Finned tube heat exchanger and application thereof and afterheat boiler

A finned tube heat exchanger and fin technology, which is applied in the field of finned tube heat exchangers and waste heat boilers, to achieve the effect of weakening the unfavorable factors of heat transfer, strengthening the radial heat transfer capacity, and improving the heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

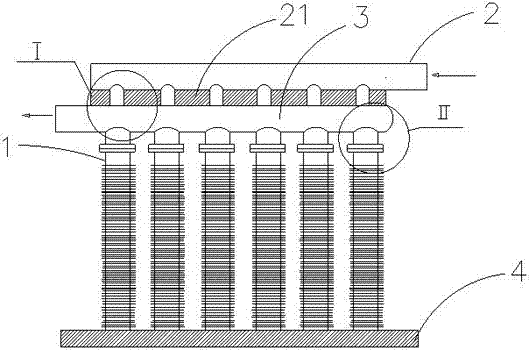

[0043] Such as Figure 1~4 As shown, this embodiment provides a finned tube heat exchanger, including a water inlet pipe 2, an outlet pipe 3 and a heat pipe 1 connecting the water inlet pipe 2 and the water outlet pipe 3, and the heat pipe 1 is also provided with a tube plate 4 for fixing the heat pipe 1 , the heat pipe 1 is connected with the water inlet pipe 2 and the water outlet pipe 3 in parallel;

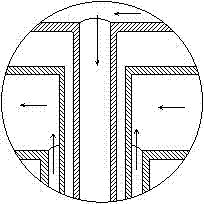

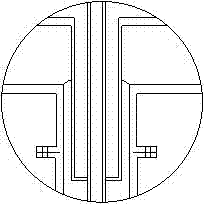

[0044] The heat pipe 1 includes a first layer inner tube 12, a second layer inner tube 11 and an outer tube 13 of different diameters, the first layer inner tube 12 and the second layer inner tube 11 form a double-layer inner tube, and the first layer inner tube 12 sets There is a second layer of inner tube 11; the outer tube 13 is covered with a double-layer inner tube; the first layer of inner tube 12 communicates with the second layer of inner tube 11; the first layer of inner tube 12 and the outer tube 13 are closed structures and constitute Annular channel heat pipe 17, ...

Embodiment 2

[0051] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, except that the heat pipe 1 is connected to the water inlet pipe 2 and the water outlet pipe 3 in series.

Embodiment 3

[0053] Such as Image 6 As shown, this embodiment provides a waste heat boiler provided with the finned tube heat exchanger, including a finned tube heat exchanger, a drum 106 and a flue 104 outside the drum, and the finned tube heat exchanger It is arranged in the flue 104 , the water inlet pipe 102 is connected to the cold water interface 105 , the water outlet pipe 103 is connected to the drum 106 , and the heat pipe 101 is perpendicular to the flue 104 .

[0054] This embodiment is an application of the finned tube heat exchanger in industrial waste heat. The finned tube heat exchanger of the present invention does not need a casing, has a small volume, and can be arranged in the flue 104 very flexibly, and the heat pipe 101 and the flue gas The channel 104 makes full use of the feature of radial heat transfer vertically to achieve the largest heat exchange area. At the same time, the water inlet pipe 102 is connected to the cold water interface 105, and the cold water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com