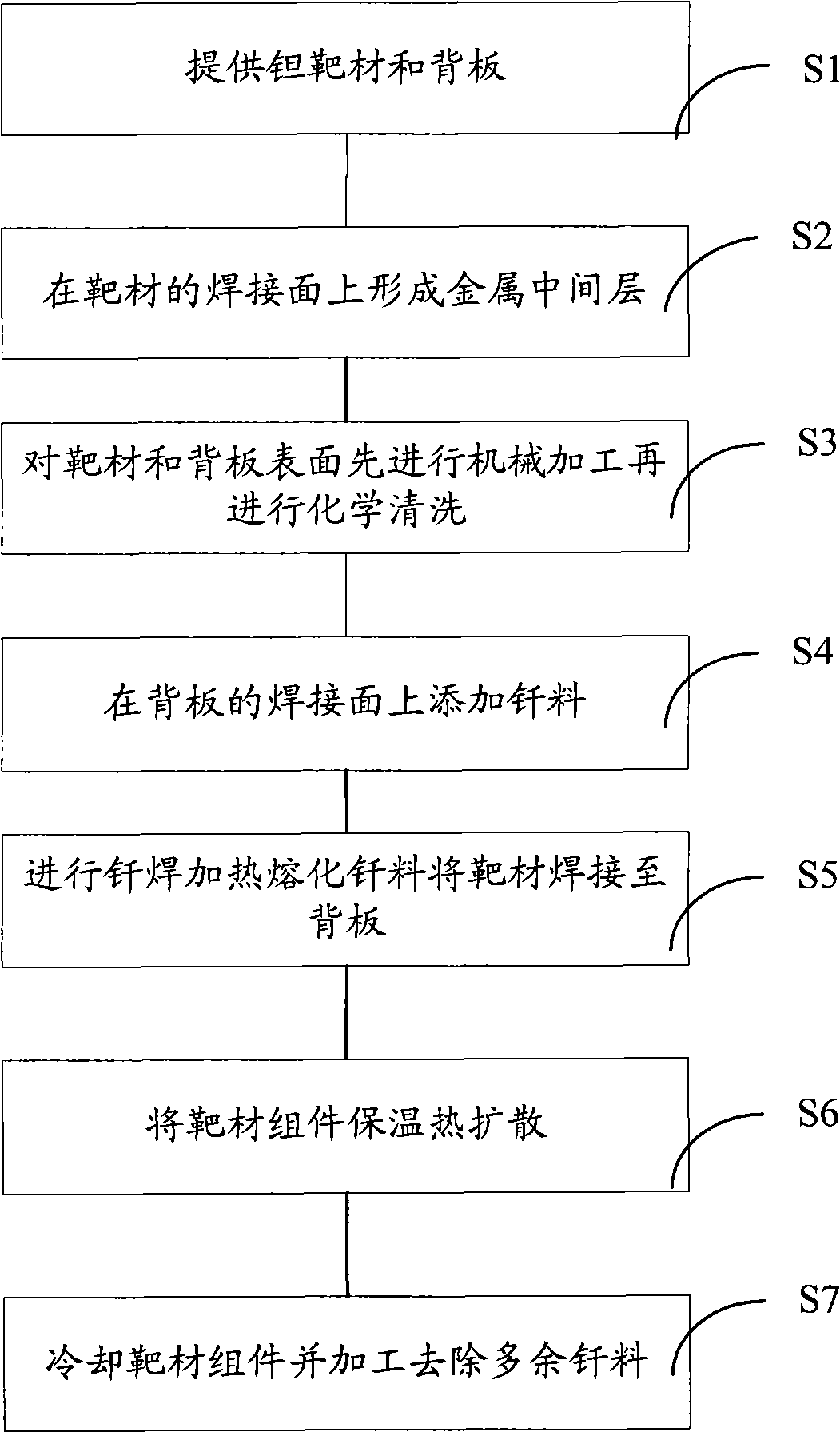

Method for welding target material and back board

A welding method and backplate technology, applied in welding medium, welding equipment, welding/welding/cutting items, etc., can solve problems such as easy oxidation of tantalum targets and affect the welding effect of target components, so as to improve the bonding strength of brazing , Improve the effect of infiltration and fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The following are the process steps and welding results of brazing the 99.99% high-purity Ta target and the 6061Al alloy back plate:

