Graphene/carbon nanotube network flexible multifunctional strain sensor preparation method

A technology of strain sensor and carbon nanotube, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low sensitivity, large gauge coefficient, small detection range, etc., achieve simple preparation process and increase specific surface area , The method is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

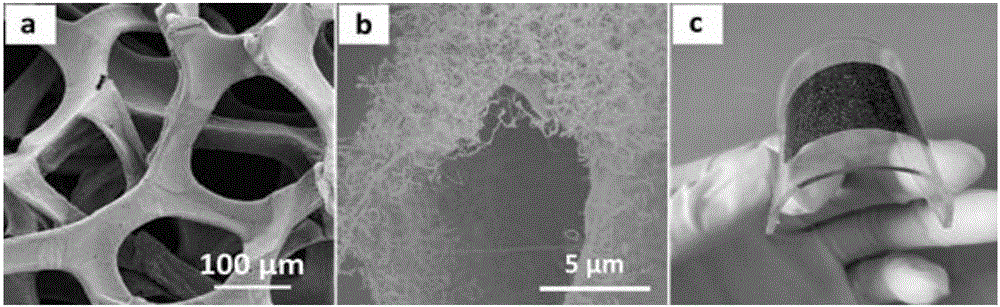

[0041] (1) Put the nickel foam substrate into a tube furnace, use ethanol as the carbon source, and grow graphene by chemical vapor deposition under normal pressure and 950°C for 10 minutes, then cool to room temperature at a rate of 50°C / min, 3 Mole / liter hydrochloric acid solution etches the nickel foam substrate to obtain a self-supporting three-dimensional graphene network.

[0042] (2) Deposit 1 mm thick metal iron nanoparticles on the surface of graphene by electron beam evaporation to obtain a composite material of three-dimensional graphene and metal iron nanoparticles.

[0043] (3) Put the composite material of three-dimensional graphene and metal iron nanoparticles into a tube furnace, and grow carbon nanotubes on the surface of three-dimensional graphene by secondary chemical vapor deposition method under normal pressure and 750°C for 15 minutes, / min rate to cool to room temperature to obtain a three-dimensional graphene / carbon nanotube network.

[0044] (4) Mix dim...

Embodiment 2

[0047] (1) Put the nickel foam substrate into a tube furnace, use methane as the carbon source under normal pressure, grow graphene by chemical vapor deposition at 1000°C for 25 minutes, cool to room temperature at a rate of 50°C / min, 3 The nickel foam substrate was etched in mole / liter hydrochloric acid solution to obtain self-supporting three-dimensional graphene.

[0048] (2) Add 0.25 mmol of nickel nitrate hexahydrate, 0.5 mmol of cobalt nitrate hexahydrate and 1.2 mmol of urea into 40 ml of deionized water, stir evenly and transfer them to a 50 ml reactor with three-dimensional graphene, and react at 120°C After 2 hours, wash with deionized water and dry to obtain a composite material of three-dimensional graphene and NiCo nanoparticles.

[0049] (3) Put the three-dimensional graphene and NiCo nanoparticle composite material into a tube furnace, grow carbon nanotubes by secondary chemical vapor deposition for 25 minutes under normal pressure and 750°C, and cool at a rate ...

Embodiment 3

[0054] (1) Put the nickel foam substrate into a tube furnace, use ethanol as the carbon source under normal pressure, grow graphene by chemical vapor deposition at 900°C for 15 minutes, and cool to room temperature at a rate of 50°C / min , the nickel foam substrate was etched in 3 mol / L hydrochloric acid solution to obtain self-supporting three-dimensional graphene.

[0055] (2) Add 0.5 mmol of nickel nitrate hexahydrate, 1 mmol of cobalt nitrate hexahydrate and 2 mmol of urea into 40 ml of deionized water, stir well and transfer them to a 50 ml reaction kettle together with three-dimensional graphene, at 120°C The three-dimensional graphene and NiCo nanoparticle composite material was obtained after reacting for 2 hours.

[0056] (3) Put the three-dimensional graphene and NiCo nanoparticle composite material into a tube furnace, grow carbon nanotubes by secondary chemical vapor deposition for 20 minutes under normal pressure and 750 °C, and cool to room temperature at a rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com