Cementitious material precise distribution and dense operation robot

A technology for operating robots and cementitious materials, which is applied in the field of precise distributing of cementitious materials and compact operating robots, which can solve problems such as high labor intensity in construction, difficult vibration, and high physical requirements for workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

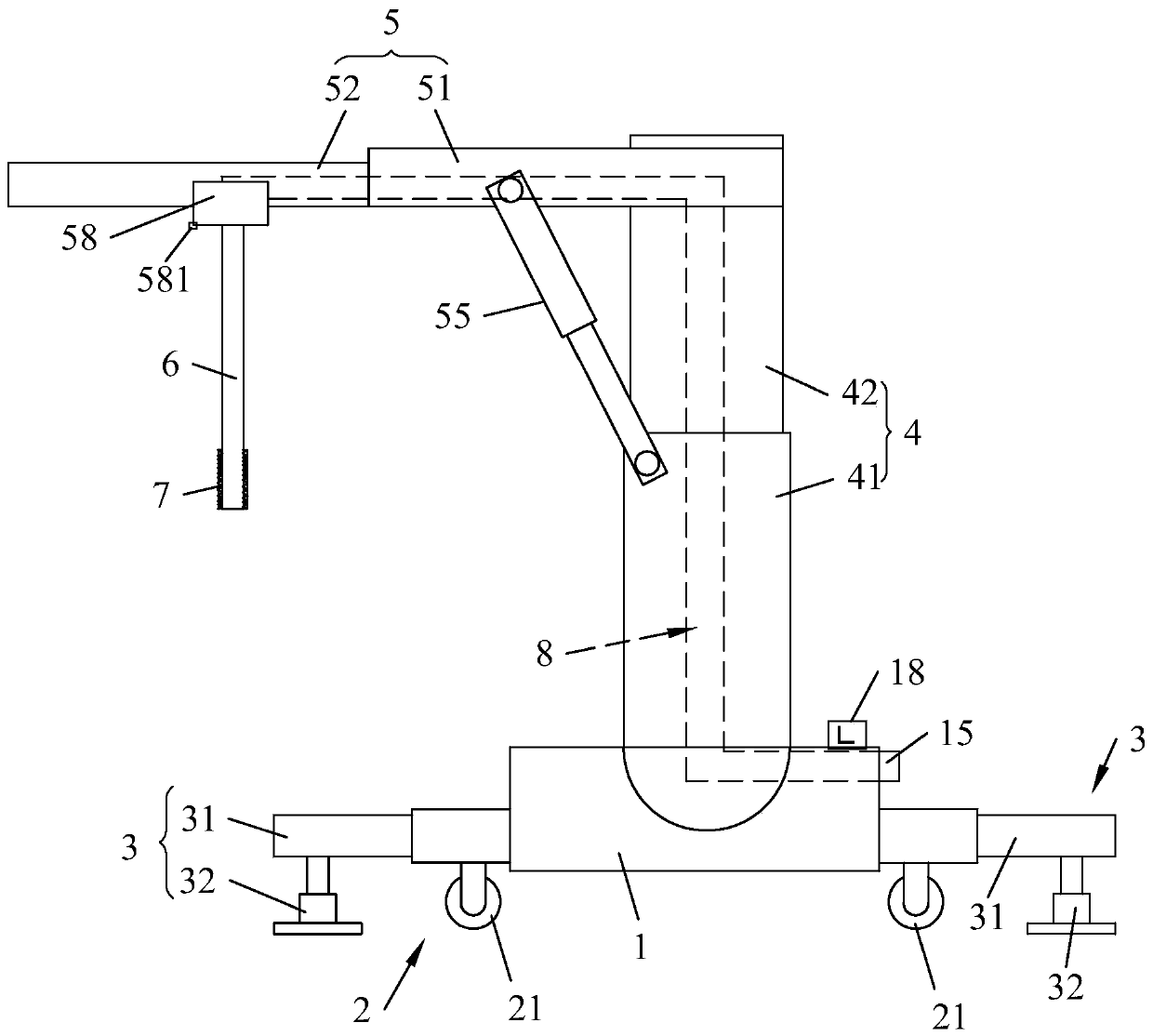

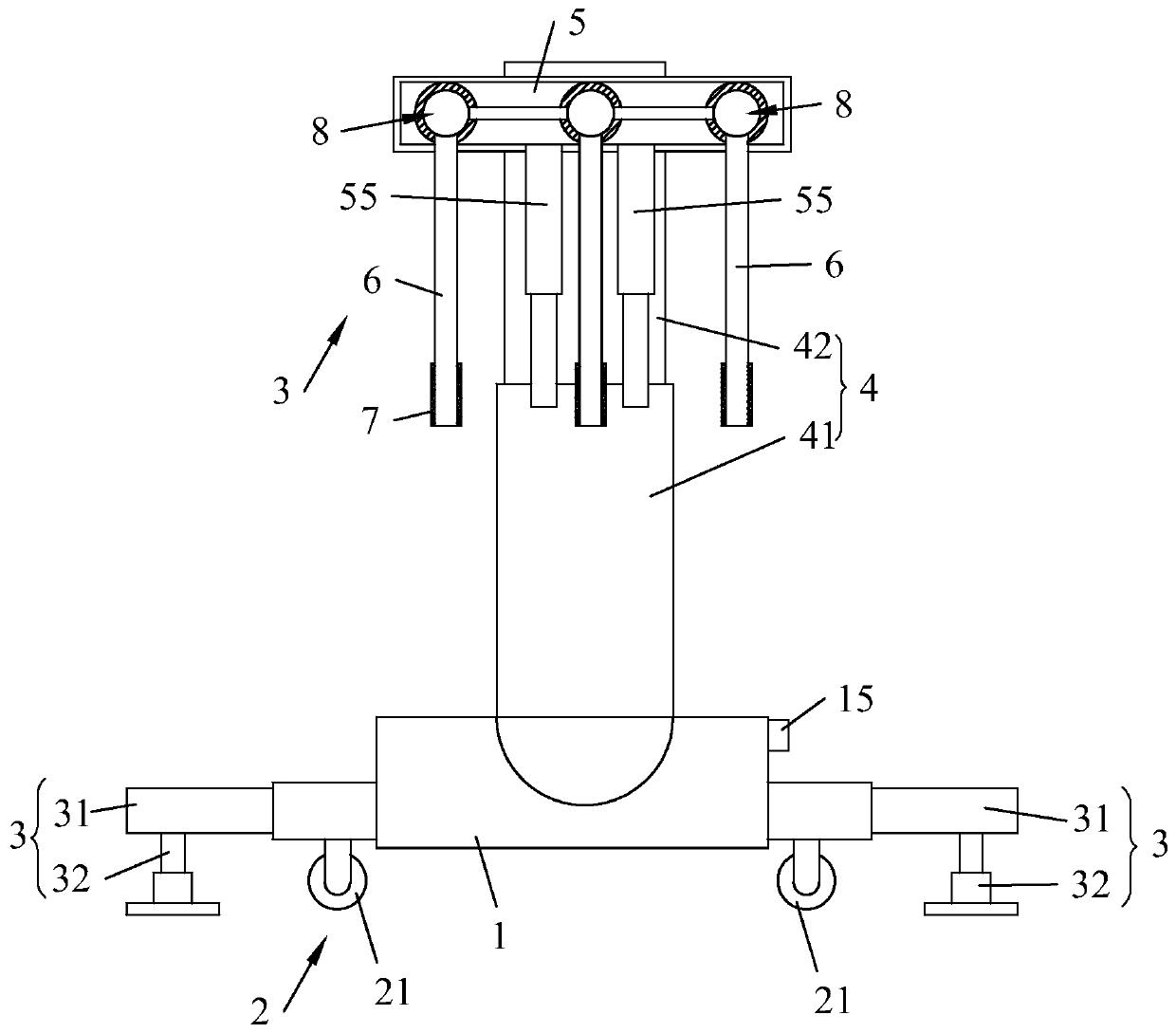

