Preparation process of multi-element composite alumina-based continuous fibers

A composite alumina and continuous fiber technology, which is applied in the field of continuous alumina-based fiber preparation technology, can solve the problems of inability to obtain continuous fibers, fiber morphology, short length of alumina fibers, etc., to improve mechanical properties, Good strength, lower sintering temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific examples.

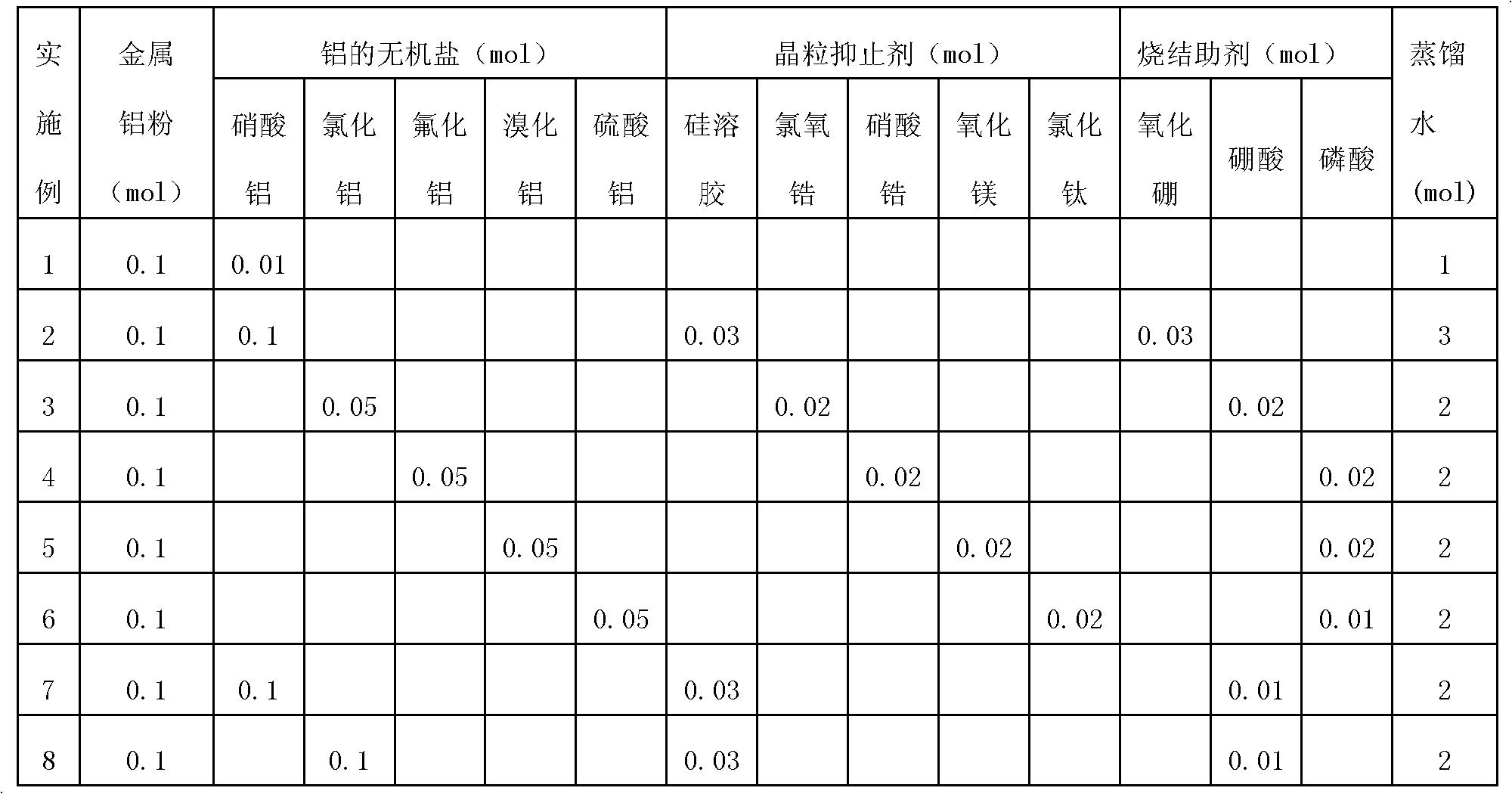

[0022] Table 1 lists the formula composition in the first step process of 8 examples numbered 1-8. The types and amounts of aluminum powder, water, aluminum inorganic salts, grain inhibitors and sintering aids were determined according to different examples in Table 1.

