High-strength thermal-insulation concrete and preparation method thereof

An insulating concrete and high-strength technology, applied in the field of building materials, can solve the problems of unsuitable high-strength concrete, high dry density of foamed concrete, poor compressive strength, etc. Effects of impact properties and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

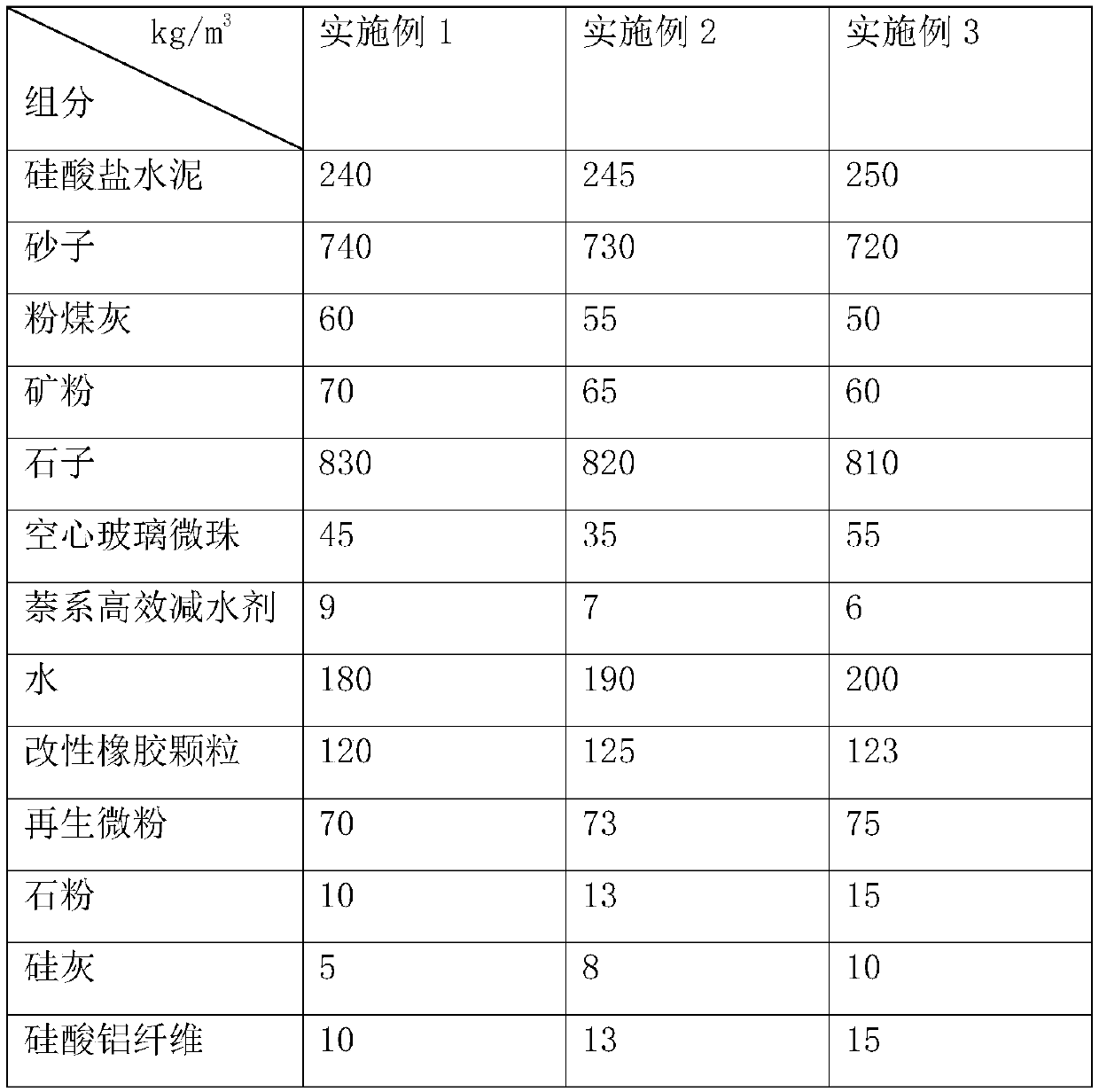

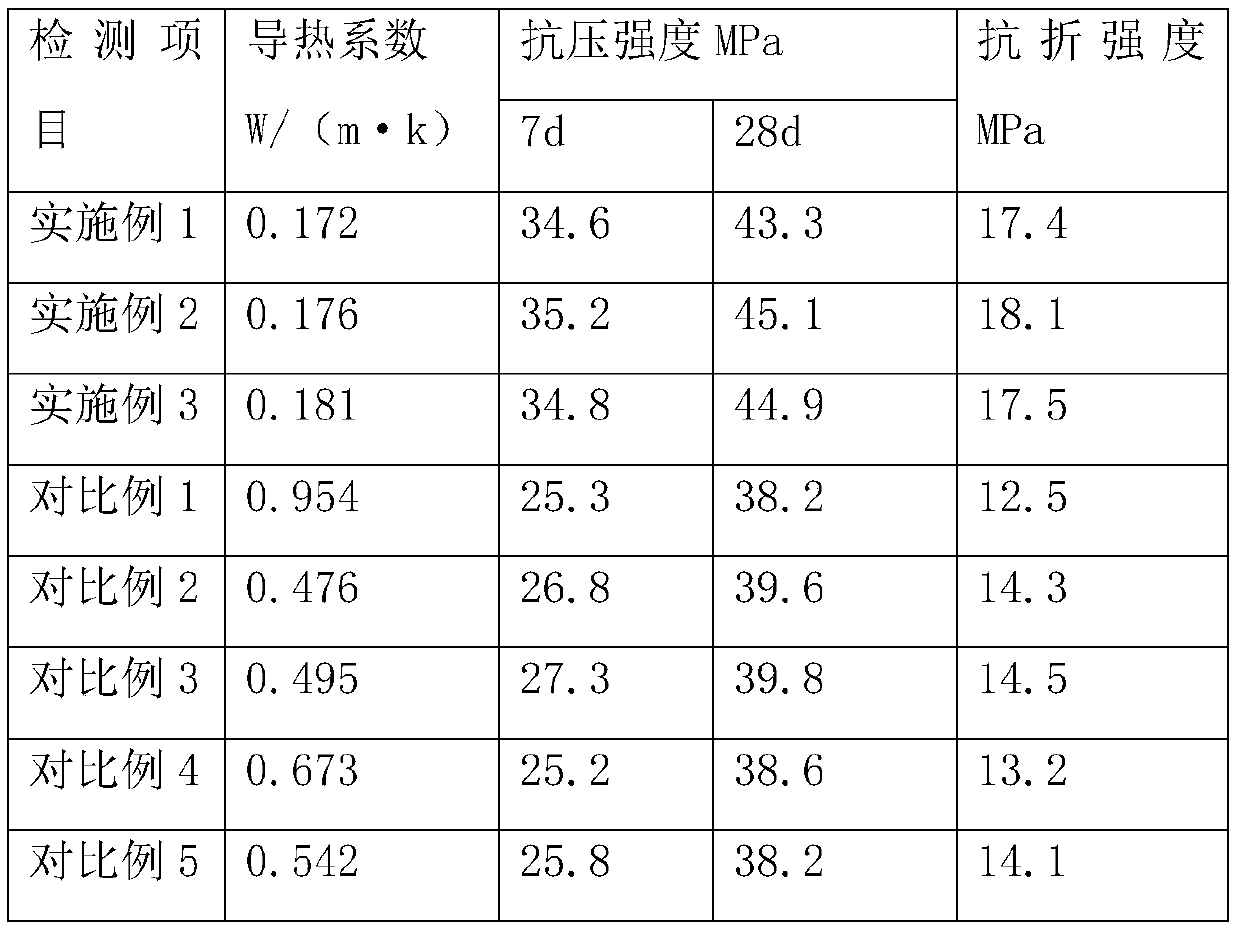

Examples

preparation example 1-3

[0037] In Preparation Examples 1-3, the PVA was selected from PVA117 sold by Guangzhou Liaohua Chemical Co., Ltd., and the water glass was selected from the water glass with the product number 001 sold by Jinan Shengyilong Chemical Technology Co., Ltd.

preparation example 1

[0038]Preparation example 1: (1) cleaning the waste rubber particles and soaking them in a saturated solution of sodium hydroxide for 10 hours; (2) dissolving PVA in water at 80° C. to make an aqueous solution with a concentration of 1%, adding the waste rubber particles into the aqueous solution, After mixing evenly, grind and dry, add water glass, stir evenly, soak for 30 minutes, and dry at 50°C. The mass ratio of waste rubber particles to aqueous solution and water glass is 1:1.5:1.3, and the particle size of waste rubber particles is from 3mm rubber particles and rubber particles with a particle size of 0.38mm are mixed according to a mass ratio of 1:1 to make water glass with a concentration of 40%, a modulus of 2.7, a density of 1.23g / mL, and Na 2 O content is 12.3%, SiO 2 The content is 35%.

preparation example 2

[0039] Preparation example 2: (1) cleaning the waste rubber particles and soaking them in a saturated solution of sodium hydroxide for 13 hours; (2) dissolving PVA in water at 85° C. to make an aqueous solution with a concentration of 1.3%, adding the waste rubber particles into the aqueous solution, After mixing evenly, grind and dry, add water glass, stir well, soak for 35 minutes, and dry at 55°C. The mass ratio of waste rubber particles to aqueous solution and water glass is 1:1.8:1.4, and the particle size of waste rubber particles is from 4mm rubber particles and 0.6mm rubber particles are mixed according to the mass ratio of 1:1.1, the concentration of water glass is 45%, the modulus is 2.8, the density is 1.28g / mL, Na 2 O content is 12.7%, SiO 2 The content is 36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com