Patents

Literature

85results about How to "Improve binding tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

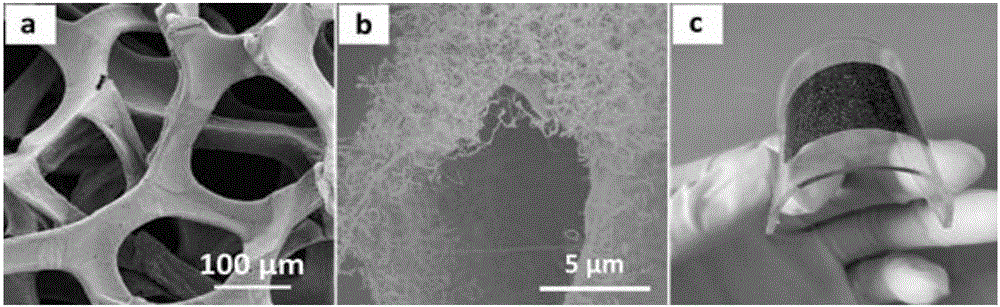

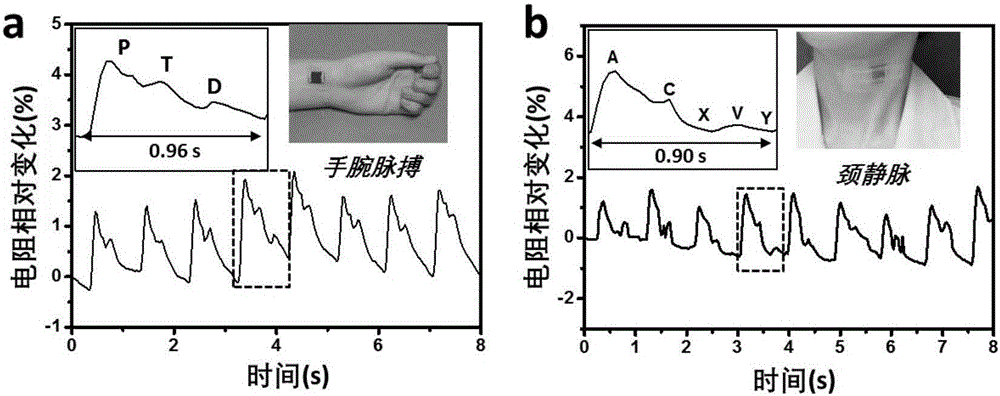

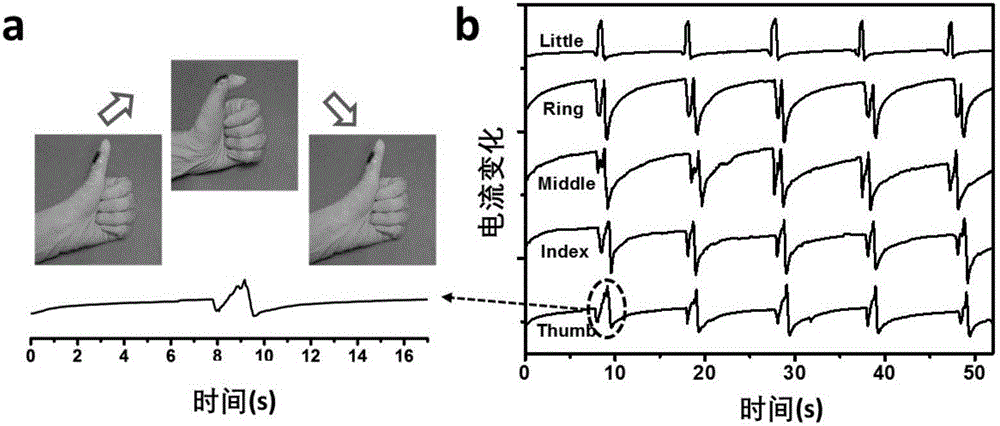

Graphene/carbon nanotube network flexible multifunctional strain sensor preparation method

ActiveCN106767374APractical application value is greatImprove tensile propertiesElectrical/magnetic solid deformation measurementCarbon nanotubeMicroheater

The invention discloses a three-dimensional graphene / carbon nanotube network flexible multifunctional strain sensor preparation method. According to the invention, the three-dimensional network of three-dimensional graphene and a one-dimensional carbon nanotube grows through two-step chemical vapor deposition; and the three-dimensional network and an elastic polymer as a flexible substrate are solidified and combined to acquire a flexible wearable multifunctional electronic strain sensor based on the three-dimensional network of the graphene and the carbon nanotube. According to the invention, the electronic strain sensor breaks the limitation relationship between the strainability and the sensitivity of the strain sensor, has an excellent electronic strain sensing performance and the function of a micro heater, realizes high sensitivity detection of human physiological signals and physical activities, shows excellent electronic skin simulation capabilities and a micro heating source application performance, has the advantage of simple process, and can be widely used in many fields such as clinical diagnosis, health monitoring, a robot, an electronic screen, electronic skin, a flexible micro heater and intelligent home.

Owner:NANJING UNIV OF TECH

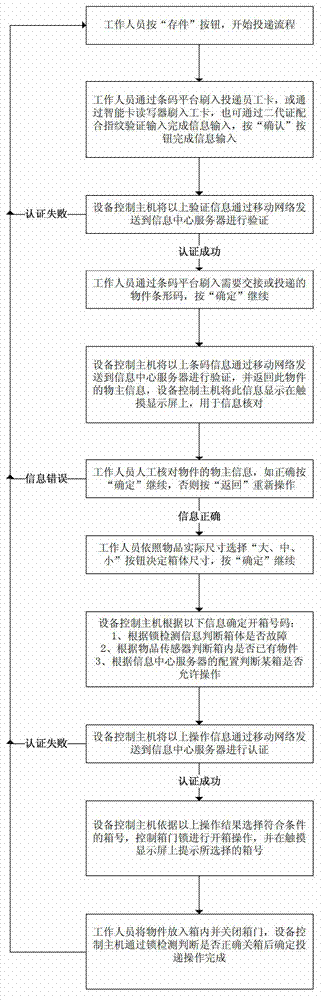

Automatic article depositing-withdrawing machine and use method thereof

InactiveCN102855704AShorten the timeEasy to take awayApparatus for meter-controlled dispensingComputer moduleElectric control

The invention designs an automatic article depositing-withdrawing machine and a use method of the automatic article depositing-withdrawing machine, to solve the technical problem that a delivery man must contact with a recipient face to face when delivering. The machine provided by the invention comprises a box body and a main computer arranged in the box body, wherein the outer surface of the box body is provided with an input device connected with the main computer through signal transmission; the box body is provided with a plurality of storage cabinets with doors; each storage cabinet is provided with an automatic door opening device electrically controlled by the main computer; and the main computer is provided with a network module. The machine provided by the invention is rational in layout, and reaches the purpose of automatically depositing and withdrawing the articles, avoids the face-to-face contact between the delivery man and the recipient, saves the time of the delivery man and improves the working efficiency; the machine provided by the invention helps the recipient to automatically schedule to take away the articles; the machine provided by the invention runs stably, mistakes are not easily made, the machine provided by the invention detects the storage cabinets and door locks of the storage cabinets in real time so as to avoid missing the articles and prevent the doors from being unlocked in time.

Owner:HANGZHOU CHIDA INFORMATION TECH

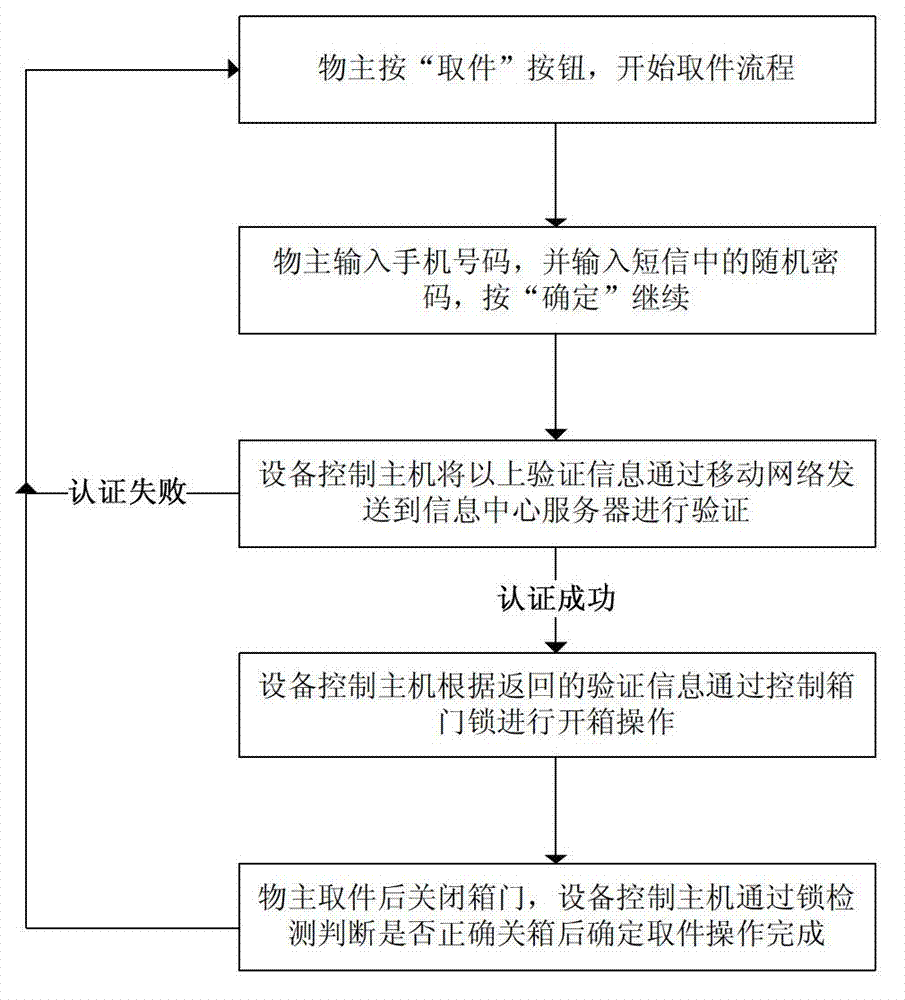

Welding method of target materials and back plates

InactiveCN101648303AImproved infiltration fusionImprove brazing bond strengthMolten spray coatingVacuum evaporation coatingSolderingCopper

The invention related to a welding method of target materials and back plates, which comprises the following steps: providing a copper target material and a back plate; forming a metal intermediate layer on a welding surface of the copper target material; adding a brazing filler metal on the welding surface of the back plate; welding the copper target material to the back plate to form a target material assembly by soldering, heating and melting the brazing filler metal; then carrying out heat preservation and thermal diffusion processing; and cooling the target material assembly, and removingthe redundant brazing filler metal through machining. The invention improves the problem of difficult soakage of weld workpieces and brazing filler metals through the metal intermediate layer, and effectively improves the bonding strength between the copper target material and the back plate; the copper target material can not be disconnected in a sputtering process, and sputter coating can be normally carried out.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

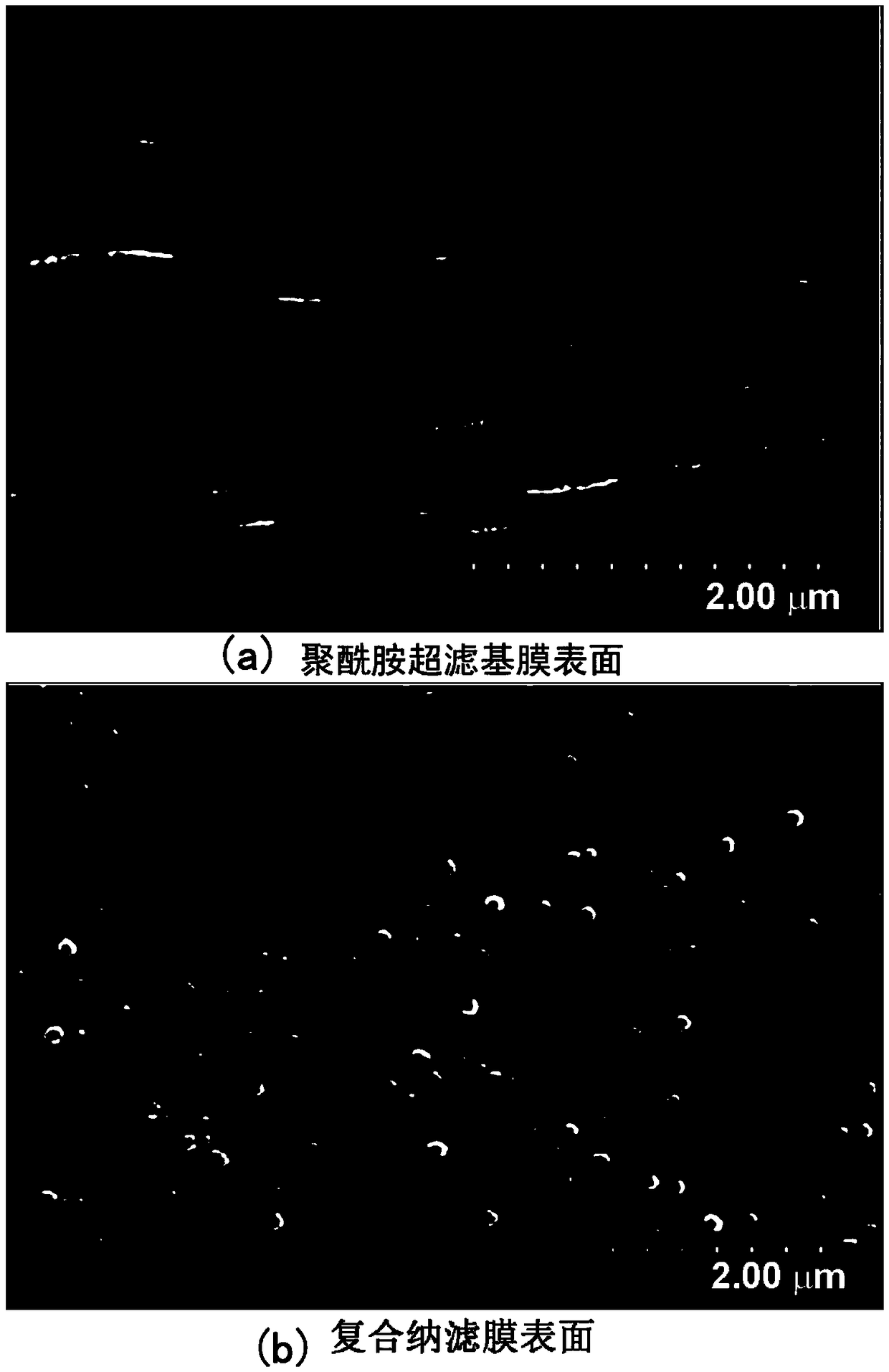

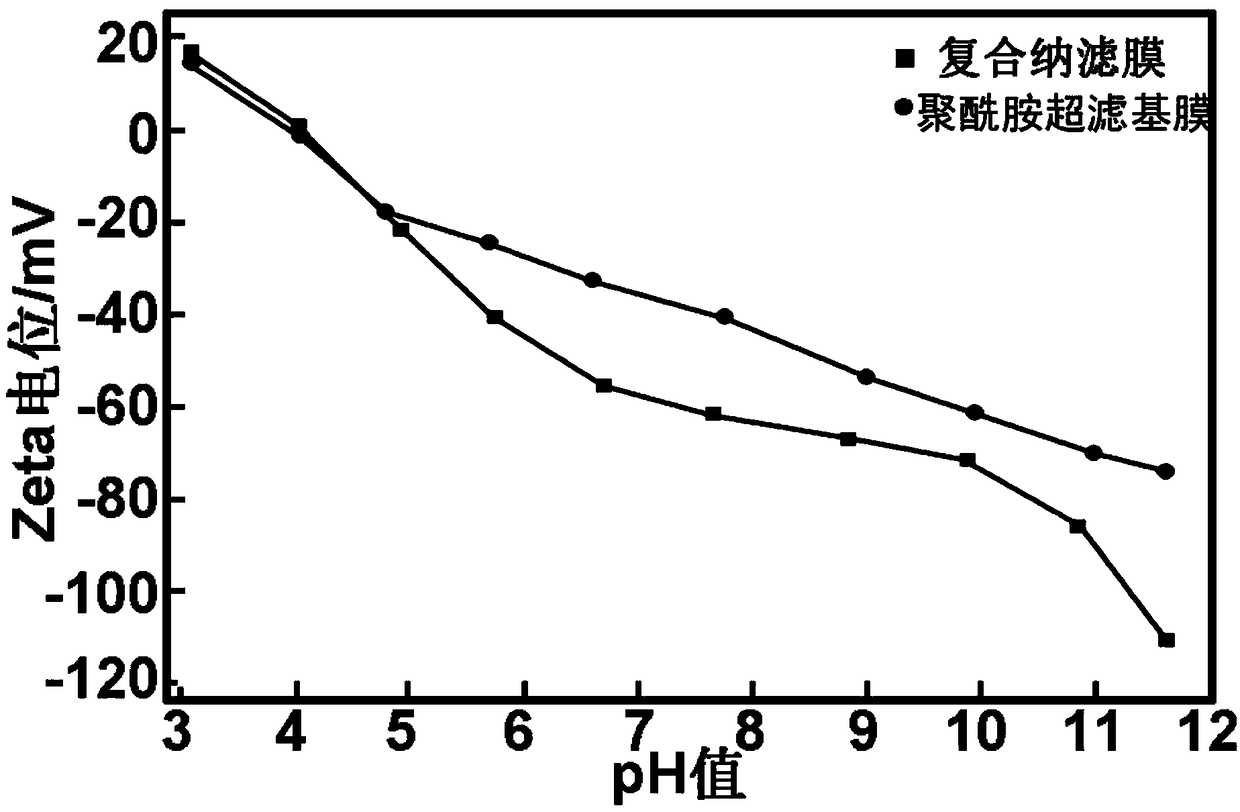

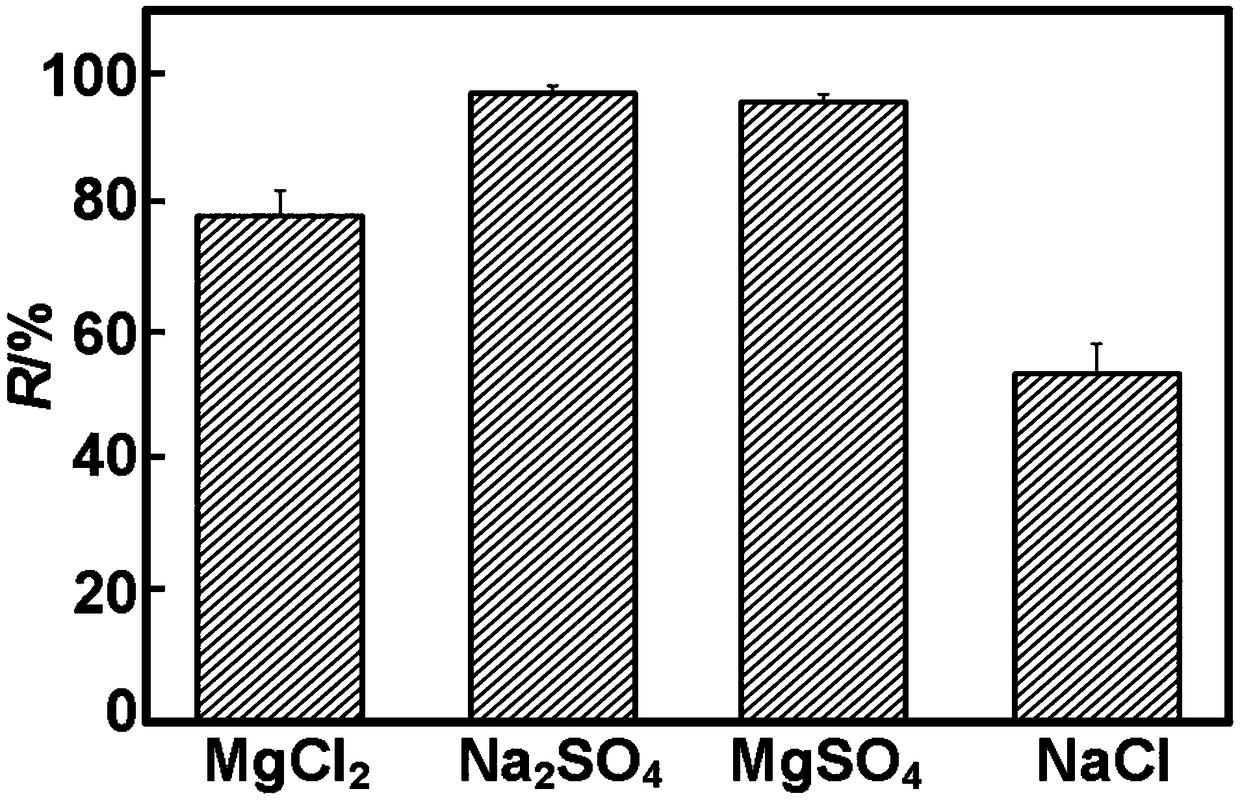

Graphene oxide modified PA (polyamide) composite nanofiltration membrane and preparation method thereof

ActiveCN109092087AHigh mechanical strengthImprove throughputSemi-permeable membranesMembranesUltrafiltrationPolyamide

The invention discloses a graphene oxide modified PA (polyamide) composite nanofiltration membrane and a preparation method thereof. The method comprises steps as follows: preparing a PA ultrafiltration basement membrane; preparing an aqueous amino graphene oxide solution; adding a crosslinking agent to the prepared aqueous amino graphene oxide solution to prepare an amino graphene oxide crosslinking solution; dip-coating the PA ultrafiltration basement membrane with a layer of the amino graphene oxide crosslinking solution with a surface coating method firstly, then coating the PA ultrafiltration basement membrane with a layer of a PA ultrafiltration membrane casting solution to prepare the graphene oxide modified PA composite nanofiltration membrane. A large quantity of free carboxyl andhydroxyl exist on the membrane surface, so that the graphene oxide modified PA composite nanofiltration membrane has the characteristics of high hydrophilcity and high throughput; meanwhile, due to the crosslinking reaction between amino graphene oxide and a PA basement membrane, tightness can be improved; the membrane surface is negatively charged, so that desalinization rate can be effectivelyincreased, and throughput and desalinization effect of the nanofiltration membrane are improved; the technical scheme has large-scale industrial application and popularization prospect.