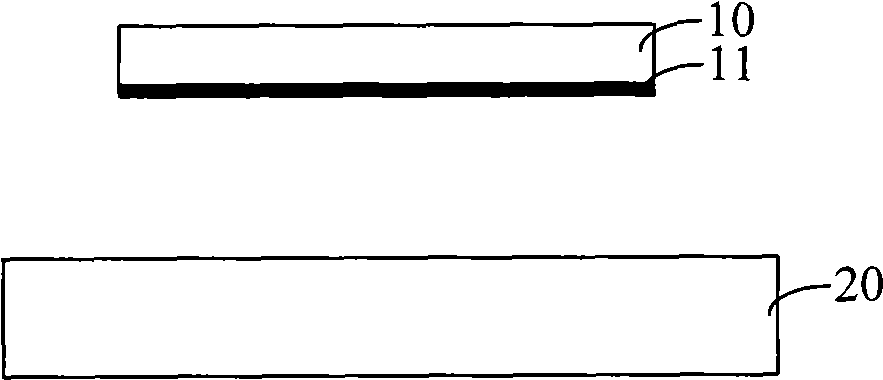

[0041] (1) Form a metal interlayer on the surface of the target: use plasma spraying technology to form a metal interlayer on the welding side of the Ta target, specifically, use the plasma arc driven by direct current as the heat source, and use Cu or Ni-Cr alloy, etc. The material soaked with solder is heated to a molten or semi-molten state, and sprayed at a high speed to the surface of the pretreated Ta blank to form a firmly adhered metal layer with a thickness of 400um.

[0042] (2) Surface processing of the target material and the back plate: Machining the surface of the Ta target and the surface of the 6061Al alloy back plate to make them bright, and the smoothness reaches 0.2-1.6um.

[0043] (3) Chemical cleaning of the target material and the back plate: the Ta target is first cleaned with an acid solution, and then cleaned wit...

Embodiment 2

[0052] The following are the process steps and welding results of brazing the 99.995% high-purity Ta target and the ZL105 aluminum alloy back plate:

[0053] (1) Form a metal interlayer on the surface of the target: use plasma spraying technology to form a metal interlayer on the welding side of the Ta target, specifically, use the plasma arc driven by direct current as the heat source, and use Cu or Ni-Cr alloy, etc. The material soaked with solder is heated to a molten or semi-molten state, and sprayed at high speed to the surface of the pretreated Ta blank to form a firmly adhered metal layer with a thickness of 200um.

[0054] (2) Surface processing of the target material and the back plate: Machining the surface of the Ta target and the surface of the ZL105 aluminum alloy back plate to make them bright, and the smoothness reaches 0.2-1.6um.

[0055] (3) Chemical cleaning of the target material and the back plate: the Ta target is first cleaned with an acid solution, and t...

Embodiment 3

[0064] The following are the process steps and results of brazing the 99.99% high-purity Ta target and the brass back plate:

[0065] (1) Form a metal interlayer on the surface of the target: use plasma spraying technology to form a metal interlayer on the welding side of the Ta target, specifically, use the plasma arc driven by direct current as the heat source, and use Cu or Ni-Cr alloy, etc. The material soaked with solder is heated to a molten or semi-molten state, and sprayed at high speed to the surface of the pretreated Ta blank to form a firmly adhered metal layer with a thickness of 200um.

[0066] (2) Surface processing of the target material and the back plate: Machining the surface of the Ta target and the surface of the brass back plate to make them bright, and the smoothness reaches 0.2-3.2um.

[0067] (3) Chemical cleaning of the target material and the back plate: the Ta target is first cleaned with an acid solution, and then cleaned with an organic solvent; an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com