High-speed steel, extrusion roller containing high-speed steel and production method of extrusion roller

A production method and high-speed steel technology, applied in the field of high-speed steel, can solve the problems of roll surface wear, poor roundness, easy to cause peeling, etc., and achieve the effects of simple heat treatment process, reduction of production cost, and reduction of brittle cracking tendency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

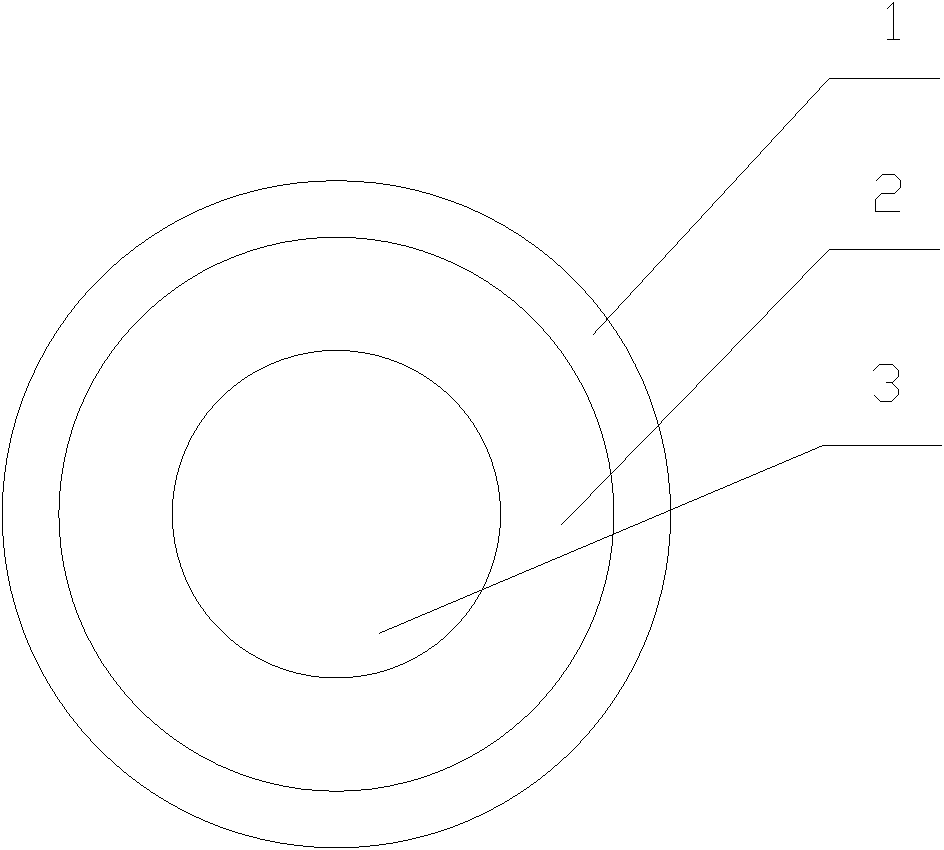

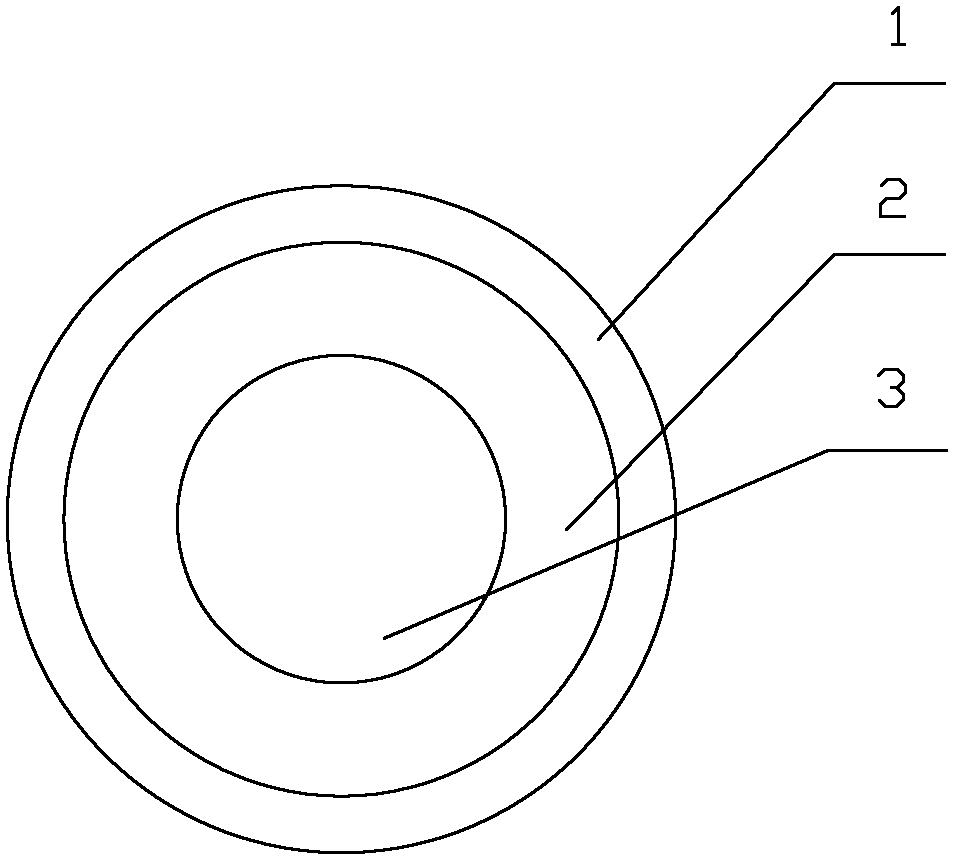

[0037] A squeeze roller, comprising a roller shaft 3 and a composite roller sleeve fixed on it by interference fit, the composite roller sleeve is provided with two layers inside and outside, and the inner layer 2 of the composite roller sleeve is made of graphite steel to form a composite roller sleeve The graphite steel composition of the inner layer 2 is (weight%): 1.1C, 1.4Si, 0.7Mn, 0.02P, 0.02S, and the balance is Fe; the outer layer 1 of the composite roll sleeve is made of high-speed steel, and is made of a composite roll sleeve The high-speed steel composition of the outer layer 1 is (weight%): 1.2C, 0.4Si, 0.7Mn, 3.2Cr, 0.6Ni, 2.8Mo, 1.9V, 1.1W, and the rest is Fe. Pattern for increasing feeding friction.

[0038] The production method of above-mentioned extrusion roller:

[0039] 1) The outer layer material and the inner layer material of the composite roller sleeve are respectively melted in an intermediate frequency induction furnace;

[0040] 2) The smelted com...

Embodiment 2

[0048] The difference with Example 1 is:

[0049]1) The high-speed steel composition of the outer layer of the composite roller sleeve is (weight%): 1.0C, 0.3Si, 0.8Mn, 3.8Cr, 1.0Ni, 2.0Mo, 2.5V, 0.5W, and the rest is Fe. The composition of the graphite steel in the inner layer is (% by weight): 1.3C, 2.0Si, 0.5Mn, 0.02P, 0.02S, and the balance is Fe.

