Manufacturing method of metal supporting plate for fuel cell

A manufacturing method and metal support technology, applied in fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as reduced structural stability, increased internal stress of batteries, and attenuation of battery performance, achieving improved integration The effect of reducing sintering deformation and eliminating sintering deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

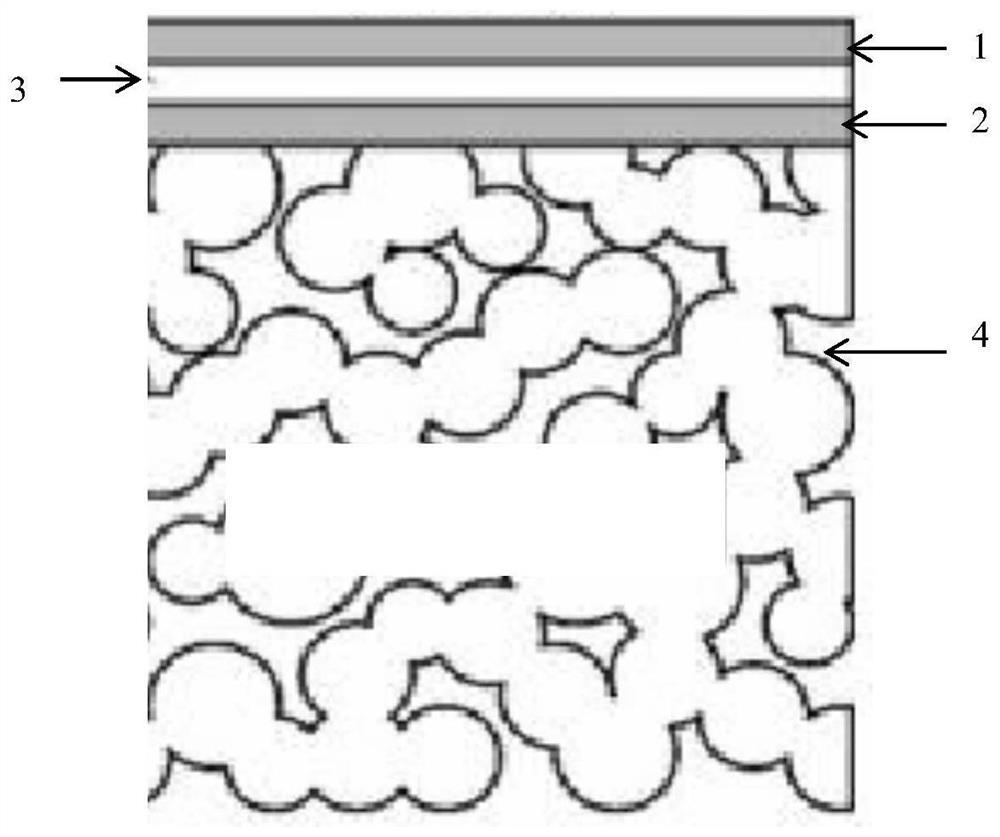

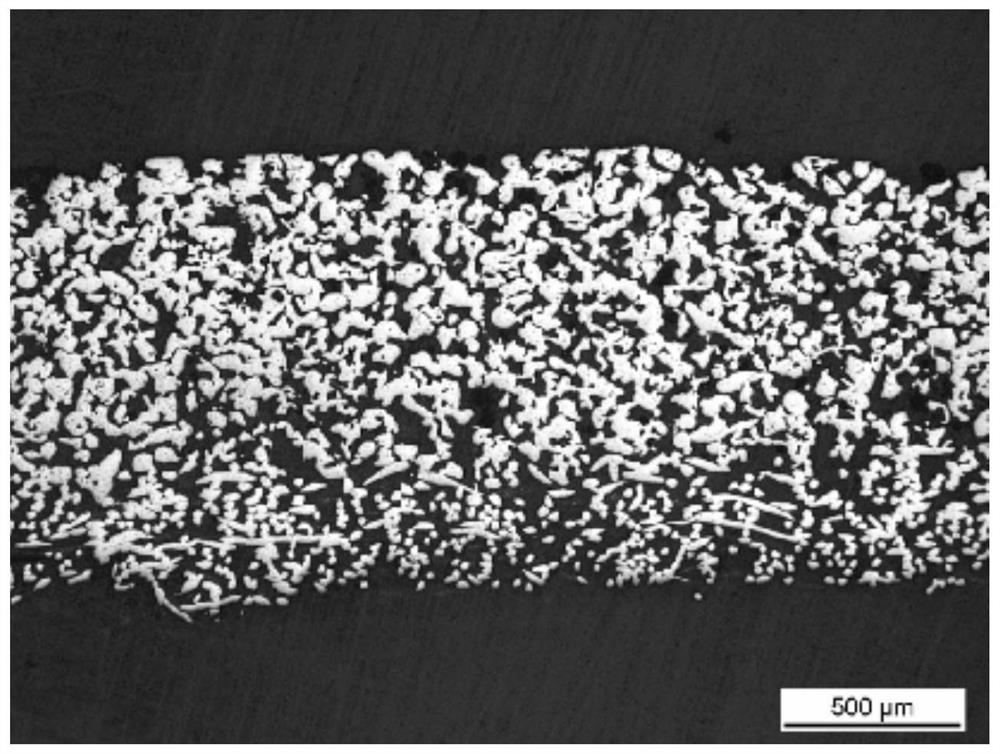

[0038] The preparation method of the metal support plate for the fuel cell in this embodiment includes the following steps in sequence:

[0039] 1) Prepare raw materials: the material is 434L stainless steel powder. According to the mass percentage, 434L stainless steel includes the following components C: 0.025%, Cr: 17.5%, Mn: 0.8%, Si: 0.6%, Mo: 1.05%, iron :margin;

[0040] 2) Sieve the above powder, the particle size range is 150 mesh to 200 mesh, and the bulk density of the powder is 2.35g / cm 3 .

[0041] 3) The setter is ceramics containing 95% alumina;

[0042] 4) Powder spreading: Another part of the material is selected as metal fiber felt. According to the mass percentage, the metal fiber felt includes the following components C: 0.015%, Cr: 18.5%, Mn: 0.6%, Si: 0.3%, Ni: 10.1 %, iron: surplus; porosity 80%, thickness 0.1mm; Metal fiber felt is cut into 125 * 125mm subsequently, and the metal fiber felt cut out is placed on the setter, then the powder of step 2) ...

Embodiment 2

[0050] The preparation method of the metal support plate for the fuel cell in this embodiment includes the following steps in sequence:

