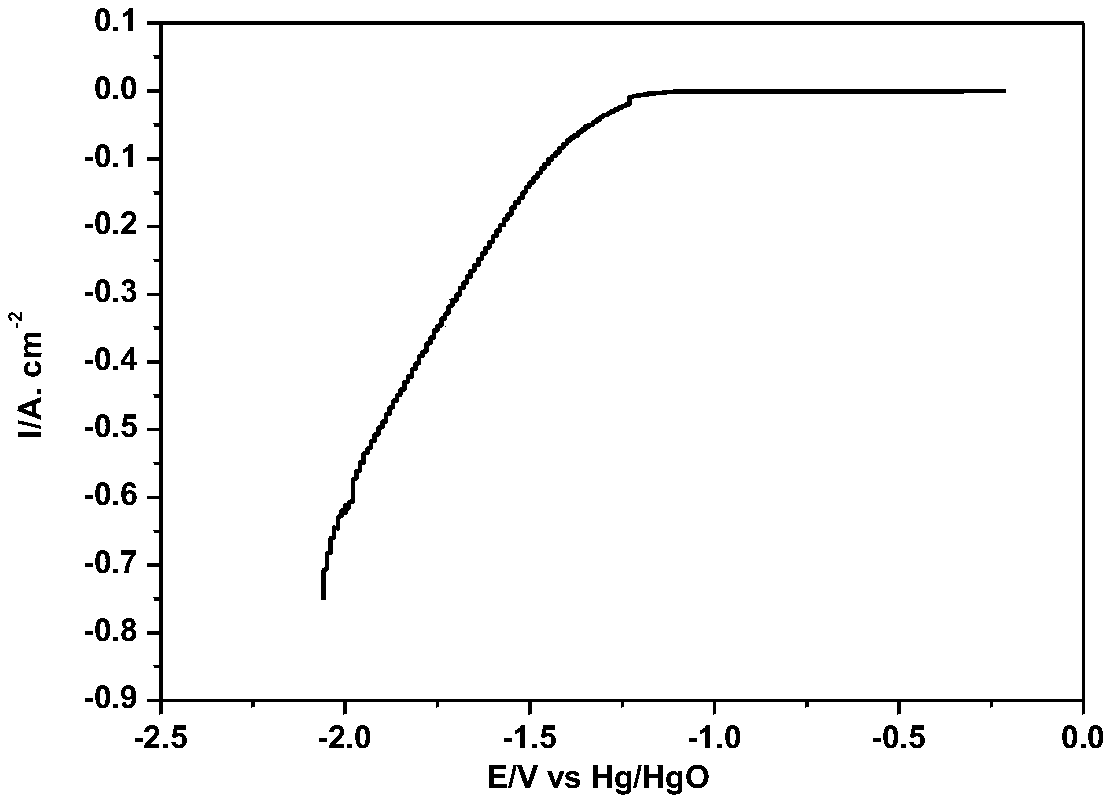

[0021] 1. Composition design of pre-alloyed Ni-Fe-Mo-Mn porous electrode materials

[0022] This embodiment is a kind of nickel powder, ferromolybdenum (FeMo70) powder block, ferromanganese (FeMn90) powder block is 15% of ferromolybdenum, 15% of ferromanganese, 8% of iron powder and nickel powder as the balance.

[0023] 2. Preparation of pre-alloyed Ni-Fe-Mo-Mn porous electrode material

[0024] (1) Powder preparation process: Mix nickel powder, ferromolybdenum (FeMo70), and ferromanganese (FeMn90) powders according to the mass percentage of ferromolybdenum 15%, ferromanganese 15%, iron powder 8%, and nickel powder as the balance. uniform.

[0025] (2) Atomized pulverization: ①Put the allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com