Graphene oxide modified PA (polyamide) composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and graphene modification technology, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc. Poor water resistance, weak anti-pollution ability of nanofiltration membrane and other problems, to achieve the effect of easy operation, enhanced interlayer bonding tightness, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of graphene oxide modified polyamide composite nanofiltration membrane, described method specifically comprises the steps:

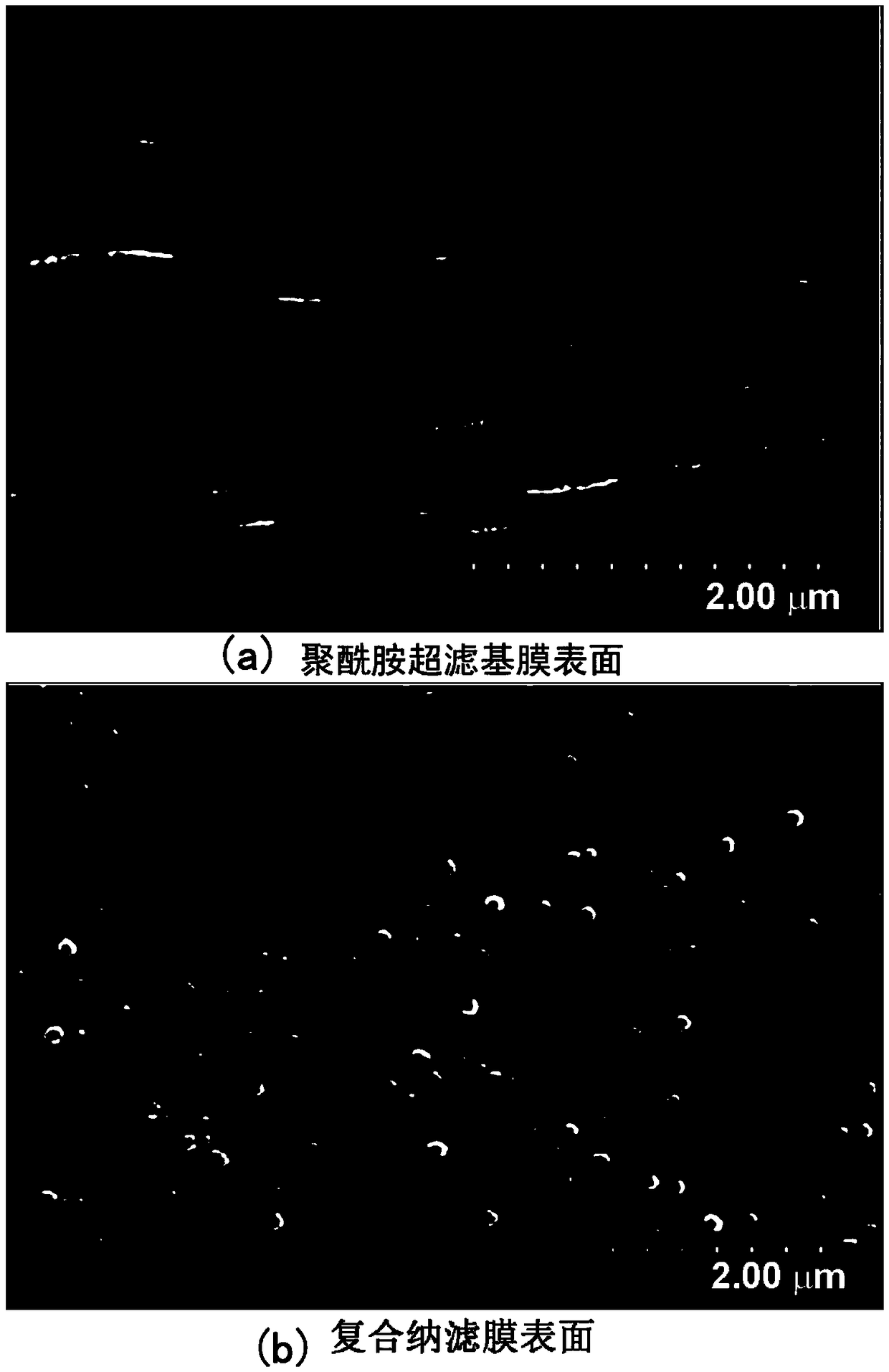

[0034] Step 1: Prepare polyamide ultrafiltration base membrane: dissolve polyamide in N,N-dimethylformamide to prepare a casting solution containing polyamide with a mass concentration of 20-25%, at 65°C-70°C Stir, let stand at a constant temperature for degassing, cool to room temperature, pour the casting solution on a glass plate to scrape the film, put it in a water bath at 25°C to 28°C to solidify to form a film, soak it in deionized water to obtain a polyamide ultrafiltration base membrane ;

