A kind of mixing process of red butyl rubber

A butyl rubber and mixing technology, which is applied in the field of rubber, can solve the problems such as the inconspicuous toning effect, and achieve the effects of improving the toning effect, compacting the section, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, 9kg of filler, 9kg of titanium dioxide, 3kg of softener, 15kg of accelerator, 186kg of pottery clay, and 9kg of red pigment, the ratio of pottery clay in step (2) to step (3) is 1:1.

[0023] A mixing process method of red butyl rubber, comprising the following steps:

[0024] (1) Carry out raw rubber mastication, then put in filler, titanium dioxide, softener, accelerator, and carry out three-minute pressing and banburying;

[0025] (2) Put in half of the pottery clay and red pigment, and press and banbury for three minutes;

[0026] (3) Put in the other half of the pottery clay, and press and banbury for four minutes;

[0027] (4) The temperature is raised to 110°C and then the rubber is discharged, and the vulcanizing agent is added to the open mill.

[0028] Wherein, the filler in the step (1) is precipitated hydrated silica, and the red pigment in the step (2) is ferric oxide.

Embodiment 2

[0030] In this example, 9kg of filler, 9kg of titanium dioxide, 3kg of softener, 15kg of accelerator, 186kg of pottery clay, and 9kg of red pigment, the ratio of pottery clay in step (2) to step (3) is 1:1.

[0031] A mixing process method of red butyl rubber, comprising the following steps:

[0032] (1) Carry out raw rubber mastication, then drop into precipitated hydrated silica, titanium dioxide, softener, accelerator, and carry out three-minute pressing and banburying;

[0033] (2) Put half potter's clay and ferric oxide into, carry out three-minute pressing banburying;

[0034] (3) Put in the other half of the pottery clay, and press and banbury for four minutes;

[0035] (4) The temperature is raised to 120°C and then the rubber is discharged, and the vulcanizing agent is added to the open mill.

[0036] Wherein, the filler in the step (1) is precipitated hydrated silica, and the red pigment in the step (2) is ferric oxide.

Embodiment 3

[0038] In this example, 9kg of filler, 9kg of titanium dioxide, 3kg of softener, 15kg of accelerator, 186kg of pottery clay, and 9kg of red pigment, the ratio of pottery clay in step (2) to step (3) is 1:1.

[0039] A mixing process method of red butyl rubber, comprising the following steps:

[0040] (1) Carry out raw rubber mastication, and then put in precipitated hydrated silica, titanium dioxide, soft

[0041] (2) Put half potter's clay and ferric oxide into, carry out three-minute pressing banburying;

[0042] (3) Put in the other half of the pottery clay, and press and banbury for four minutes;

[0043] (4) After the temperature rises to 130°C, the rubber is discharged, and the vulcanizing agent is added to the open mill.

[0044] Wherein, the filler in the step (1) is precipitated hydrated silica, and the red pigment in the step (2) is ferric oxide.

