Method for controllably preparing nanometer compounds with core-shell structures on basis of adsorption driving force

A technology of nanocomposite and core-shell structure, which is applied in the field of controllable preparation of core-shell structure nanocomposite based on adsorption driving force, can solve the problem that it is difficult to realize the controllability and regulation of the core size, and achieves wide practical application value, dispersion Good sex and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of pure ZIF-8 nanoparticles

[0032] Take by weighing 8mmol zinc nitrate hexahydrate and dissolve in 100mL methanol solvent to form A solution; weigh excess (33mmol) 2-methylimidazole and dissolve in 100mL methanol solvent to form B solution; pour B solution into A solution, and Stirring was continued for 2 hours at a stirring speed of 400r / min to produce a stable precipitated sample, which was centrifuged, washed, and vacuum-dried at 40°C to finally obtain ZIF-8 nanoparticles.

[0033] Preparation of Cu-doped ZIF-8 (Cu-ZIF-8) Nanoparticles

[0034] Weigh 0.4mmol copper nitrate hexahydrate and 8mmol zinc nitrate hexahydrate and dissolve in 100mL methanol solvent to form A solution; weigh excess (33mmol) 2-methylimidazole and dissolve in 100mL methanol solvent to form B solution; pour B solution into into solution A, and continuously stirred for 2 hours at a stirring speed of 400r / min to produce a stable precipitated sample, which was centrifuged, washed, an...

