Preparation method of self-lubricating hard composite coating on surface of shield tunneling machine cutter

A shield machine tool and composite coating technology, which is applied in coating, metal material coating process, etc., can solve the problems of loose coating-substrate bonding, complicated process, unpublished self-lubricating tool hardness and friction factor, etc. parameters and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

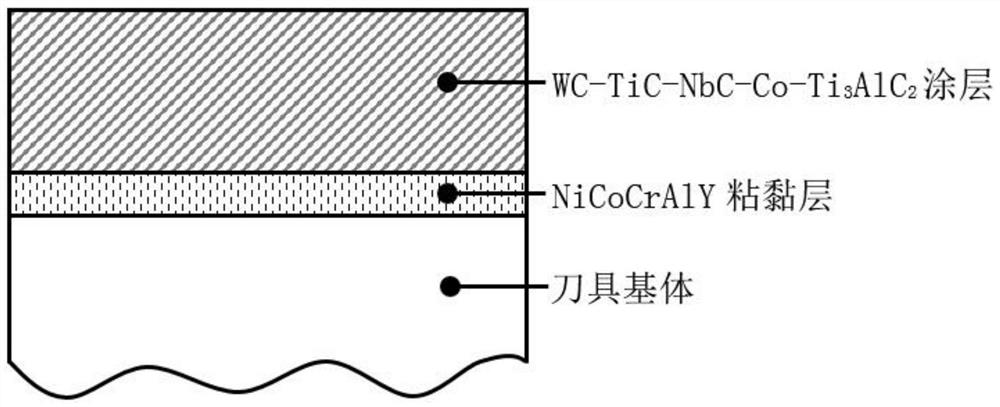

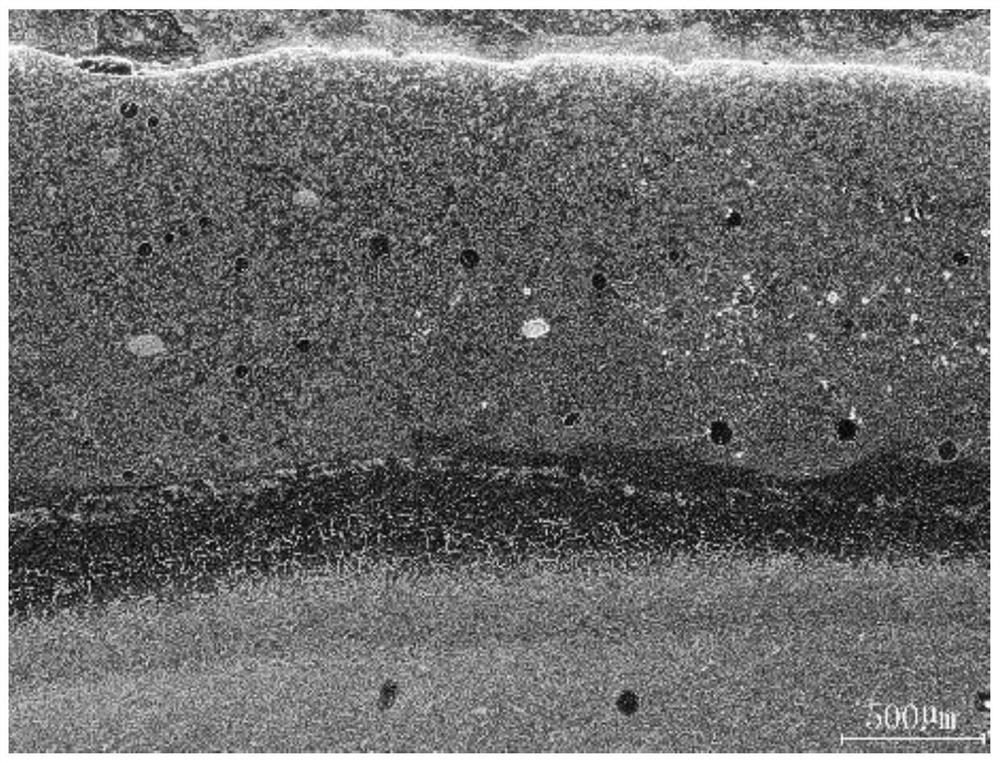

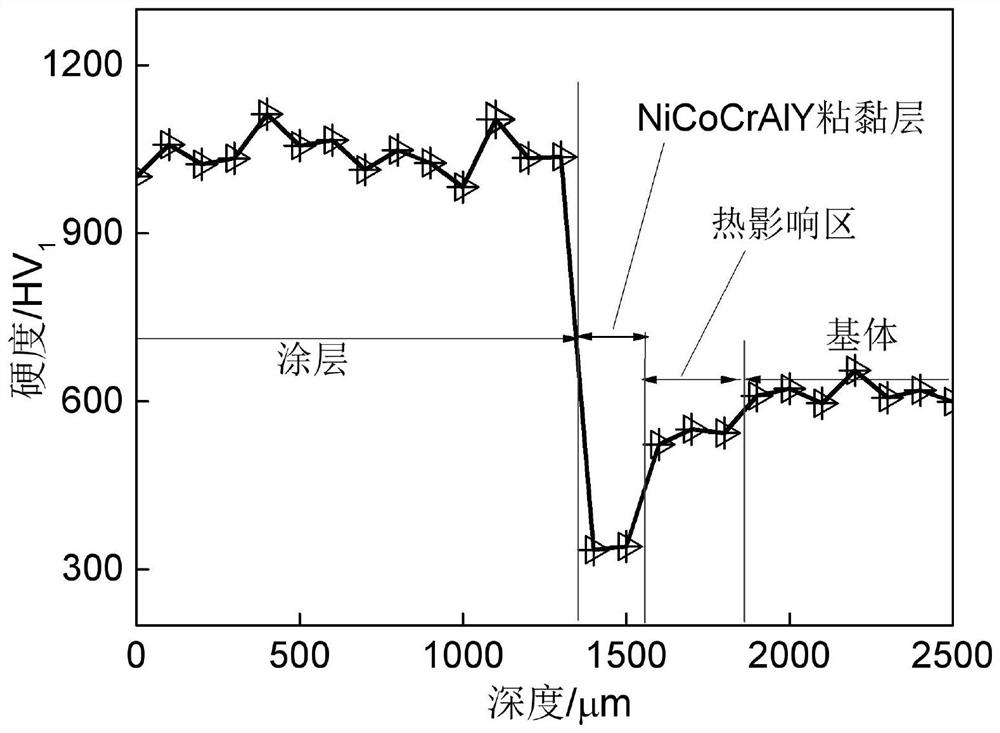

[0024] A method for preparing a self-lubricating hard composite coating on the surface of a shield machine tool. The tool matrix material is T-4241 high-speed steel, which is composed of the following components by mass fraction: 0.9-1% C, 1.5-2.5% W, 3.8- 4.4% Cr, 0.5-1.2% Mo, 0.2-0.4% Mn, 0.5-1% Si, and the rest of Fe; specifically including the following steps:

[0025] (1) Use 80~1200 # Grind the surface of the tool base with sandpaper, clean it with alcohol, and then quench and temper it after cleaning;

[0026] (2) Preparation of NiCoCrAlY alloy powder: the alloy powder is obtained by mixing and ball milling and drying the raw materials of the following mass fractions: 23% of Co powder, 17% of Cr powder, 12% of Al powder, 0.5% of Y powder, and Ni powder of the remainder; Preparation of WC-TiC-NbC-Co-Ti 3 AlC 2 Alloy powder, which is obtained by mixing ball milling and drying the following raw materials in mass fraction: WC powder 78.5%, TiC powder 5.6%, NbC powder 3.7...

Embodiment 2

[0035] A method for preparing a self-lubricating hard composite coating on the surface of a shield machine tool. The tool matrix material is T-4241 high-speed steel, which is composed of the following components by mass fraction: 0.9-1% C, 1.5-2.5% W, 3.8- 4.4% Cr, 0.5-1.2% Mo, 0.2-0.4% Mn, 0.5-1% Si, and the rest of Fe; specifically including the following steps:

