Fuel cell assembly and preparation method thereof

A fuel cell and component technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve problems such as large interface resistance and unfavorable overall power density of the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

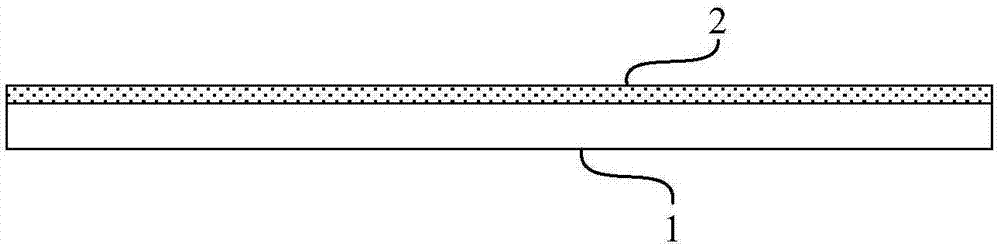

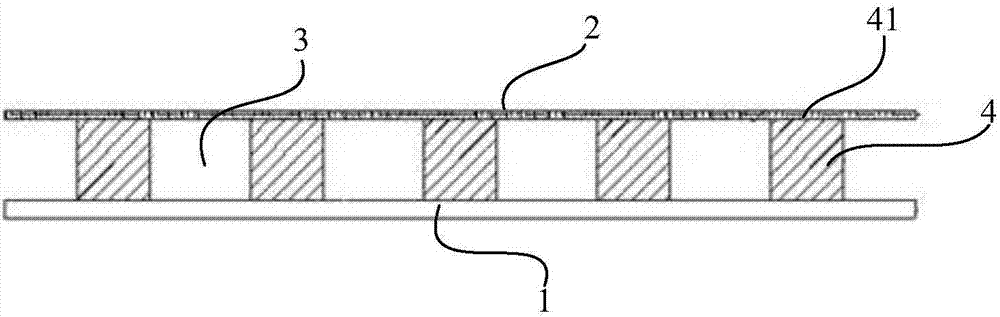

[0042] On the other hand, an embodiment of the present invention provides a method for preparing a fuel cell assembly as described above, including:

[0043] The organic slurry is spun on one side surface of the bipolar plate by an electrospinning process, and the organic slurry layer formed on the one side surface of the bipolar plate is carbonized by calcination, and formed after the carbonization treatment The interface between the gas diffusion layer and the bipolar plate is combined in the form of a compound or a solid solution.

[0044]An embodiment of the present invention provides a method for preparing a fuel cell assembly, in which an organic slurry layer is spun on one side of the bipolar plate by using an electrospinning process, and the organic slurry layer is carbonized by calcination , the gas diffusion layer made of carbon fiber material can be obtained, and at the same time, the interface between the carbon fiber material and the bipolar plate can be combined ...

Embodiment 1

[0059] 1. Preparation of electrospinning solution:

[0060] The mass fraction of ferric nitrate (analytical pure AR) is 3%, the mass fraction of absolute ethanol (analytical pure) is 31%, the mass fraction of deionized water is 28%, and the mass fraction of polyvinylpyrrolidone is 38% for use. The electrospinning solution was prepared with a viscosity of 200dPa·s.

[0061] 2. Preparation of gas diffusion layer:

[0062] The electrospinning voltage is controlled to be 20kV, and the electrospinning time is 1-30min. A flow channel with a width of 2 mm is engraved on the carbon bipolar plate, and a polymer fiber layer with a thickness of 5 μm is spun on the side of the structural layer forming the flow channel away from the surface of the bipolar plate;

[0063] Place the bipolar plate with the polymer fiber layer at 280°C, pre-oxidize it in the air for one hour, then put it in a high-temperature furnace, and calcinate it at 1000°C for 60 minutes in an inert atmosphere (argon or...

Embodiment 2

[0066] 1. Preparation of electrospinning solution:

[0067] The mass fraction of cobalt nitrate (analytical pure AR) is 4%, the mass fraction of DMF (analytical pure) is 20%, the mass fraction of deionized water is 25%, and the mass fraction of polyethylene is 51%. , its viscosity is 800dPa·s

[0068] 2. Preparation of gas diffusion layer:

[0069] The electrospinning voltage is controlled to be 20kV, and the electrospinning time is 1-30min. A flow channel with a width of 20 microns is printed on the metal bipolar plate, and a polymer fiber layer with a thickness of 20 μm is spun on the side of the structural layer (carbon conductive paste) forming the flow channel away from the surface of the bipolar plate ;

[0070] Place the bipolar plate with the polymer fiber layer at 280°C, pre-oxidize it in the air for one hour, then put it into a high-temperature carbonization furnace, and calcinate it at 500°C for 40 minutes to form a carbon fiber layer (85% porosity, pore diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com