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

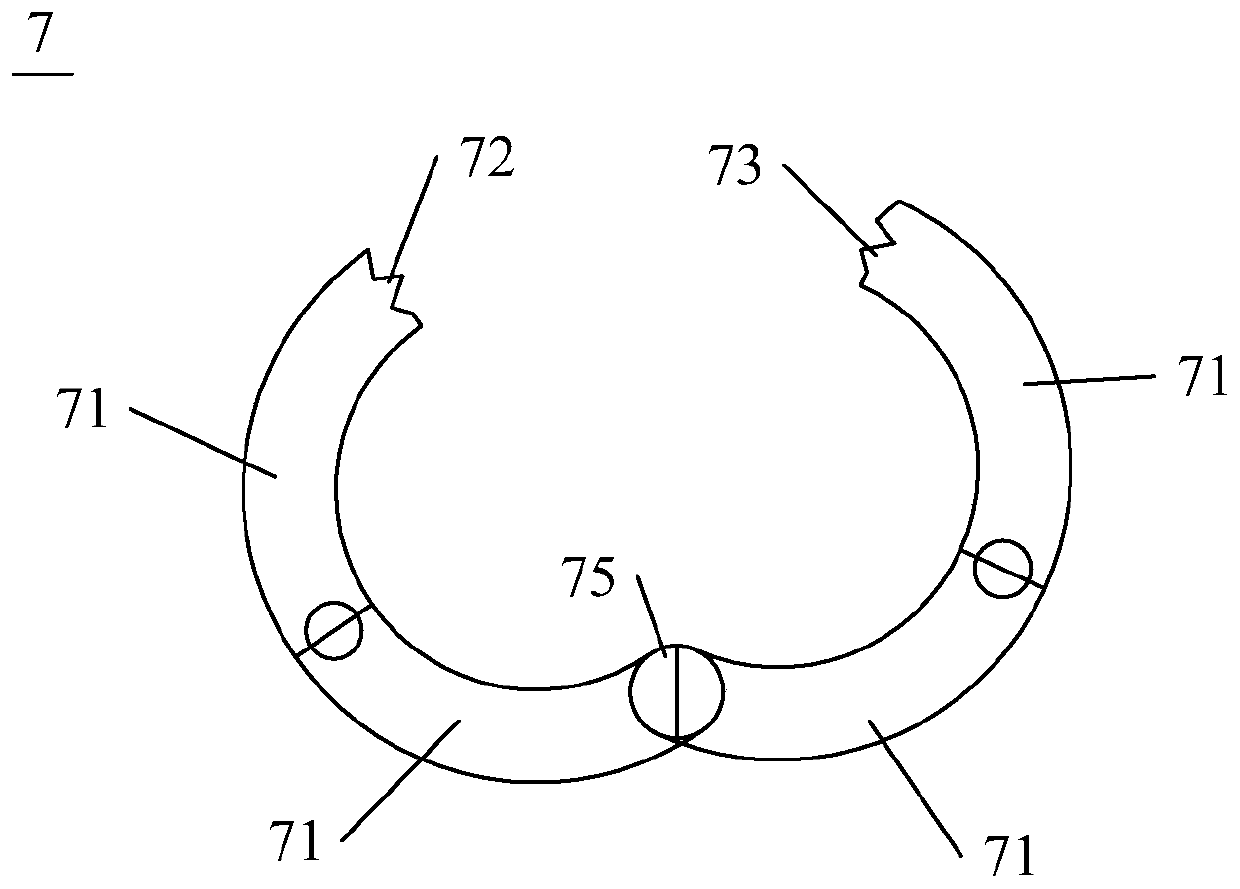

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a robot for precise distributing and compacting of cementitious materials (hereinafter referred to as the robot), which can automatically complete the wall forming operation of pouring cementitious material into the mold cavity between two formworks at the construction site. The robot includes a main body, a walking device 2, two balancing devices 3, a pipe frame 5, a cloth pipe 6, a retractable mechanism and a vibrator 7, wherein the main body is the main bearing part of the robot, and the main body includes a base 1 and a 1 on the lifting device 4.

[0027] The walking device 2 is arranged in the base 1 to drive the precise distribution of the entire gel material and the movement of the compact operation robot. The running device 2 includes a wheel 21 located at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com