Ceramic dielectric material and COG type multilayer ceramic capacitor

A ceramic dielectric and modification technology, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems that the dielectric layer cannot be thinned, cannot achieve large capacity, and cannot achieve large capacity, etc., to achieve excellent dielectric properties, Improve the dielectric performance and reliability, and the effect of uniform cross-section of the porcelain body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

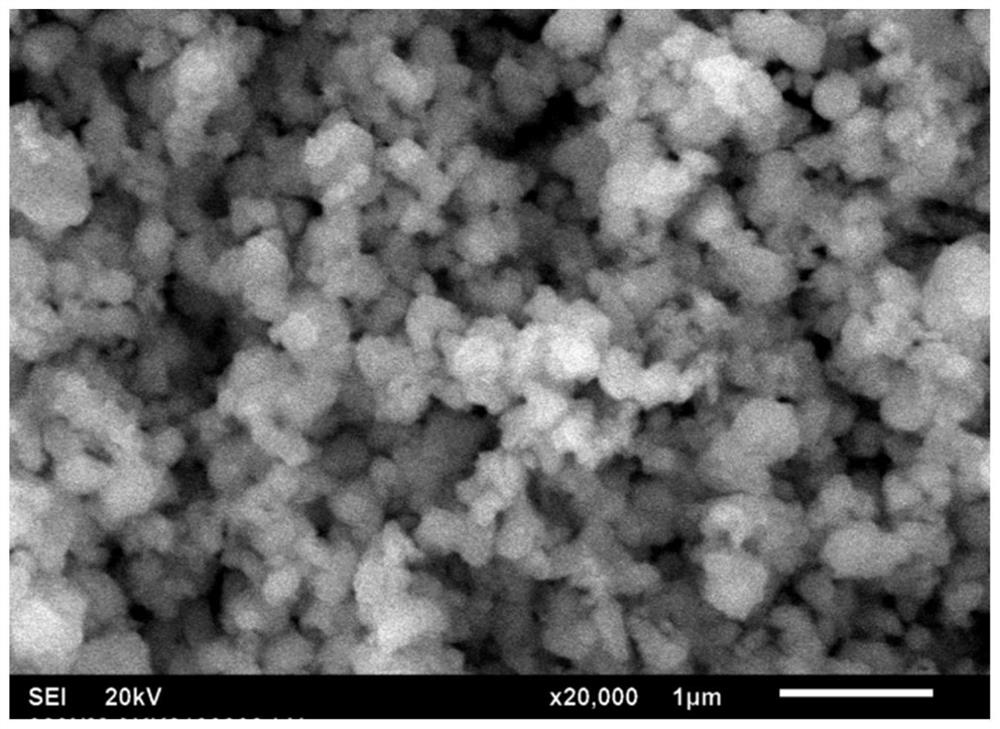

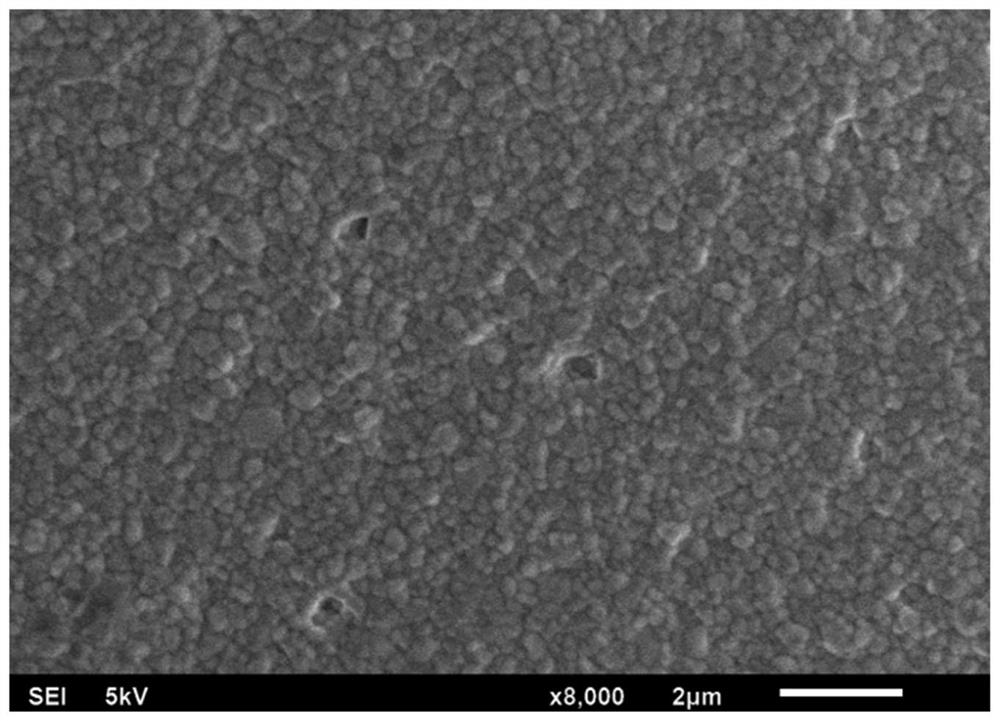

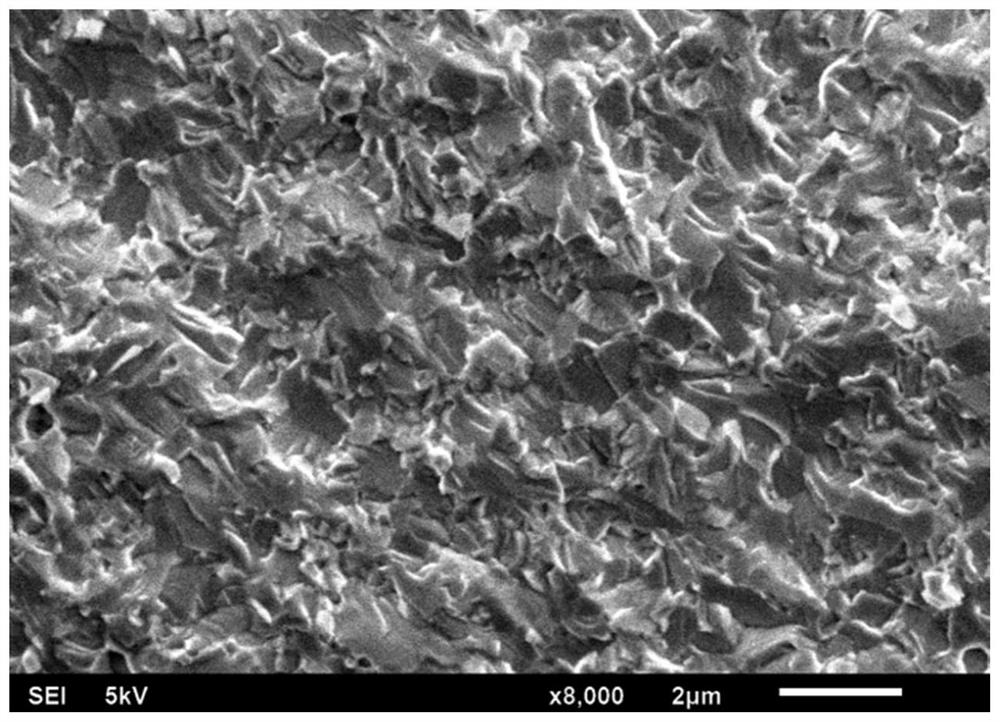

Image

Examples

Embodiment 1~32

[0029] This embodiment provides a kind of ceramic dielectric material, by the main crystal phase (xCaZrO 3 +ySrZrO 3 , x / y=10), modifying additives and sintering aids, the specific formula is shown in Table 1.

[0030] Table 1 Formulation composition of main crystal phase, modifying additives and sintering aids

[0031]

[0032]

[0033] The preparation method of the ceramic dielectric material of above-mentioned each embodiment is as follows:

