Manufacturing method of target structure

A production method and target technology, which are applied in the fields of manufacturing tools, heat treatment process control, metal material coating process, etc., can solve problems such as poor tightness, and achieve the effect of strong resistance to deformation under heat and high bonding tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

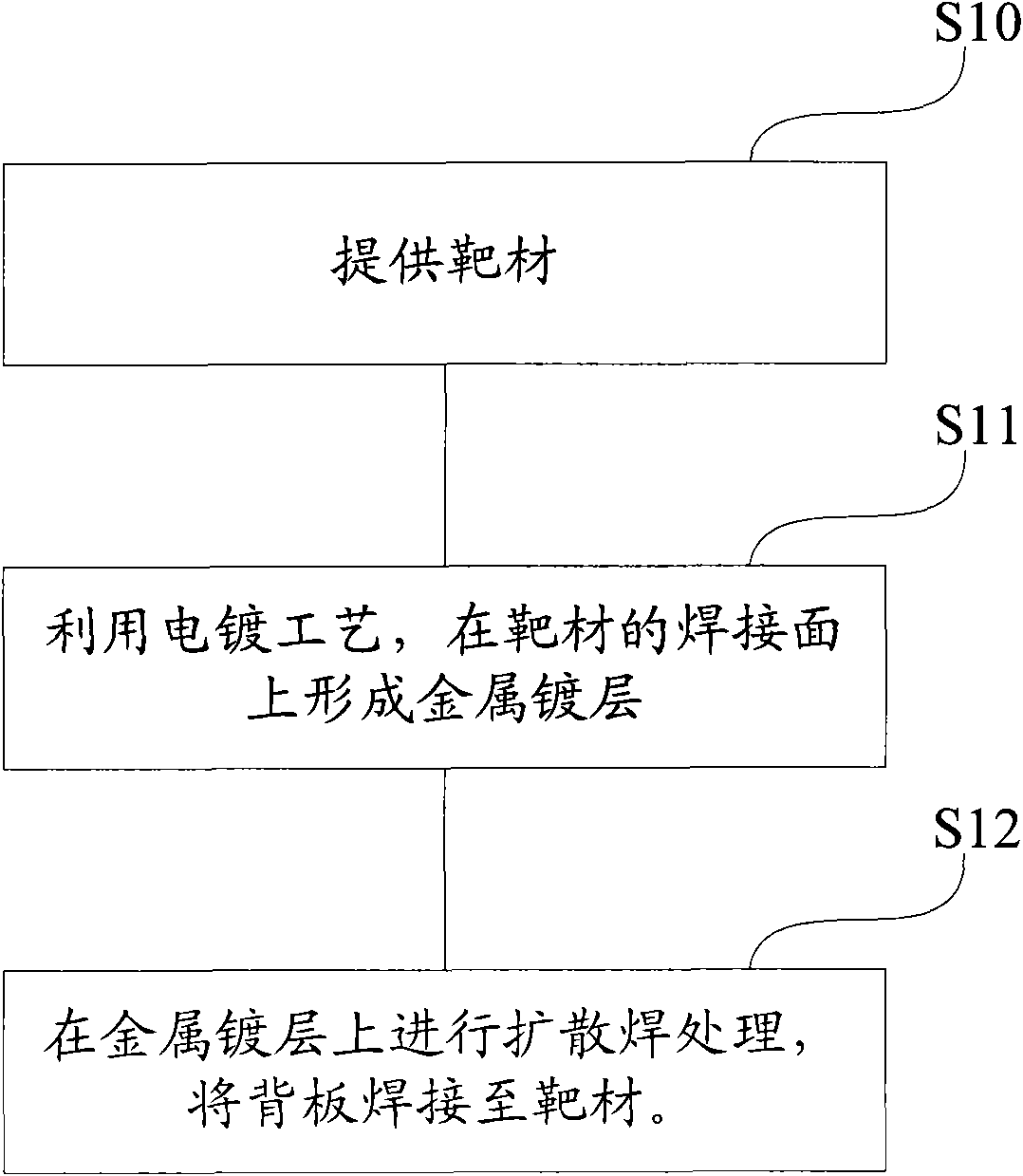

[0023] The inventors of the present invention have found that when making the target structure, if the properties of the target are relatively stable (for example, the melting point of the tantalum target is relatively high), and the properties of the back plate are relatively active (for example, the surface of the copper back plate is easily oxidized), it is better to use welding Direct welding of the target and the backplane will result in a poor combination of the two. In view of this, it is proposed to add a metal coating as an intermediate medium between the target and the back plate, so that the combination of the target and the back plate can be achieved through the metal coating that can be tightly combined with the target and the back plate at the same time. , to complete the fabrication of the target structure. Therefore, according to one aspect of the present invention, a target structure is provided, wherein a metal coating is included between the target and the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com