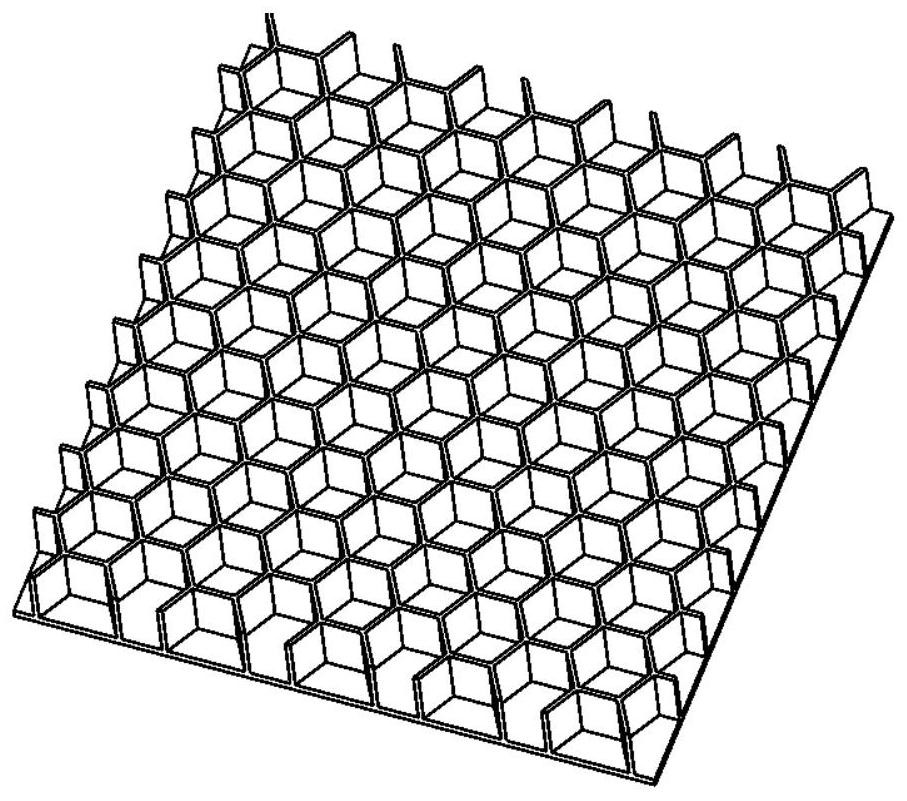

A method for preparing superalloy honeycomb insulation board based on injection molding

A high-temperature alloy and injection molding technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low material utilization rate, large deformation of sintered products, and high raw material cost, and achieve excellent high-temperature mechanical properties and corrosion resistance. The cost of raw material powder and the effect of avoiding complicated processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Superalloy honeycomb heat insulation board prepared by mixing master alloy powder and carbonyl nickel powder in a ratio of 40:60

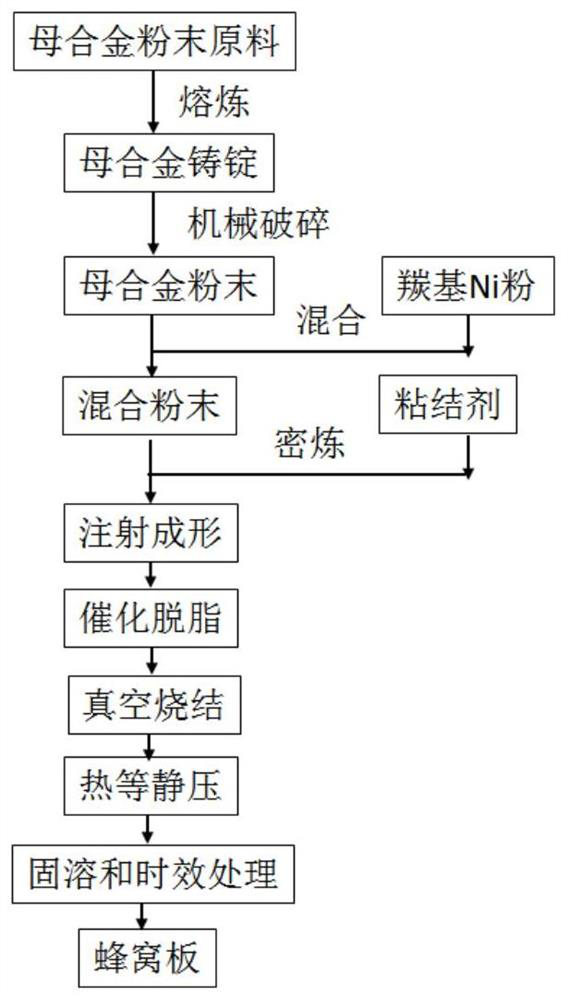

[0047] The preparation method of the superalloy honeycomb insulation board is carried out according to the following steps:

