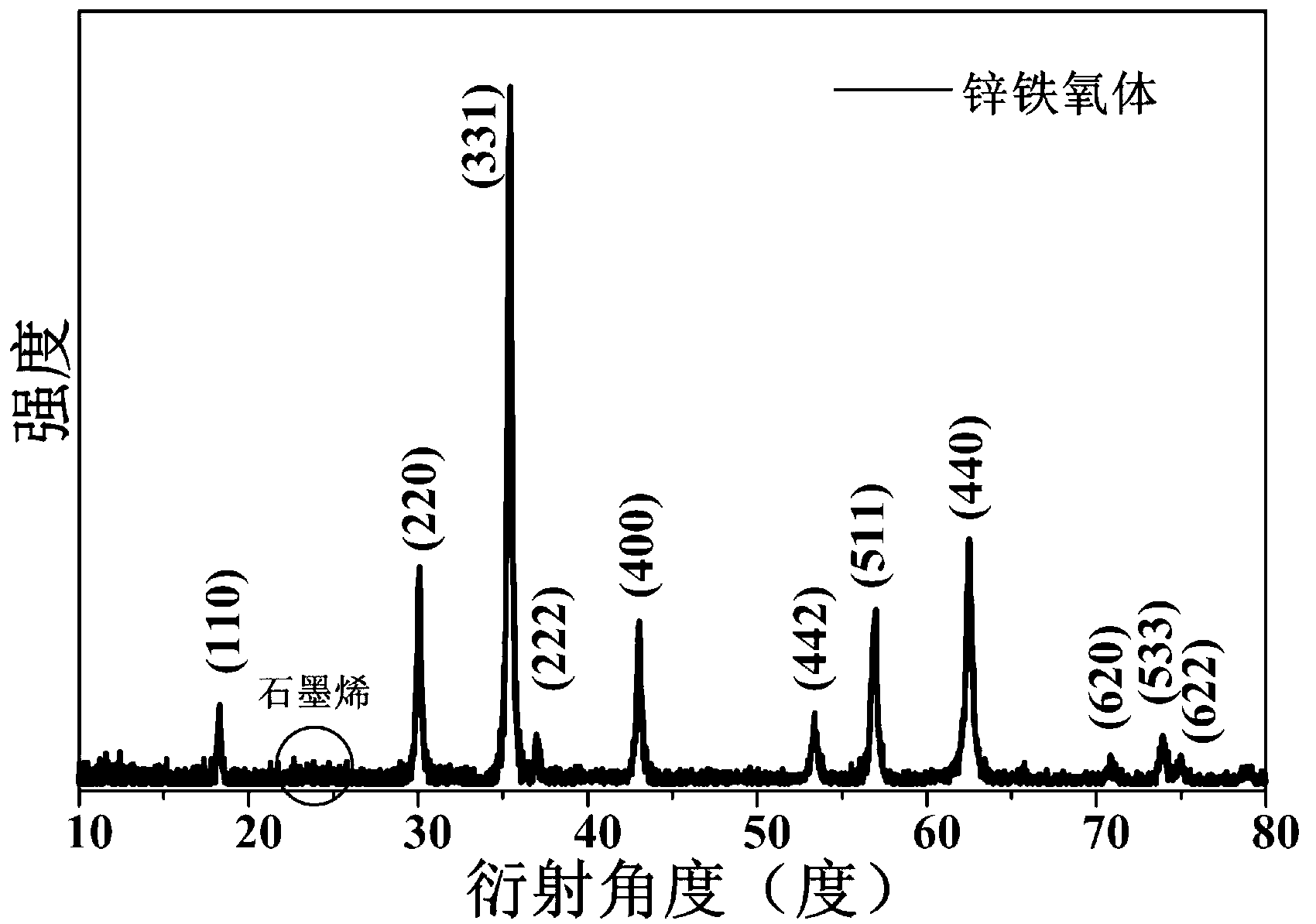

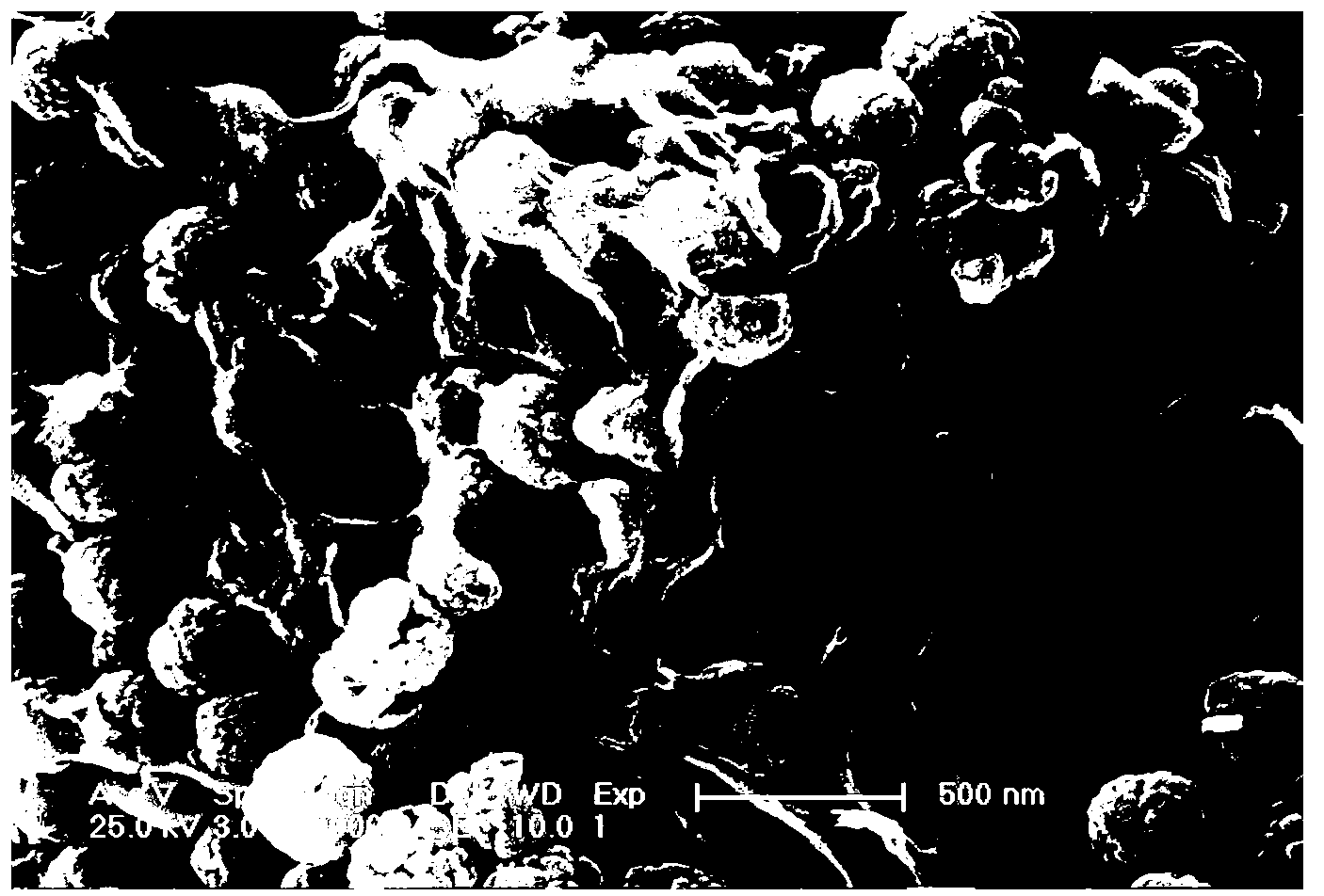

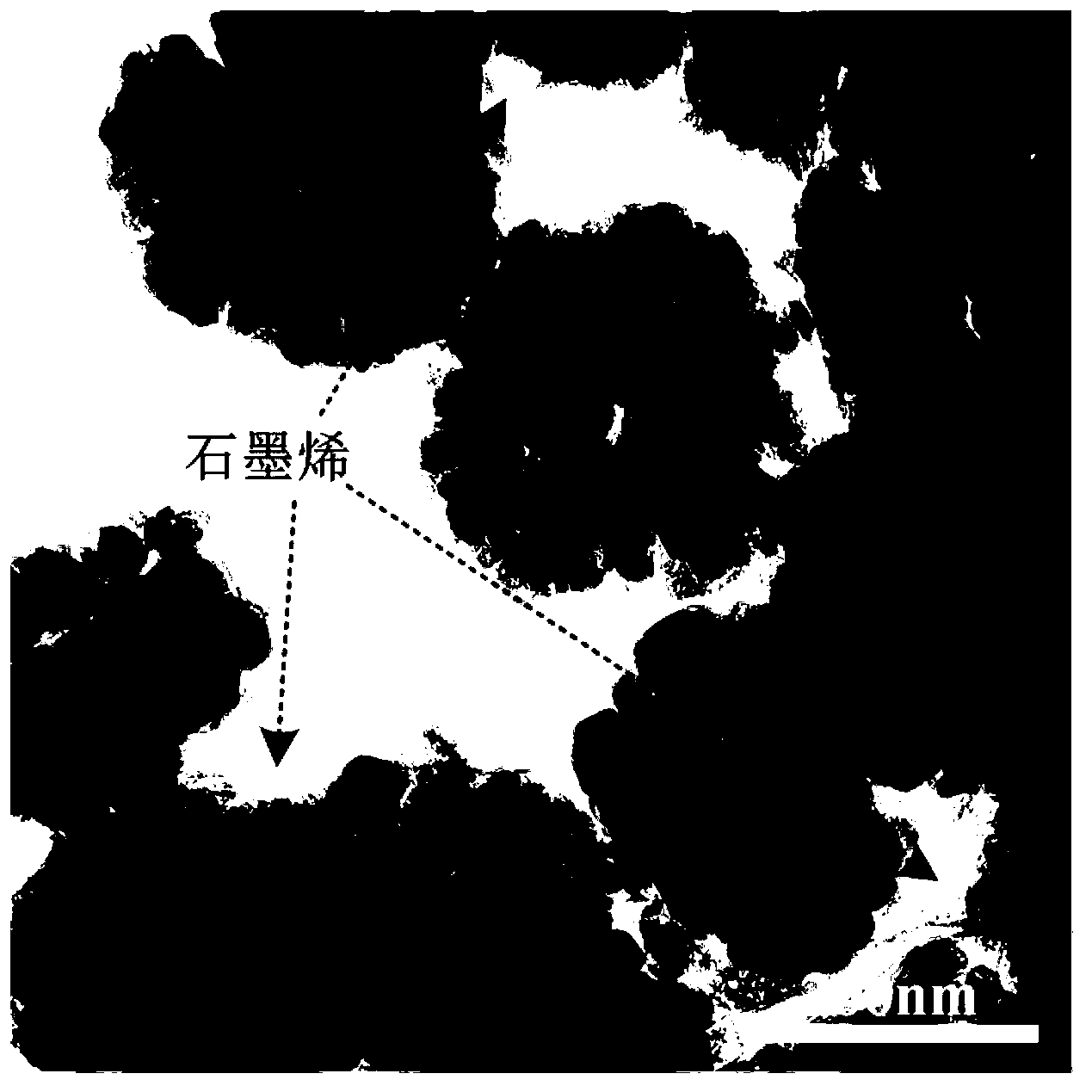

Method for preparing zinc ferrite coated by graphene

A graphene-coated, zinc-ferrite technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of electrical conductivity, toxicity and easy pollution, and high production cost, so as to avoid additives, reduce pollution, and pack uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Disperse the graphene oxide nanolayer in ethylene glycol at a concentration of 0.9-1.5 mg / ml, and stir until uniformly dispersed after ultrasonication for 30-40 minutes;

[0029] (2) Add ferric chloride, zinc chloride and urea to the above suspension, the concentration ratio of ferric chloride and zinc chloride is 2:1, wherein the concentration of ferric chloride is 0.1-0.25 mol / L, stir for 0.5-5.0 hours until uniformly dispersed;

[0030] (3) Put the mixed solution into a reaction kettle, and preheat at 80-150° C. for 1.0-4.0 hours to form metal alkoxide nanoparticles, and the nanoparticles are attached to the surface of the graphite oxide nanolayer;

