Low temperature dynamic constraint load sintering method for preparing metal polyporous material

A dynamic constraint, metal porous technology, applied in the field of preparation of metal porous materials, can solve the problems of high cost, huge equipment, complicated process, etc., and achieve the effects of controllable porosity, lower sintering temperature, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

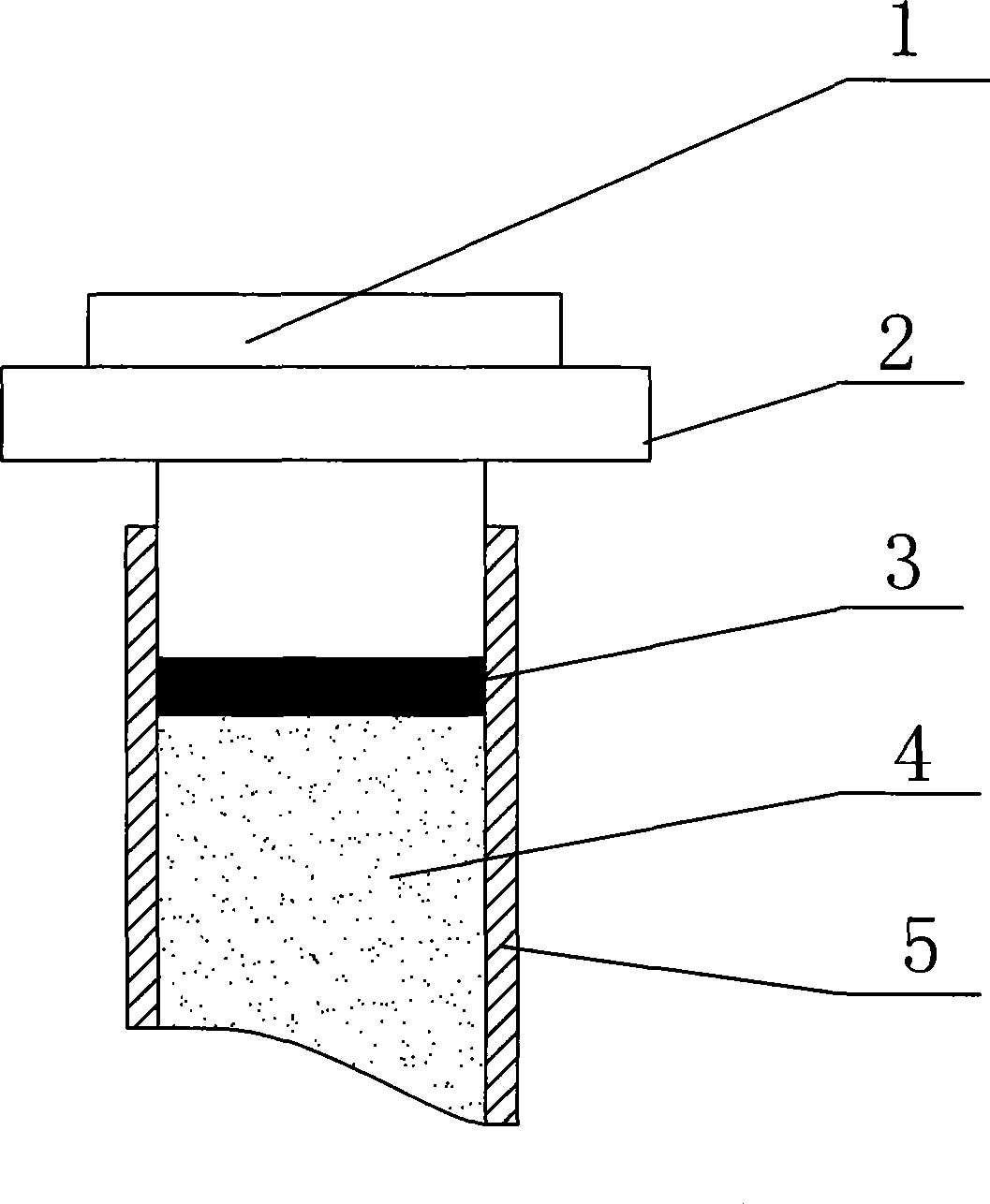

[0018] Preparation of nickel micro-flow control core: select nickel powder with a particle size of -80 ~ -400 mesh, directly put it into the sintering mold 5 dense nickel tube, press molding at 2.5 ~ 5.0MPa, and then sandwich a piece of ZrO 2 The isolation layer 3, and then press the molybdenum block with the limit block 2 (that is, the load weight 1), and use the weight of the molybdenum block to load when sintering and softening. The pressure is 2.0-15.0KPa. Vacuum sintering at ~850°C for 2 to 4 hours, when the molybdenum block falls to the limit block 2, stop falling. A small-sized (Φ3-6mm) nickel throttling body (i.e. metal porous material 4) with a porosity of 20-40% is prepared, which is used in a micro-flow controller, which can realize precise and efficient control of micro-flow and improve the efficiency of the throttling device. service life and reliability.

Embodiment 2

[0020] Preparation of large-area titanium porous plates for SPE water electrolysis electrodes: select titanium powder with a particle size of -80 ~ +400 mesh, loosely pack and vibrate into the sprayed ZrO 2 Sand (ZrO 2 In the stainless steel sintering mold 5 with sand as the isolation layer 3 (the upper template has a limit block 2), the weight of the stainless steel plate (that is, the weight 1) is used to load when sintering and softening, the pressure is 1.0-5.0KPa, and the vacuum sintering In the furnace, vacuum sinter at a temperature of 800-1000° C. for 2-4 hours, and stop falling when the stainless steel upper template falls to the limit block 2 . A large-sized (Φ140-200 mm) titanium porous plate (ie metal porous material 4) with a porosity of 40-60% is obtained, which is thin and non-deformable, and is used as an electrode for SPE water electrolysis, and has excellent conductivity, air permeability and resistance Electrochemically corrosive.

Embodiment 3

[0022] Preparation of stainless steel fiber porous plate: select stainless steel fiber with a suitable diameter in the range of 5-30μm, cut it into the required size, lay it layer by layer to a height of 200-500mm, and press molding at 8.0-10.0MPa, sandwiching a layer at the top and bottom Al 2 o 3 Ceramic paper (i.e. isolation layer 3), then put into dense stainless steel sintering mold 5, press the stainless steel plate (i.e. loading weight 1) with stopper 2 on the top of the fiber, utilize the weight of stainless steel plate to soften during sintering Time loading, the pressure is 0.5 ~ 1.0KPa, in the vacuum sintering furnace, vacuum sintering at a temperature of 800 ~ 900 ° C for 2 ~ 4 hours, when the pressed stainless steel plate drops to the limit block 2, it stops falling. A stainless steel porous fiberboard (i.e. metal porous material 4) with a porosity of 30-60% and a size of 20-500×20-500×2-50mm is obtained, which has high strength, good impact resistance and vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com