Owner:NANJING POLYTECHNIC INSITUTE

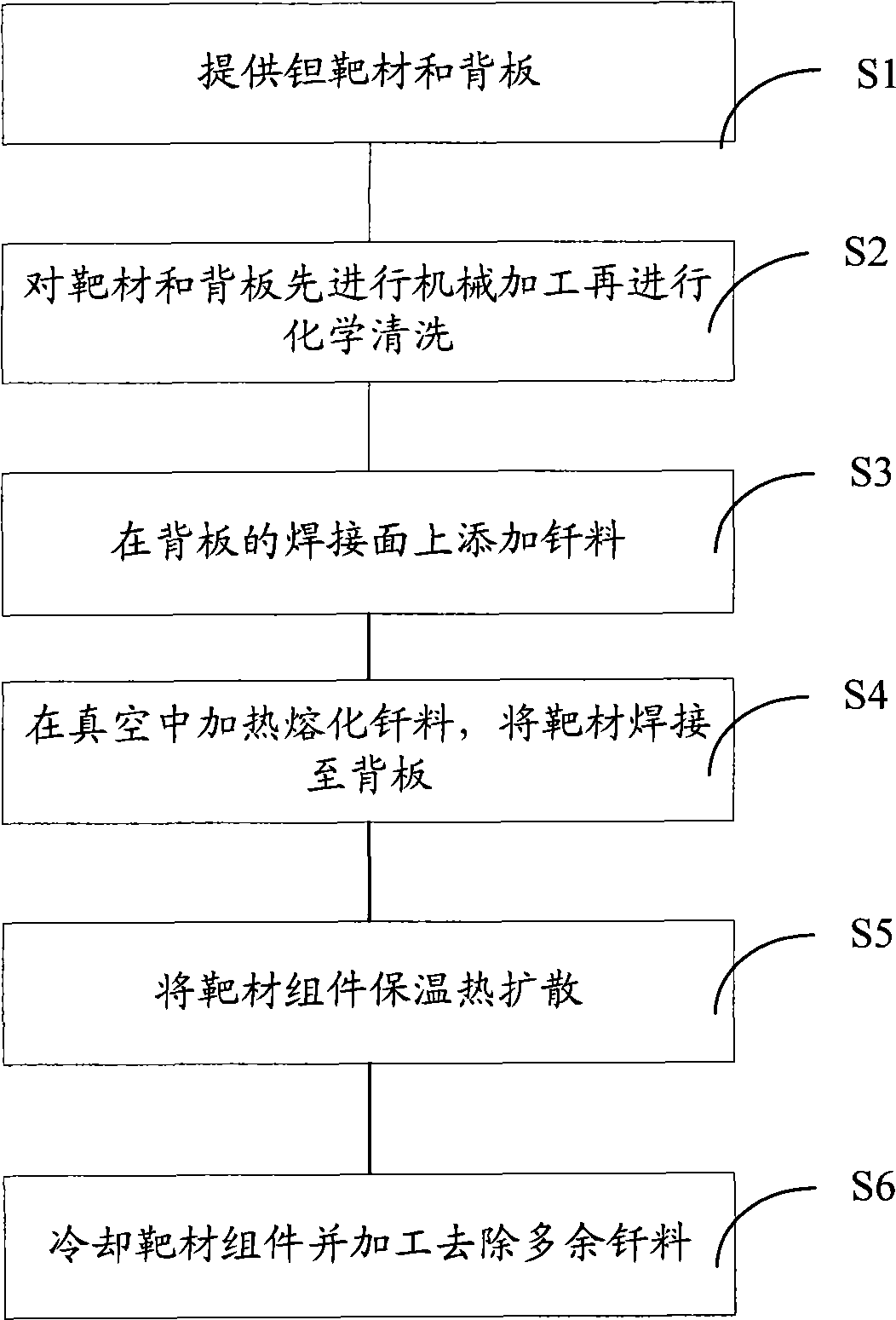

Method for welding target material and back board

InactiveCN101543924APrevent disengagementPrevent oxidationVacuum evaporation coatingSputtering coatingThermal insulationCentral layer

A method for welding a target material and a back board includes a step of providing a tantalum target material and a back board; a step of adding solder on a welding surface of the back board; a step of forming a metal central layer on a welding surface containing the tantalum target material in vacuum; a step of implementing thermal insulation and heat diffusion treatment; and a step of cooling the target material component, and removing the redundant solder through a mechanical treatment. By means of implementing a large area welding in a vacuum circumstance, the method of the invention is capable of preventing a metallic welding surface from being oxidized, is favorable to infiltrate the solder and the metal, the bonding strength between the tantalum target material and the back board is improved, thereby the abjunction of the tantalum target material is avoided from the back board during a sputtering process, and a sputter coating may be implemented normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

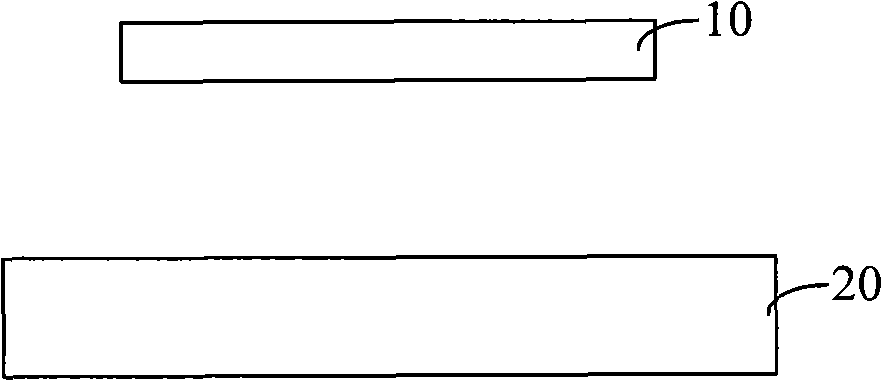

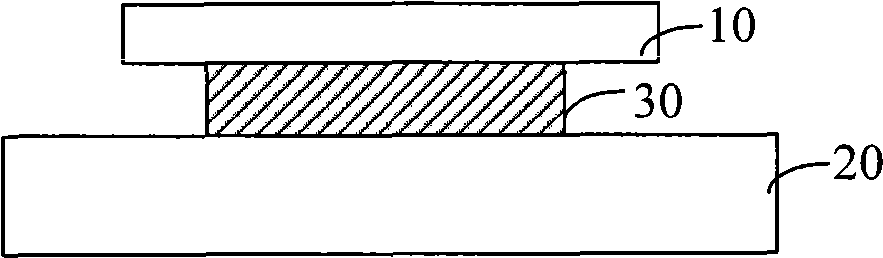

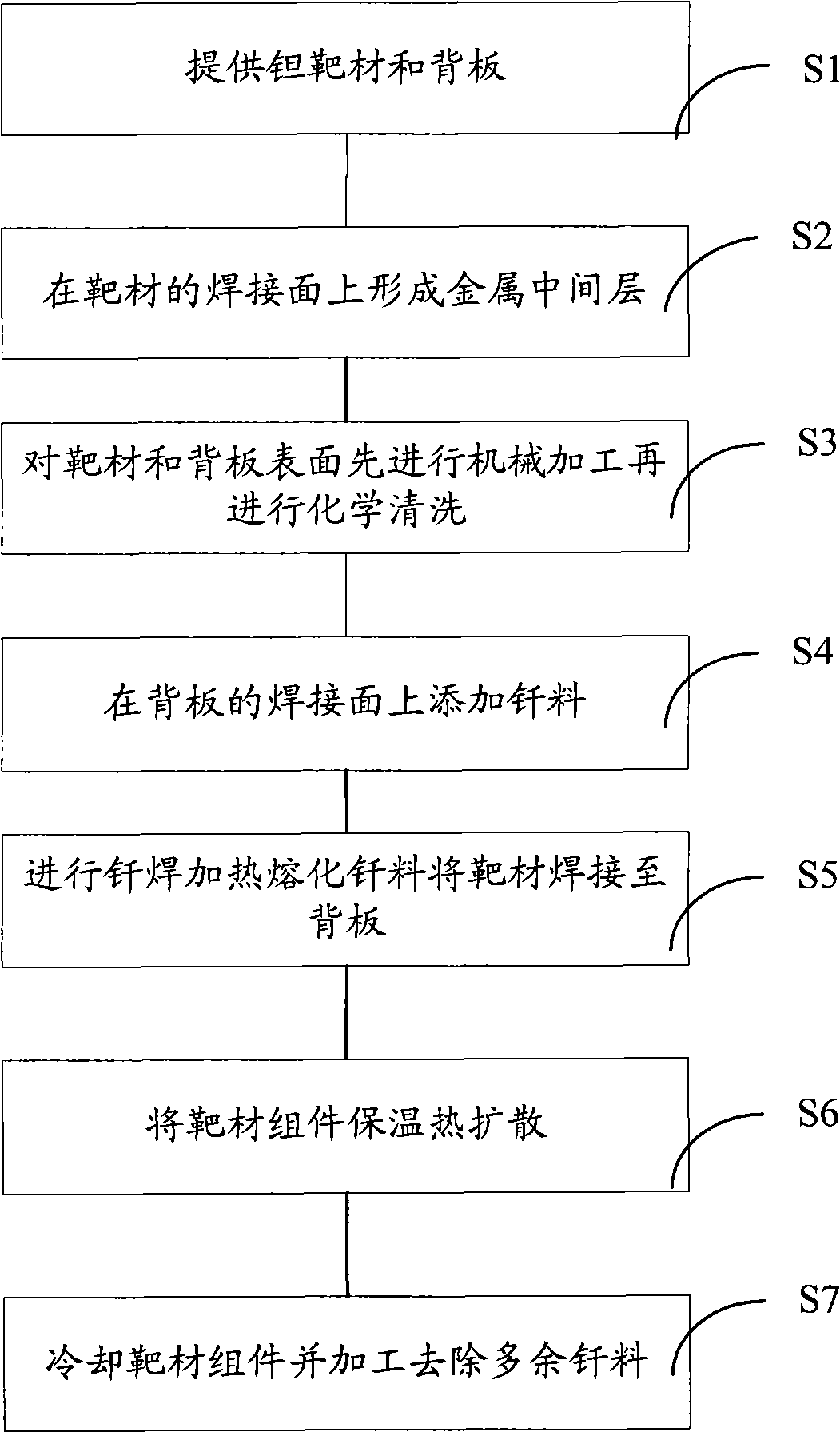

Method for welding target material and back board

ActiveCN101543923AImproved infiltration fusionImprove brazing bond strengthMolten spray coatingVacuum evaporation coatingThermal insulationCentral layer

A method for welding a target material and a back board includes a step of providing a tantalum target material and a back board; a step of forming a metal central layer on a welding surface containing the tantalum target material; a step of adding solder on a welding surface of the back board; a step of welding the tantalum target material to the back board to form a target material component by brazing, heating and fusing the solder; a step of implementing thermal insulation and heat diffusion treatment; and a step of cooling the target material component, and removing the redundant solder through a mechanical treatment. The invention improves a problem that a welding workpiece and the solder are difficult to infiltrate by the metal central layer, the bonding strength between the tantalum target material and the back board is improved effectively, the tantalum target material will not be unhitched during a sputtering process, and a sputter coating may be implemented normally.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

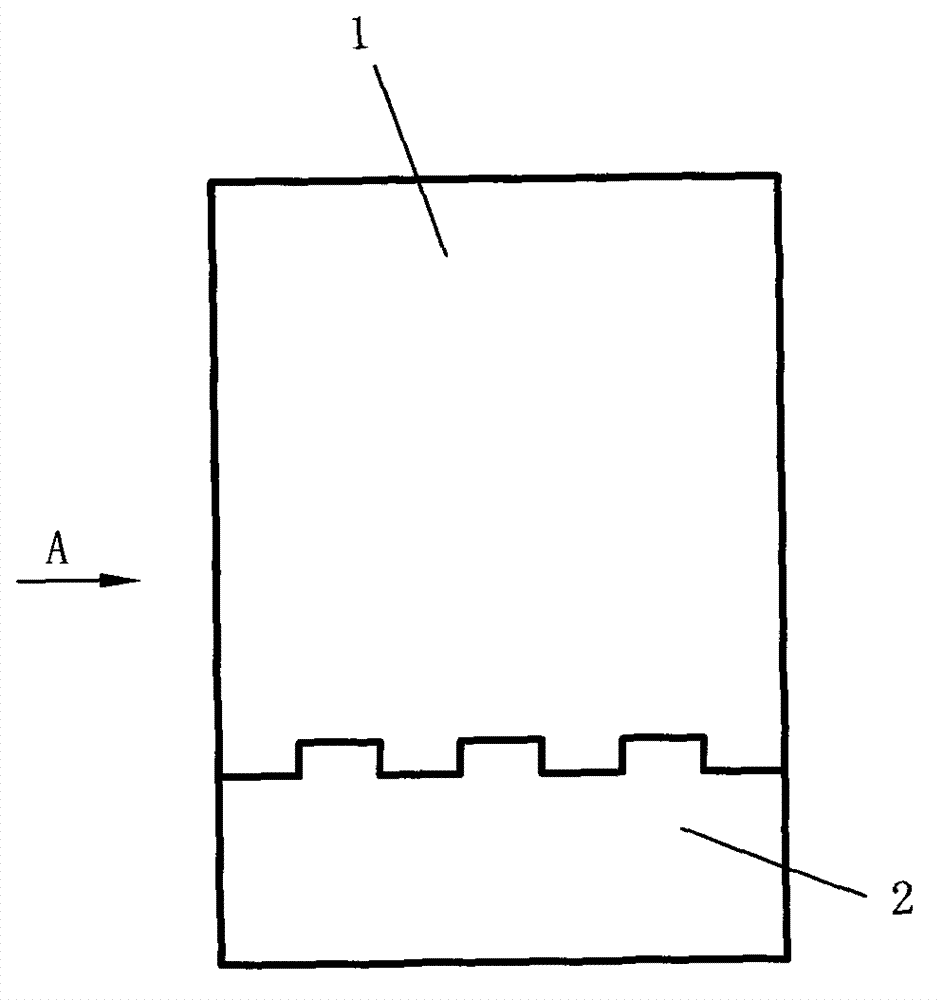

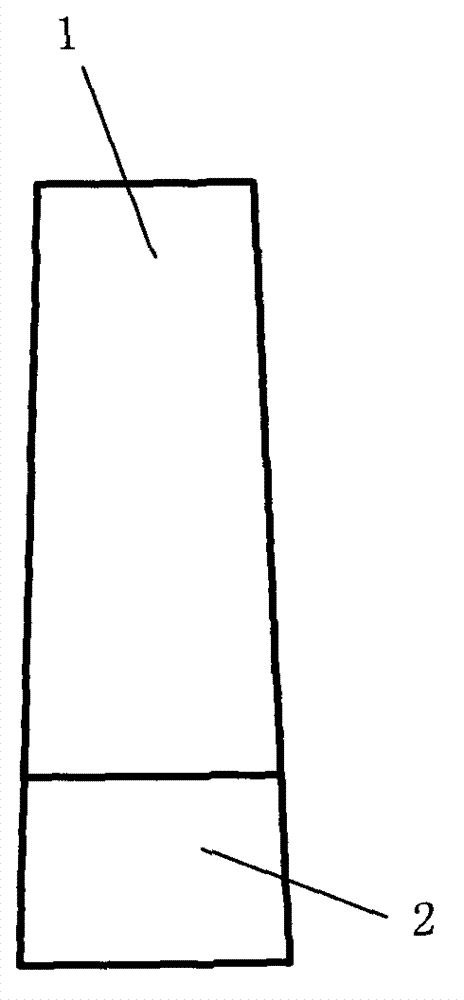

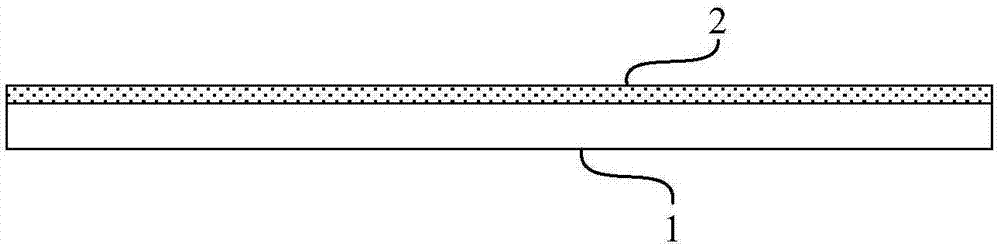

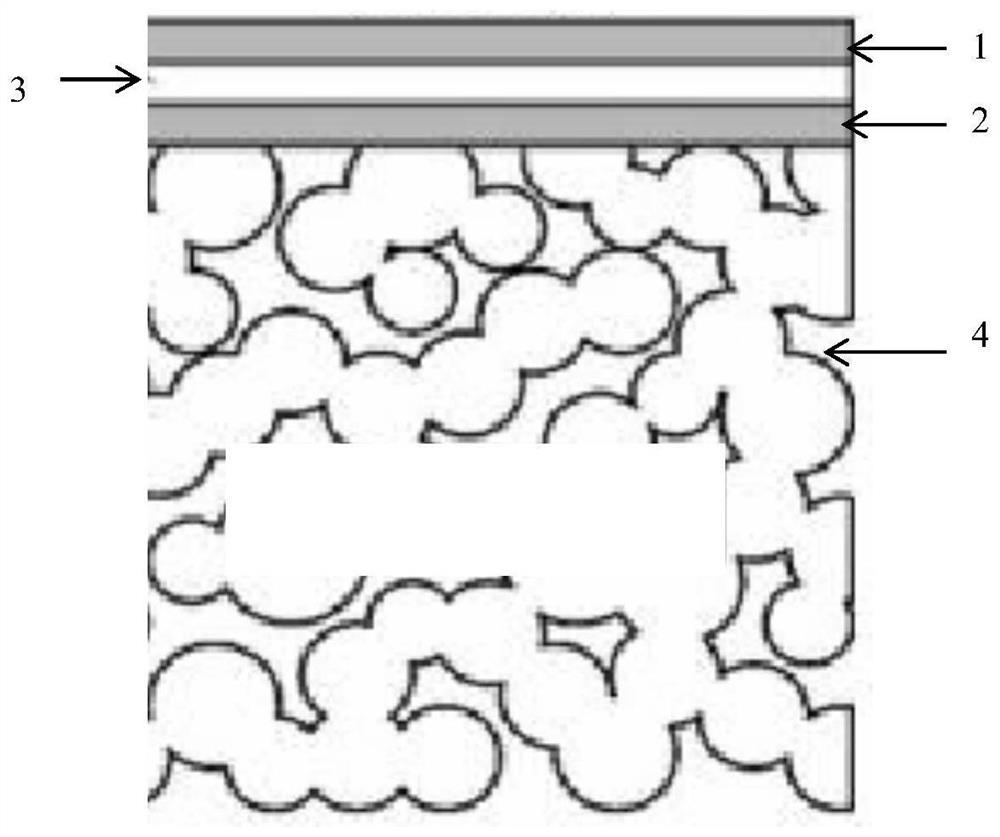

Special composite firebrick for rotary kiln and preparation method thereof

InactiveCN102788497AEnhanced resistance to peelingImprove thermal shock resistanceFurnace componentsRotary drum furnacesMicrosphereThermal insulation

The invention relates to a special composite firebrick for a rotary kiln and a preparation method thereof. The special composite firebricks are divided in to common firebricks and special firebricks which are in the same appearance and size, both the common firebrick and the special firebrick consist of working layers (1) and thermal insulation layers (2), and adhesion agents and binding agents are combined between the working layers (1) and thermal insulation layers (2); the adhesion agents are prepared by mixing fluorite powders, hollow microspheres, sub-white fused alumina hollow spheres, mullite hollow spheres, sphere clay powders and silica fumes according to certain proportions to form slurry by utilizing inorganic bonds; the binding agents are inorganic bonds, such as one or mixture of phenolic resin glue, polyvinyl acetate resin glue and urea resin. The special composite firebrick for the rotary kiln can be used for building the inside liner of a rotary kiln calcined by cement, fireproof material, fracturing propping agent for petroleum well, lime and the like, and has the functions of strip resistance, thermal shock resistance, high refractoriness under load and wear resistance.

