Polyperfluorinated ethylene propylene hollow fiber membrane preparation formula and preparation method

A polyperfluoroethylene propylene, fiber membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve problems hindering the coordinated development of economy, policy and environment, poor acid and alkali resistance and corrosion resistance of membrane, water resources Shortage and other problems, to achieve the effect of improving melt flow properties, not easy to agglomerate, and avoiding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing polyperfluoroethylene propylene hollow fiber membrane (method for short), which is characterized in that the method includes the following steps:

[0027] Step 1. After the formula is uniformly mixed by a high-speed mixer, it is extruded and pelletized by a twin-screw extruder to obtain uniformly mixed particles, and the particles are automatically fed into the twin-screw extruder through a feeding hopper at 260 ~ It is extruded quantitatively through the hollow spinneret module at 380°C. Inert gas (nitrogen in this example) is introduced into the module. After the spinning melt is solidified in an air bath, it is then drawn through a hot roller at 100-150°C and then drawn online. Stretching and winding, the on-line stretching ratio is 1 to 2 times to obtain the nascent hollow fiber membrane;

[0028] Specifically: the spinning melt enters the first winding after passing through the 20-250mm air layer, after curing i...

Embodiment 1

[0033] Combine 55wt% of polyperfluoroethylene propylene (FEP) powder, 12wt% of dioctyl phthalate (DOP), 33wt% of calcium carbonate (CaCO 3 ) Use a high-speed mixer to mix evenly, feed the above blend into a twin-screw extruder, extrude and granulate to obtain uniformly mixed particles, and automatically feed into the twin-screw extruder through a feeding hopper at 305℃ It is extruded quantitatively through the hollow spinneret module, and the inside of the module is filled with nitrogen. After the spinning melt is solidified in the air bath, it is then stretched and wound on-line after passing through a 140°C hot roller. The on-line stretching ratio is 1 times. Newborn hollow fiber membrane;

