Processing method of whole grain vermicelli

A processing method and whole grain technology, applied in the processing field of whole grain dried noodles, can solve problems such as unreported industrial production, and achieve the effects of wide processing range, strong adhesion, smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

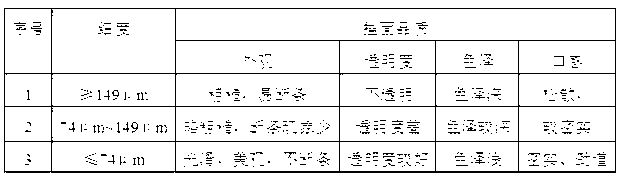

[0032] (1) The whole wheat that has been dried, cleaned, grading, stone-removed, and milled is superfinely pulverized by a mechanical impact shear mill to obtain a whole wheat superfine powder with a fineness of less than 74μm;

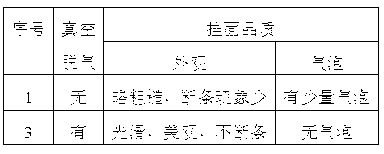

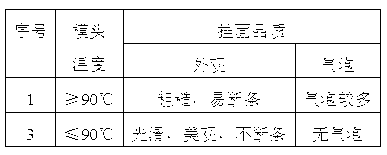

[0033] (2) Take the prepared whole wheat ultrafine powder, adjust the moisture content of the material to 10%, and then feed the material into the twin-screw extruder, once gelatinized and extruded into strips, set the extrusion conditions as 40℃ in one zone, and two zones 60°C, 80°C in the third zone, 80°C in the fourth zone, 120°C in the fifth zone, 70°C in the sixth zone, the extruded noodles are dried (tunnel drying), cooled, cut, and packaged to obtain the noodle product; The screw extruder has a vacuum degassing device.

Embodiment 2

[0035] (1) The brown rice that has been dried, cleaned, classified, de-stoned, and coarsely pulverized is ultra-finely pulverized by an airflow ultra-fine grinding mill to obtain ultra-fine brown rice powder with a fineness of less than 74 μm;

[0036] (2) Take the prepared brown rice ultra-fine powder, adjust the moisture content of the material to 30%, and then feed the material into the twin-screw extruder, one-time gelatinization extrusion and forming, set the extrusion conditions as 50℃ in the first zone and 70 in the second zone ℃, 100℃ in three zones, 100℃ in four zones, 130℃ in five zones, and 80℃ in six zones. The extruded noodles are dried (microwave drying), cooled, cut into strips, and packed to obtain noodle products; wherein, the twin-screw extruder The press has a vacuum degassing device.

Embodiment 3

[0038] (1) The oats that have been dried, cleaned, grading, de-stoned, and milled are superfinely pulverized using a ball mill to obtain superfine oats powder with a fineness of less than 74 μm;

[0039] (2) Take the prepared oatmeal superfine powder, adjust the moisture content of the material to 50%, and then feed the material into the twin-screw extruder, one-time gelatinization extrusion to form a strip, set the extrusion conditions as 60℃ in the first zone and 80 in the second zone. ℃, three zones 120℃, four zones 120℃, five zones 150℃, six zones 90℃, the extruded noodles are dried (hot air drying), cooled, cut, and packaged to obtain noodle products; wherein, the twin screw extruder The press has a vacuum degassing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com