Owner:厚波

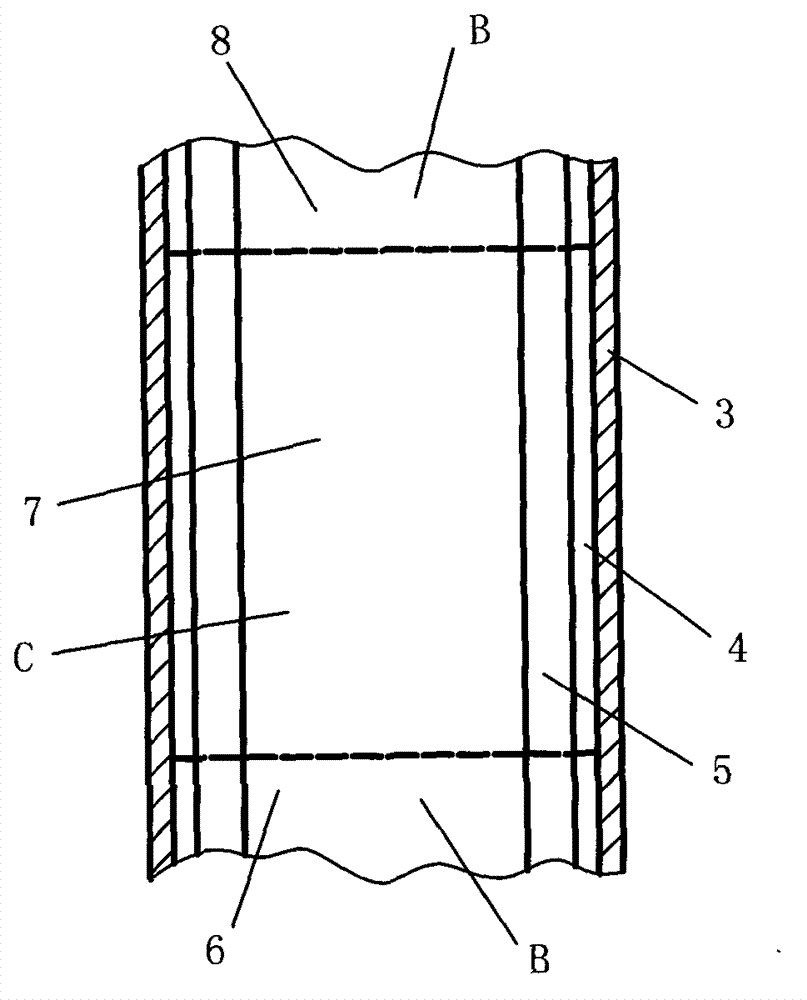

Target material structure and method for producing the same

ActiveCN101543934AImprove bindingImprove binding tightnessSoldering apparatusVacuum evaporation coatingMaterial structureTa element

The present invention provides a target material structure and a method for producing the same. The method includes a step of providing the target material; a step of forming a bonding layer on a welding face of the target material; a step of implementing a diffusion weld treatment on the bonding layer, and welding a back board to the target material. Comparing with the present technology, the method of the invention may ensure the combination of a tantalum target material and a copper back board to be reliable, and the quality of the target material structure is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

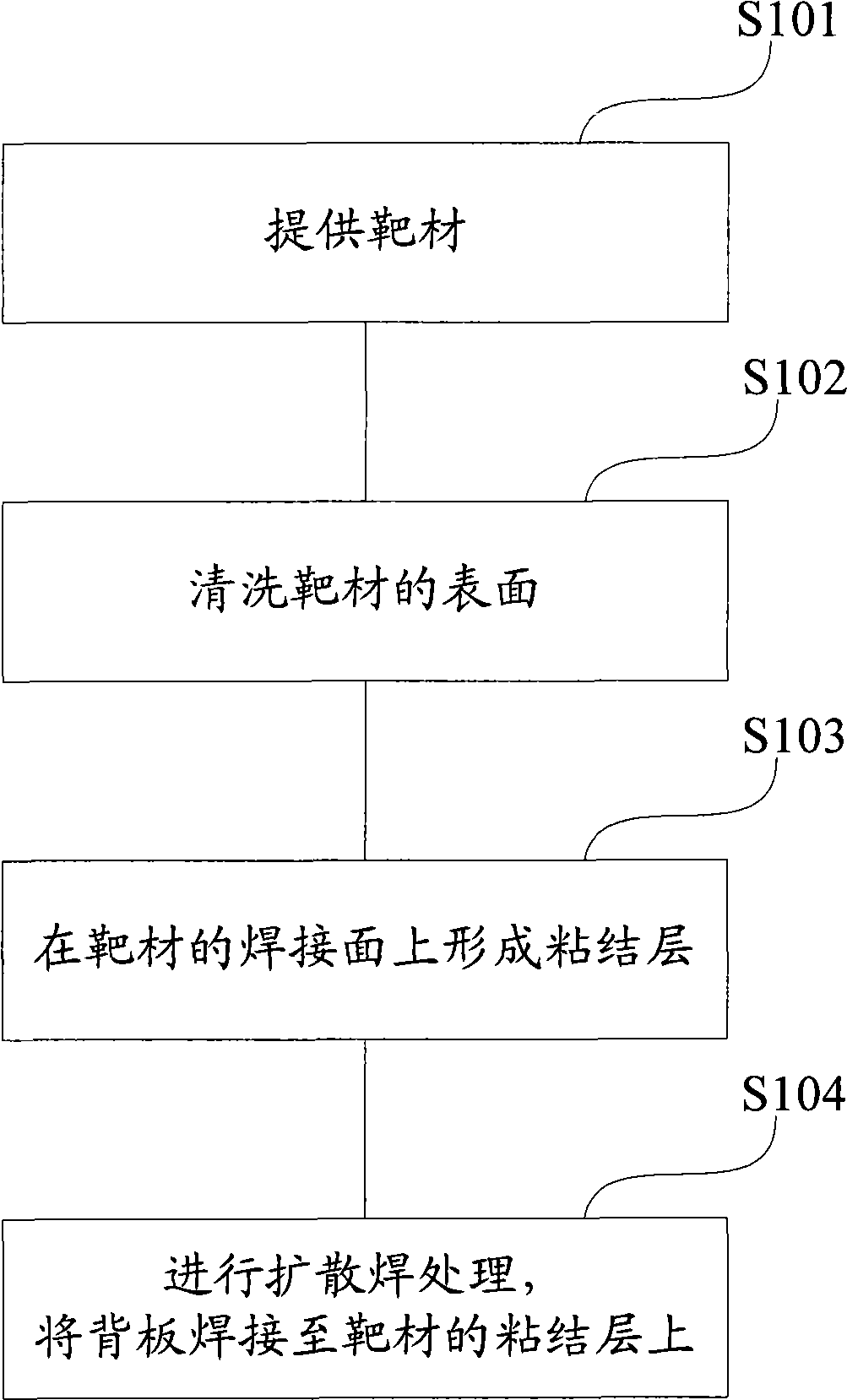

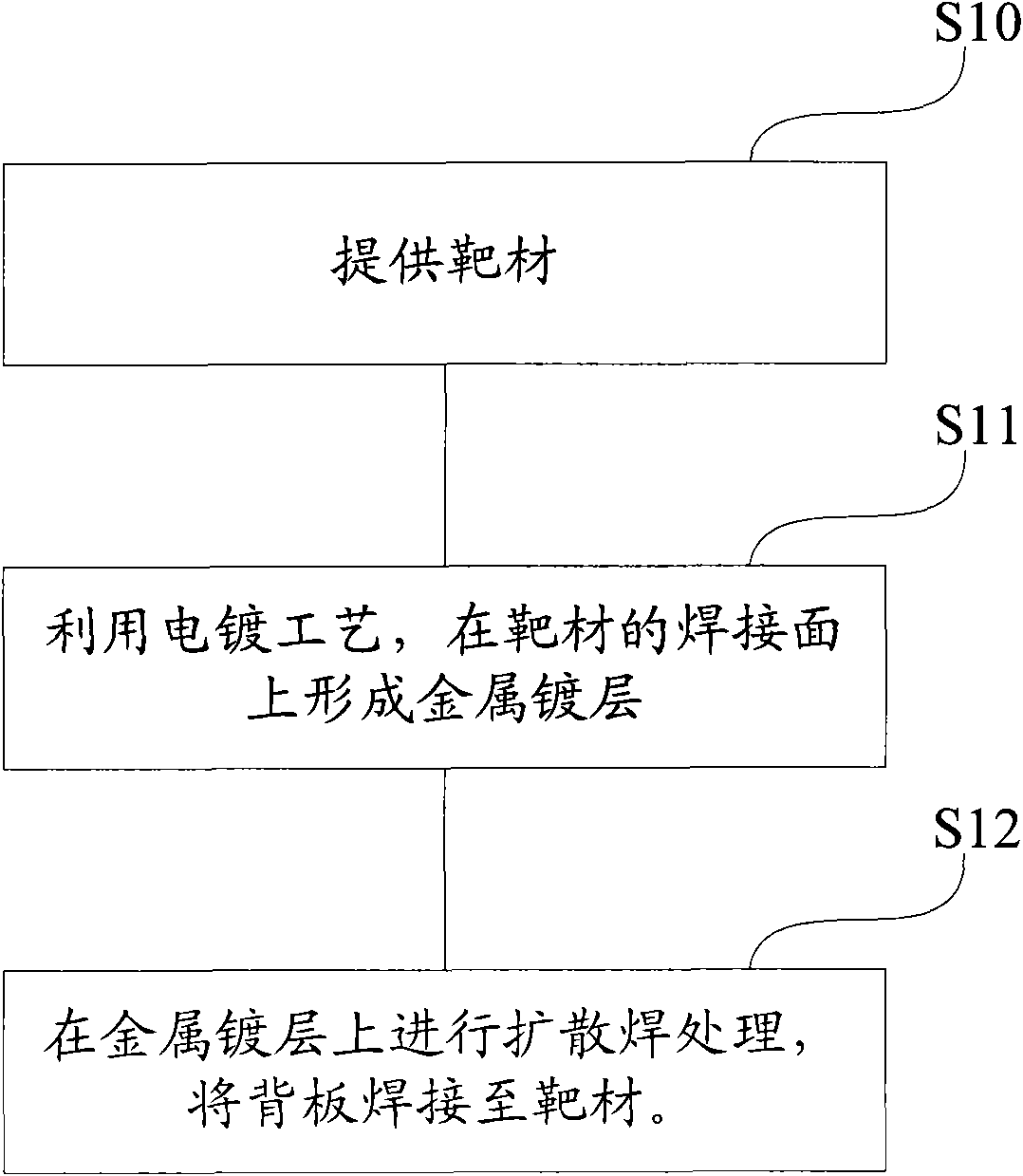

Manufacturing method of target structure

ActiveCN101537530AImprove bindingImprove binding tightnessSoldering apparatusVacuum evaporation coatingCopperTantalum

The invention provides a manufacturing method of a target structure. The method includes the following steps of: providing a target that is tantalum or tantalum alloy; using electroplating technology to form a metal plating on the welding surface of the target; and conducting diffusion welding on the metal plating and welding a back board to the target. Compared with the prior art, the method can realize the reliable combination of the tantalum target and a copper back board and boost the quality of the target structure.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Laser-assisted graphene tooth 3D printing process

ActiveCN106725944APermanent wear resistanceHigh mechanical strengthAdditive manufacturing apparatusDental prostheticsCvd grapheneLaser assisted

The invention discloses a laser-assisted graphene tooth 3D printing process. The technique is combined with the graphene and the laser heat treatment technique, a high-quality graphene tooth is obtained through 3D printing, the graphene is added into a tooth base material, the property of the base material is not changed, the coefficient of thermal expansion of the tooth is reduced, the overall mechanical property is improved, and the ultra-intense laser is radiated on the tooth material in the laser heat treatment technique to improve the wear resistance, the metal-ceramic binding tightness and the material density of the tooth material. Based on the laser, the characteristics of instantaneous high temperature, controllable irradiation and short quenching time are provided, the printed graphene tooth not only is accurately fitted with the alveolar ridge of a patient, but also is high in stability, wear resistance and mechanical strength, a plurality of tests like the metal-ceramic binding strength test, the thermal expansion coefficient experiment and the surface roughness test indicate that the graphene tooth prepared through the technique has better properties than the traditional material, and has an industrialized development future.

Owner:GUANGZHOU FENGSHANG ELECTRIC APPLIANCE

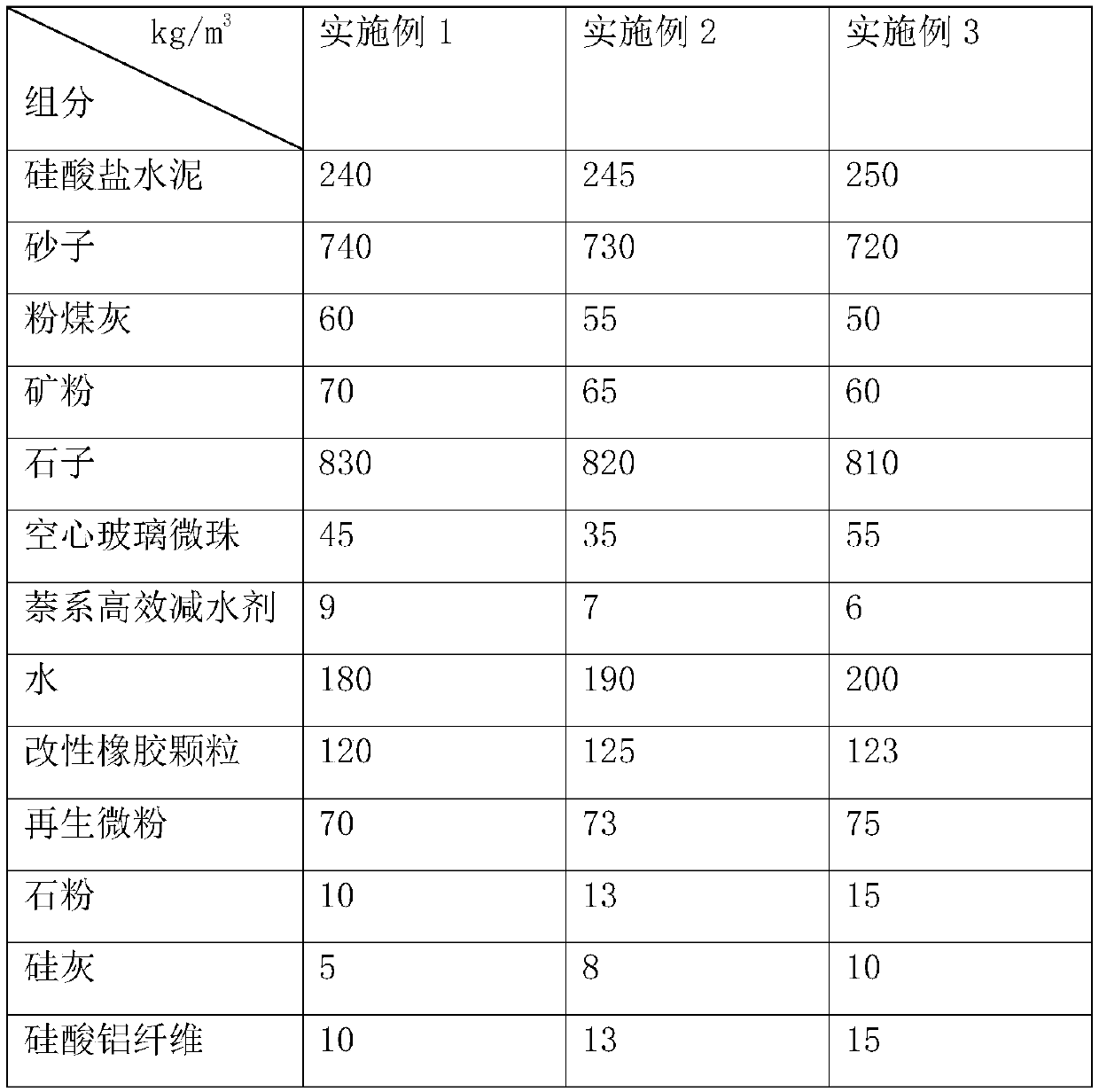

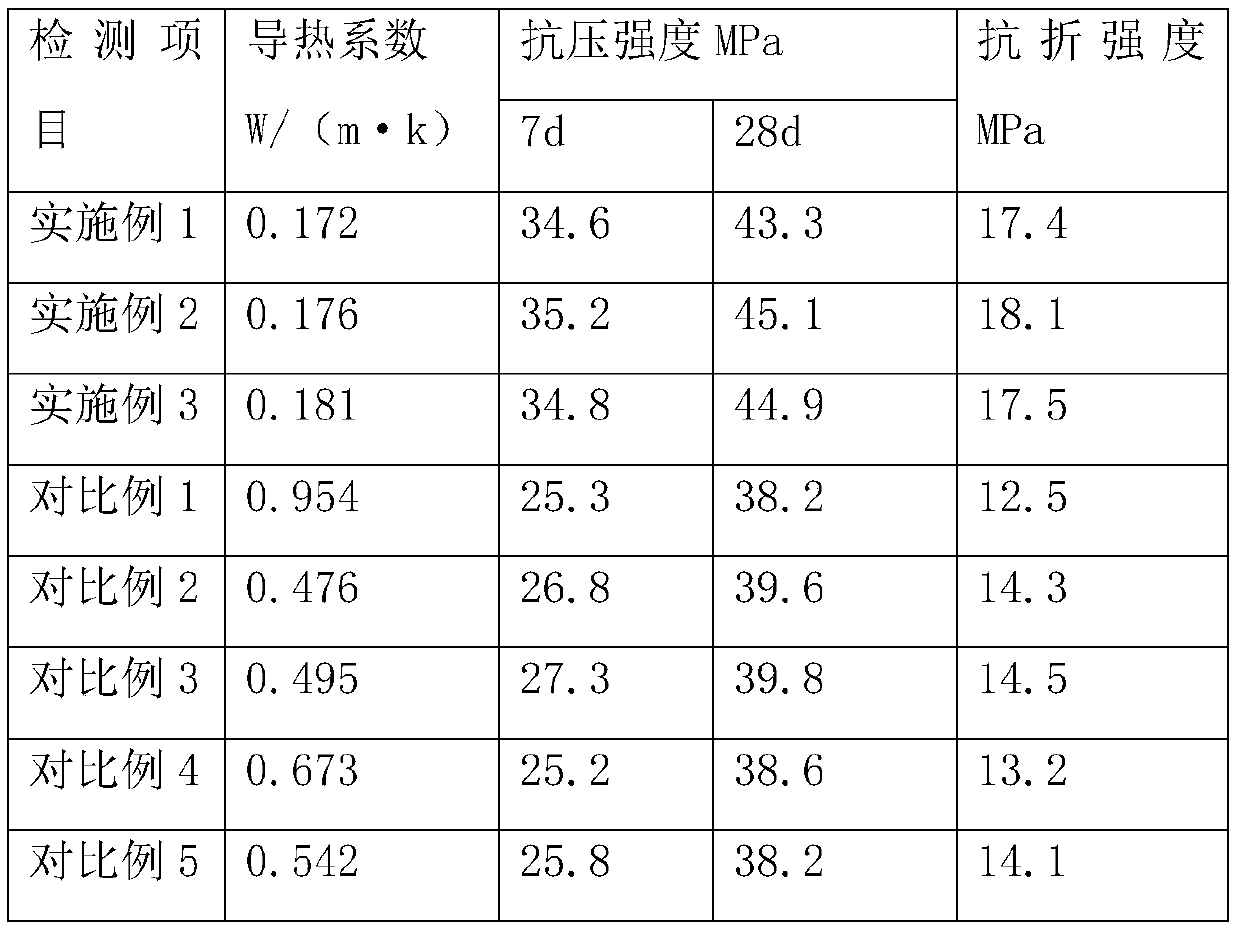

High-strength thermal-insulation concrete and preparation method thereof

The invention discloses high-strength thermal-insulation concrete, a preparation method and uses thereof, wherein the high-strength thermal-insulation concrete comprises, by weight, 240-250 parts of Portland cement, 720-740 parts of sand, 50-60 parts of fly ash, 60-70 parts of mineral powder, 810-830 parts of stone, 35-55 parts of hollow glass micro-beads, 6-9 parts of a naphthalene-based efficient water reducing agent, 180-200 parts of water, 120-125 parts of modified rubber particles, 70-75 parts of regenerated micro-powder, 10-15 parts of stone powder, 5-10 parts of silica fume, and 10-15 parts of aluminum silicate fiber. According to the present invention, the high-strength thermal-insulation concrete has the physical and mechanical properties of ordinary concrete, has good thermal insulation performance, and meets the advantages of environmental protection building materials.