[0034] (1) Preparation of main crystal phase components: CaCO with a purity of more than 99.5% is selected 3 , SrCO 3 , ZrO 2 Raw materials, according to CaZrO 3 , SrZrO 3 The composition ratios were weighed separately and calcined separately to obtain CaZrO 3 , SrZrO 3 , then the CaZrO 3 , SrZrO 3 Weigh and reserve according to the molar ratio of x / y.

[0035] (2) Preparation of ceramic dielectric material: The main crystal phase, modification additives, and sintering aids obtained in the previous step were wet-mixed,...

Embodiment 33

[0037] This embodiment provides a ceramic dielectric material whose main crystal phase is xCaZrO 3 +ySrZrO 3 , x / y=1, its formula is 100mol of main crystal phase, MnCO 3 2mol, Al 2 o 3 0.7mol, SrCO 3 0.8mol, MgTiO 3 0.2mol, CaTiO 3 2.0mol, Y 2 o 3 0.66mol, sintering aid ZnO0.8mol, H 3 BO 3 0.6mol, SiO 2 1.7mol.

Embodiment 34

[0039] This embodiment provides a ceramic dielectric material whose main crystal phase is xCaZrO 3 +ySrZrO 3 , x / y=5, its formula is 100mol of main crystal phase, MnCO 3 2mol, Al 2 o 3 0.7mol, SrCO 3 0.8mol, MgTiO 3 0.2mol, CaTiO 3 2mol, Y 2 o 3 0.66mol, sintering aid ZnO0.8mol, H 3 BO 3 0.6mol, SiO 2 1.7mol. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com