[0035]Step 2: Prepare an aqueous solution of aminated graphene oxide: add an alkaline solution to the graphene oxide solution, disperse evenly, and adjust the pH value of the solution to neutrality with hydrochloric acid, then centrifugally wash with deionized water, dissolve the product in deionized water and Add 1-(3-dim...

specific Embodiment

[0045] Specific examples are as follows:

[0046] A kind of preparation method of graphene oxide modified polyamide composite nanofiltration membrane, described preparation method specifically comprises the following steps:

[0047] (1) Preparation of polyamide ultrafiltration base membrane: dissolving polyamide in N,N-dimethylformamide to prepare a casting solution containing polyamide mass concentration of 20-25% (22, 23, 24), Stir at 65°C-70°C for 2.5-3.5 hours, and let it stand at constant temperature for 3-4 hours to degas. The membrane was removed from the glass plate and soaked in deionized water for 20-22 hours to obtain the polyamide ultrafiltration base membrane;

[0048] (2) Preparation of an aminated graphene oxide aqueous solution: add an alkaline solution to the graphene oxide solution, disperse evenly through ultrasound, and adjust the pH value of the solution to neutral with hydrochloric acid, then centrifugally wash with deionized water, and wash the product ...

Embodiment 4~6

[0058] Table 2 embodiment 4~6 concrete implementation scheme

[0059]