[0023] Table 1. Recipe of raw materials

[0024]

[0025] Note: The addition amount of silica sol is calculated according to the content of silicon oxide in silica sol.

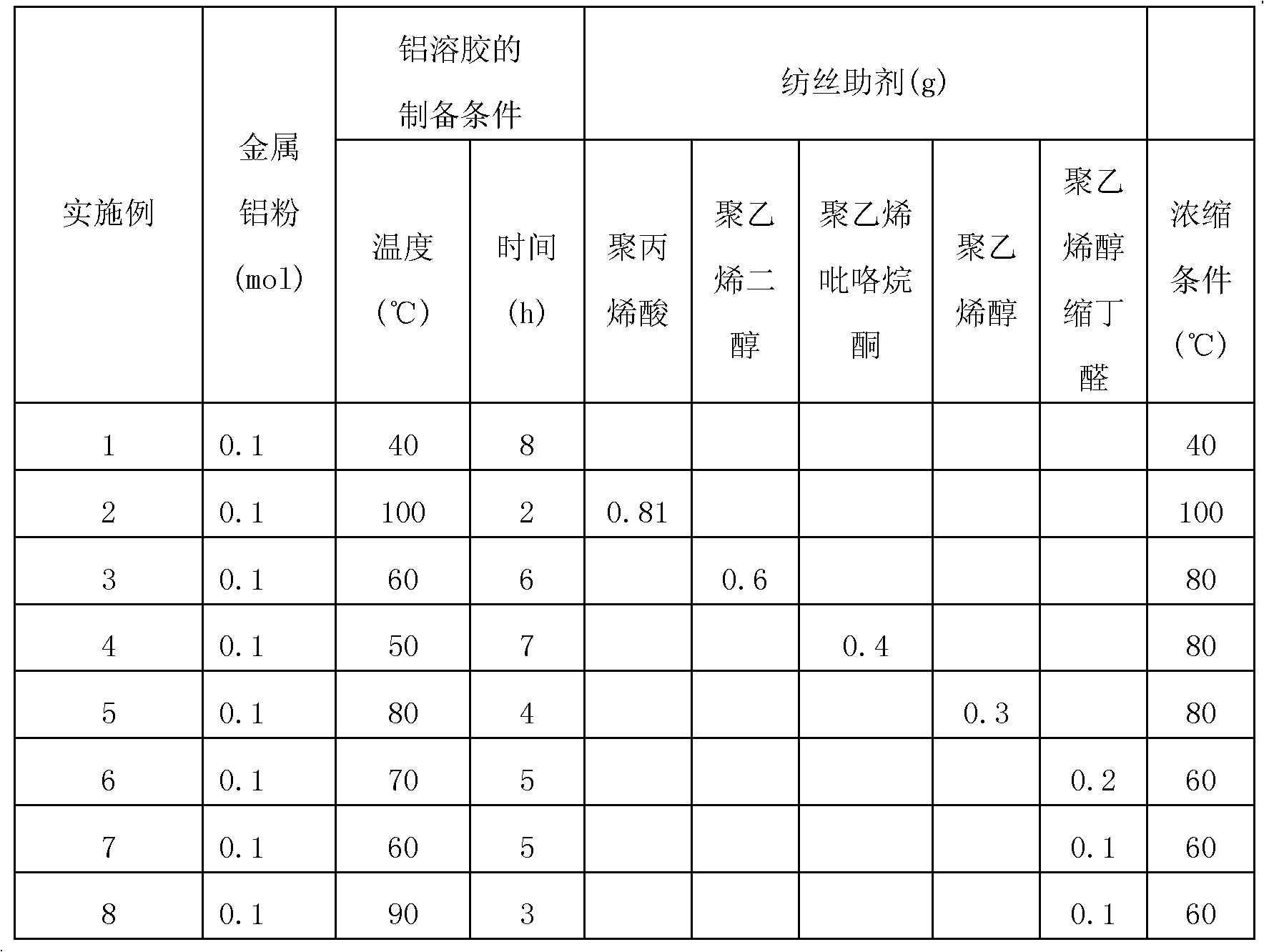

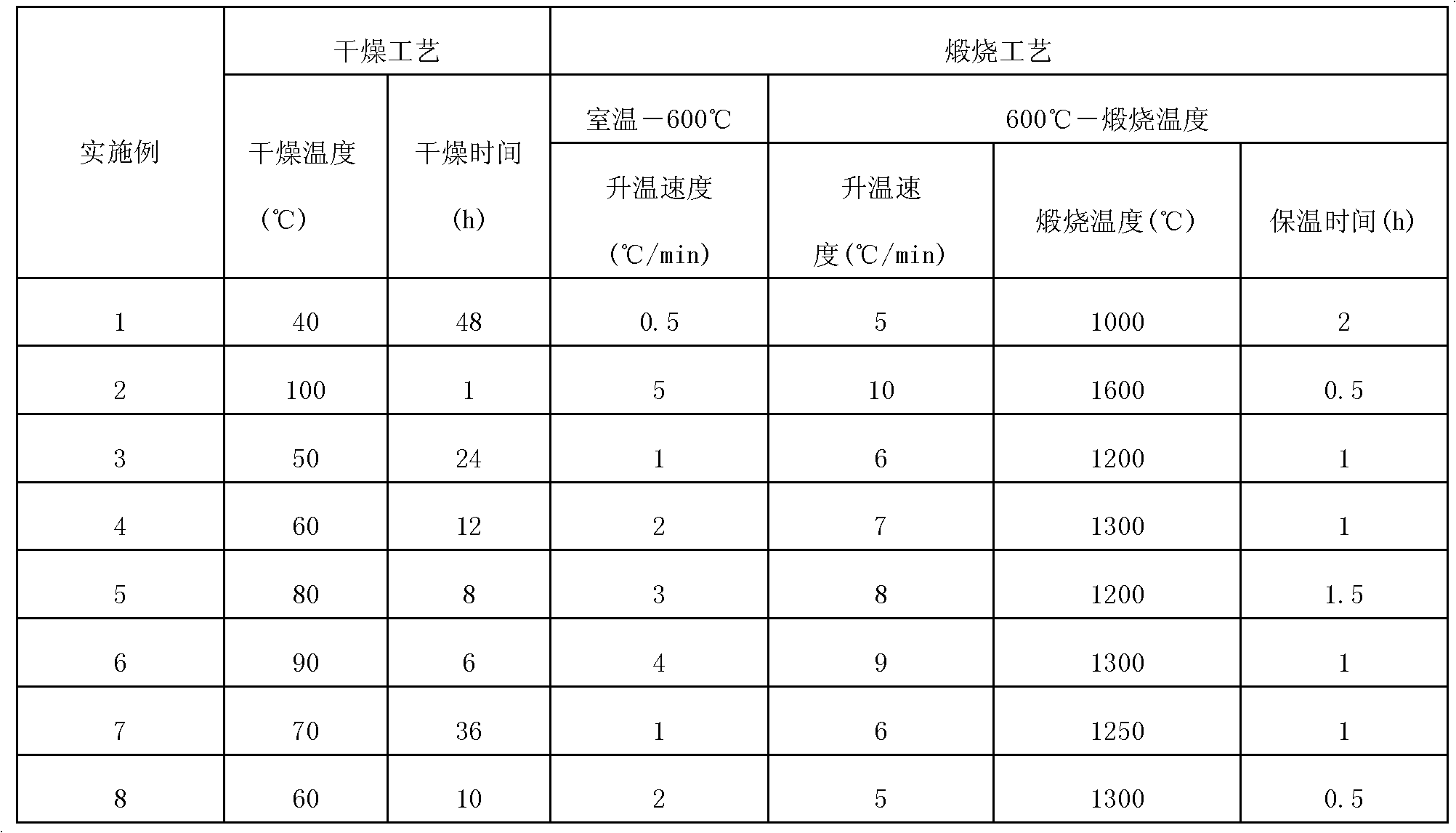

[0026] Table 2 lists the process conditions of the first, second and third steps of the embodiment in Table 1: the preparation conditions of the aluminum solution are determined according to the different embodiments in Table 2, and the aluminum solution is prepared. A high polymer spinning aid was added to the aluminum solution, and a spinnable alumina-based fiber precursor sol was prepared according to the concentration condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com