[0036] (1) Preparation of NiCoCrAlY alloy powder: the alloy powder is obtained by mixing and ball milling and drying the raw materials of the following mass fractions: 22% of Co powder, 18% of Cr powder, 11.5% of Al powder, 0.6% of Y powder, and Ni powder of the remainder; Preparation of WC-TiC-NbC-Co-Ti 3 AlC 2 Alloy powder, which is obtained by mixing ball milling and drying the following raw materials in mass fraction: WC powder 78%, TiC powder 5.1%, NbC powder 3.6%, Ti 3 AlC 2 powder 6.2%, the balance of Co powder; the particle size of the two alloy powders is 50-100 μm; the two alloy powders are mixed evenl...

Embodiment 3

[0044] A method for preparing a self-lubricating hard composite coating on the surface of a shield machine tool, wherein the tool base material is high-speed steel, specifically includes the following steps:

[0045] (1) Use 80~1200 # Grind the surface of the tool base with sandpaper, clean it with alcohol, and then quench and temper it after cleaning;

[0046] (2) Preparation of NiCoCrAlY alloy powder: the alloy powder is obtained by mixing and ball milling and drying the raw materials of the following mass fractions: 24% Co powder, 16% Cr powder, 12.5% Al powder, 0.4% Y powder, and Ni powder in the remainder; Preparation of WC-TiC-NbC-Co-Ti 3 AlC 2 Alloy powder, which is obtained by mixing ball milling and drying the following raw materials in mass fraction: WC powder 79%, TiC powder 5.3%, NbC powder 3.5%, Ti 3 AlC 2 Co powder 6.3%, the balance of Co powder; the particle size of the two alloy powders are both 50 ~ 100μm;

[0047] (3) Laser cladding is carried out on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com