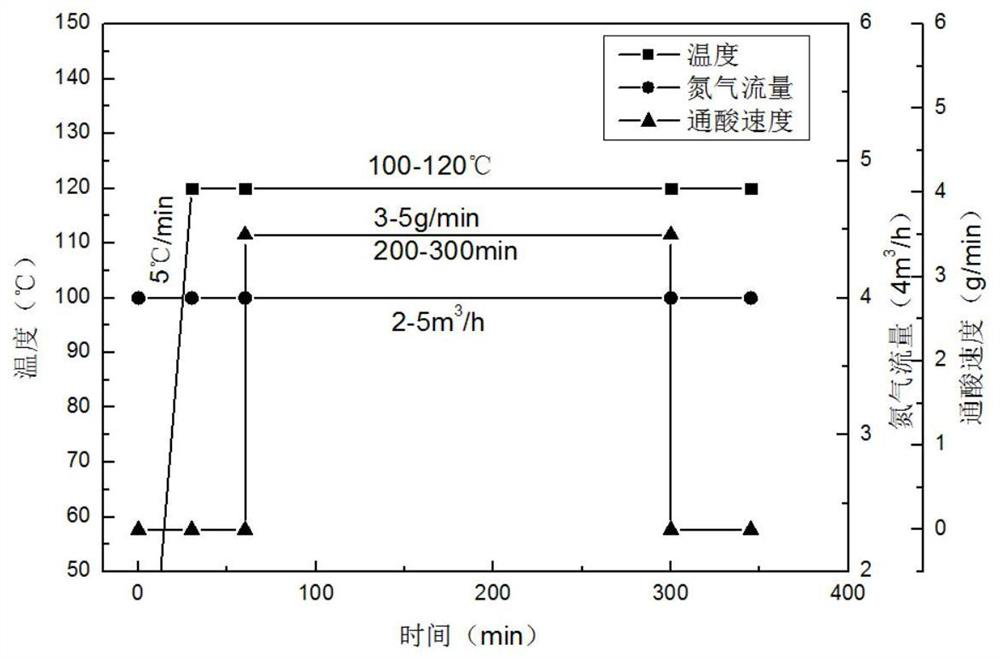

[0048] S1. Master alloy powder preparation: mix 15 parts of Ni, 25 parts of Cr, 25 parts of Co, 14 parts of Al, 13 parts of Ti, 7.5 parts of Mo and 0.2 parts of B to obtain a master alloy; melt the master alloy in a vacuum melting furnace Finally, the master alloy ingot was obtained, and the vacuum melting process was as follows: argon gas was introduced at room temperature for 40 minutes, the purity of the argon gas was 99.999%, the flow rate of the argon gas was 5 L / min, and then the vacuum was evacuated to 10 -3 Pa, then raise the temperature to 1000°C at a heating rate of 10°C / min, hold for 10 minutes, then raise the temperature to 2000°C at a heating rate of 10°C / min, hold for 30 minutes, then raise the ...

Embodiment 2

[0057] Example 2: Superalloy honeycomb insulation board prepared by mixing master alloy powder and carbonyl nickel powder at a ratio of 50:50

[0058] The preparation method of the superalloy honeycomb insulation board is carried out according to the following steps:

[0059] S1. Master alloy powder preparation: mix 32 parts of Ni, 20 parts of Cr, 20 parts of Co, 11 parts of Al, 10 parts of Ti, 6 parts of Mo and 0.2 parts of B to obtain a master alloy; melt the master alloy in a vacuum melting furnace Finally, the master alloy ingot is obtained, and the vacuum melting process is as follows: argon gas is introduced at room temperature for 30 minutes, the purity of the argon gas is 99.999%, the flow rate of the argon gas is 5 L / min, and then vacuumed to 10 -3 Pa, then raise the temperature to 1000°C at a heating rate of 10°C / min, hold for 20 minutes, then raise the temperature to 2000°C at a heating rate of 10°C / min, hold for 40 minutes, then raise the temperature to 2800°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flat compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com