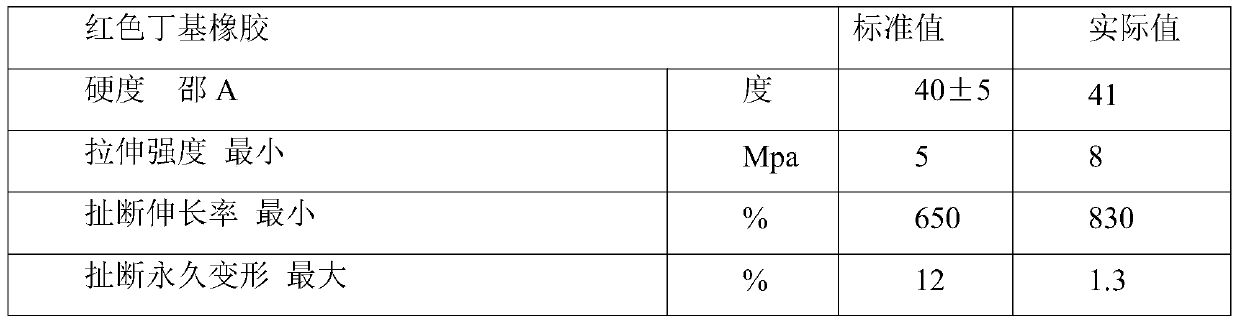

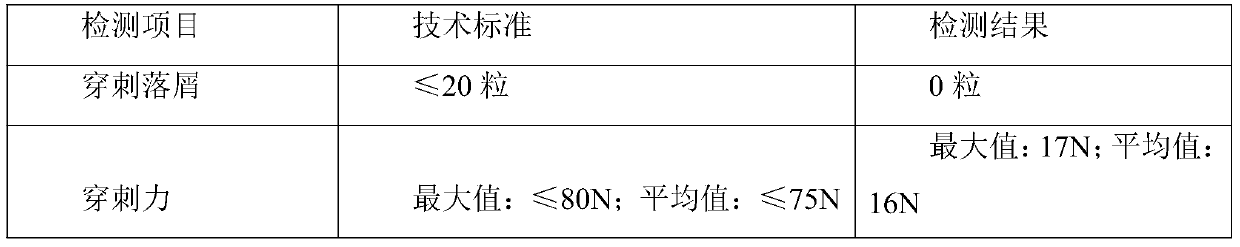

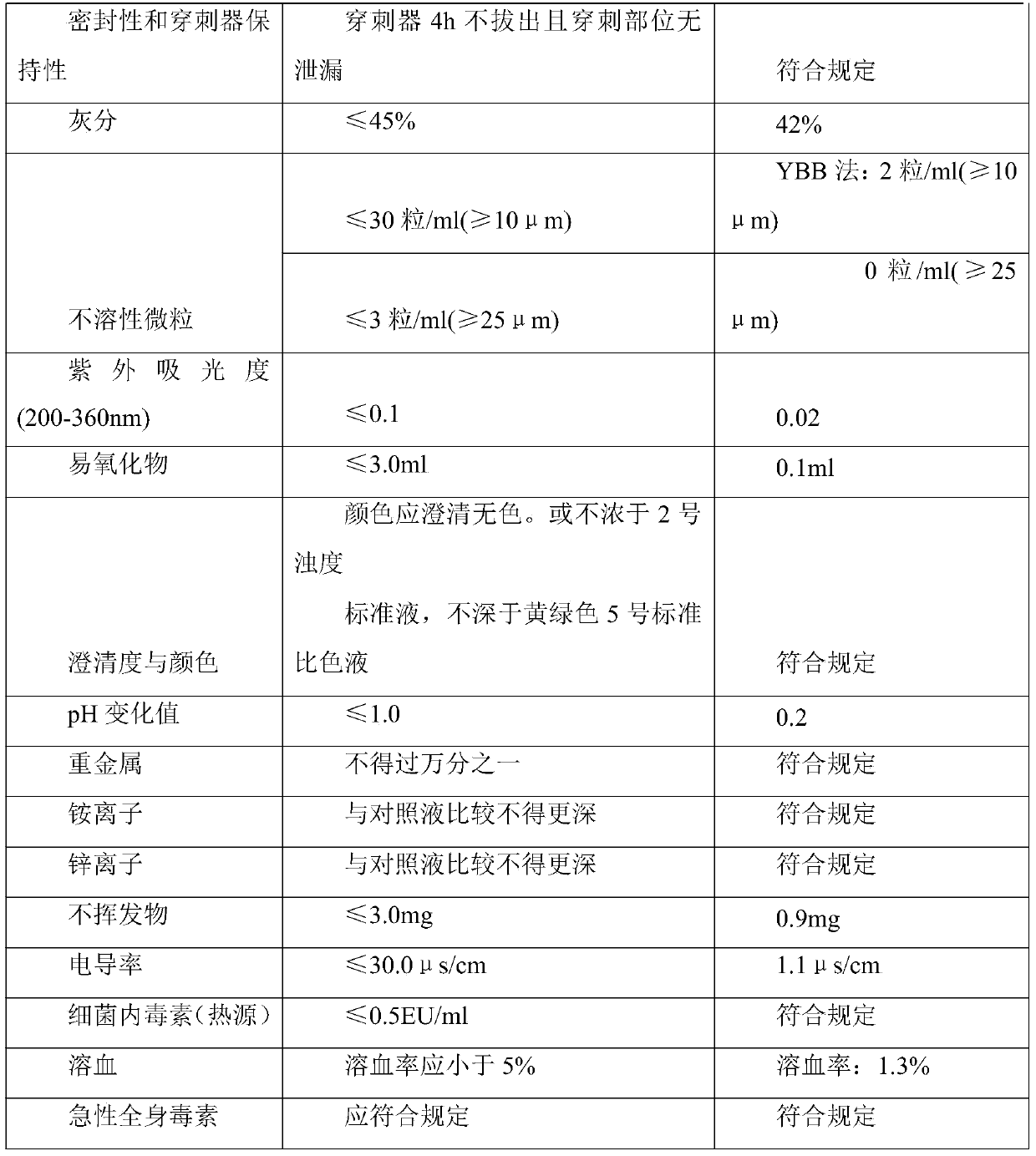

[0045] The mixing process of the red butyl rubber of embodiment 2 of the present invention, the test index of its mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com