Making method for particle substrate

A production method and substrate technology, applied in planting substrates, botany equipment and methods, culture media, etc., can solve the problems of poor water permeability, emergence rate and root growth in the later stage, and low fertilizer content in powdered seedling raising substrates, etc., to achieve High fertilizer content, beneficial to the emergence rate and the effect of root growth in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

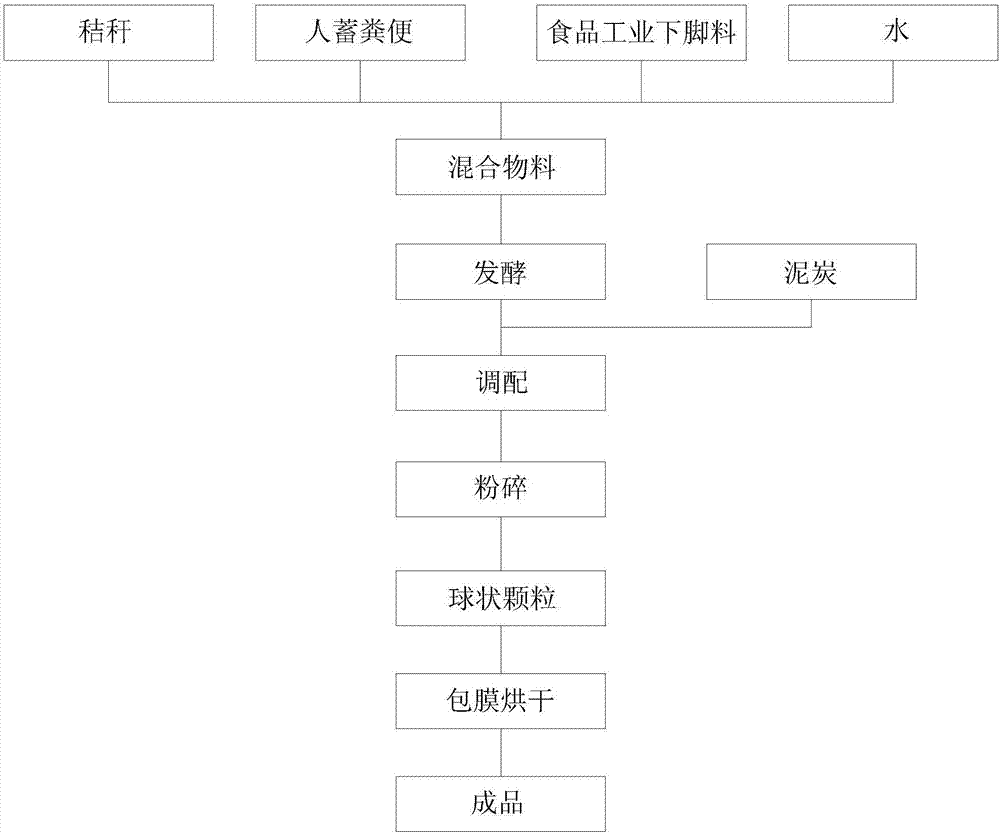

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0017] As shown in the figure, a method for making a granular matrix includes the following steps:

[0018] Step 1: Mix straw, human feces, and leftovers from the food industry at a volume ratio of 2:1:1, and then add water to make a mixed material. The mass of water in the mixed material accounts for 60%, and fermented bacteria are added to the mixed material After fully stirring, it is sent to the fermentation tank;

[0019] Step 2: Detect the temperature of the material in the fermentation tank. When the temperature of the material in the fermentation tank only drops but does not rise, the fermentation of the material is completed, and the total mass content of nitrogen, phosphorus and potassium in the fermented material is greater than 5.0%, and the carbon-to-nitrogen ratio is less than 30% :1;

[0020] Step 3, adding 30% peat to the fermented material in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com