Owner:北京建工一建工程建设有限公司

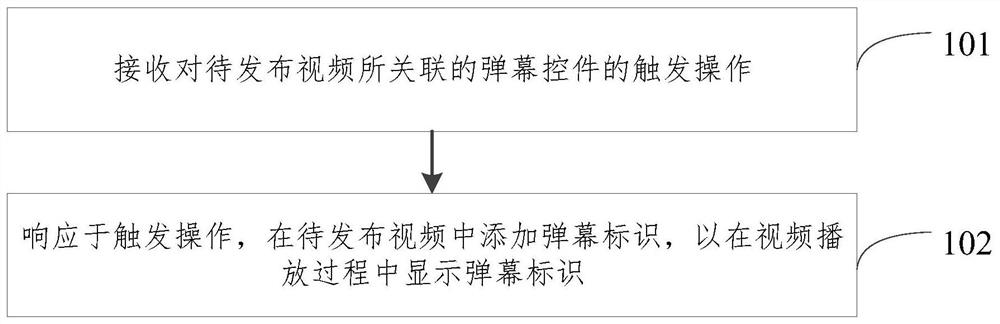

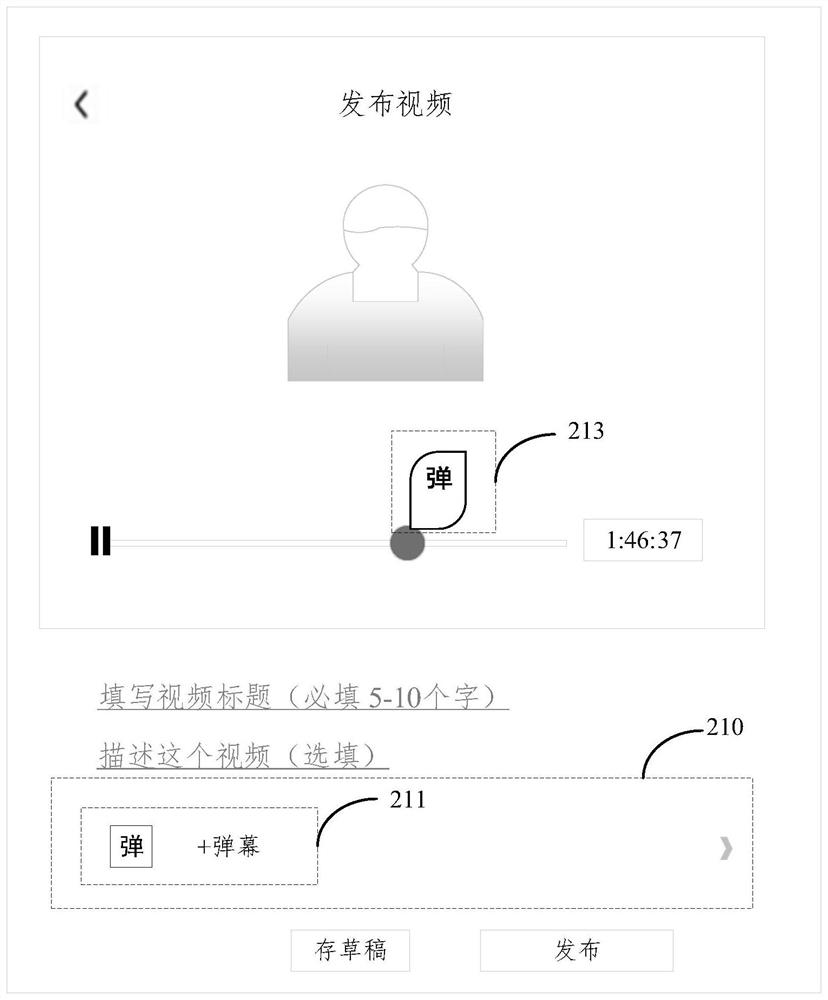

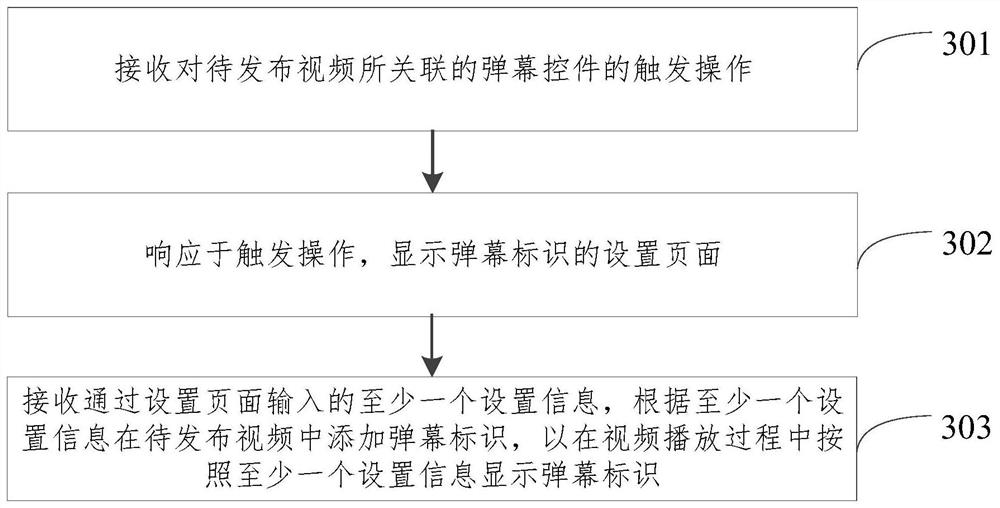

Video processing method and device, electronic equipment and storage medium

ActiveCN113542854AImprove binding tightnessRealize independent creativitySelective content distributionInput/output processes for data processingComputer graphics (images)Video processing

Embodiments of the invention relate to a video processing method and apparatus, an electronic device and a storage medium. The method comprises the steps of receiving a trigger operation of a bullet screen control associated with a to-be-released video; and in response to the trigger operation, adding a bullet screen identifier in the to-be-released video so as to display the bullet screen identifier in a video playing process. By adopting the technical scheme, the video creator can exert independent creativity, add the bullet screen identifier in the to-be-published video and add the bullet screen identifier in the to-be-published video by combining the video content so as to guide the video viewer to trigger the bullet screen identifier to send the bullet screen, and the combination tightness of the bullet screen and the video content can be improved.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

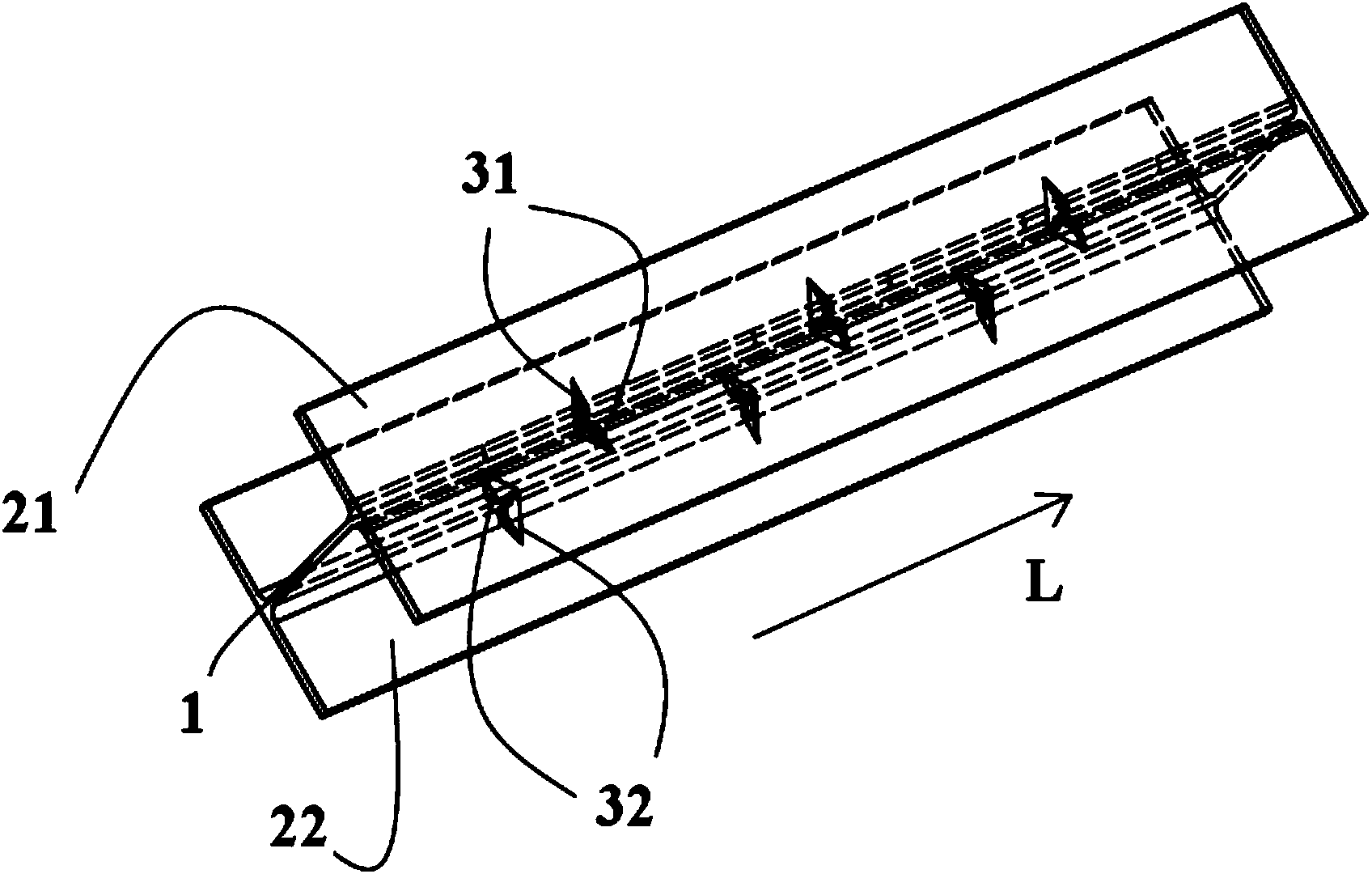

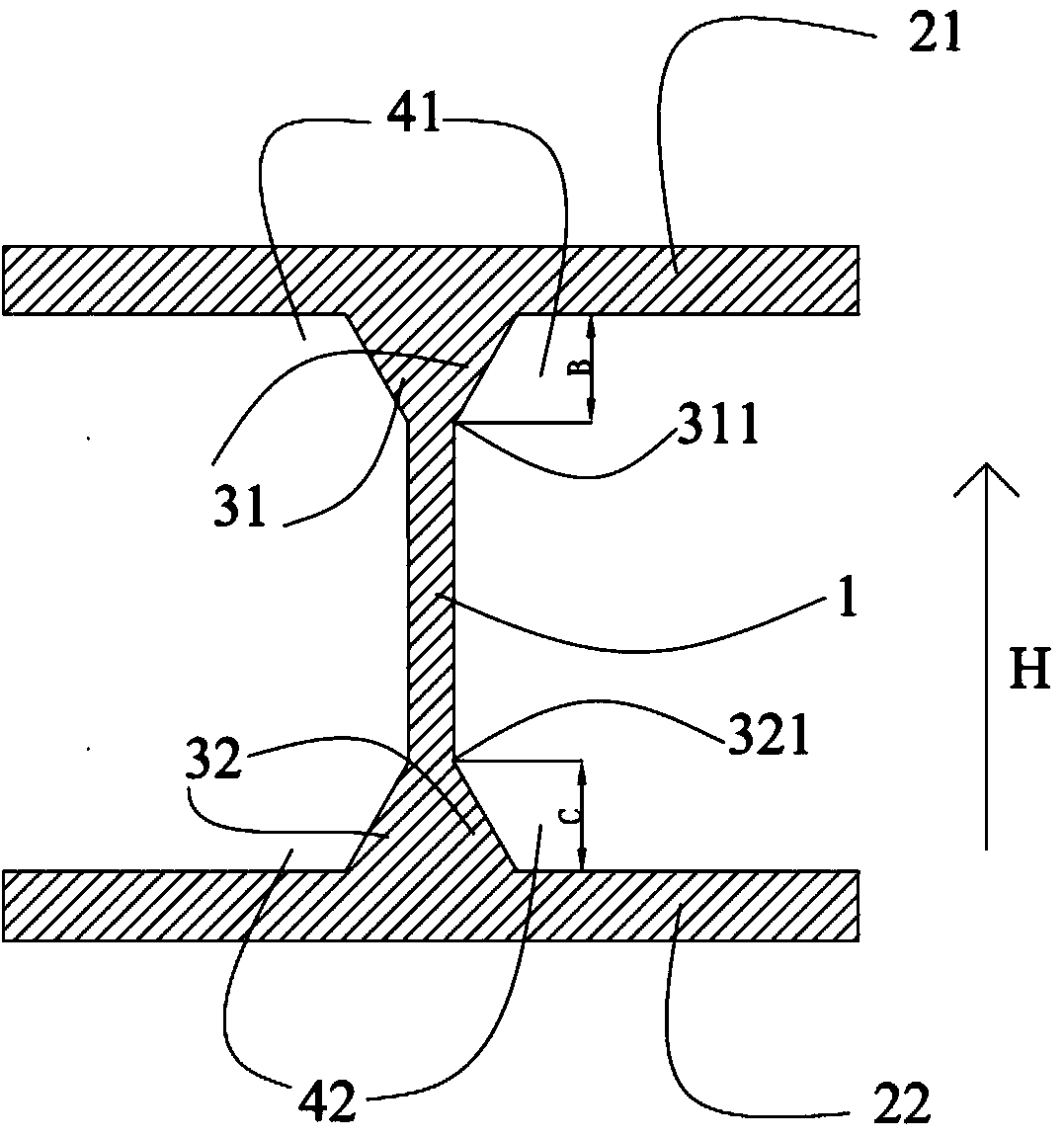

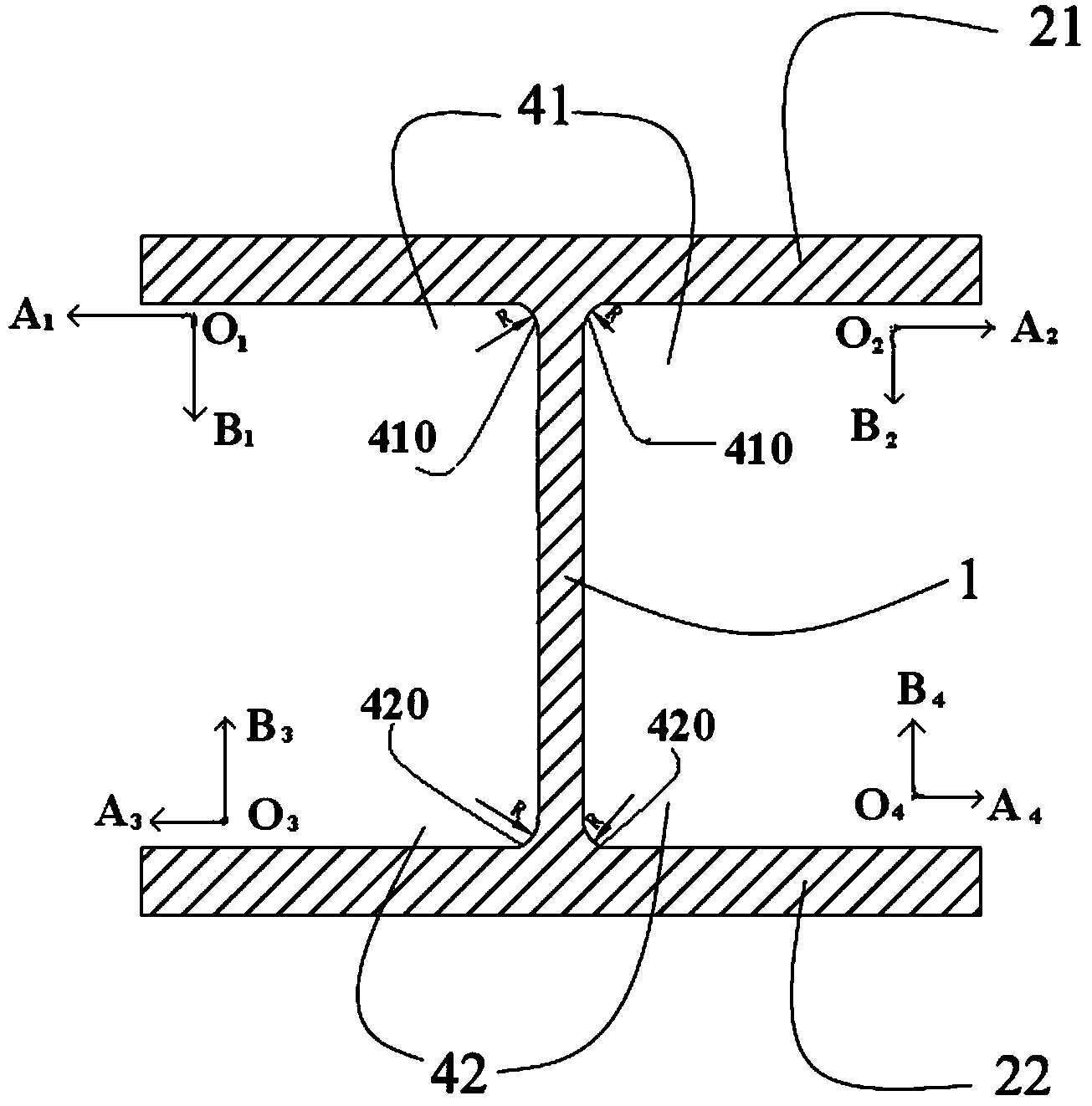

H-shaped steel with rib and concrete structure of H-shaped steel with rib

The invention discloses H-shaped steel with a rib and a concrete structure of the H-shaped steel with the rib. The H-shaped steel with the rib comprises a web, a top flange and a bottom flange, wherein the web is located between the top and bottom flanges and is respectively connected with the top and bottom flanges. The H-shaped steel with the rib further comprises an upper rib formed in an upper included angle formed by connecting the web and the top flange and a lower rib formed in a lower included angle formed by connecting the web and the lower flange. The upper and lower ribs are integrally formed with the web, the top and bottom flanges through hot rolling. The concrete structure of the H-shaped steel with the rib comprises a reinforcing steel bar, concrete and the H-shaped steel with the rib. The reinforcing steel bar is arranged around the H-shaped steel with the rib, the concrete is poured between the H-shaped steel with the rib and the reinforcing steel bar, and the H-shaped steel with the rib is the above H-shaped steel with the rib. Through the technical scheme disclosed by the invention, the bonding compactness of the H-shaped steel with the rib and the concrete can be improved.

Owner:LAIWU IRON & STEEL GRP

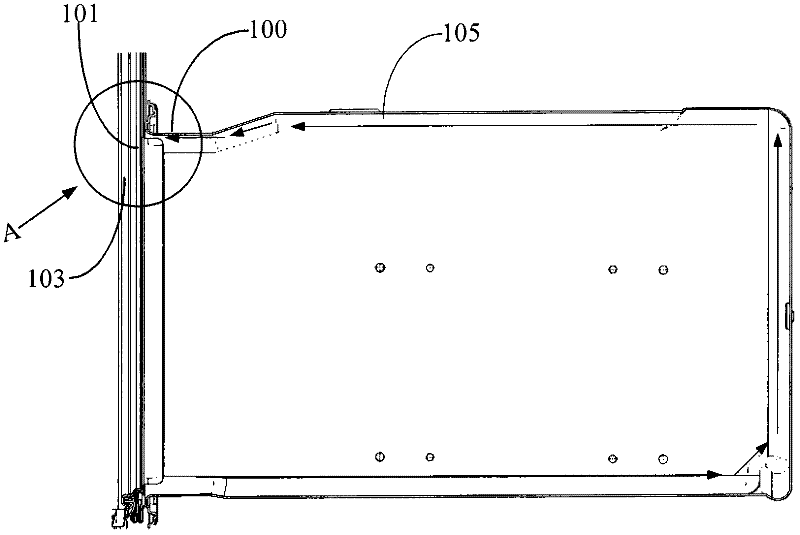

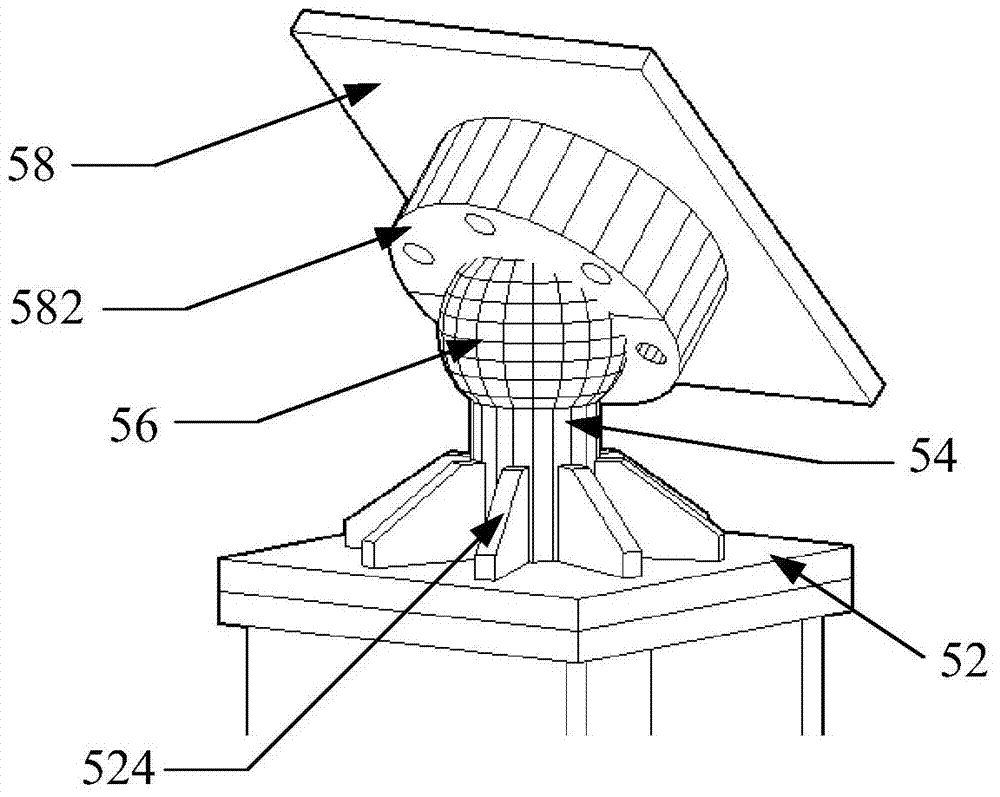

Solar panel device

ActiveCN109217797AImprove binding tightnessPrevent leakagePhotovoltaicsPhotovoltaic energy generationEngineeringFlange

The invention relates to a solar panel device. The solar panel device comprises a first solar panel and a second solar panel, the edge of the first solar panel is provided with a first connecting bar,the edge of the second solar panel is provided with a second connecting strip, A plurality of engagement flanges are protruded on the first engagement bar, wedge-shaped tips are formed on each engagement flange, a plurality of engagement grooves are concave on the second engagement bar, the engagement tips of the plurality of engagement flanges are respectively clamped in the plurality of engagement grooves, and insertion tips are protruded on the second engagement bar. The water-proof effect of the solar panel device is good.