[0031] (4) Raise the temperature to 180-210°C at a heating rate of 3-5°C / min, keep it warm for 22-29 hours, the nanoparticles are assembled, and the attached graphene nanolayer is guided and coated on its surface, centrifuged, washed, The nanoparticle-assembled zinc ferrite hollow spheres coated with graphene were o...

Embodiment 2

[0033] (1) Disperse the graphite oxide nanolayer in ethylene glycol at a concentration of 0.5-1.0 mg / ml, and stir until evenly dispersed after ultrasonication for 40-60 minutes;

[0034] (2) Add ferric chloride, manganese nitrate and urea to the above suspension, the molar concentration ratio of ferric chloride and zinc chloride is 2:1, wherein the concentration of ferric chloride is 0.05-0.15 moles / L, stir for 0.5-5.0 hours until uniformly dispersed;

[0035] (3) Put the mixed solution into a reaction kettle, and preheat at 80-120°C for 1.0-3.0 hours to form metal alkoxide nanoparticles, and the nanoparticles are attached to the surface of the graphene oxide nanolayer;

[0036] (4) Raise the temperature to 170-200°C at a heating rate of 2-3°C / min, keep it warm for 20-25 hours, the nanoparticles are assembled, and the attached graphene nano-layer is guided and coated on its surface, centrifuged, washed, After drying, the nanoparticle-assembled manganese ferrite hollow sphere...

Embodiment 3

[0038] (1) Disperse the graphene oxide nanolayer in ethylene glycol at a concentration of 0.2-1.2 mg / ml, and stir until uniformly dispersed after ultrasonication for 20-40 minutes;

[0039] (2) Add ferric chloride, nickel sulfate and urea to the suspension, the concentration ratio of ferric chloride and zinc chloride is 2:1, wherein the concentration of ferric chloride is 0.07-0.14 moles / liter, stir for 0.5-4.0 hours to disperse evenly; (3) put the mixed solution into the reaction kettle, and preheat for 0.5-5.0 hours at 100-150°C to form metal alkoxide nanoparticles, and the nanoparticles are attached to the graphite oxide ene nanolayer surface;

[0040] (4) Raise the temperature to 190-230°C at a heating rate of 2-5°C / min, keep it warm for 24-30 hours, the nanoparticles are assembled, and the attached graphene nano-layer is guided and coated on its surface, centrifuged, washed, Nanoparticle-assembled nickel ferrite hollow spheres coated with graphene were obtained after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com