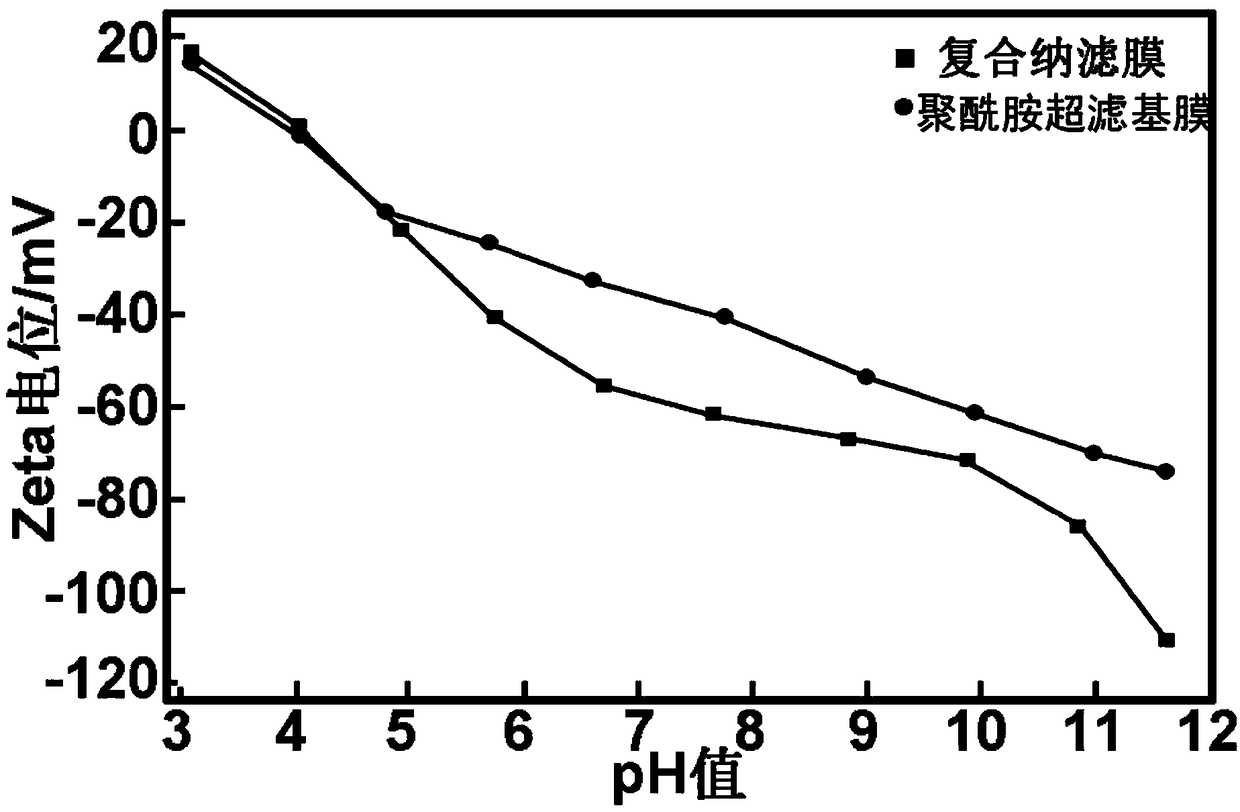

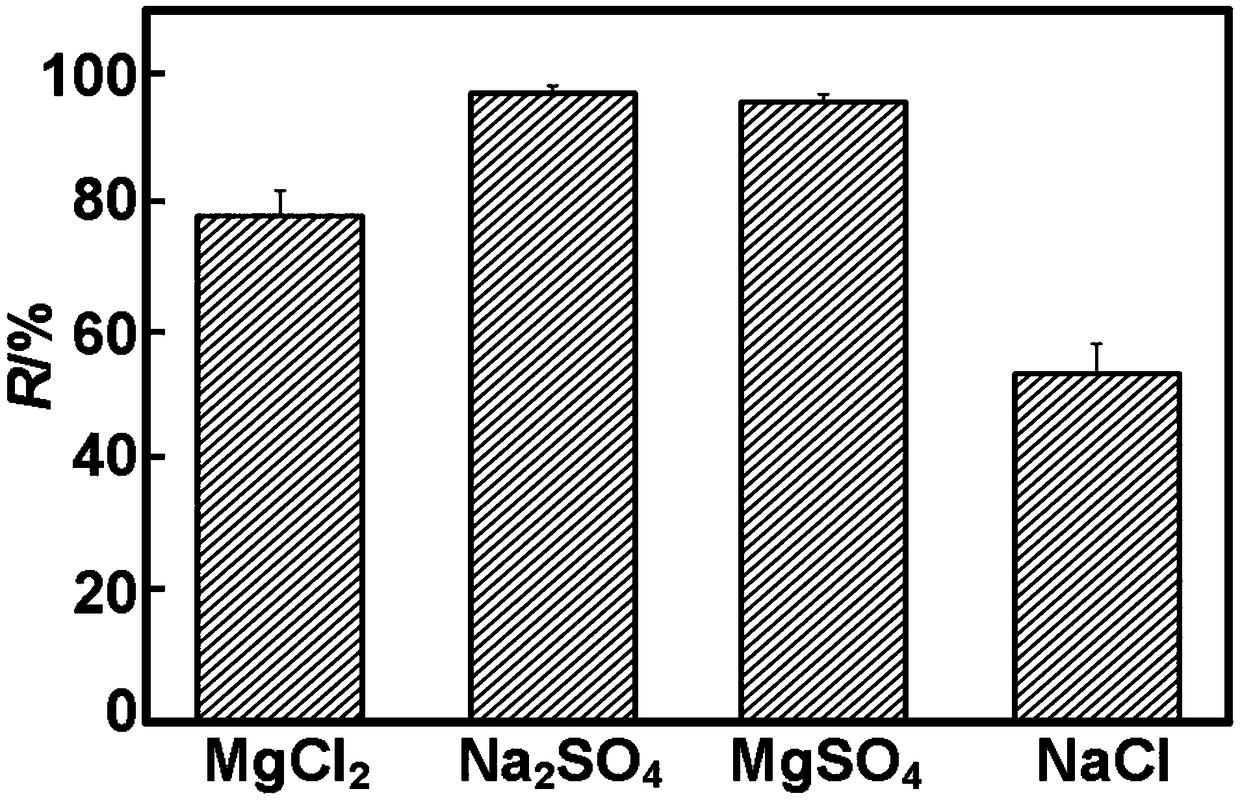

[0060] In conjunction with Table 2, it is known that when the final pH value of the aminated graphene oxide crosslinking solution is 12.5, the flux and desalination effect of the composite nanofiltration membrane are the best, wherein the rejection rate of sodium sulfate is 92.6%, and the rejection rate of magnesium sulfate is 92.6%. The rejection rate is 88.3%, the rejection rate of sodium chloride is 44.3%, the rejection rate of magnesium chloride is 77.2%, and the pure water flux is 35.6L m -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com