Process for preparing alumina-based continuous fiber with sol-gel method

A sol-gel method and continuous fiber technology, which is applied in the field of preparation technology of continuous alumina-based fibers, can solve the problem of high sintering temperature, and achieve the effects of improving strength and toughness, compact fiber section and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples.

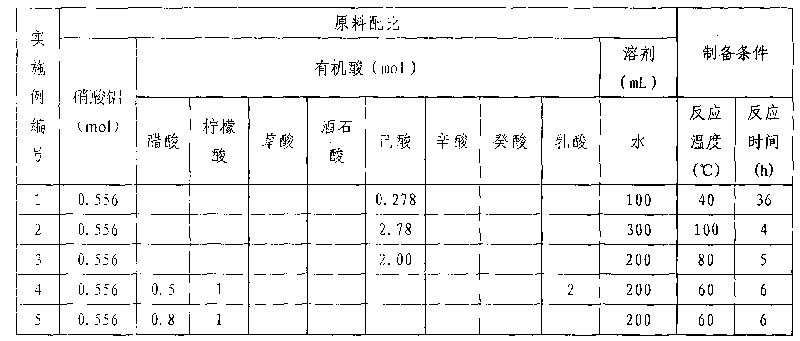

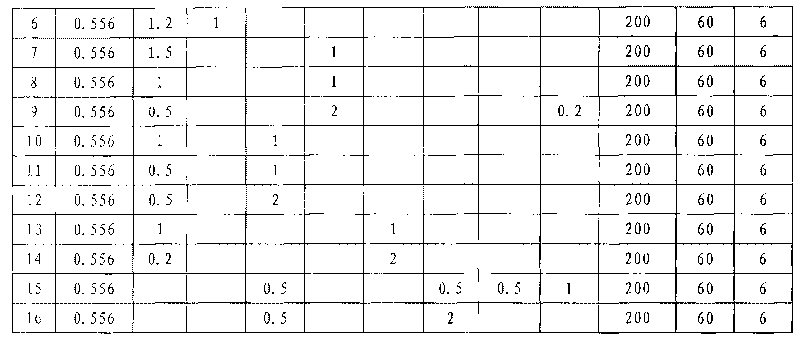

[0021] Table 1 has listed numbering as 16 embodiment first step processes of 1-16: determine the kind and the addition of aluminum nitrate, water, organic acid according to the different embodiments of table 1, and determine the preparation condition of aluminum carboxylate sol , to prepare aluminum carboxylate sol.

[0022] Table 1. Preparation of aluminum carboxylate sol

[0023]

[0024]

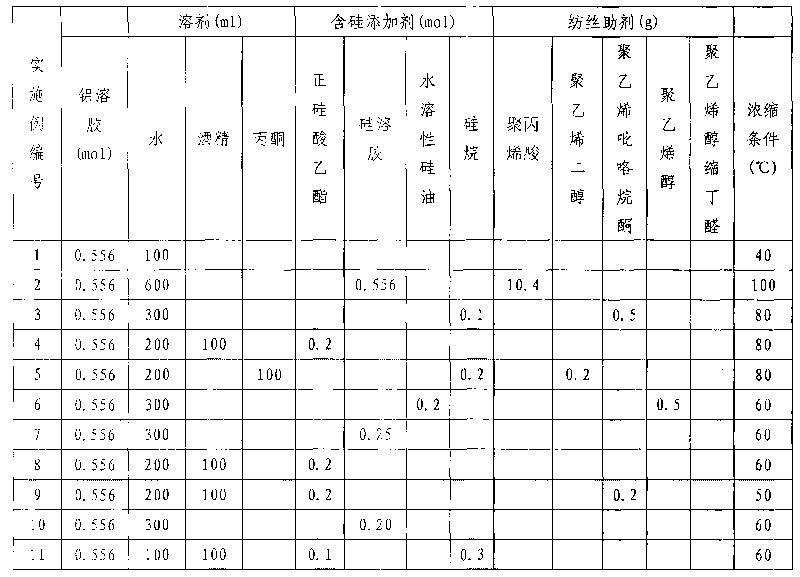

[0025] Table 2 has listed the second and third step process conditions of the embodiment of table 1: according to the different embodiments of table 2, add solvent, silicon-containing substance, spinning aid in the aluminum carboxylate sol, prepare according to the concentration conditions of table 2 Alumina-based fiber precursor sol. In the fourth step, the concentrated precursor sol is put into a liquid storage tank with a nozzle, and the alumina-based continuous fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com