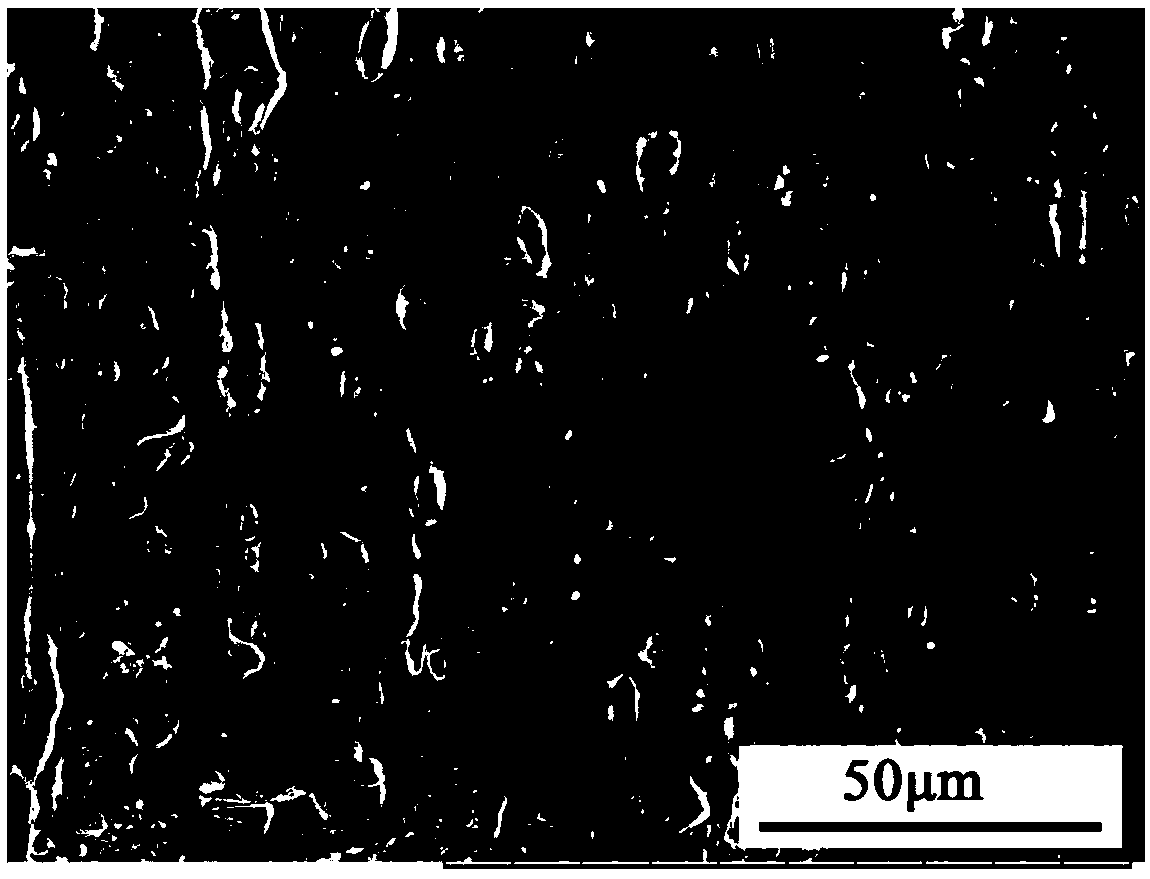

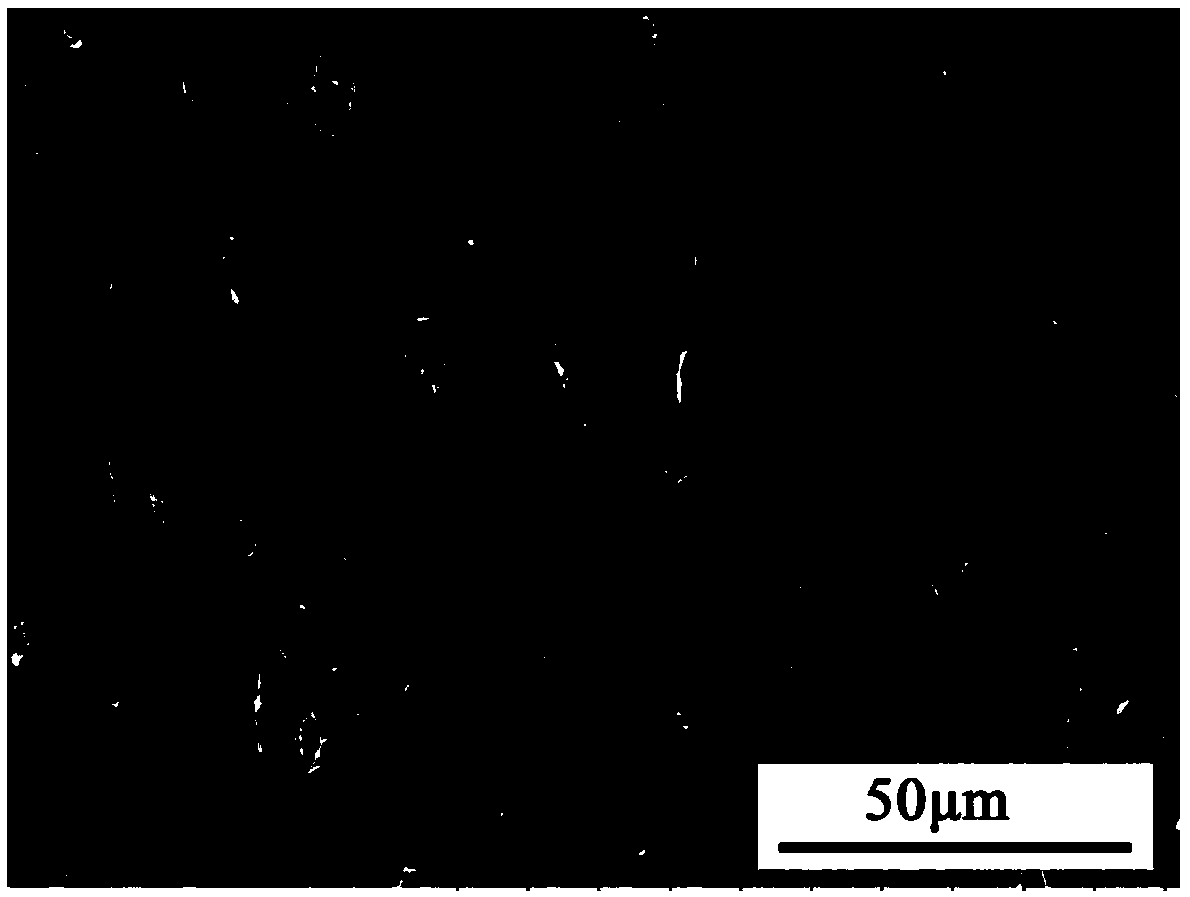

[0034] The nascent hollow fiber membrane was post-stretched and heat-set in a 140℃ hot oven stretcher at a stretching rate of 1mm / min, a stretching ratio of 0.4, and a fixed length heat-setting for 30 minutes, and then the filament was immersed in 10wt% hydrochloric acid Treated in an aqueo...

Embodiment 2

[0036] Combine 55wt% of polyperfluoroethylene propylene (FEP) powder, 12wt% of dioctyl phthalate (DOP), 33wt% of calcium carbonate (CaCO 3 ) Use a high-speed mixer to mix evenly, feed the above blend into a twin-screw extruder, extrude and granulate to obtain uniformly mixed particles, and automatically feed into the twin-screw extruder through a feeding hopper at 310°C It is extruded quantitatively through the hollow spinneret module, and the inside of the module is filled with nitrogen. After the spinning melt is solidified in the air bath, it is then stretched and wound on-line after passing through a 140°C hot roller. The on-line stretching ratio is 1 times. Newborn hollow fiber membrane;

[0037] The nascent hollow fiber membrane is post-stretched, and the post-stretching heat setting is carried out in a 140℃ hot oven stretcher, the drawing rate is 2mm / min, the drawing ratio is 0.2, the fixed length heat setting is 30min, and then the film filament is immersed In 10wt% hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com