Owner:徐州中伦光伏材料有限公司

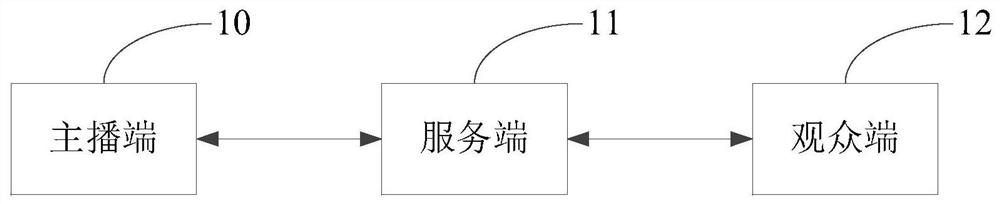

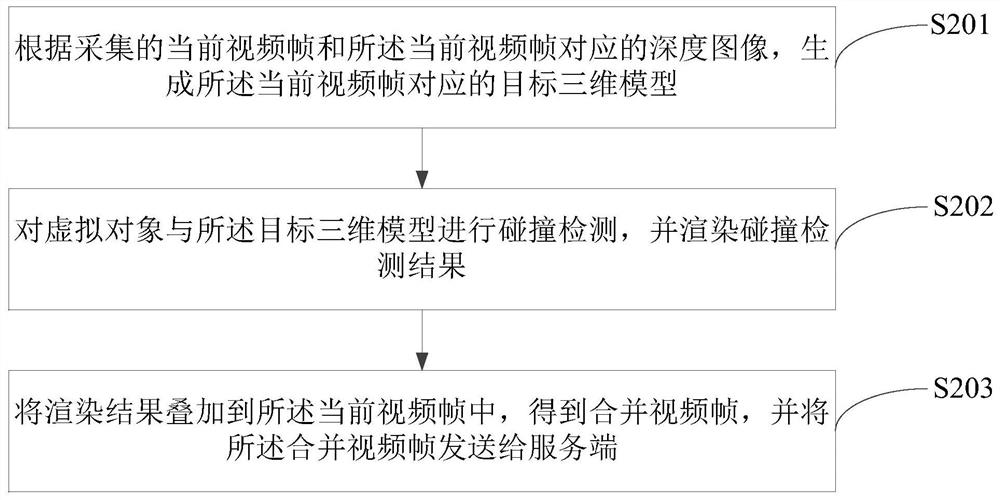

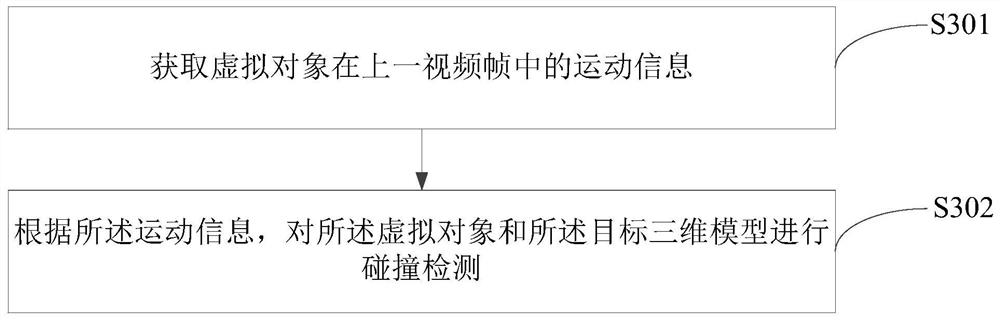

Live video processing method and device, equipment and storage medium

ActiveCN113038264AAccurate physical occlusion relationshipCollision detection real-time responseSelective content distributionImage generationCollision detectionVideo processing

The embodiment of the invention provides a live video processing method and device, equipment and a storage medium. The method comprises the following steps: generating a target three-dimensional model corresponding to a current video frame according to the collected current video frame and a depth image corresponding to the current video frame; carrying out collision detection on a virtual object and the target three-dimensional model and rendering a collision detection result, wherein the virtual object is triggered in the live broadcast process; and superposing the rendering result into the current video frame to obtain a combined video frame, and sending the combined video frame to a server. According to the method, the motion trail of the virtual object in the real live broadcast environment can be simulated, so that the interactive information triggered in the live broadcast process can be closely combined with the live broadcast video frame and fused with the live broadcast video frame, and therefore, the combination closeness of the interactive information and the live broadcast video is improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Fuel cell assembly and preparation method thereof

ActiveCN107978768AImprove binding tightnessImprove conductivityFinal product manufactureCollectors/separatorsFuel cellsEngineering

The invention relates to the technical field of fuel cells, and particularly relates to a fuel cell assembly and a preparation method thereof, which can effectively reduce the interface resistance between a bipolar plate and a gas diffusion layer and improve the overall power density of a stack. The embodiment of the invention provides the fuel cell assembly, comprising the bipolar plate and the gas diffusion layer arranged on one side of the bipolar plate, wherein the gas diffusion layer and an interface of the bipolar plate are combined by forming a compound or a solid solution. The embodiment of the invention is used for the preparation and assembly of fuel cells.

Owner:BEIJING IN POWER NEW ENERGY

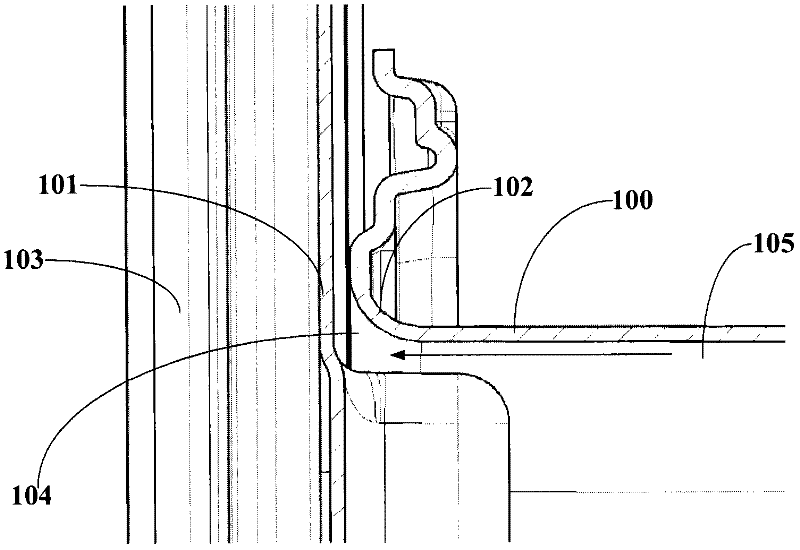

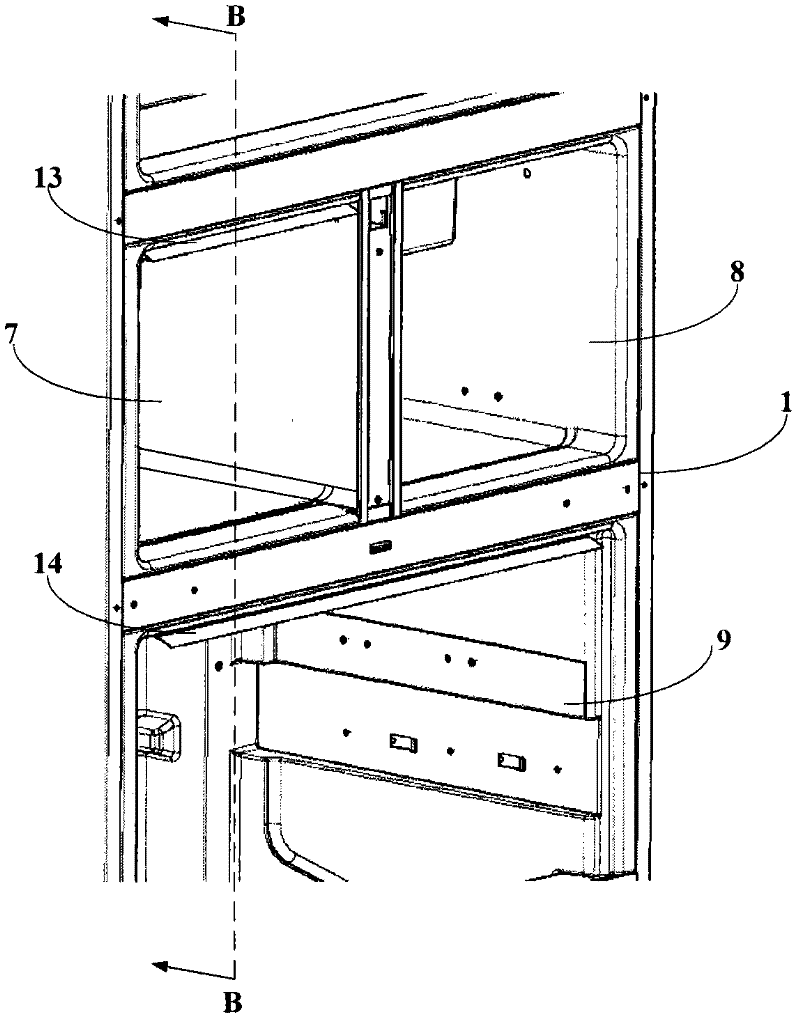

Refrigerating equipment and air guide component thereof

ActiveCN102478339ASmooth circulationReduce energy consumptionLighting and heating apparatusCooling fluid circulationCold airEngineering

The invention provides refrigerating equipment and an air guide component thereof. When a door of the refrigerating equipment is in a closed state, the junction of a door liner and a box liner of the refrigerating equipment is provided with a gap space, wherein the air guide component is fixed between the door liner and the box liner; the gap space and a refrigerating space inside the box liner are separated by the air guide component; and the refrigerating equipment comprises the air guide component. Due to the utilization of the refrigerating equipment and the air guide component thereof, when inner cold air is circulated and rushes to the gap space, the cold air is stopped by an air guide part of the air guide component to enter the refrigerating space, and thus, the cold air cannot be filled in the gap space, so that the unnecessary energy consumption is reduced; and meanwhile, the cold air is circulated and can directly enter the refrigerating space without entering the gap space, so that the cold air is more smooth to circulate.

Owner:博西华家用电器有限公司

Jig frame top tool for temporarily supporting and uploading steel structure

ActiveCN103758356AFacilitate contact areaImprove binding tightnessBuilding material handlingSlide plateEngineering

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

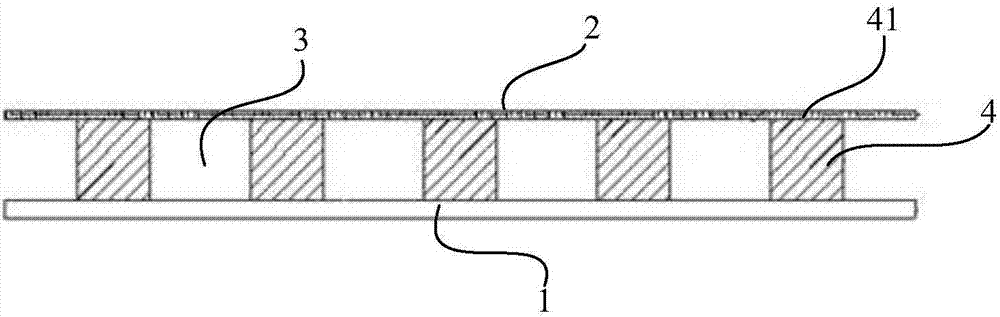

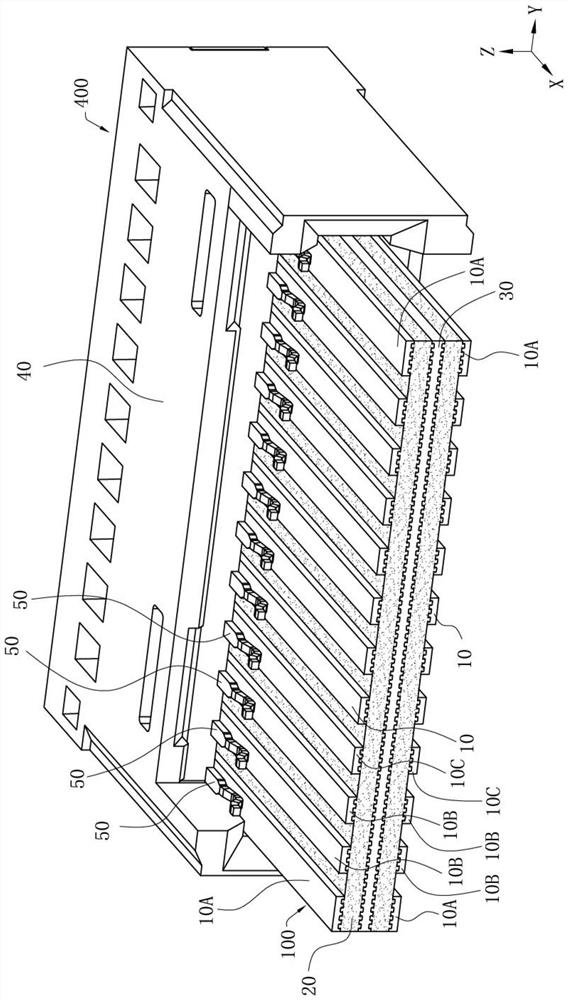

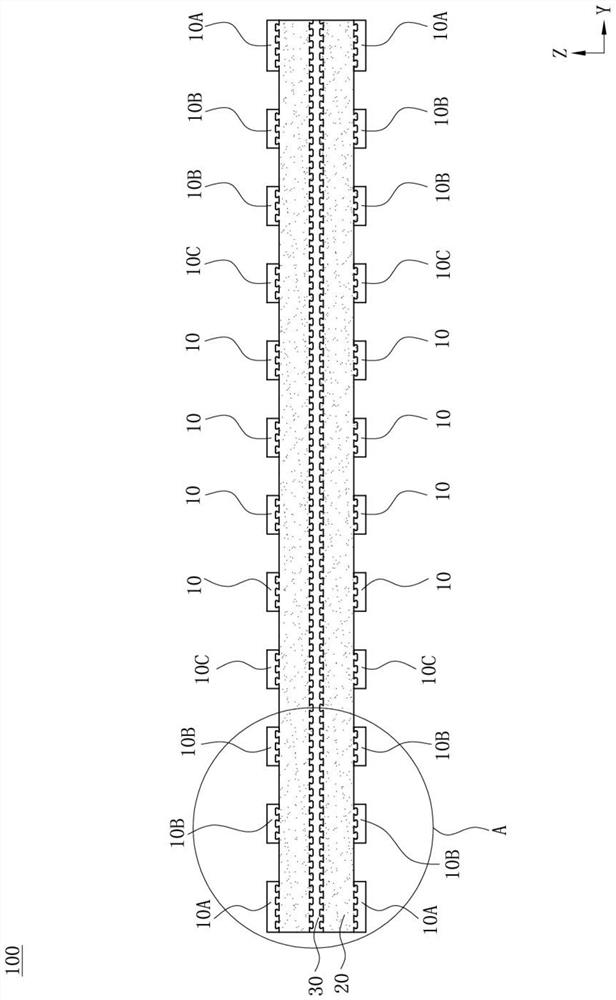

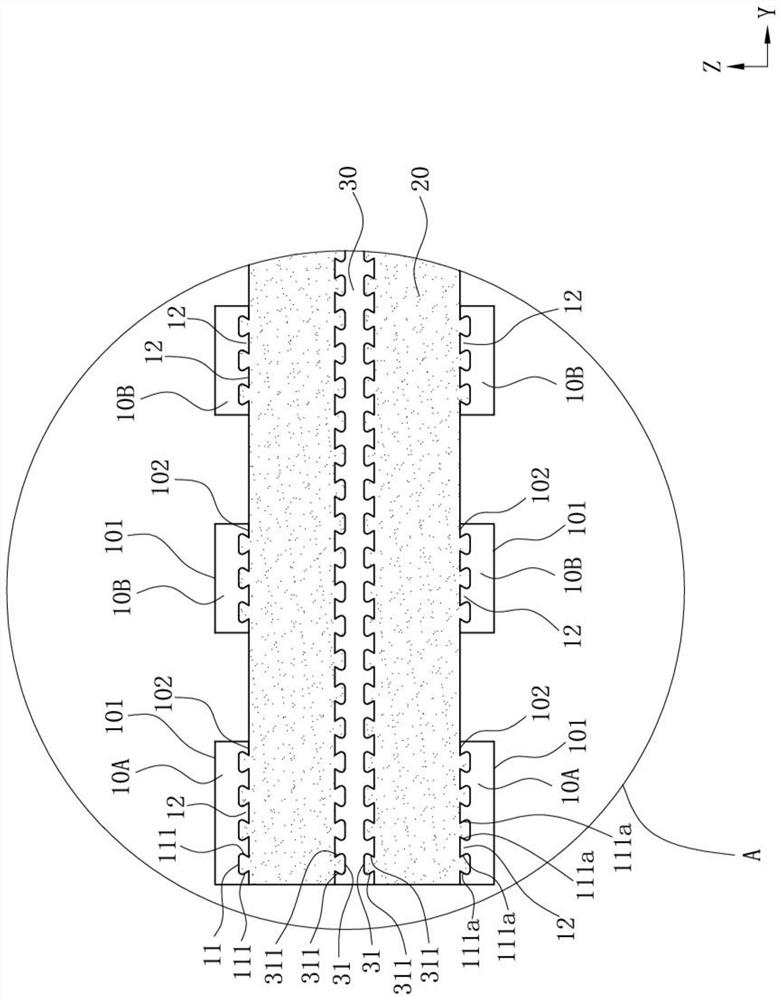

Electronic substrate, connector assembly and manufacturing method of electronic substrate

ActiveCN111986837AImprove binding tightnessGuaranteed uniformityCoupling device connectionsCommunication cablesConductive materialsMechanical engineering

The invention discloses an electronic substrate. The electronic substrate comprises a polytetrafluoroethylene base layer and a plurality of conductive strips arranged on the polytetrafluoroethylene base layer, each conductive strip is provided with a first surface and a second surface which are opposite up and down, wherein at least one groove is concavely formed from the second surface to the first surface; the grooves do not penetrate through the conductive strips in the vertical direction; the grooves extend along the front-back direction, the polytetrafluoroethylene base layer partially fills the grooves, the groove walls of the grooves are provided with at least one stopping surface, the stopping surface prevents the part, filling the grooves, of the polytetrafluoroethylene base layerfrom being separated from the conductive strips in the direction opposite to the concave direction of the grooves, and a conductive path of the conductive strip is defined to transmit signals in thefront-back direction. Compared with the prior art, the polytetrafluoroethylene material and the conductive material in the electronic substrate are tightly combined, loss can be reduced when signals are transmitted on the conductive strip, and transmission is stable.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

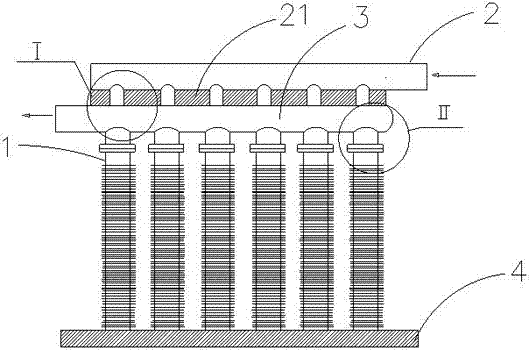

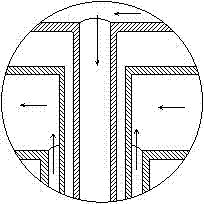

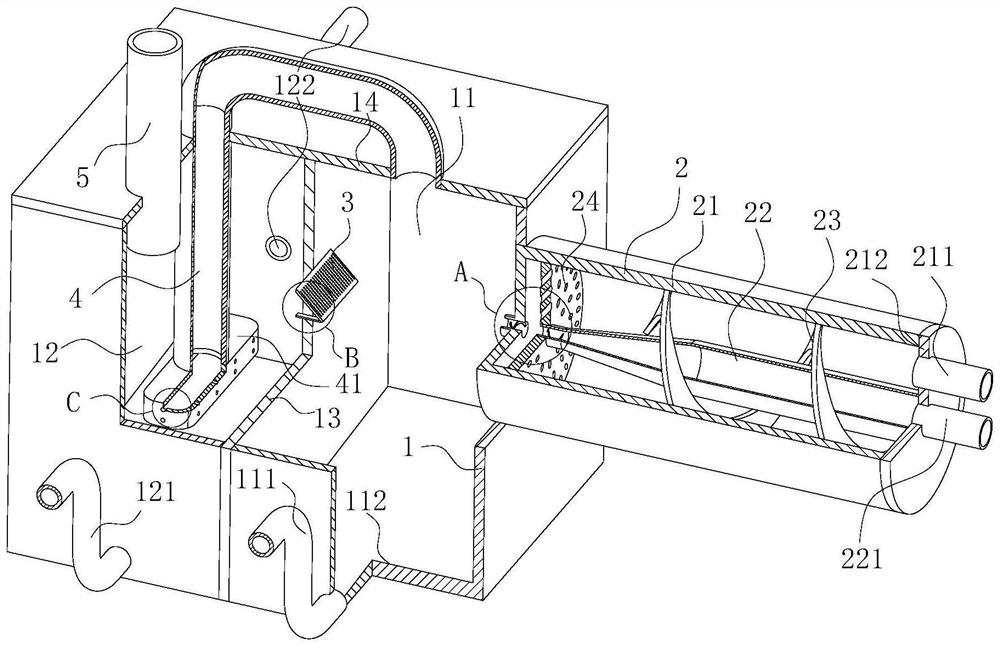

Finned tube heat exchanger and application thereof and afterheat boiler

ActiveCN106895727AImprove heat transfer efficiencyLow costIndirect heat exchangersCombustion technology mitigationEvaporationEngineering

The invention relates to the technical field of heat exchangers, and discloses a finned tube heat exchanger and application thereof and an afterheat boiler. The finned tube heat exchanger belongs to a radial heat transfer heat tube, and has the advantages of high heat transfer efficiency, short axial length, small size and light unit heat exchange weight; a sucking core has no need to be arranged in the tube; and inner tube fins of a first layer of inner tubes can be used for guiding condensed water to flow onto the inner walls of outer tubes to absorb heat for evaporation, so that the whole inner walls of the outer tubes become the heat absorption evaporation surface area of phase change liquid. The finned tube heat exchanger is applied to industrial afterheat, can reduce industrial pollution, and also can fully use the industrial afterheat; and the industrial afterheat is secondarily converted to energy for recycling by human. The afterheat boiler adopts the finned tube heat exchanger consisting of heat tubes to recover heat; the finned tube heat exchanger is small in size, and can be flexibly arranged on a flue; and the heat tubes belong to radial heat transfer, so that the heat exchange area with waste smoke in the flue is largely increased, and the heat exchange efficiency is improved.

