Novel efficient sludge curing agent prepared from ardealite solid waste and preparation method thereof

A sludge curing agent, phosphogypsum technology, applied in chemical instruments and methods, solid waste removal, fixed/solidified sludge treatment, etc., can solve the problems of unfavorable sludge follow-up treatment, poor durability, difficult to mix evenly , to achieve the effect of improving the powder coating effect, improving the contact sufficiency, and improving the bonding tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method for preparing a novel high-efficiency sludge solidifying agent from phosphogypsum solid waste, the preparation method is applicable to the preparation of a novel high-efficiency sludge solidifying agent from the aforementioned phosphogypsum solid waste; the preparation method comprises the following steps:

[0045] S1: Crushing and grinding quicklime to obtain quicklime powder; at the same time, pulverizing and grinding phosphogypsum, and putting the ground powder into a rotary kiln for high-temperature calcination to obtain phosphogypsum powder;

[0046] S2: Put phosphogypsum powder, quicklime powder, fly ash, ordinary Portland cement (P.O 42.5), quick-setting agent, water reducer, and triethanolamine into the stirring tank in turn on the basis of step S1, and fully stir , to obtain the first mixture;

[0047] S3: put the mineralizer into the amplification culture tank, and the population of carbonate mineralizing bacteria and phosphate mineralizin...

Embodiment approach

[0055] As an embodiment of the present invention, in the sludge solidifying agent preparation step, a coating device is used to coat the quicklime powder and 1 / 2 of the zeolite powder adsorbed with the mineralizer;

