Excavator dipper tooth assembly with improved connecting structure

A technology for excavator bucket teeth and connecting structure, which is applied in the field of parts and components, can solve the problems of unstable connection between the socket part of the tooth base and the cavity of the tooth sleeve, the use is not very safe, the structure of the locking piece is complicated, and the like, and the structure is simple, Ease of processing and reduced possibility of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

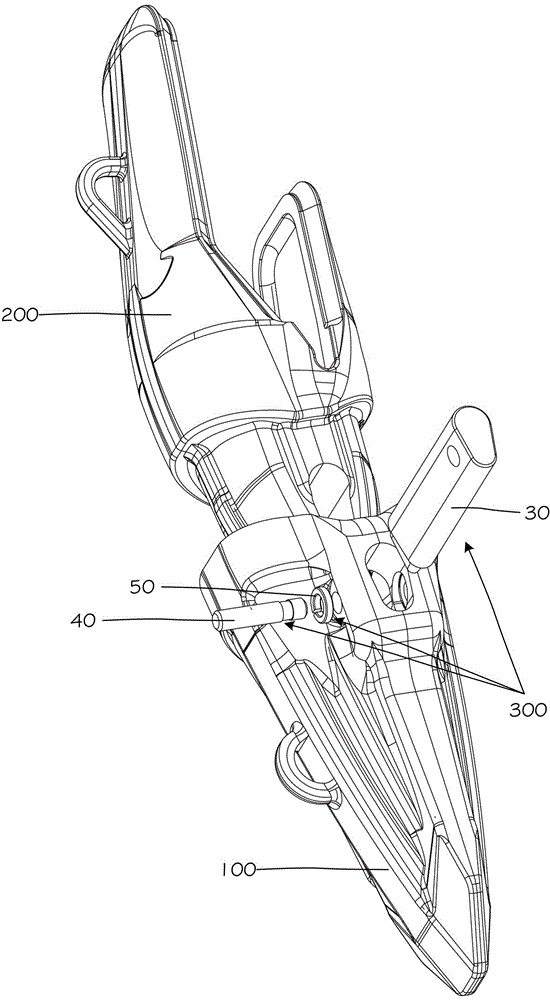

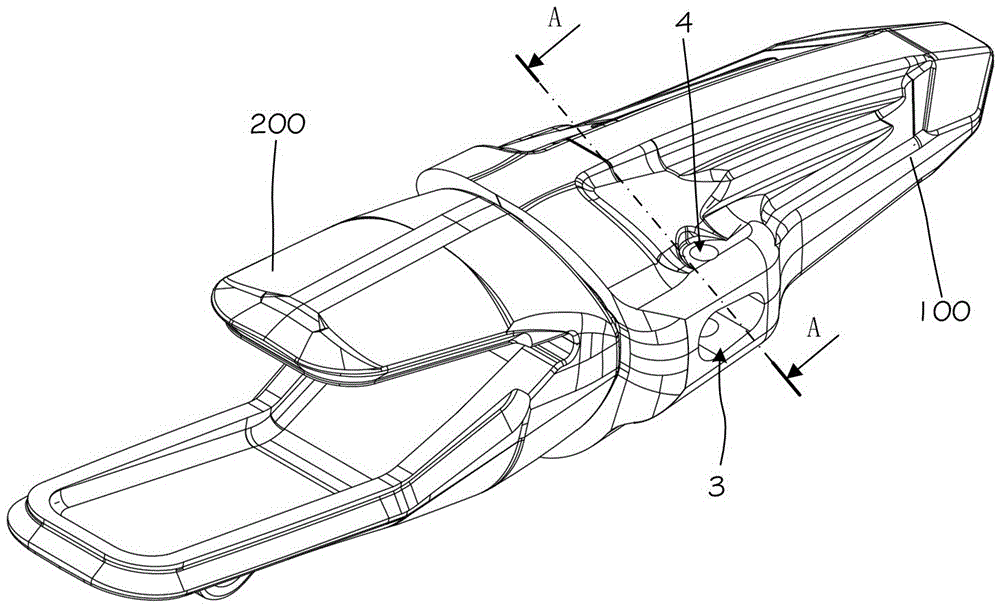

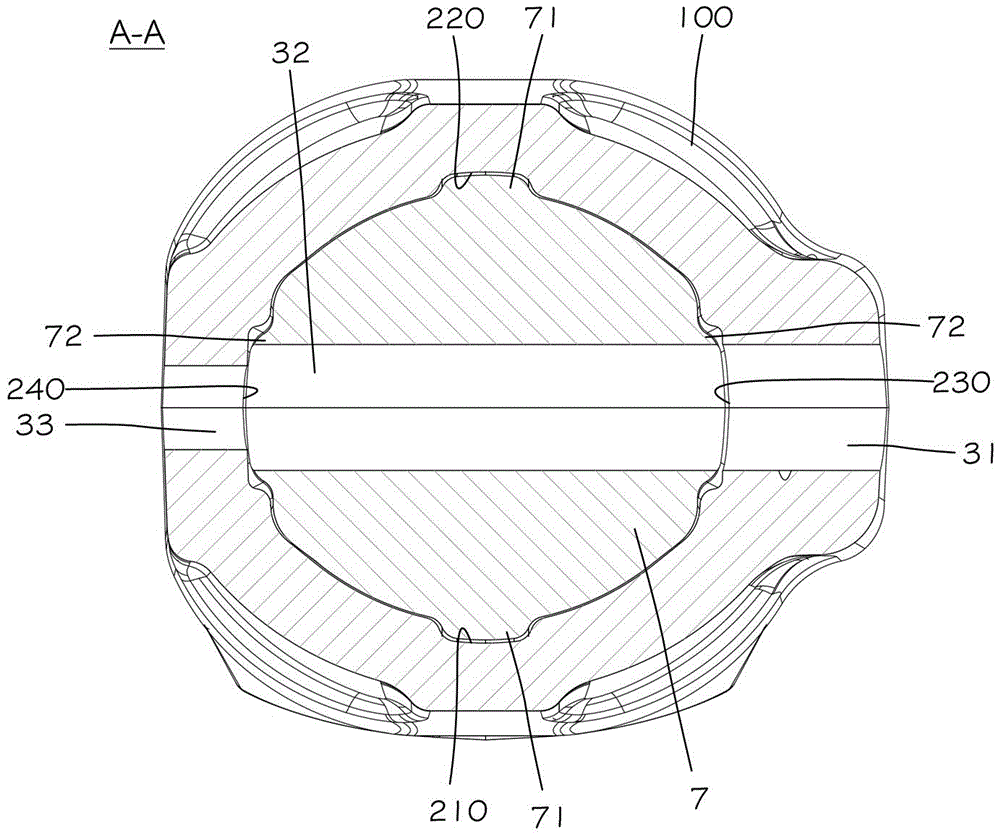

[0035] Such as Figures 1 to 12 The excavator bucket tooth assembly of the present invention with an improved connection structure is shown, which includes a bucket tooth 100, a tooth seat 200 and a lock pin 300, and the bucket tooth 100 and the tooth seat 200 pass through the lock pin 300 Fixed connection.

[0036] The shape of the bucket teeth 100 is similar to that of commonly used excavator teeth, both of which are flat, with wide upper and lower sides and narrow left and right sides. The bucket tooth 100 includes a tip portion 1 and a connecting portion 2 , and the size gradually increases from the tip portion 1 to the connecting portion 2 . The connecting part 2 is provided with a socket 20, the socket 20 is narrow inside and wide outside, the upper and lower sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com