Owner:HUNAN UNIV OF TECH

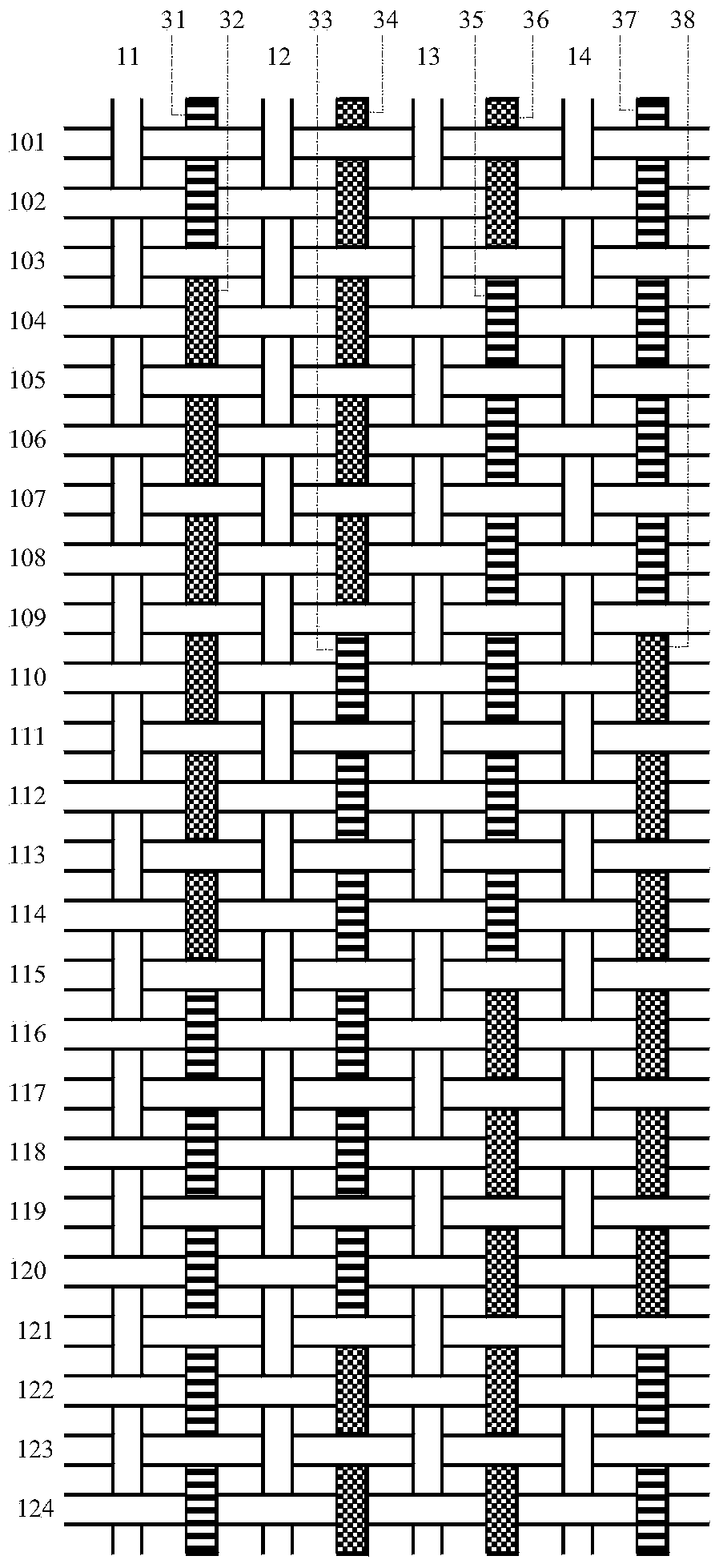

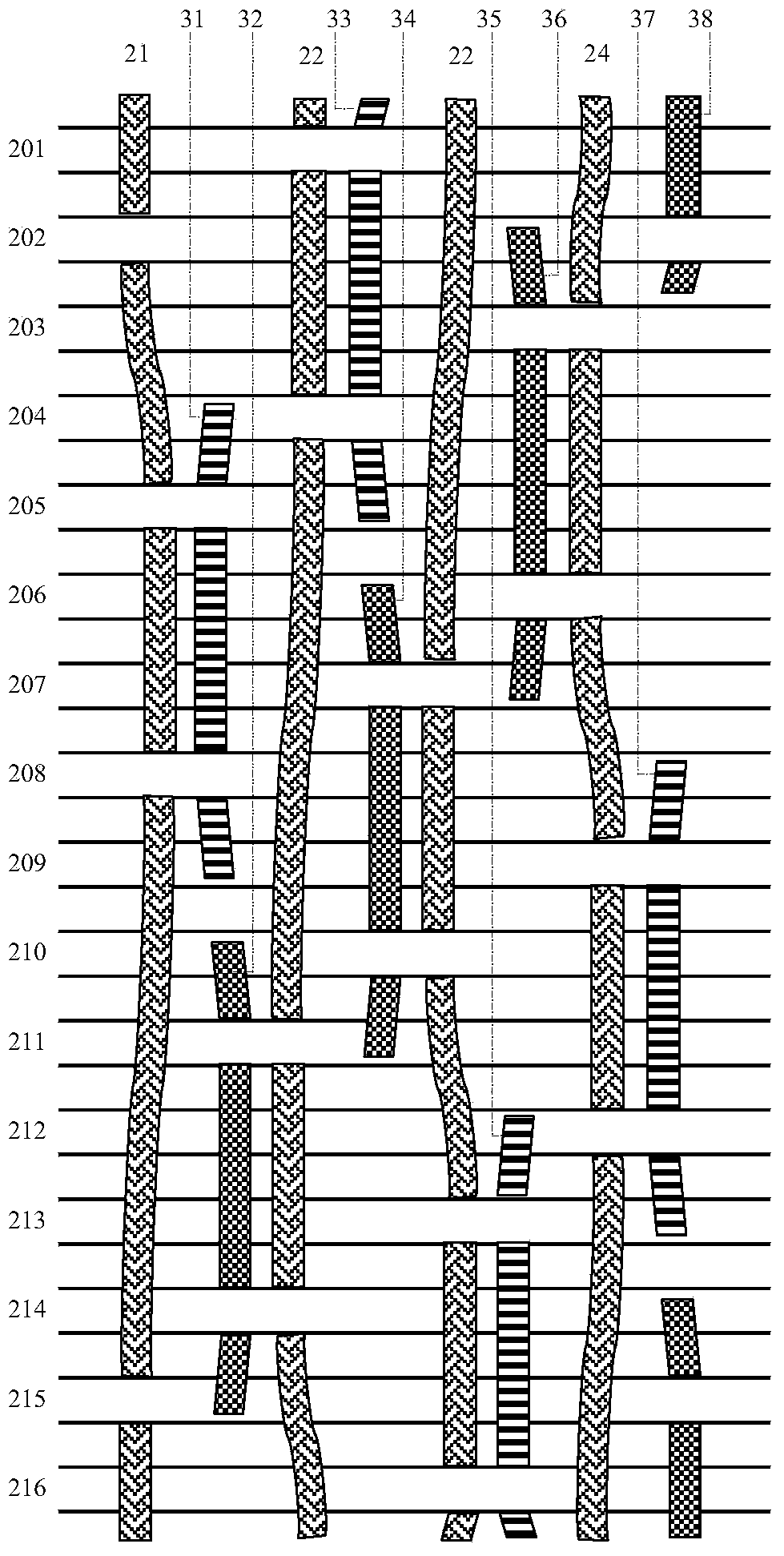

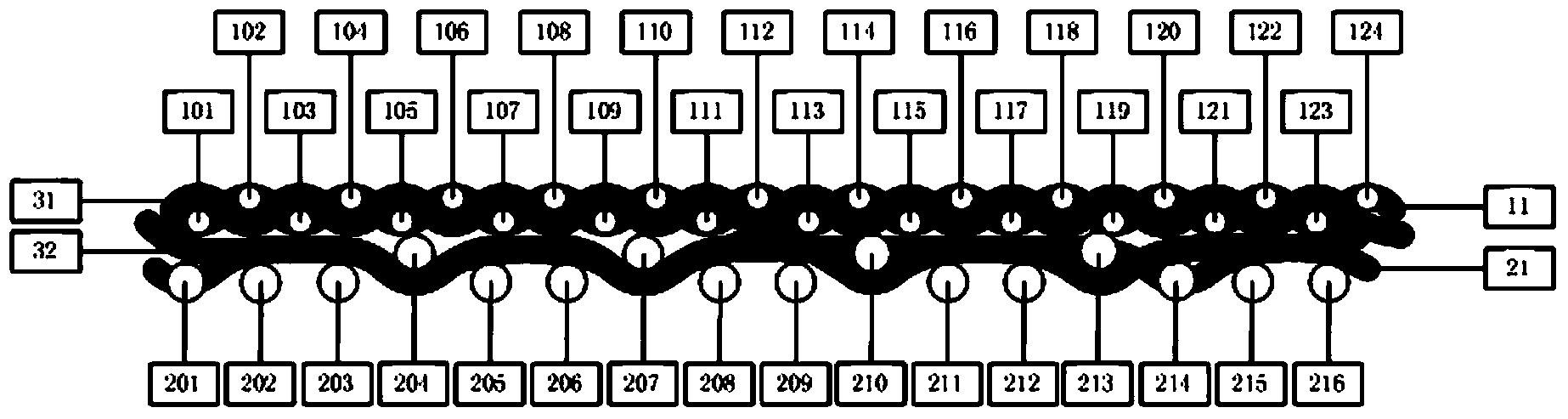

Method for manufacturing forming fabric for warp connection paper making

InactiveCN103643582AAvoid stratificationFirmly connectedMachine wet endMulti-ply fabricsProduct inspectionManufactured form

The invention discloses a method for manufacturing forming fabric for warp connection paper making. The manufacturing process of the forming fabric comprises the following steps of filament detection, beaming, mesh weaving, mesh inspection, primary sizing, mesh cutting, insertion, secondary sizing, finished-product inspection, packaging and storage. When a mesh is weaved, three system warps and two system wefts are interwoven, wherein independent let-off of the three system warps is conducted through three let-off shaft systems. Tension of the three system warps is controlled by three corresponding let-off shaft systems, so that a surface layer mesh is firmly connected with a bottom layer mesh, combination compactness is good, a single filament in a mesh body has no inner friction, and the layering problem in the use process of the forming fabric is solved. A first system warp and a third system connection warp interweave with a first system weft to form the surface layer mesh for supporting paper sheet fibers, surface evenness is good, and a paper sheet has not filament marks. A second system warp and a third system connection warp interweave with a second system weft to form the bottom layer mesh for being resistant to abrasion of a paper machine. Abrasion-resistant performance is good, and a service life is long.

Owner:安徽华辰造纸网股份有限公司

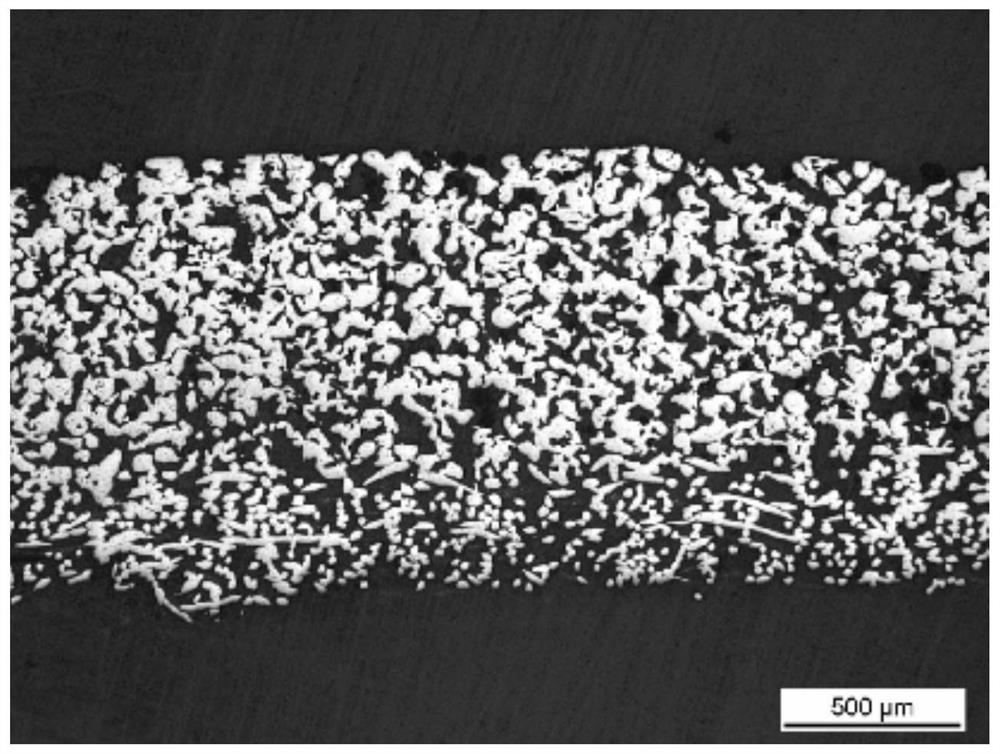

Manufacturing method of metal supporting plate for fuel cell

PendingCN113054215AReduce sintering deformationElimination of sintering deformationFinal product manufactureFuel cellsFuel cellsSlurry

The invention relates to a manufacturing method of a metal supporting plate for a fuel cell. The manufacturing method sequentially comprises the following steps: 1) adopting one of sintered stainless steel, heat-resistant steel, nickel-based alloy, cobalt-based alloy, titanium alloy and chromium-based alloy; 2) screening the powder in the step 1), wherein the particle size of the selected powder is 13-250 microns; 3) placing the powder in an inner hole of a measuring vessel, removing a redundant powder, and placing the measuring vessel on a load bearing plate; 4) sintering the load bearing plate on which the measuring vessel is placed; 5) coating an anode slurry on the upper surface of a metal substrate so as to form an anode layer on the upper surface of the metal substrate; 6) coating an electrolyte slurry on the upper surface of the anode layer to form an electrolyte coating on the surface of the anode layer; and 7) coating the cathode slurry on the upper surface of the electrolyte coating to form a cathode layer on the upper surface of the electrolyte coating so as to produce a metal support plate. Sintering deformation is eliminated, and the combination tightness between the anode layer and the metal substrate is improved.

Owner:NBTM NEW MATERIALS GRP

Novel metal compounding process

InactiveCN102717551AHarm reductionHigh strengthLamination ancillary operationsLaminationExplosive claddingMetal

The invention discloses a novel metal compounding process. The process comprises the following steps of: (1) performing surface roughening treatment to ensure that the surfaces of bonding layers are dissolved and roughened; (2) preparing a complex, namely adding an interlayer metal material with low melting point and high electric conductivity between substrate-layer metal and composite-layer metal so as to ensure that the interlayer metal material is permeated between the substrate-layer metal and the composite-layer metal to form metallurgical bonding; and (3) rolling the complex on a roller mill so as to closely bond the substrate-layer metal and the composite-layer metal. According to the process, an explosive cladding link is eliminated in a production environment, so that the harm of explosive cladding to the environment is reduced; the production cost is saved, and the production cycle is shortened; and moreover, the welding and rolling of all bonding surfaces are combined, so that the bonding compactness is relatively high.