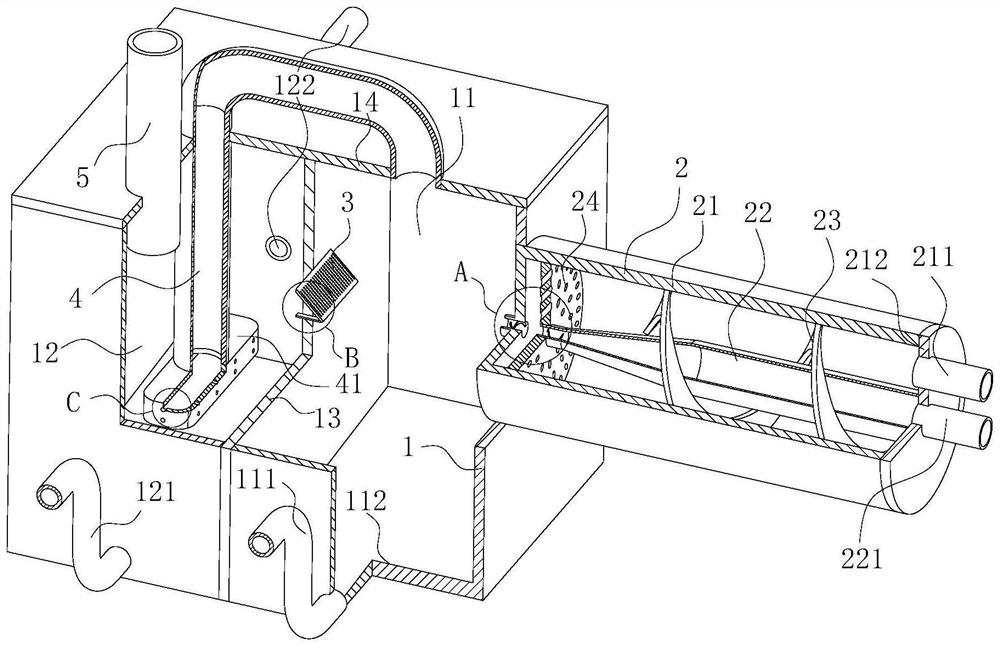

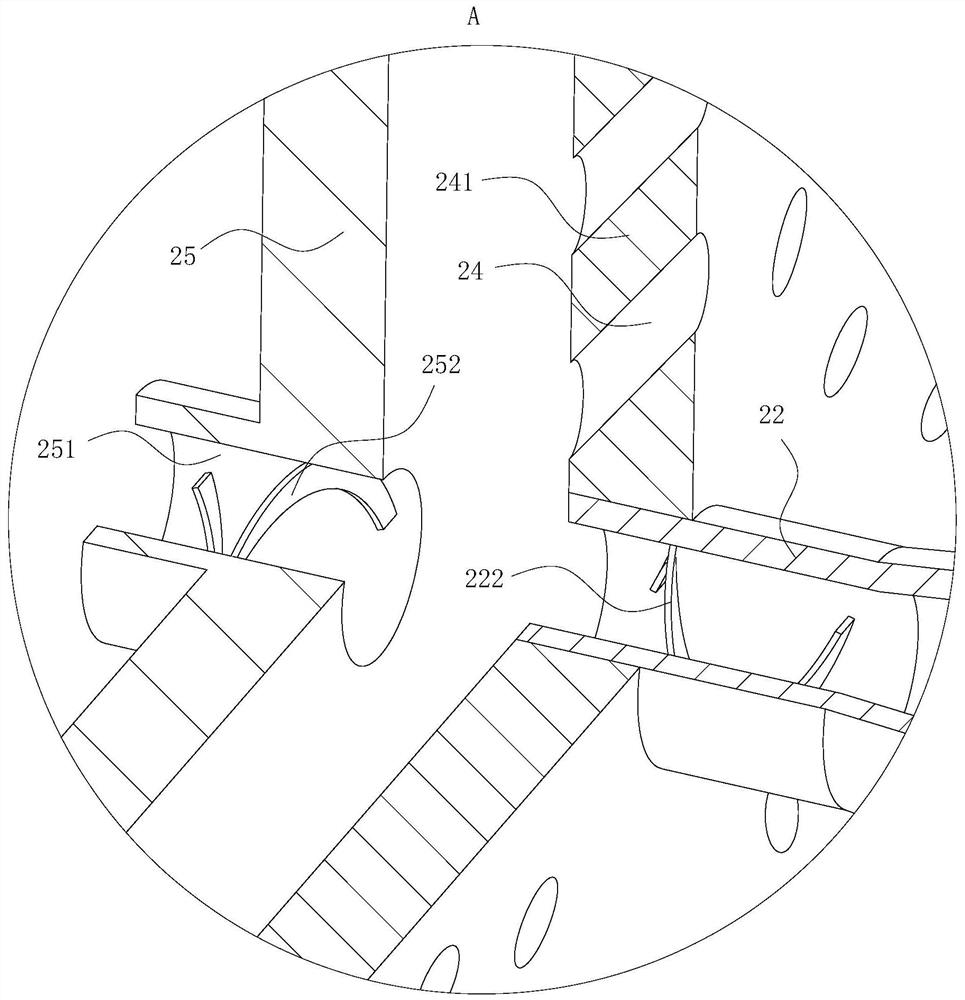

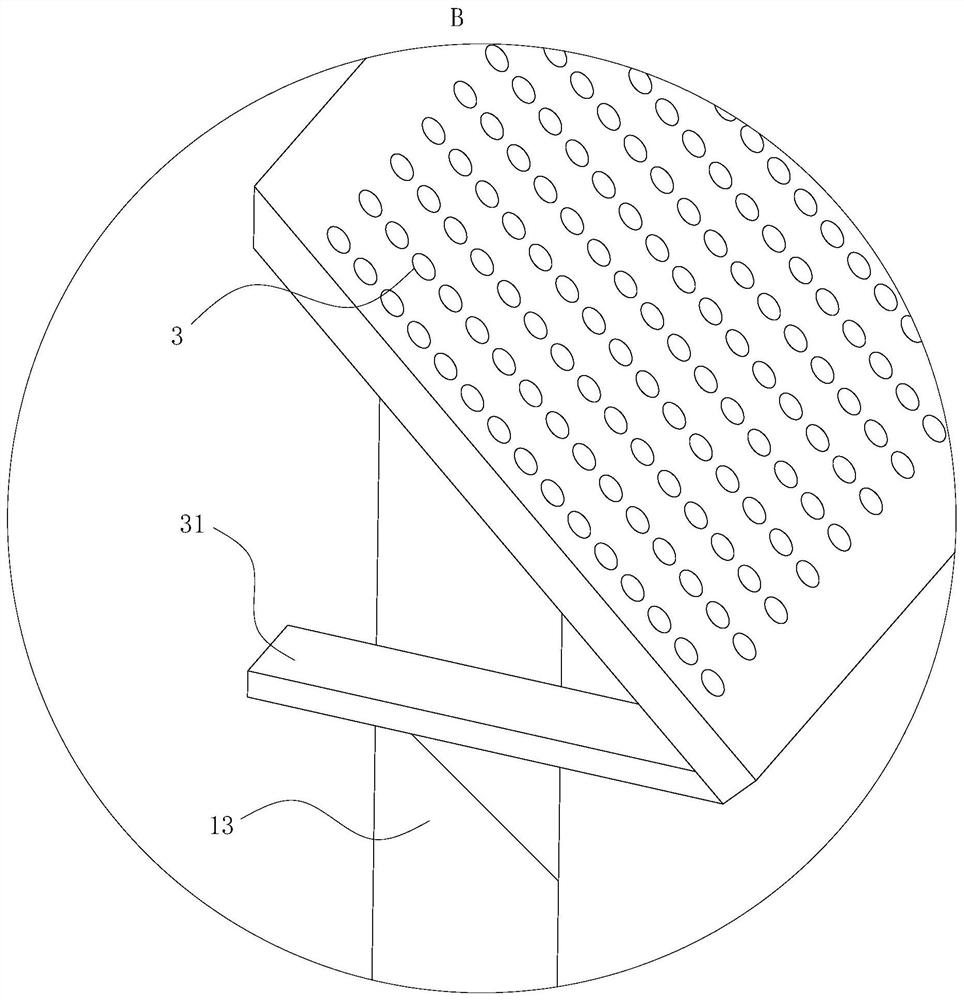

[0056] The coating device includes a main body 1; a partition 13 is fixedly installed in the main body 1; the partition 13 divides the space in the main body 1 into two parts of equal size, namely space one 11 and space two 12; An upper cover 14 is fixedly installed above the main body 1; a communication pipe 4 is fixedly installed on the upper cover 14; the communication pipe 4 communicates the space one 11 with the space two 12; the lower end of the communication pipe 4 is fixedly installed with Dispersion plate 41; the interior of the dispersion plate 41 is hollow, and the vertical side of the dispersion plate 41 is uniformly provided with through holes 411; the communication pipe 4 communicates with the internal space of the dispersion plate 41; the dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com