Preparation method and application of temperature-sensitive composite hydrogel by utilizing synergistic effect of photocatalysis and temperature sensitivity

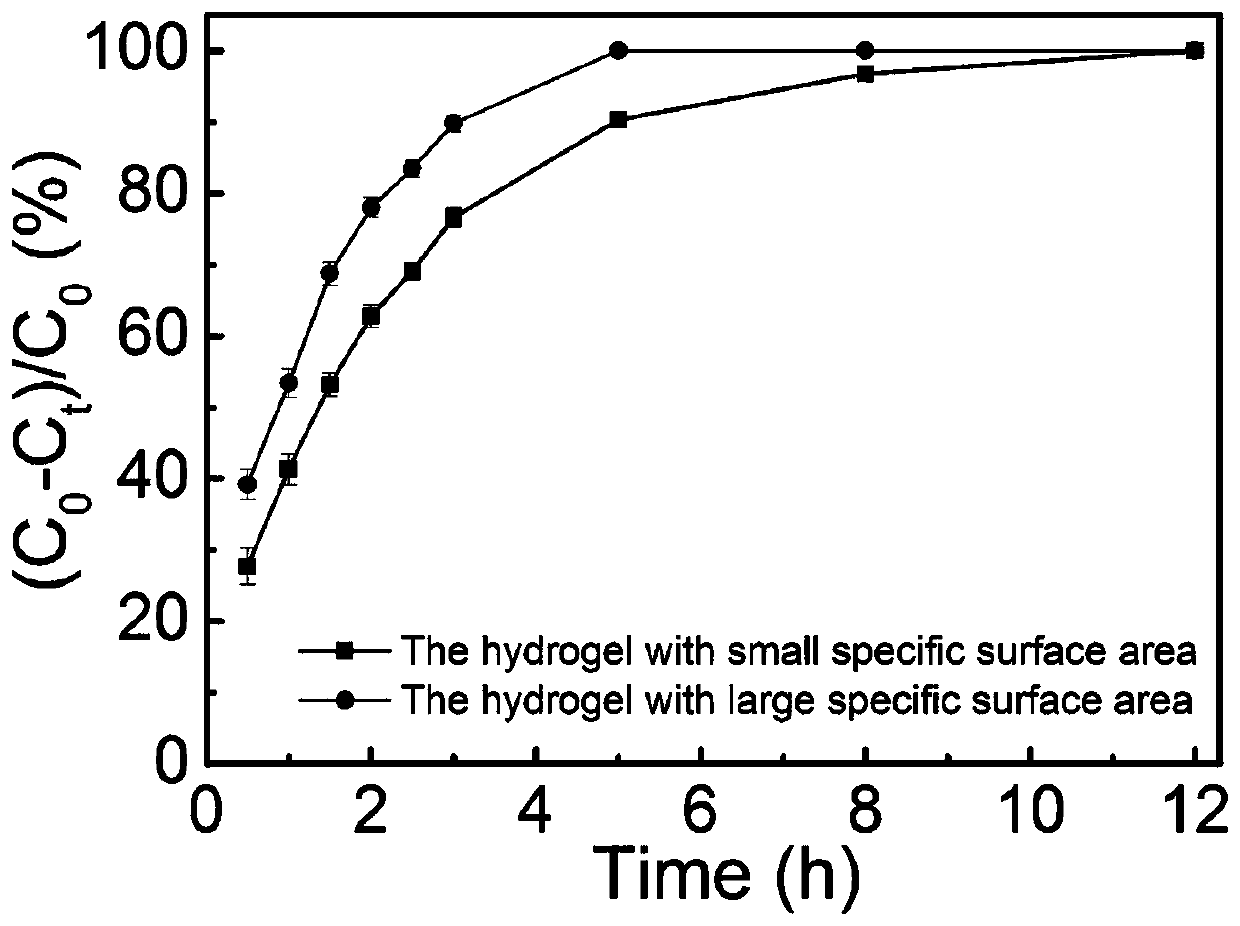

A composite hydrogel, synergistic technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of catalyst catalytic activity and selectivity reduction, catalyst loss, difficult separation, etc., and achieve high adsorption and degradation. performance, enhance adsorption performance, enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