Owner:常荣波

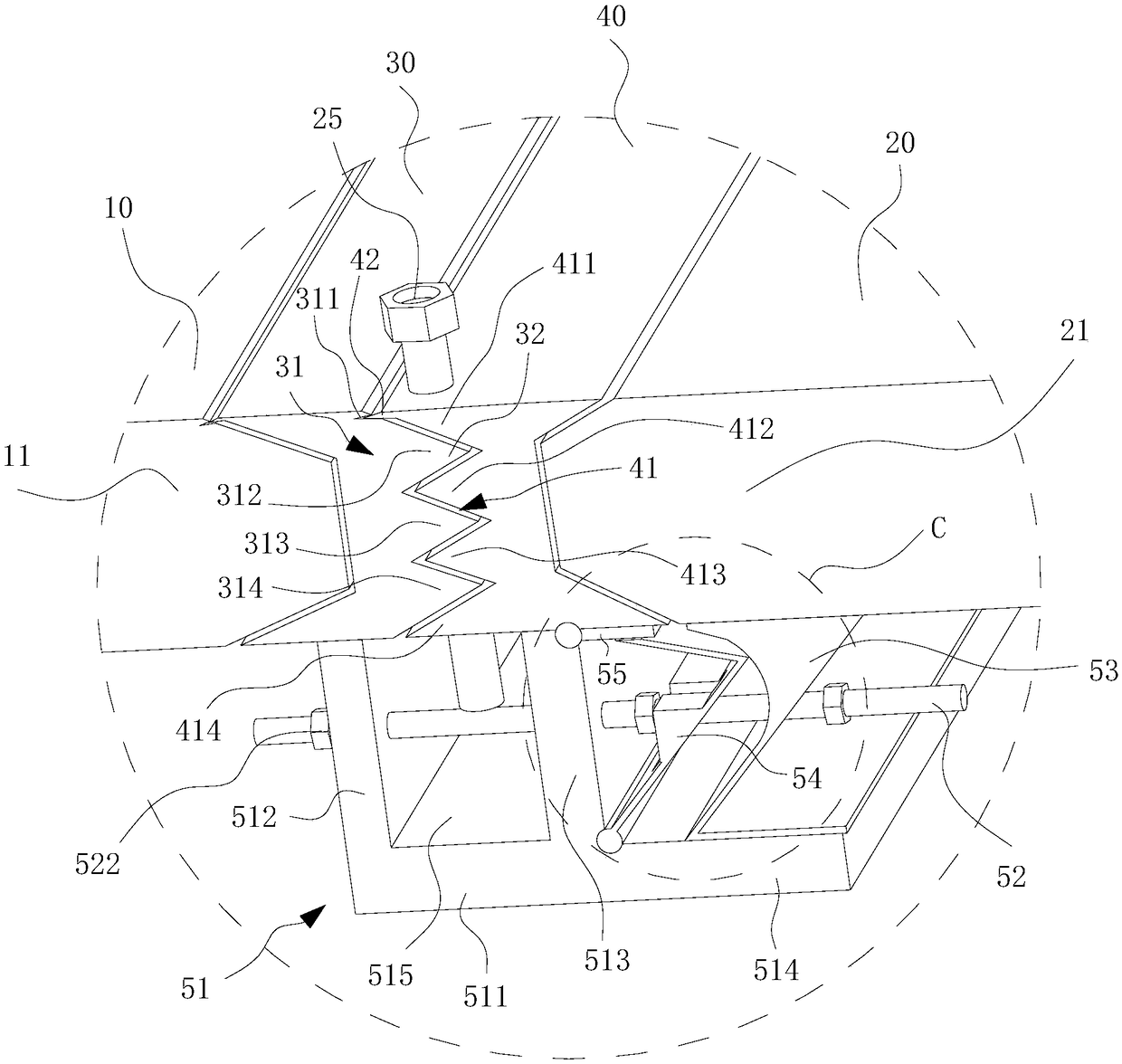

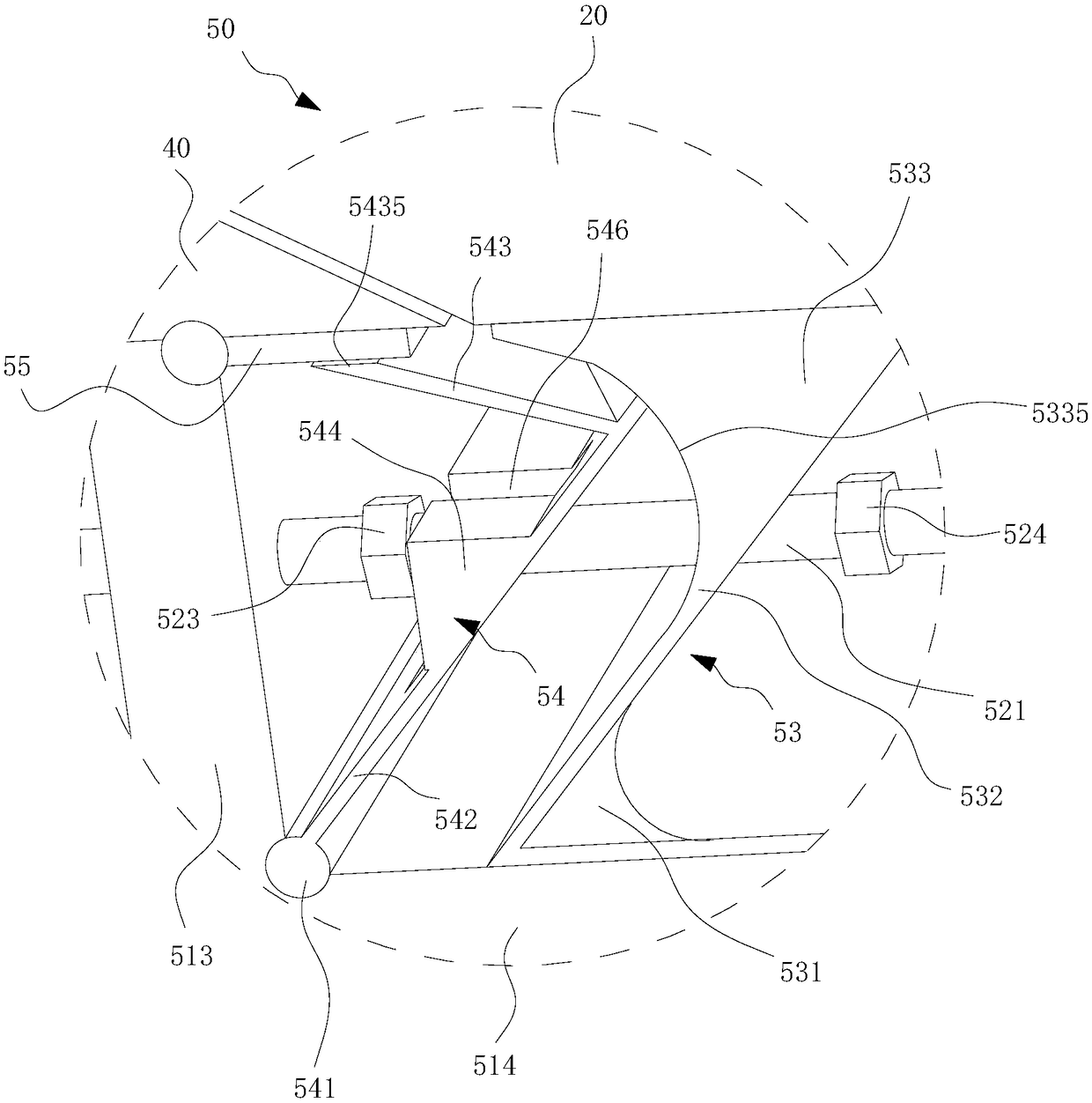

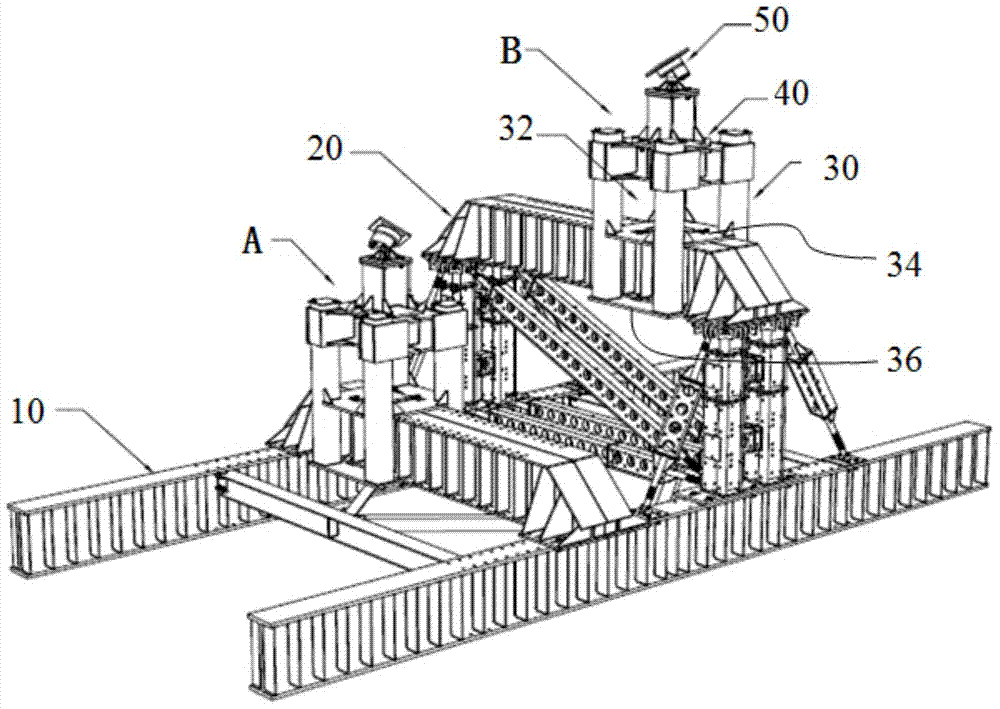

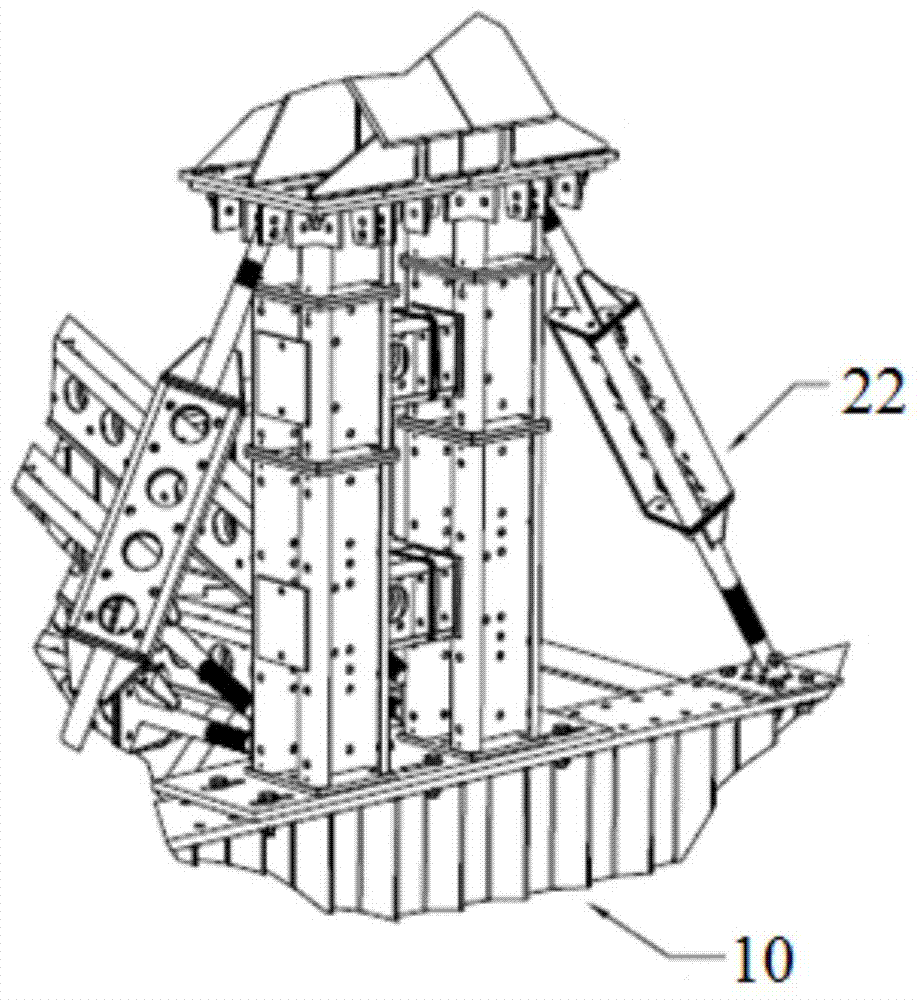

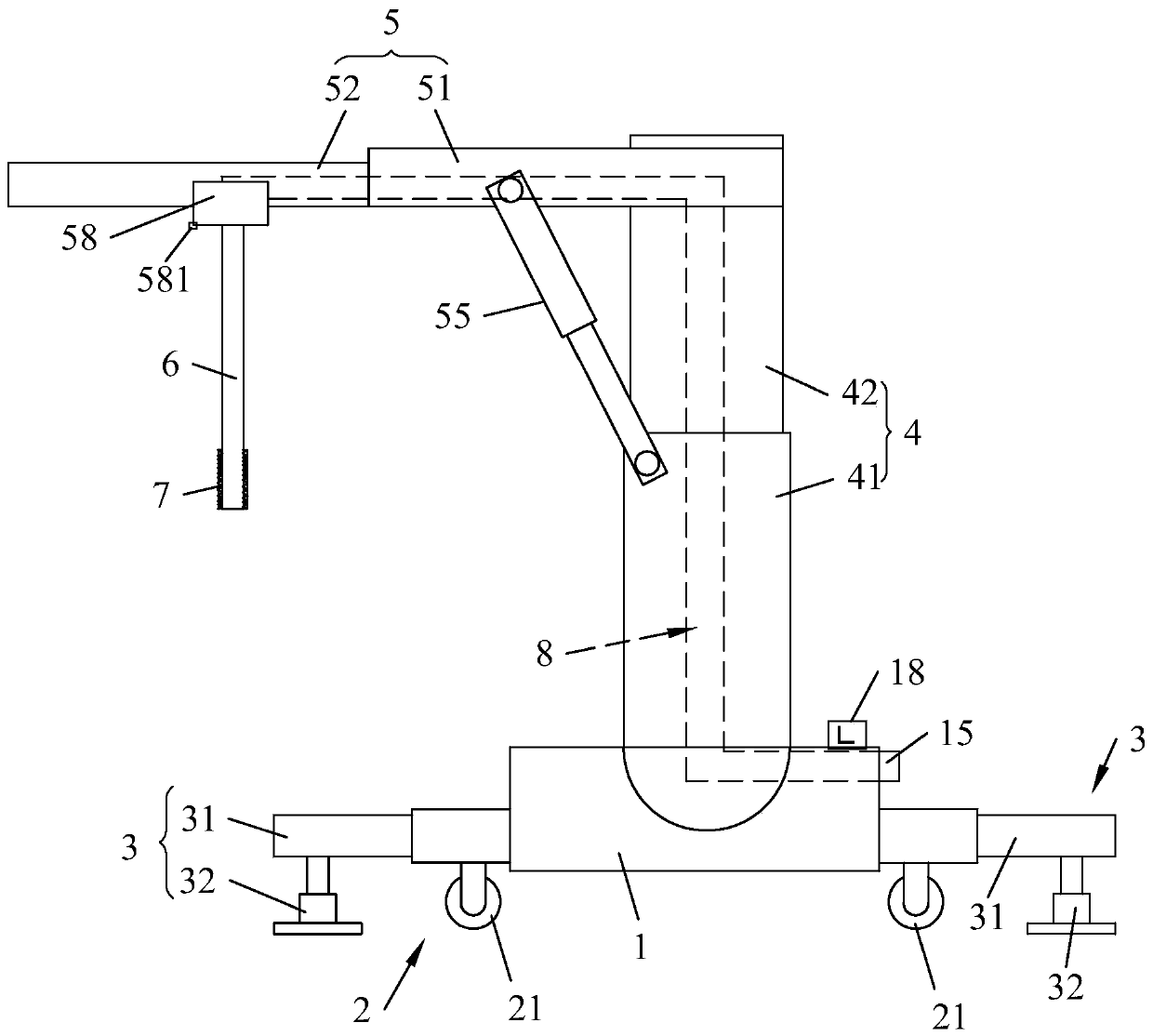

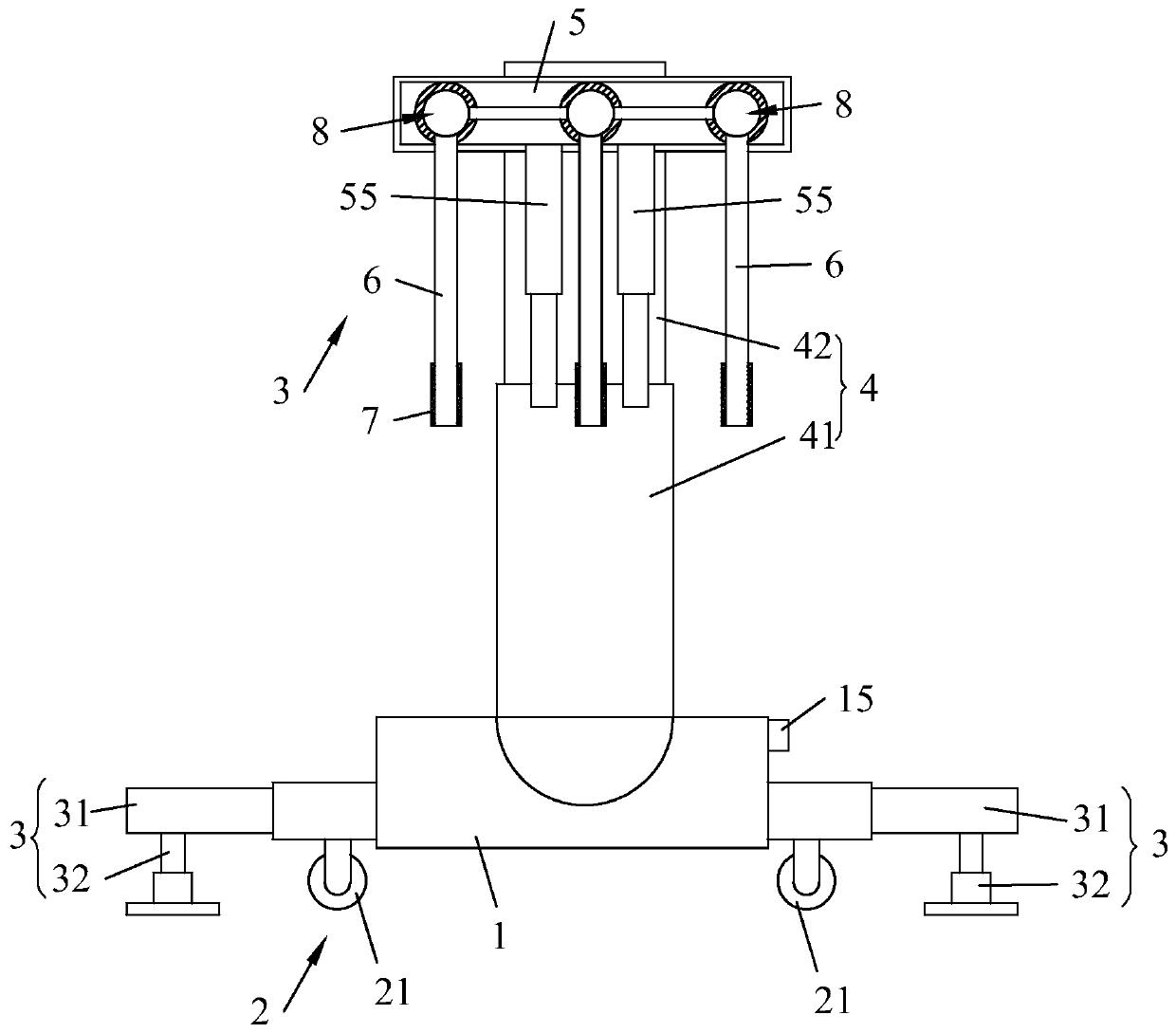

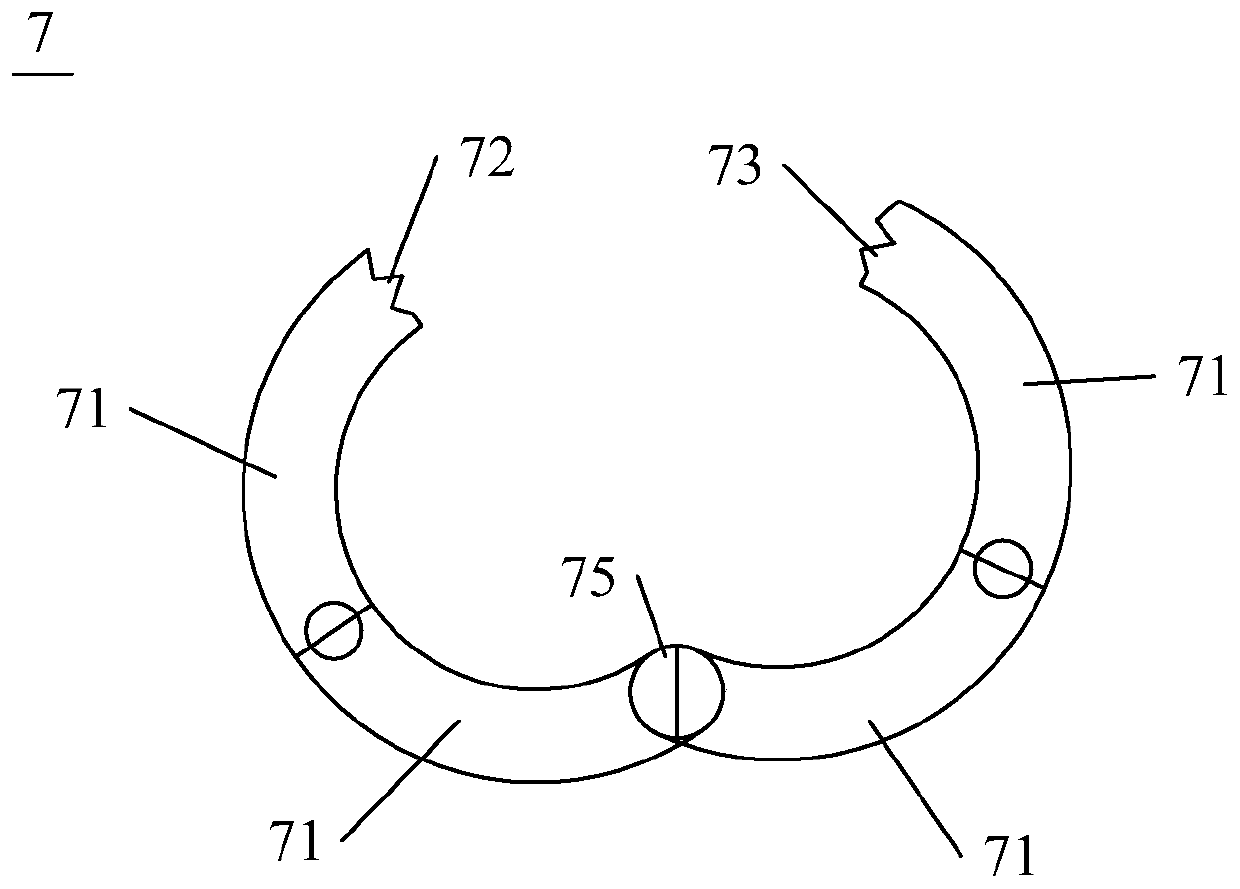

Cementitious material precise distribution and dense operation robot

PendingCN110469114ACombined denseAchieving a vibrating effectBuilding material handlingConstruction industryEngineering

The invention discloses a cementitious material precise distribution and dense operation robot which comprises a main body, a running gear, a pipe frame, a material distributing pipe, an extending-retracting mechanism and a vibrator, wherein the running gear is arranged in the main body to drive the entire cementitious material precise distribution and dense operation robot to move; the pipe frameis fixed on the main body; the material distributing pipe is mounted on the pipe frame and extends downwards; the extending-retracting mechanism is arranged on the pipe frame and controls the material distributing pipe to retract or put down relative to the pipe frame; the vibrator is fixed on the material distributing pipe to drive the material distributing pipe to vibrate; a feeding port is further formed in the base; and the cementitious material precise distribution and dense operation robot is further provided with a feeding passage communicating between the feeding port and the materialdistributing pipe. The cementitious material precise distribution and dense operation robot vibrates through changing the pouring manner while pouring to improve the concrete material combining compactness and ensure the quality of a wall component, can automatically finish wall pouring forming to improve the operation automation and liberate labor force, and is suitable for being popularized inthe construction industry.

Owner:广东山众建筑科技有限公司

Method for regenerating abraded punch-die in car part punch die

The invention discloses a method for regenerating an abraded punch-die in a car part punch die. The method for regenerating the abraded punch-die in the car part punch die includes the following steps. Firstly, with the hot dip technology, a tombarthite zinc-aluminum alloy clad layer is formed in an abraded part of the punch-die. Secondly, filled materials are heated and molten and then coated in the abraded part of the punch-die. Thirdly, the regeneration position of the abraded part of the punch-die is made flat and smooth through mechanical machining. According to the method for regenerating the abraded punch-die in the car part punch die, combination capacity of the filled materials and the surface of the die can be favorably improved by forming a transition layer in the hot dip technology. The optimized filled materials can play a good role of combining and meet the requirement for high mechanical rigidity so that the regenerated punch-die has better firmness and strength in order to achieve the effect of regenerating the abraded punch-die. With the technology, manufacturing and fixing cost and a machining period of the punch die are greatly reduced, reliability of the regenerated punch-die is improved and the method for regenerating the abraded punch-die in the car part punch die provides a novel way of thinking and a novel method for an existing technology.

Owner:安徽振华汽车部件有限责任公司

Salty lime-flavored melon seeds and preparation method thereof

InactiveCN106262564ARich flavorPrevent slaggingInorganic compound food ingredientsFood ingredient as flavour affecting agentBiotechnologyTriticum turgidum

The invention relates to the technical field of food processing and particularly discloses salty lime-flavored melon seeds and a preparation method thereof. The salty lime-flavored melon seeds are prepared from 380-420 parts of shelled melon seeds, 250.3-270.3 parts of high-gluten wheat flour, 115.1-145.1 parts of low-gluten wheat flour, 80-94 parts of corn starch, 27.2-35.2 parts of glutinous rice flour, 18.8-22.8 parts of edible salt, 4.0-5.6 parts of bulking agent, 108-120 parts of sweetening agent, 108-120 parts of water and 1.1-1.3 parts of lime essence. Crispy shells are formed on the surfaces of the shelled melon seeds, so that the melon seeds are crispy and delicious in taste; after being fried, the melon seeds are sallow in color and smooth in appearance, suffuse the lime smell and the oil smell all around, enable people to enhance the appetite and can supplement energy lacking in the body in time. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:ZHENGZHOU RONGLIDA BIOLOGICAL TECH CO LTD

Rubber production technology

The invention discloses a rubber production technology and relates to the field of rubber production. According to the rubber production technology, EPDMs (ethylene propylene diene monomers), carbon black, regenerated rubber, a softening agent, an activating agent and an aid are extracted to be mixed, subjected to high-temperature and high-pressure desulfurization, smelted coarsely and then refined. The rubber production technology has the advantages as follows: the rubber production process is simple and convenient, produced rubber is high in oxidation resistance, corrosion resistance and wear resistance, mutual effects of all components are avoided, the production effectiveness and safety are guaranteed, the temperature range is strictly controlled in a calendering technology, draping of a framework material with the rubber is guaranteed, the density of cords is uniform, and the uniformity of the thickness of the rubber on two sides of the cords is improved.

