Method for manufacturing forming fabric for warp connection paper making

A technology of warp connection and manufacturing method, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of poor vertical and horizontal stability, shortened service life, insufficient tightness, etc., and achieves good bonding tightness, long service life, Good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

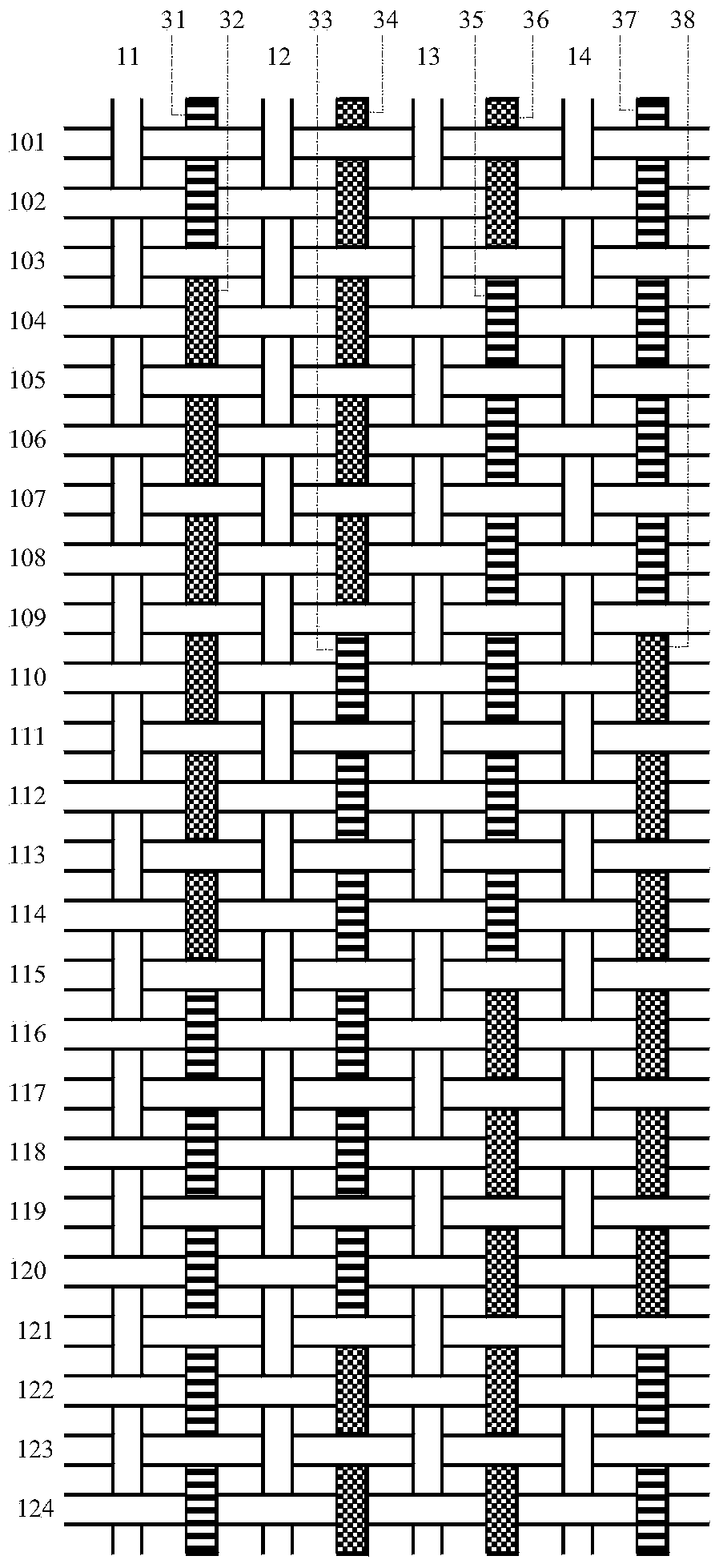

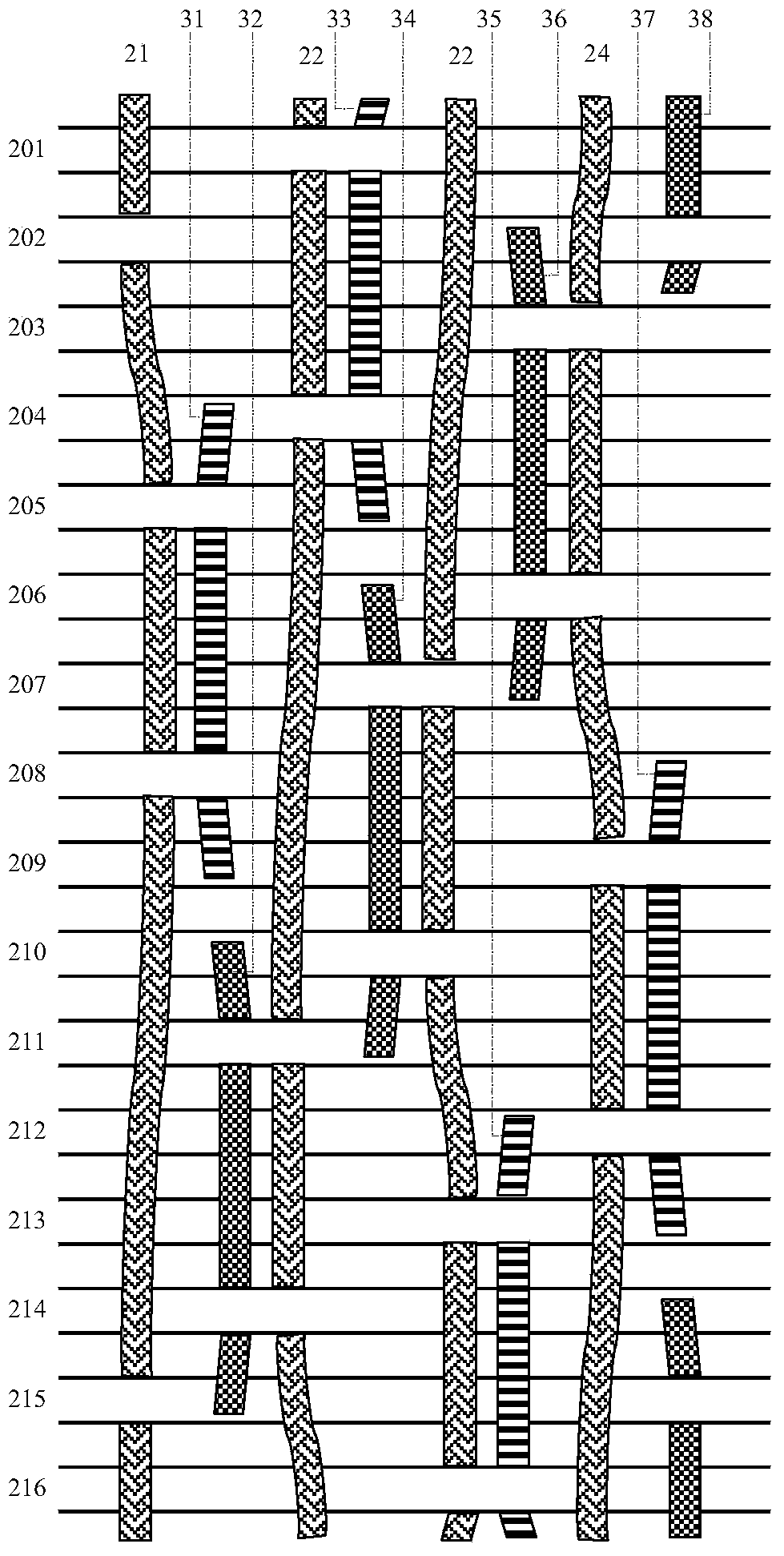

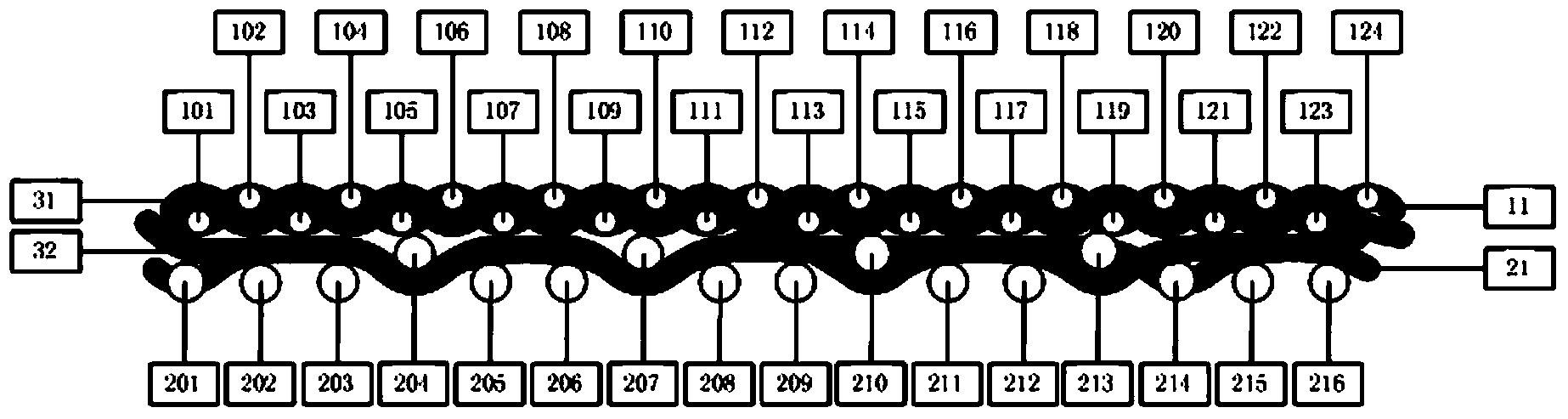

[0025] Attached below picture , through the description of the best embodiment, the specific implementation manner of the present invention will be described in further detail.

[0026] The manufacturing method of the warp-connected forming net for papermaking, the manufacturing process of the forming net is: wire inspection-warping-weaving-net-inspection-primary shaping-cutting-net-plugging-secondary shaping-finished product inspection-packing and storage ; 16 heald frames are used for weaving, and three system warp threads and two system weft threads are used for interweaving and weaving during weaving, wherein the three system warp threads adopt three warp let-off shaft systems for independent warp let-off; other processes are similar to those used for papermaking in the prior art The netting process is the same.

[0027] The three system warps are respectively the first system warp, the second system warp and the third system connecting warp, and the two system wefts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com