Special composite firebrick for rotary kiln and preparation method thereof

A refractory brick and rotary kiln technology, applied in the field of refractory materials, can solve the problems that affect the economic benefits of enterprises, complex masonry process, poor refractory and thermal insulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

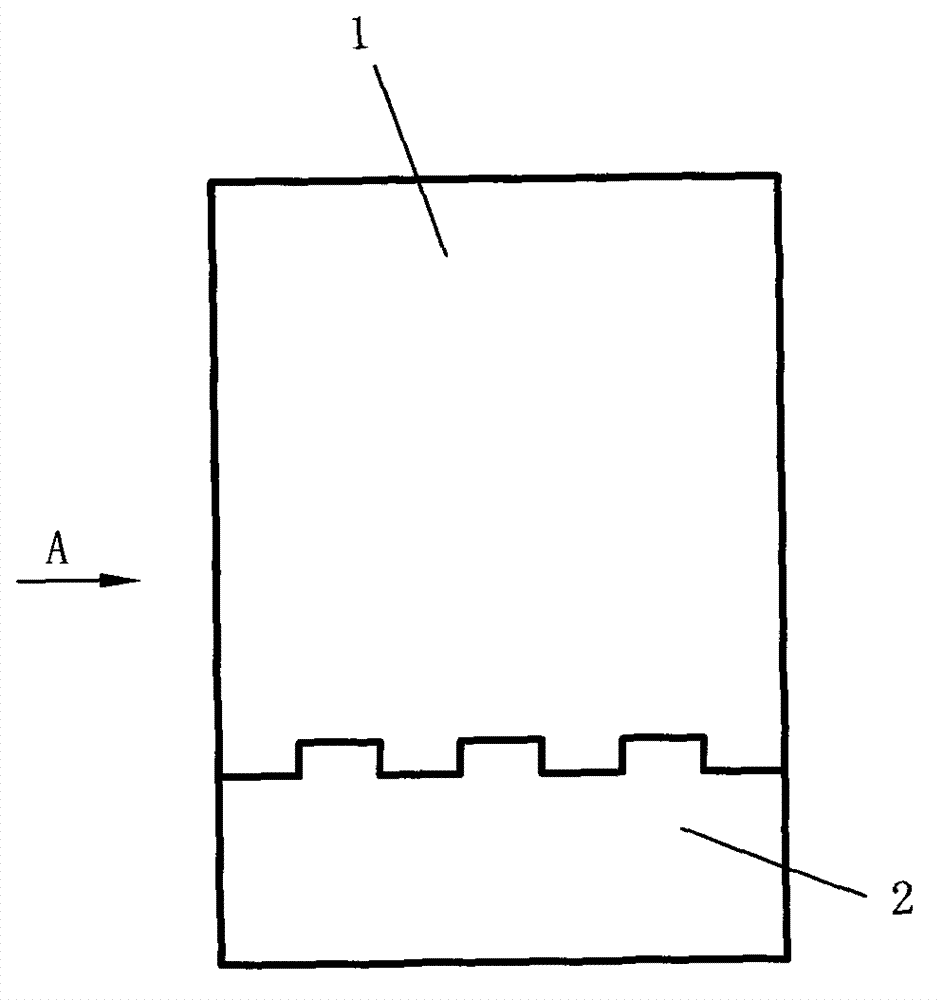

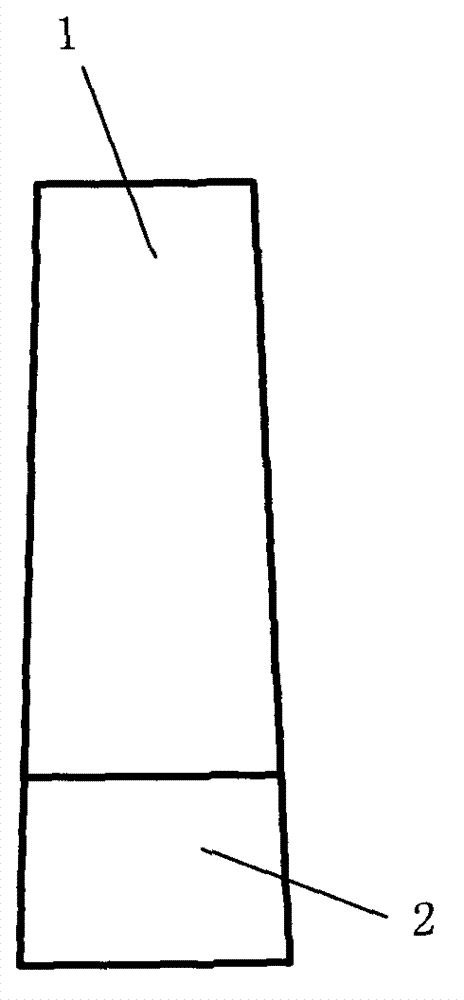

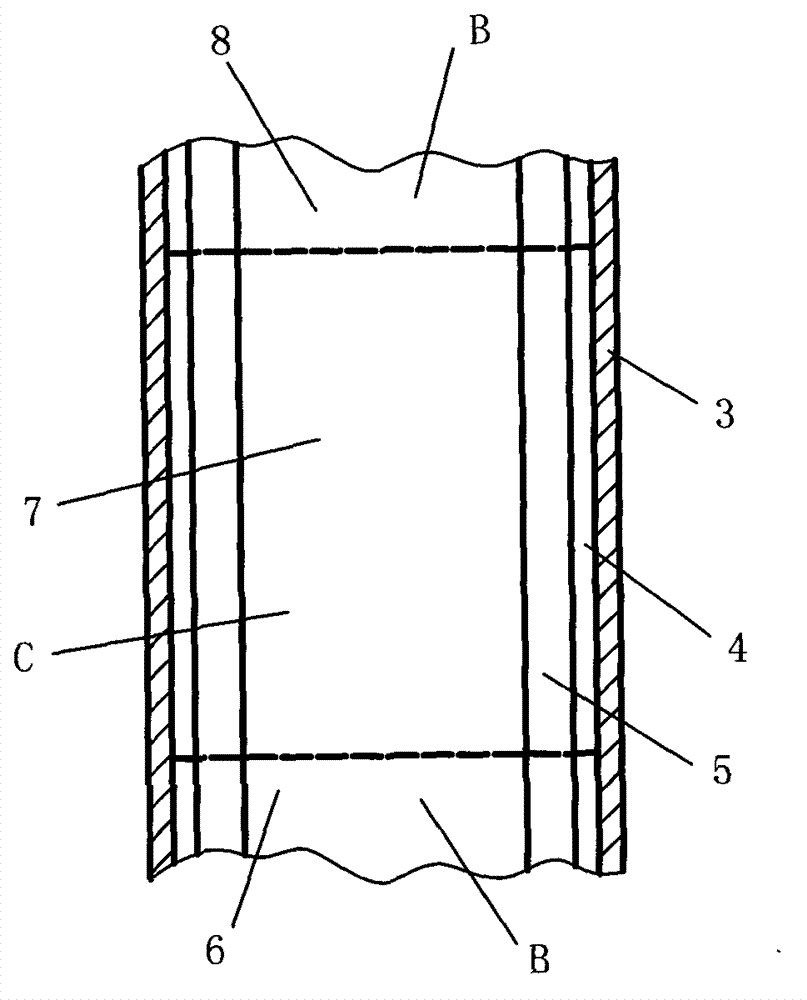

[0016] As shown in the figure, the composite refractory bricks of the present invention are divided into ordinary refractory bricks and special refractory bricks with the same appearance and specifications. Both ordinary refractory bricks and special refractory bricks are composed of a working layer 1 and a heat insulation layer 2

[0017] It is characterized in that an interface agent and an adhesive are combined between the working layer 1 and the heat insulating layer 2;

[0018] The interface agent is made of fluorite powder, floating beads, sub-white corundum hollow spheres, mullite hollow spheres, spherical clay powder, and silica fume in proportion, and is made into a slurry with an inorganic binder; the purpose is to prevent the work The heat conduction and consumption of the calcined materials in the layer masonry surface combine the working layer 1 and the heat insulation layer 2 into an integral structure;

[0019] The binder refers to an inorganic binder, such as o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com