Owner:ANHUI MEIXIANG IND

Novel efficient sludge curing agent prepared from ardealite solid waste and preparation method thereof

InactiveCN113003903AImprove curing effectImprove 28d unconfined compressive strengthRotary stirring mixersSolid waste disposalSludgeSorbent

The invention belongs to the technical field of ardealite solid waste recycling, and particularly relates to a novel efficient sludge curing agent prepared from ardealite solid waste and a preparation method thereof. The sludge curing agent is prepared from the following raw materials in percentage by mass: 65.1% of phosphogypsum, 14.2% of quick lime, 14.2% of ordinary Portland cement (P.O42.5), 2% of fly ash, 3% of an adsorbent, 1% of a mineralizer, 0.07% of an accelerator, 0.07% of a water reducing agent and 0.36% of triethanolamine. The production difficulty is low, the production cost is low, and the prepared curing agent has a good curing effect on sludge.

Owner:刘志浩

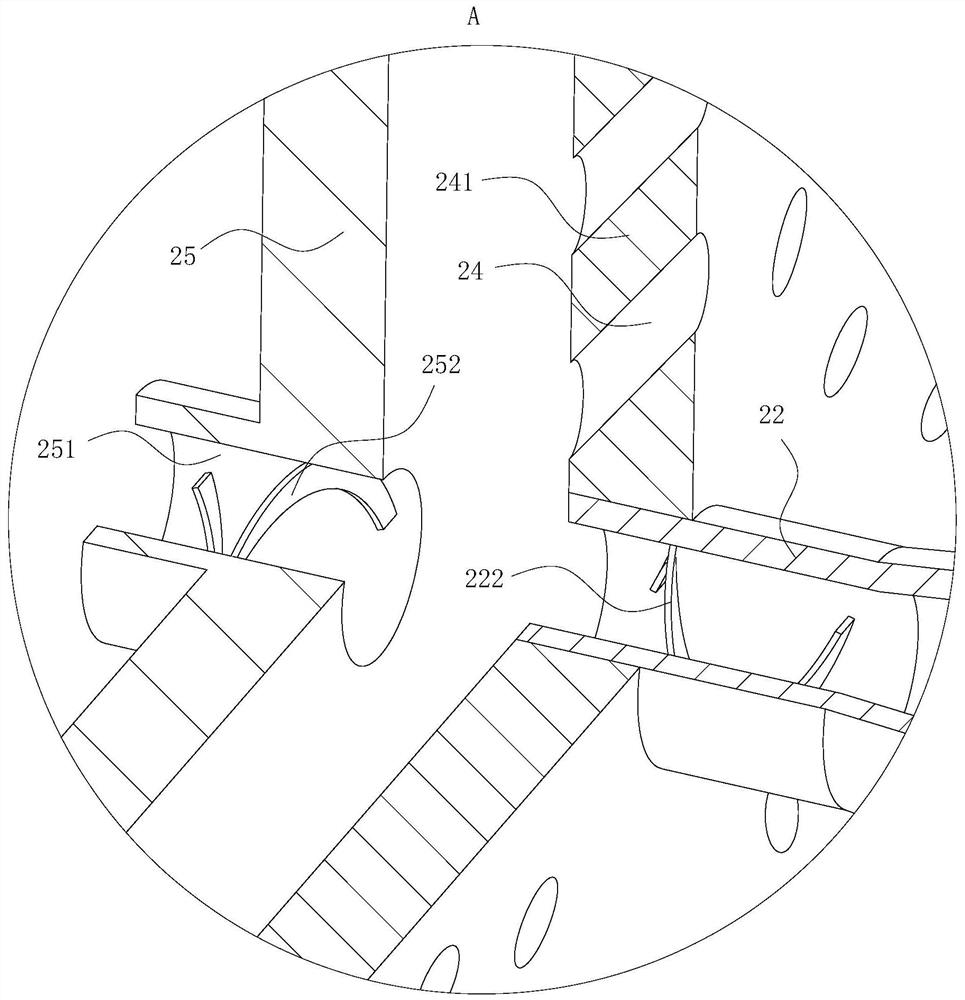

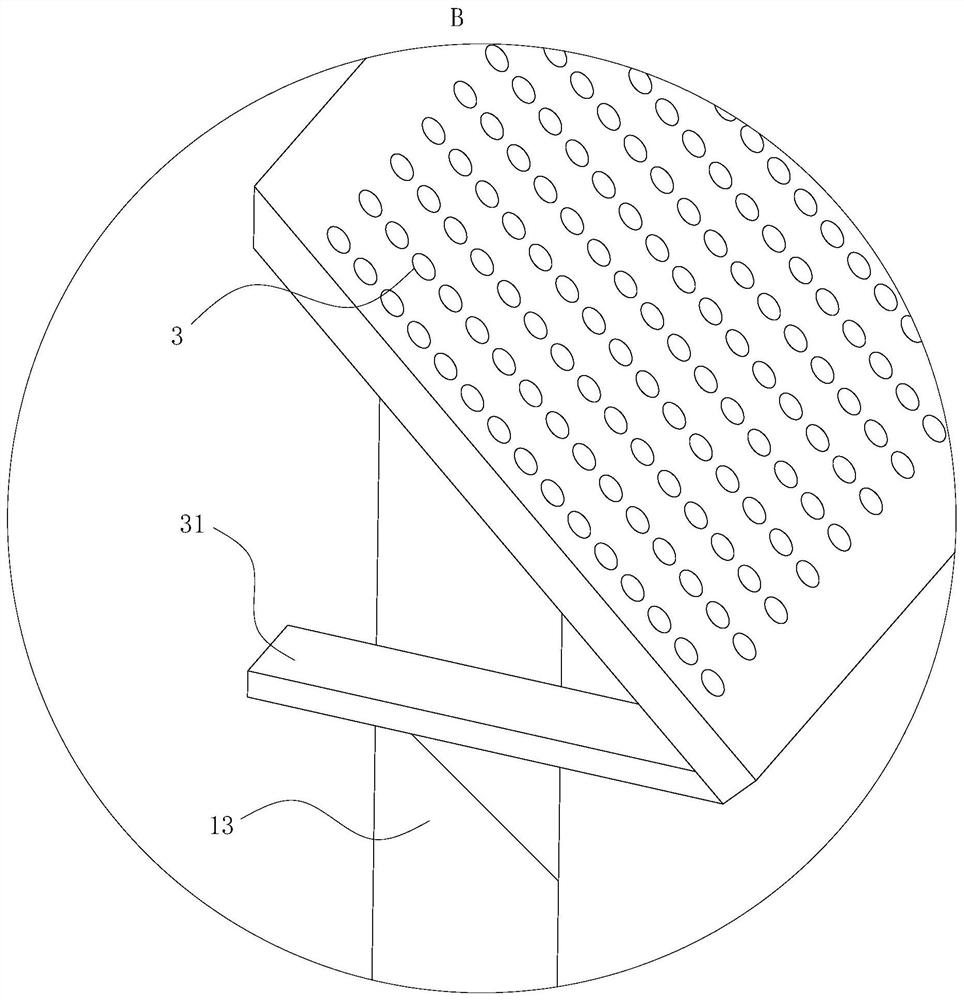

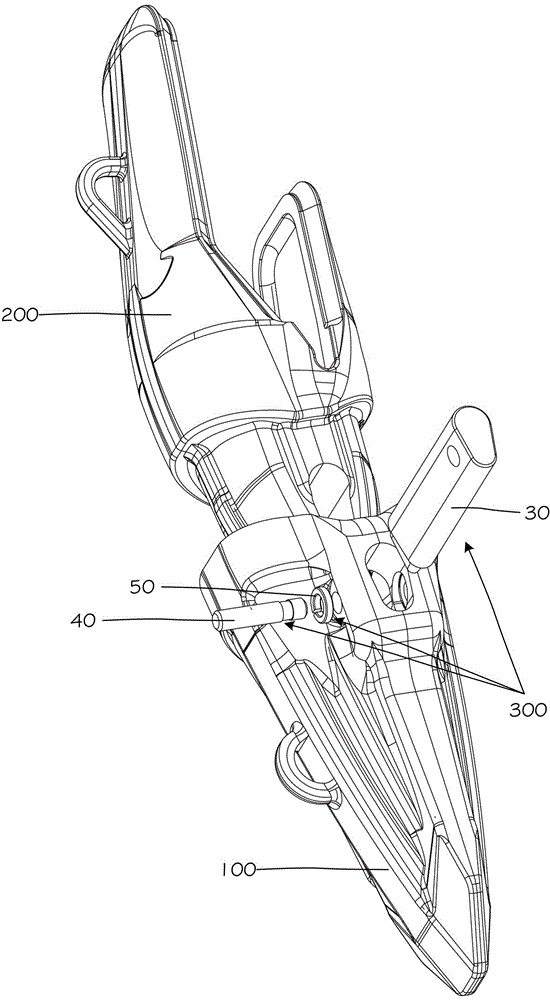

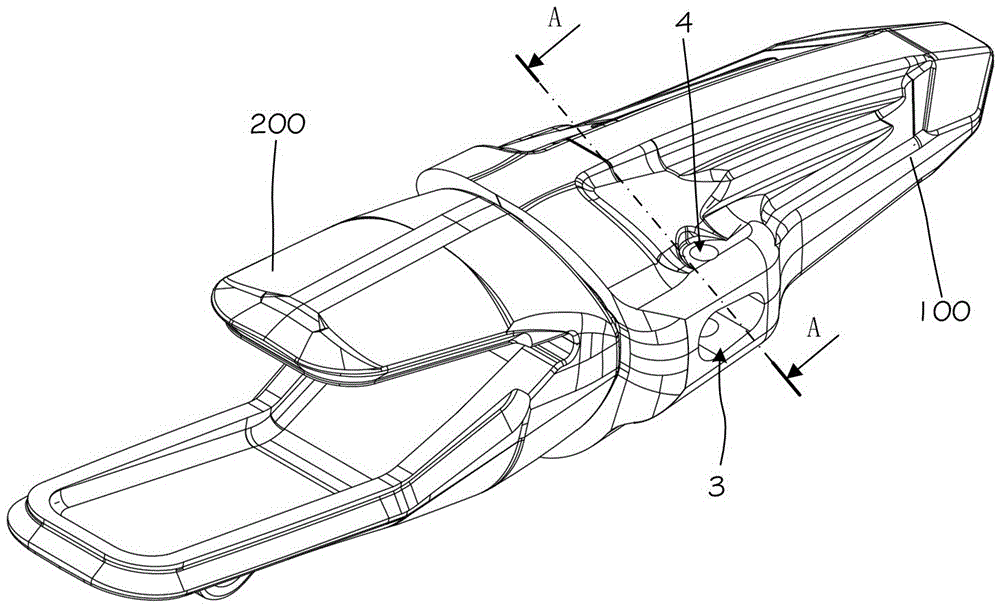

Excavator dipper tooth assembly with improved connecting structure

InactiveCN106638759AReduce sheddingHigh bonding strengthSoil-shifting machines/dredgersEngineeringExcavator

The invention discloses an excavator dipper tooth assembly with the improved connecting structure. The excavator dipper tooth assembly comprises a dipper tooth, a tooth base and a lock pin piece. The dipper tooth is fixedly connected with the tooth base through the lock pin piece, and the lock pin piece comprises a transverse pin, a vertical pin and a clamping spring. A protruding part of the tooth base is inserted into an inserting opening of the dipper tooth, the transverse pin is inserted into a transverse pin hole, the vertical pin is inserted into a vertical pin hole and a through hole, and the clamping spring is clamped in an annular groove in the vertical pin. According to the excavator dipper tooth assembly with the improved connecting structure, the dipper tooth is connected with the tooth base through the transverse pin and the vertical pin, the bonding strength and the bonding compactness between the dipper tooth and the tooth base are enhanced, the falling-off possibility of the dipper tooth is reduced, and trouble and labor are saved during working of an excavator device accordingly.

Owner:熊丽

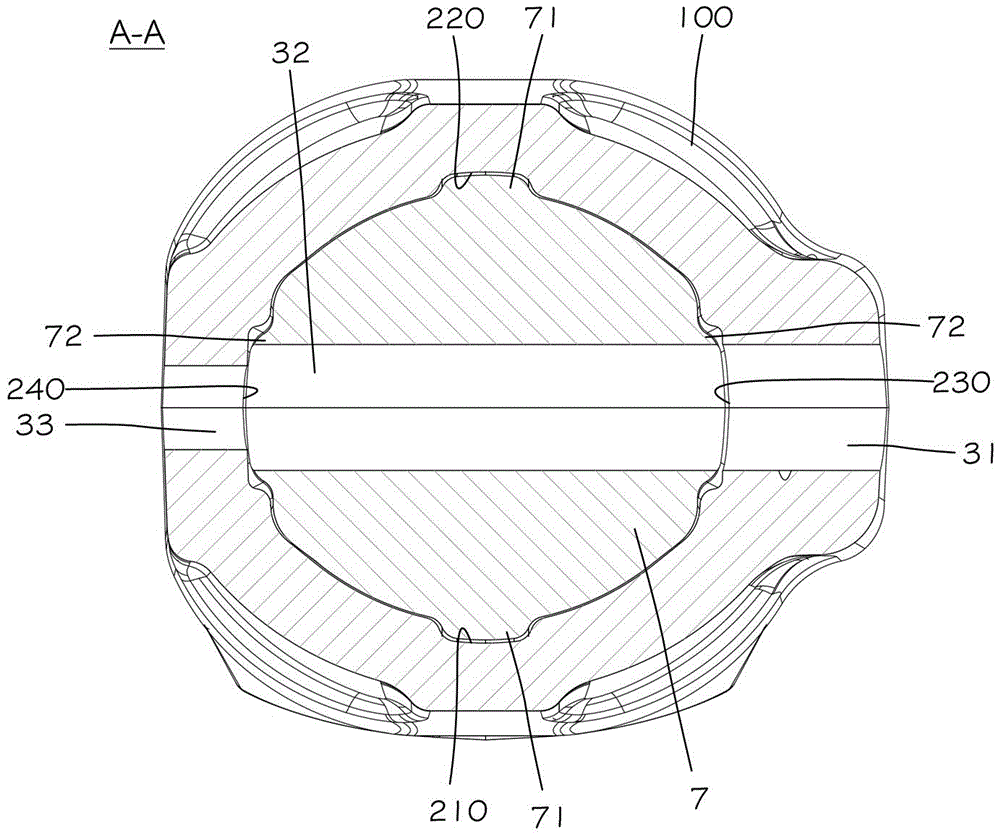

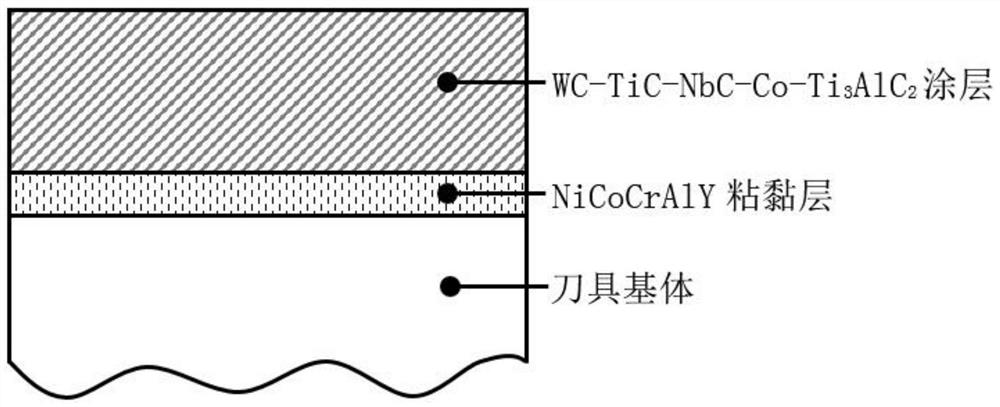

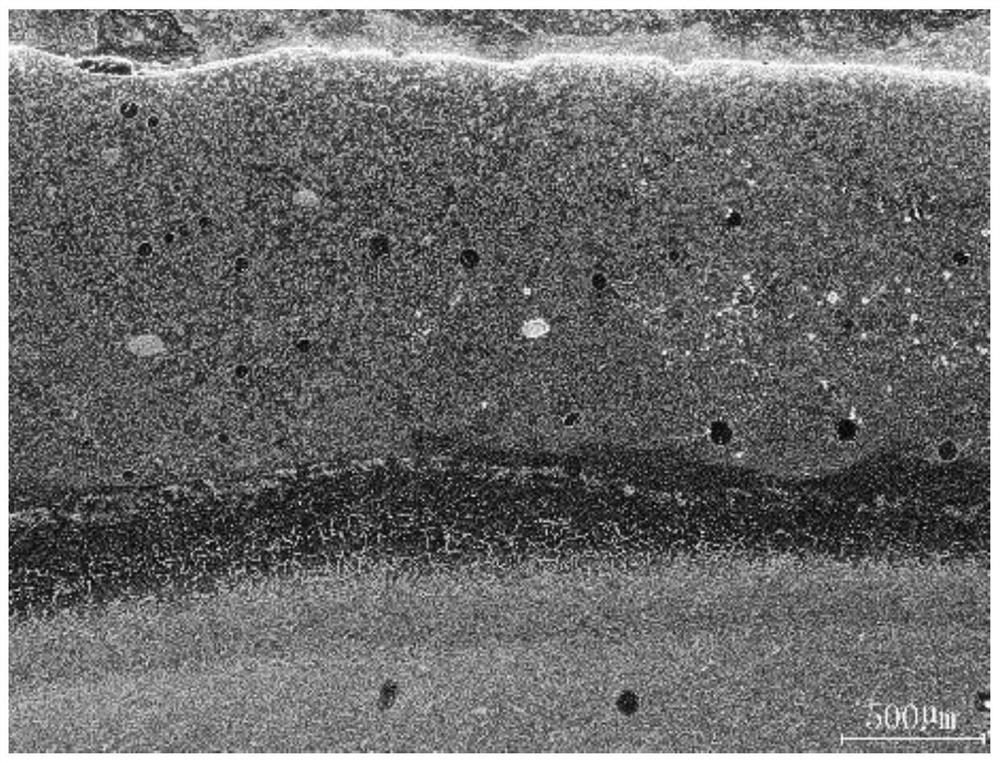

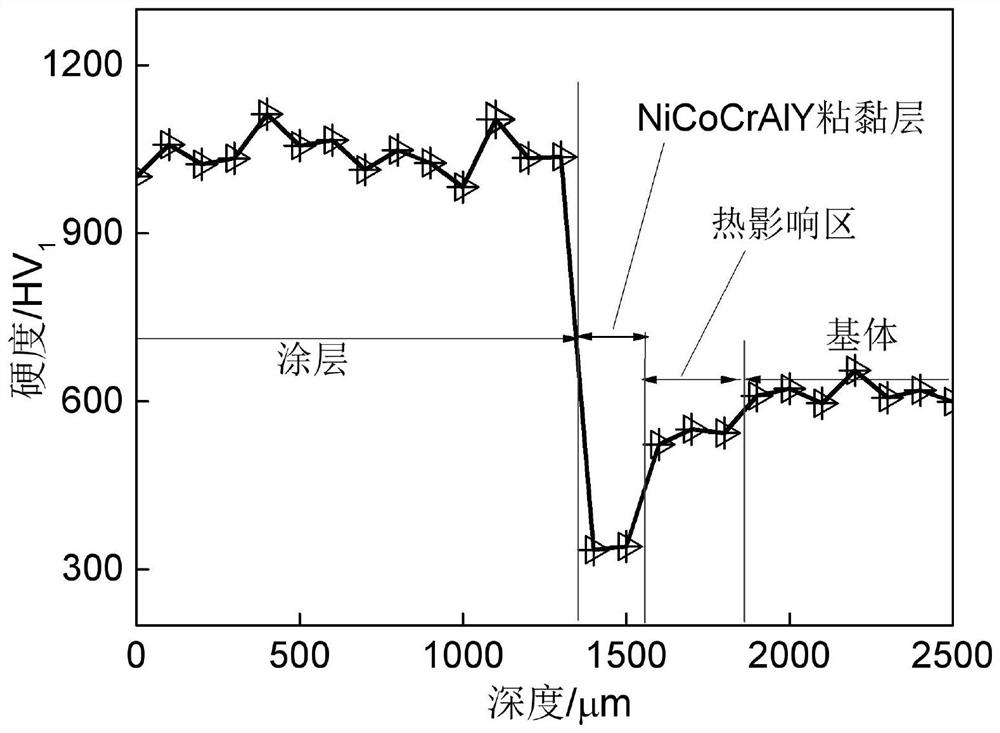

Preparation method of self-lubricating hard composite coating on surface of shield tunneling machine cutter

ActiveCN113584478AGood self-lubricating performanceIncrease stickinessMetallic material coating processesCrack freeShield tunneling

The invention discloses a preparation method of a self-lubricating hard composite coating on the surface of a shield tunneling machine cutter. According to the preparation method of the self-lubricating hard composite coating on the surface of the shield tunneling machine cutter, a cutter base body is made of high-speed steel, and a NiCoCrAlY adhesion layer and a WC-TiC-NbC-Co-Ti3AlC2 coating are sequentially prepared on the surface of the cutter base body through laser cladding. The WC-TiC-NbC-Co-Ti3AlC2 coating prepared through the method is free of cracks and forms good metallurgical bonding with the base body, and the NiCoCrAlY adhesion layer has a good adhesion effect. In a WC-TiC-NbC-Co-Ti3AlC2 system, WC, TiC and NbC are all hard phases, so that the coating has high hardness, Co plays a role in connecting the hard phases, Ti3AlC2 has good self-lubricating performance, and the friction factor of the coating is greatly reduced. The coating has high hardness and good wear resistance, the cutting capacity of the shield tunneling machine cutter is greatly improved, and the service life of the cutter is prolonged.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com