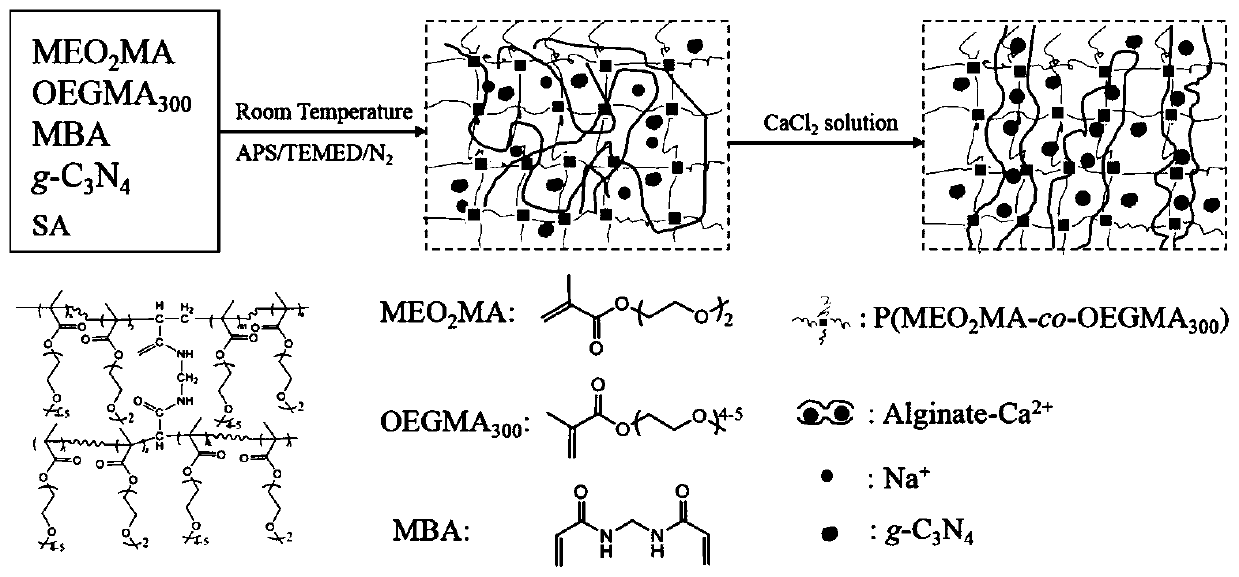

[0039] Preferably, the preparation method specifically includes the following steps:

[0040] 1) Add temperature-sensitive monomer M1, temperature-sensitive monomer M2, chemical crosslinking agent M3, photocatalyst M4 and alginate M5 into deionized water in sequence to prepare an aqueous solution with a mass concentration of 5-20%. In a sealed container at 25°C, pass inert gas and stir for 30-70 minutes until completely dispersed to form a uniform mixed solution.

[0041] 2) Add an initiator to the mixed solution, inject a stabilizer after 5-15 minutes, and continue to react for 25-35 minutes under the protection of an inert gas until the mixed solution begins to appear gel-like.

[0042] 3) Put the gel-like mixed solution at 20-30°C and seal it for 10-36 hours, then place the reaction product in a divalent cation solution to replace the cations in the alginate; take it out and soak it in After 1-3 days in deionized water, the temperature-sensitive composite hydrogel is obtai...

Embodiment 1

[0053] 1) Add 929 μL (5 mmol) of MEO to the sample bottle 2 MA monomer (molecular formula is Purchased from SigmaAldrich), 2857 μL (10 mmol) of OEGMA 300 (Molecular formula sound Purchased from SigmaAldrich) monomer, 0.2g of sodium alginate was dissolved in 10mL of deionized water to obtain mixed solution A;

[0054] 2) Add 5mg of crosslinker MBAA and 1gg-C to mixed solution A 3 N 4 Photocatalyst, ultrasonically dispersed uniformly to obtain mixed solution B;

[0055] 3) Add 0.02g (0.088mmol) initiator APS and 10μL (0.067mmol) accelerator TEMED to the mixed solution B after bubbling nitrogen for 20min, then inject nitrogen gas for 30min, seal and react for 12h;

[0056] 4) After the reaction, use calcium chloride (CaCl) with a concentration of 5% (w / v) 2 ) solution for 5 hours to form an interpenetrating network structure hydrogel, then soak in deionized water and change the water at regular intervals to remove unreacted monomers and cross-linking agents.

[0057] Cal...