[0051] 1) Prepare the raw materials. The material is 430L stainless steel powder. According to the mass percentage, 430L stainless steel includes the following components: C: 0.025%, Cr: 17.2%, Mn: 0.9%, Si: 0.5%, iron: the balance;

[0052] 2) Sieve the above powder, the particle size is 200-320 mesh, and the bulk density of the powder is 2.25g / cm 3 .

[0053] 3) The setter plate is a ceramic plate containing 95% alumina;

[0054] 4) Powder spreading: Another part of the material is selected as metal fiber felt. According to the mass percentage, the metal fiber felt includes the following components C: 0.015%, Cr: 17.5%, Mn: 0.6%, Si: 0.3%, Ni: 13.4 %, Mo: 2.46%, iron: the balance; the porosity of the metal fiber felt is 60%, and the thickness is 1.1mm; then the metal fiber felt is cut to 125×125mm, and the cut metal fiber felt is placed ...

Embodiment 3

[0061] The preparation method of the metal support plate for the fuel cell in this embodiment includes the following steps in sequence:

[0062] 1) Prepare the raw materials. The material is 434L stainless steel powder. According to the mass percentage, 434L stainless steel includes: C: 0.025%, Cr: 17.5%, Mn: 0.8%, Si: 0.6%, Mo: 1.05%, Iron: I quantity;

[0063] 2) Sieve the above-mentioned stainless steel powder, choose a particle size of 100-150 mesh, and the bulk density of the powder is 2.55g / cm 3 .

[0064] 3) The setter plate is a ceramic plate containing 95% alumina;

[0065]4) Powder spreading: Another part of the material is metal fiber felt. According to the mass percentage, the metal fiber felt includes the following components C: 0.015%, Cr: 17.2%, Mn: 0.9%, Si: 0.5%, porosity 60% , iron: surplus; the thickness of the metal fiber felt is 0.4mm; then the metal fiber felt is cut to 125×125mm, and the cut metal fiber felt is placed on the setter, and then the powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com