[0050] 2) The pouring temperature of the outer layer material of the composite roller sleeve is 1400°C, and the pouring temperature of the inner layer material is 1500°C.

[0051] 3) The heating rate for the first tempering is 20°C / h, the heating temperature is 500°C, and the temperature is kept for 6 hours. The heating rate of the second tempering is 20°C / h, the heating temperature is 240°C, and the temperature is kept for 6 hours.

[0052] 4) The outer diameter of the composite roller sleeve is F1200mm, the length is 800mm, the outer wall thickness is 80mm, and the inner wall thickness is 170mm.

[0053] 5) After testing, ...

Embodiment 3

[0056] The difference with Example 1 is:

[0057] 1) The high-speed steel composition of the outer layer of the composite roller sleeve is (weight%): 2.0C, 0.8Si, 1.0Mn, 2.0Cr, 0.5Ni, 4.0Mo, 3.0V, 0.5W, and the rest is Fe. The composition of the graphite steel in the inner layer is (% by weight): 1.0C, 1.4Si, 0.5Mn, 0.02P, 0.02S, and the balance is Fe.

[0058] 2) The pouring temperature of the outer layer material of the composite roller sleeve is 1500°C, and the pouring temperature of the inner layer material is 1470°C.

[0059] 3) The heating rate for the first tempering is 10°C / h, the heating temperature is 600°C, and the temperature is kept for 10 hours. The heating rate of the second tempering is 12°C / h, the heating temperature is 300°C, and the heat preservation is 8 hours.

[0060] 4) The outer diameter of the composite roller sleeve is F1200mm, the length is 800mm, the outer wall thickness is 50mm, and the inner wall thickness is 200mm.

[0061] 5) After testing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com