Embodiment 1

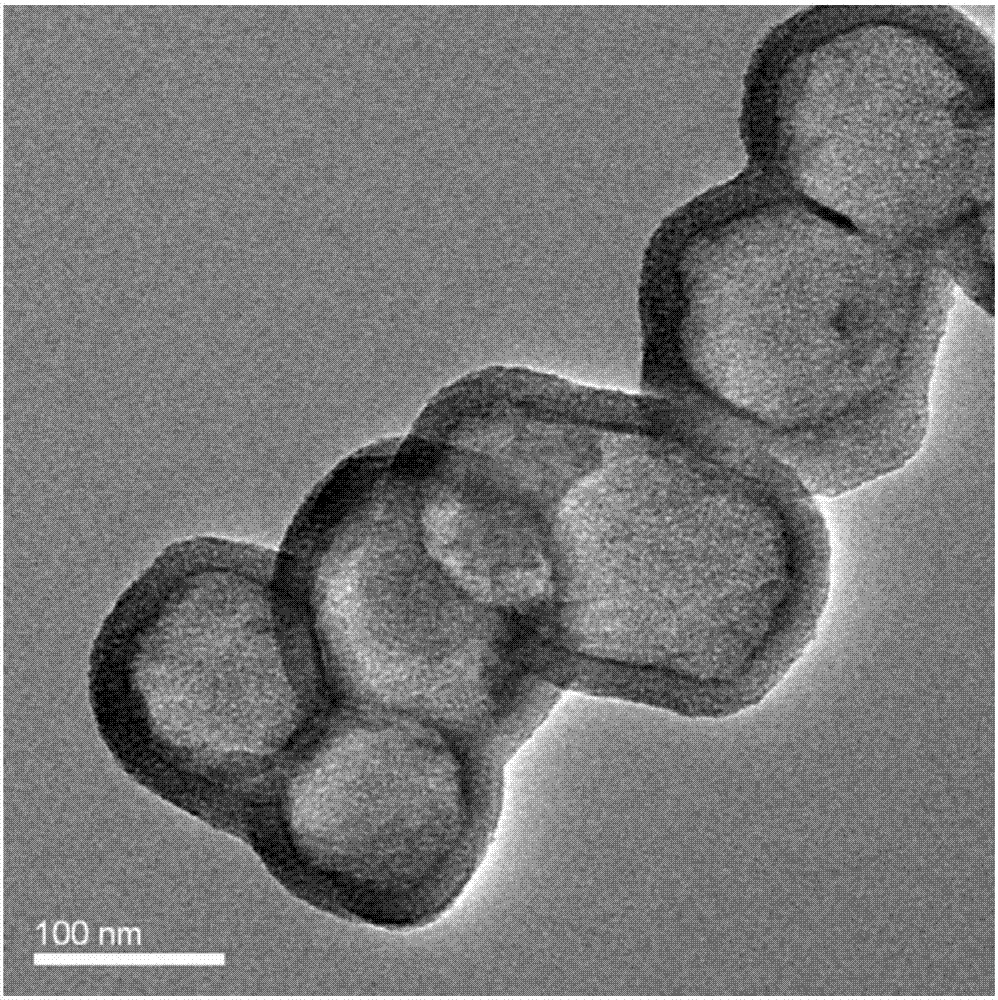

[0036] Disperse the prepared 50mg ZIF-8 into 100mL water solvent (corresponding to 0% methanol-water mixed solution), add 5mL 0.1mol / L NaOH solution under stirring, adjust the pH to 8-10, weigh 0.2g CTAB and add Stir into the system for 5 minutes, add 1.2mL TEOS dropwise (control the dropping rate at 0.05mL / s), continue to stir for 5 minutes, let stand for 5 minutes, centrifuge, wash, and vacuum dry at 40°C to obtain a hollow core-shell structure ZIF-8@mSiO 2 Nanomaterials, the TEM images of the prepared samples are shown in figure 1 .

Embodiment 2

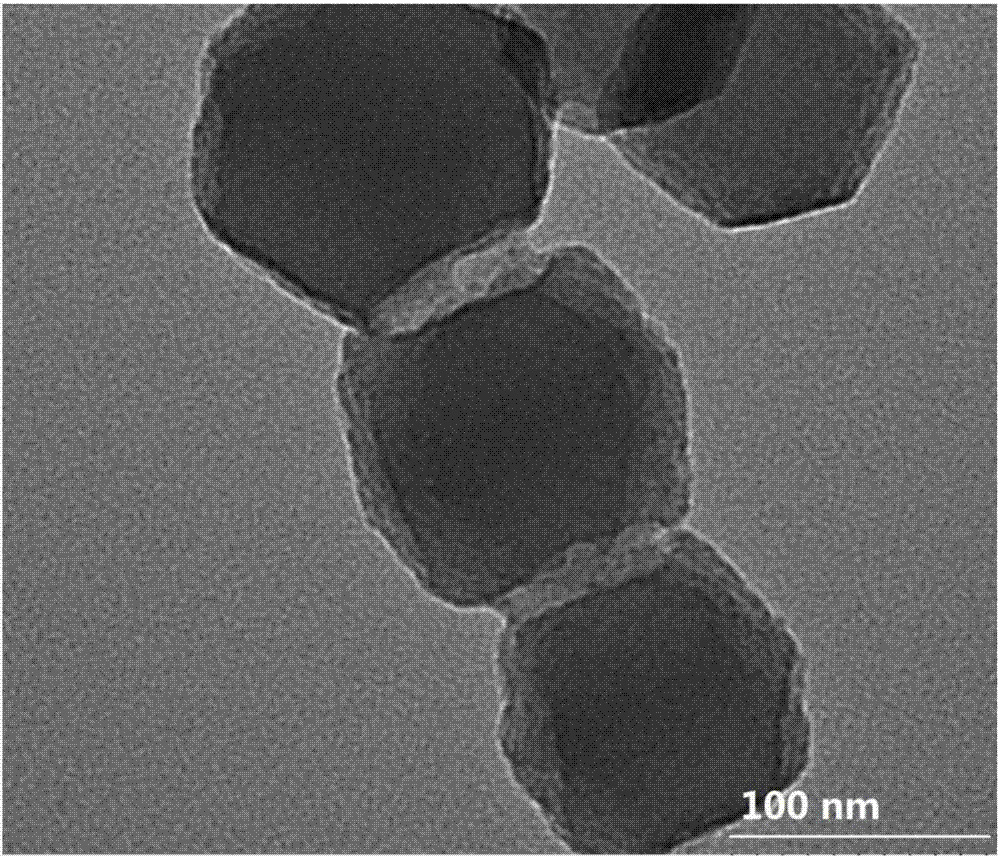

[0038] Disperse the prepared 50mg ZIF-8 into 100mL alcohol solvent (corresponding to 100% methanol-water mixed solution), add 5mL 0.1mol / L NaOH solution under stirring, adjust the pH to 8-10, weigh 0.2g CTAB and add Stir into the system for 5 minutes, add 1.2mL TEOS dropwise (control the dropping rate at 0.5mL / s), continue to stir for 5 minutes, let stand for 5 minutes, centrifuge, wash, and dry under vacuum at 40°C, separate from water-alcohol Add ZIF-8@mSiO with the same adsorption system and no bell-shaped structure 2 Core-shell nanomaterials to obtain a solid core-shell structure ZIF-8@mSiO 2 Nanomaterials, the TEM images of the prepared samples are shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com