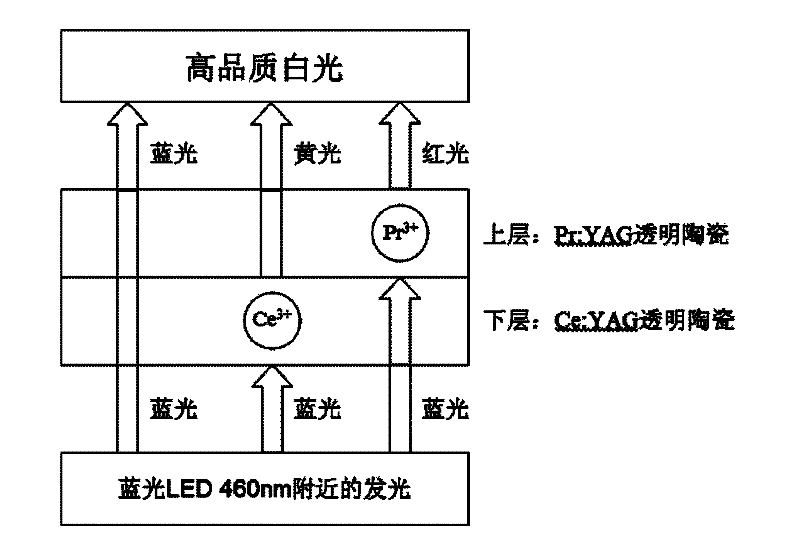

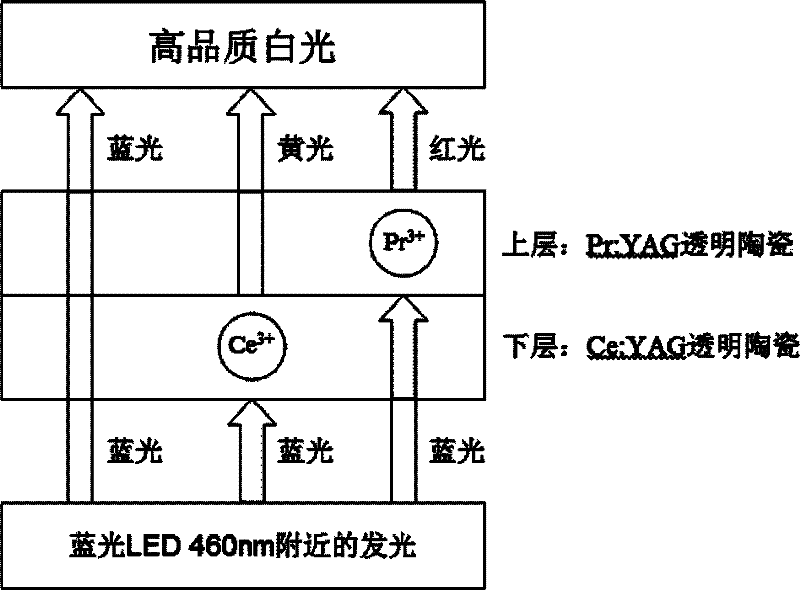

Composite transparent ceramic used for white-light LED fluorescence conversion and preparation method thereof

A transparent ceramic and fluorescent technology, which is applied in the direction of ceramic layered products, chemical instruments and methods, and layered products, can solve the problems of reduced luminous efficiency, large temperature influence, and insufficient red light components, and achieve low cost and high luminescence The effect of high quenching temperature and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

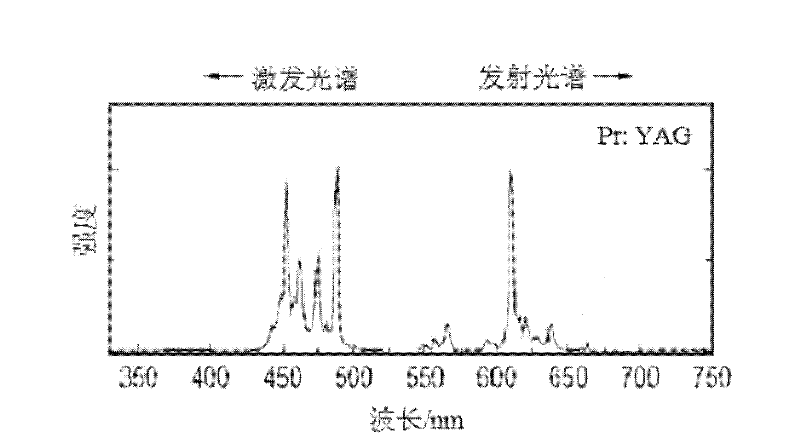

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of this composite transparent ceramic is:

[0026] Using yttrium oxide (Y 2 o 3 ), alumina (Al 2 o 3 ), praseodymium oxide (Pr 2 o 3 ), cerium oxide (CeO 2 ) as raw material, according to (Pr x Y 1-x ) 3 al 5 o 12 , (Ce y Y 1-y ) 3 al 5 o 12 (wherein, 0.0003≤x≤0.06, 0.0001≤y≤0.06) are composed of two kinds of powder raw materials, respectively, and then use wet ball milling to prepare ceramic powder with absolute ethanol or deionized water as the medium, and the two kinds of powder Respectively dried, sieved, and pressed into tablets; then subjected to cold isostatic pressing above 150MPa to form a green body; then put into a vacuum or hot-pressed sintering furnace and sintered at a certain temperature for several hours to obtain (Pr x Y 1-x ) 3 al 5 o 12 , (Ce y Y 1-y ) 3 al 5 o 12 Transparent ceramics, the surface of the obtained two transparent fluorescent ceramic materials is polished, and then bonded on the side of th...

Embodiment 1

[0028] Using yttrium oxide (Y 2 o 3 ), alumina (Al 2 o 3 ), praseodymium oxide (Pr 2 o 3 ), cerium oxide (CeO 2 ) as raw material, according to (Pr 0.0003 Y 0.9997 ) 3 al 5 o 12 , (Ce 0.0003 Y 0.9997 ) 3 al 5 o 12 The chemical composition of the two kinds of powders were prepared respectively 50g, and then the ceramic powders were prepared by wet ball milling with absolute ethanol as the medium. The two kinds of powders were dried, sieved, and pressed respectively; Cold isostatic pressing into green bodies, each placed in a vacuum sintering furnace and sintered at 1650°C for 24 hours to obtain (Pr 0.0003 Y 0.9997 ) 3 al 5 o 12 , (Ce 0.0003 Y 0.9997 ) 3 al 5 o 12 Transparent fluorescent ceramics are obtained by polishing the surface of the two transparent ceramic materials and then bonding them on the side of the junction (Pr 0.0003 Y 0.9997 ) 3 al 5 o 12 / (Ce 0.0003 Y 0.9997 ) 3 al 5 o 12 Composite transparent ceramic.

Embodiment 2

[0030] Sintering holding temperature is 1680 ℃, and sintering holding time is 20 hours, and other conditions are the same as embodiment 1, can obtain equally (Pr 0.0003 Y 0.9997 ) 3 al 5 o 12 / (Ce 0.0003 Y 0.9997 ) 3 al 5 o 12 Composite transparent ceramic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com