Embodiment 2

[0060] 1) add the NIPAM monomer of 566mg (5mmol) (molecular formula is Purchased from Macklin), 2857 μL (10 mmol) of OEGMA 300 (molecular formula is Purchased from Sigma Aldrich) monomer, 0.1g of calcium alginate was dissolved in 10mL of deionized water to obtain mixed solution A;

[0061] 2) Add 10mg of cross-linking agent MBAA and 0.2g of TiO to mixed solution A 2 Photocatalyst, ultrasonically dispersed uniformly to obtain mixed solution B;

[0062] 3) Add 0.03g (0.132mmol) initiator APS and 15μL (0.1005mmol) accelerator TEMED to the mixed solution B after bubbling nitrogen for 20min, then inject nitrogen gas for 30min, seal, and react for 12h;

[0063] 4) After the reaction, use barium chloride (CaCl) with a concentration of 2% (w / v) 2 ) solution for 5 hours to form an interpenetrating network structure hydrogel, then soak in deionized water and change the water at regular intervals to remove unreacted monomers and cross-linking agents.

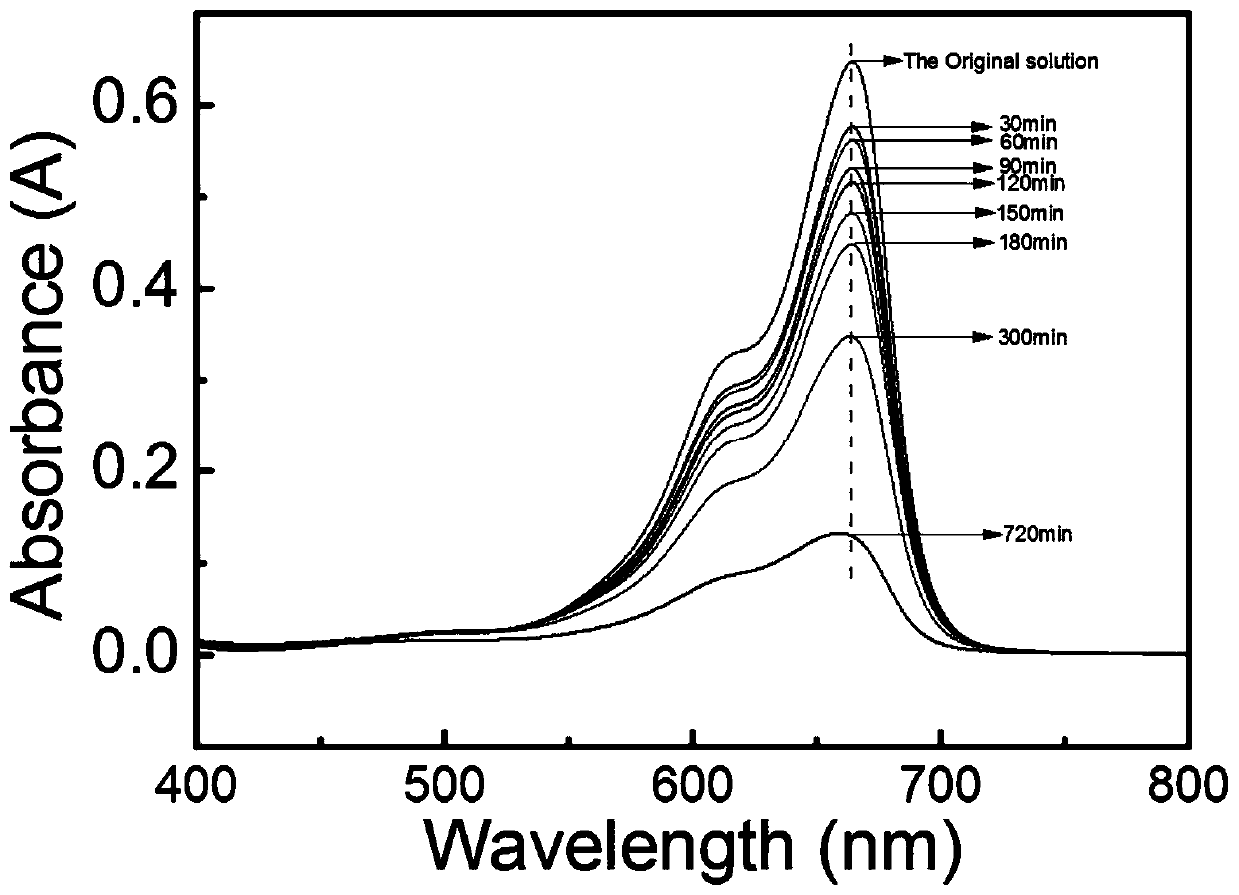

[0064] The absorbance of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com